Abstract

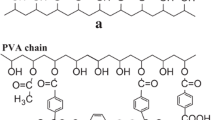

This study aims to develop a LED curable composite with higher compressive strength. We are reporting the synthesis of copolymers from acrylic and itaconic acid using simple free radical polymerization technique. The synthesized copolymer (acrylic-co-itaconic acid) was then grafted with bisphenol A-glycidyl methacrylate (Bis-GMA) using conventional condensation polymerization technique. The synthesized and purified copolymer was then characterized using FTIR, DSC, and TGA. We also synthesized glass ionomer powder using well established melt and quench method using various inorganic components, such as, SiO2, Al2O3, CaO, NaF, AlF3, P2O5, and Na3AlF6. The synthesized glass ionomer powder was characterized using powder X-ray diffraction and scanning electron microscopic techniques. Finally, we prepared the copolymer-glass ionomer composite by mixing the grafted copolymer and the glass ionomer with hydroxymethacrylate and camphorquinone. The resultant composite was cured with a LED light (440–480 nm) for 20 s and its surface morphology was studied using scanning electron microscopy. The compressive strength of the developed LED cured composite material and the commercially available Vitrebond (3M ESPE), a resin modified glass ionomer was compared using Universal Tensile Machine. It was found that the developed composite is 35% more strong in terms of compressive strength as compared to Vitrebond (3M ESPE).

Similar content being viewed by others

REFERENCES

D. S. R. Reddy, R. A. Kumar, S. M. Venkatesan, G. S. Narayan, D. Duraivel, and R. Indra, J. Conservative Dent. 17, 436 (2014).

V. Chandrasekhar, J. Conservative Dent. 13, 23 (2010).

E. C. Vouvoudi, D. S. Achilias, and I. D. Sideridou, Thermochim. Acta 599, 63 (2015).

F. Bayindir, N. O. Ilday, Y. Z. Bayindir, O. Karatas, and A. Gurpinar, J Conservative Dent. 19, 46 (2016).

A. Agrawal, N. U. Manwar, S. G. Hegde, M. Chandak, A. Ikhar, and A. Patel, J. Conservative Dent. 18, 136 (2015).

S. Nandini, J. Conservative Dent. 13, 184 (2010).

S. Shang, S. J. Huang, and R. A. Weiss, Polymer 50, 3119 (2009).

R. V. Toms, M. S. Balashov, A. A. Shaova, A. Yu. Gerval’d, N. I. Prokopov, A. V. Plutalova, N. A. Grebenkina, and E. V. Chernikova, Polym. Sci., Ser. B 62, 102 (2020).

M. R. Shaik, M. Kuniyil, M. Khan, N. Naushad Ahmad, A. Warthan, M. R. H. Siddiqui, and S. F. Adil, Molecules 21, 292 (2016).

T. Sehgal and S. Rattan, Int. J. Polym. Sci. 2010, 1(2010).

Z. Wang, L. Wu, D. Zhou, P. Ji, X. Zhou, Y. Zhang, and P. He, Polym. Sci., Ser. B 62, 238 (2020).

G. E. Damrawi, A. Behairy, and A. M. Abdelghany, New J. Glass Ceram. 8, 23 (2018).

F. S. Sayyedan, M. Fathi, H. Edris, A. Doostmohammadi, V. Mortazavi, and F. Shirani, Dent. Res. J. 10, 452(2013).

N. Upadhya, K. K. Srinivasan, A. Vasudeva Adhikari, and L. N.Satapathy, Technologies 3, 58 (2015).

F. Moztarzadeh, M. Keyanpour-Rad, and V. Shabani, Iran. Polym. J. 12, 211 (2003).

K. Kinoshita, Y. Takano, N. Ohkouchi, and S. Deguchi, ACS Omega 2, 2765 (2017).

S. H. Hsiao and Y. J. Chen, Eur. Polym. J. 38, 815 (2002).

A. Stamboulis, R. V. Lawb, and R. G. Hill, Biomaterials 25, 3907 (2004).

K. H. M. Tohamy, N. Abd El Sameea, T. M. Tiama, and I. Soliman, Egypt. J. Biophys. Biomed. Eng. 13, 53 (2012).

M. Todica, R. Stefan, C. Pop, and L. Olar, Acta Phys. Pol., A 128, 128 (2015).

J. Gaviria, C. G. Garcia, E. Velez, and J. Quijano, Model. Numer. Simul. Mater. Sci. 3, 149 (2013).

K. Buła, A. Palatyńska-Ulatowska, and L. Klimek, Arch. Mater. Sci. Eng. 103 (2), 75 (2020).

L. S. Pintado, E. D. N. Torre, M. D. S. Selayaran, R. V. D. Carvalho, C. H. Zanchi, F. R. M. Leite, and A. Etges, J. Conservative Dent. 21, 74 (2018).

L. T. Prieto, C. T. P. Araújo, J. J. A. Pierote, D. C. R. S. D. Oliveira, E. K. Coppini, and L. A. M. S. Paulillo, J. Conservative Dent. 21, 47 (2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Mayuri Gupta, Tyagi, A.K. & Raula, M. Synthesis of Bis-GMA Grafted Co-Polymer of Acrylic–Itaconic Acid and its Composite. Polym. Sci. Ser. B 64, 506–517 (2022). https://doi.org/10.1134/S1560090422700130

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090422700130