Abstract

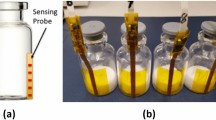

The purpose of this research was to evaluate a new wireless and battery-free sensor technology for invasive product temperature measurement during freeze-drying. Product temperature is the most critical process parameter in a freeze-drying process, in particular during primary drying. The product temperature over time profile and a precise detection of the endpoint of ice sublimation is crucial for comparison of freeze-drying cycles. Traditionally, thermocouples are used in laboratory scale units whereas resistance thermal detectors are applied in production scale freeze-dryers to evaluate temperature profiles. However, both techniques show demerits with regard to temperature comparability and biased measurements relative to vials without sensors. A new generation of wireless temperature sensors (Temperature Remote Interrogation System, TEMPRIS) were used in this study to investigate for the first time their value when applied to freeze-drying processes. Measurement accuracy, capability of accurate endpoint detection and effect of positioning were delineated by using product runs with sucrose, mannitol and trehalose. Data were compared to measurements with 36-gauge thermocouples as well as to non-invasive temperature measurement from Manometric Temperature Measurements. The results show that the TEMPRIS temperature profiles were in excellent agreement to thermocouple data when sensors were placed center bottom in a vial. In addition, TEMPRIS sensors revealed more reliable temperature profiles and endpoint indications relative to thermocouple data when vials in edge position were monitored. The results of this study suggest that TEMPRIS may become a valuable tool for cycle development, scale-up and routine manufacturing in the future.

Similar content being viewed by others

References

M. J. Pikal. Freeze Drying. Encyclopedia of Pharmaceutical Technology, Marcel Dekker, New York, 2002.

J. F. Carpenter, M. J. Pikal, B. S. Chang, and T. W. Randolph. Rational design of stable lyophilized protein formulations: Some practical advice. Pharm. Res. 148:969–975 (1997).

U.S. Food and Drug Administration. FDA-approved protein, peptide, vaccine, oligonucleotide, and cell based products grouped according to dosage form. http://www.fda.gov/cder/ (accessed 02/12/08).

X. Tang, and M. J. Pikal. Design of freeze-drying processes for pharmaceuticals: Practical advice. Pharm. Res. 212:191–200 (2004).

M. J. Pikal, and S. Shah. The collapse temperature in freeze drying: Dependence on measurement methodology and rate of water removal from the glassy phase. Int. J. Pharm. 62:165–186 (1990).

S. Rambhatla, J. P. Obert, S. Luthra, C. Bhugra, and M. J. Pikal. Cake shrinkage during freeze drying: A combined experimental and theoretical study. Pharm. Dev. Technol. 1:33–40 (2005).

W. Wang. Lyophilization and development of solid protein pharmaceuticals. Int. J. Pharm. 203:1–60 (2000).

H. Gieseler, T. Kramer, and M. J. Pikal. Use of manometric temperature measurement (MTM) and SMART freeze dryer technology for cycle development of an optimized freeze-drying cycle. J. Pharm. Sci. 9612:3402–3418 (2007).

G. W. Oetjen. Freeze Drying, Wiley-VCH, Weinheim, 1999.

H. Gieseler. Process Analytical Technology (PAT) in drying operations: Applications to freeze drying and beyond. Proc. AAPS National Biotechnology Conference, San Diego, CA, USA, June 24–27 (2007).

I. Presser. Innovative online measurement procedures to optimize freeze-drying processes [Innovative Online Messverfahren zur Optimierung von Gefriertrocknungsprozessen], PhD Thesis 2003, Department of Pharmaceutics, University of Munich. Available online: http://edoc.ub.uni-muenchen.de/1665/ (accessed 10/23/07).

K. Hammerer. Wireless temperature-measurement as an innovative PAT-method. Proc. 2nd congress on life science process technology, Nuremberg, Germany, March 28 (2007).

S. von Graberg, and H. Gieseler. Freeze drying from 96-well PCR-plates: Transferability of heat transfer coefficients obtained from sublimation tests to product runs and considerations for cycle design. Proc. AAPS Annual Meeting and Exposition; San Diego, CA, USA, Nov. 11–15 (2007).

S. Rambhatla, and M. J. Pikal. Heat and mass transfer scale-up issues during freeze drying I: Atypical radiation and the edge vial effect. AAPS PharmSciTech. 42:111–120 (2003)Article 14.

S. Rambhatla, R. Ramot, C. Bhugra, and M. J. Pikal. Heat and mass transfer scale-up issues during freeze drying: II. Control and characterization of the degree of supercooling. AAPS PharmSciTech. 54:1–9 (2004)Article 58.

X. Tang, S. L. Nail, and M. J. Pikal. Freeze-drying process design by manometric temperature measurement: Design of a smart freeze-dryer. Pharm. Res. 224:685–700 (2005).

W. Wang, S. Singh, D. L. Zeng, K. King, and S. Nema. Antibody structure, instability, and formulation. J. Pharm. Sci. 961:1–26 (2007).

J. A. Searles, J. F. Carpenter, and T. W. Randolph. The ice nucleation temperature determines the primary drying rate of lyophilization for samples frozen on a temperature-controlled shelf. J. Pharm. Sci. 907:860–871 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schneid, S., Gieseler, H. Evaluation of a New Wireless Temperature Remote Interrogation System (TEMPRIS) to Measure Product Temperature During Freeze Drying. AAPS PharmSciTech 9, 729–739 (2008). https://doi.org/10.1208/s12249-008-9099-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-008-9099-8