Abstract

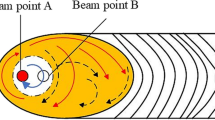

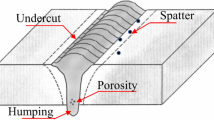

The influence of ultrasonic vibrations on the formation of a weld structure is studied. The laws of changing the structure from the weld surface to the base metal are considered, and the mechanisms of ultrasonic action on the crystallizing metal are described.

Similar content being viewed by others

REFERENCES

N. V. Babchenko, O. V. Seliverstova, S. K. Sundukov, and D. S. Fatyukhin, “Improving the operational properties of welds by ultrasonic methods,” Vestn. Mosk. Avt.-Dorozh. Gos. Tekh. Univ. (MADI), No. 1 (36), 44–49 (2014).

N. I. Baurova and A. Yu. Konoplin, “The structure of welded spot and heat-affected zone in adhesive-weld joint,” Glues. Sealants. Technology 3, 29–33 (2019).

A. M. Dal’skii, I. A. Arutyunova, T. M. Barsukova, et al., Technology of Structural Materials (Mashinostroenie, Moscow, 1977).

V. Prikhodko, M. Karelina, S. Sundukov, A. Sukhodolya, and V. Moiseev, “Improvement of operational properties of parts of permanent joints using ultrasound technologies,” J. Phys.: Conf. Ser. 1353 (1), 012081.

V. M. Prikhod’ko, V. F. Kazantsev, B. A. Kudryashov, et al., Development of Next-Generation Ultrasonic Equipment for the Production and Processing of Transport Engineering Parts and Components (MADI (GTU), Moscow, 2007).

R. I. Nigmetzyanov, D. D. Panasenko, and S. K. Sundukov, “Effect of ultrasonic hardening treatment on the structure and properties of the weld surface by atomic force microscopy methods,” Naukoemk. Tekhnol. Mashinostr., No. 3(21) (2013).

I. I. Mukhanov and K. M. Golubev, “Surface layer of steel machine parts after ultrasonic and hardening treatment,” Metalloved. Term. Obrab. Met., No. 9, 141–147 (1969).

A. Rusinko, “Analytical description of ultrasonic hardening and softening,” Ultrasonics 51 (6), 709–714 (2011).

A. Peslo, “Ultrasonic hardening of aluminum alloys,” Ultrasonics 22 (1), 37–41 (1984).

E. Sh. Statnikov, V. Yu. Fedorov, R. N. Kiyamov, N. I. Petridi, and E. I. Snyatkov, “Method of manual electric arc welding,” USSR Patent 946841, Byull. Izobret., No. 28 (1982).

E. Sh. Statnikov and V. L. Senyukov, “Method of excitation of high-frequency elastic vibrations in structures,” USSR Patent 931236, Byull. Izobret., No. 20 (1982).

L. D. Wen, “Effects of high-intensity ultrasonic-wave emission on the weldability of aluminum alloy 7075-T6,” Mater. Lett., No. 57 (2003).

H. Dong et al., “Improving arc joining of Al to steel and Al to stainless steel,” Mater. Sci. Eng., A 534, 424–435 (2012).

T. V. Da Cunha and C. E. Niño Bohórquez, “Ultrasound in arc welding: a review,” Ultrasonics 56, 201–209 (2015).

T. Watanabe et al., “Improvement of mechanical properties of ferritic stainless steel weld metal by ultrasonic vibration,” J. Mater. Process. Technol., No. 210, 1646–1651 (2010).

Y. Cui, C.L. Xu, and Q. Han, “Microstructure improvement in weld metal using ultrasonic vibrations,” Adv. Eng. Mater. 9 (3) (2007).

Y. Y. Fan, C. L. Fan, C. L. Yang, W. G. Liu, and S. B. Lin, “Research on short circuiting transfer mode of ultrasonic assisted GMAW method,” Sci. Technol. Welding Joining 17 (1), 3 (2012).

M. Wu et al., “Study on mechanism of arc-excited ultrasonic,” Chinese J. Mech., No. 12(1) (1999).

B. Cong, Q. I. Bojin, X. Zhou, and J. Lou, “Influence of ultrasonic pulse square-wave current parameters on microstructures and mechanical properties of 2219 aluminum alloy weld joints,” Acta Metall. Sinica, No. 45 (9), (2009).

Funding

This work was performed in terms of project no. FSFR-2020-0011 (2019-1342), and the experimental studies were conducted using the equipment of the MADI core facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Sundukov, S.K., Nigmetzyanov, R.I. & Fatyukhin, D.S. Structure of the Weld Formed during the Application of Ultrasonic Vibrations. Russ. Metall. 2021, 1667–1672 (2021). https://doi.org/10.1134/S0036029521130309

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521130309