Abstract

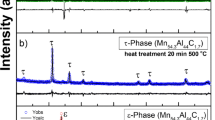

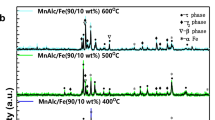

Combined studies of hard magnetic Nd2Fe14B/α-Fe nanocomposites are performed. They were prepared by mechanical alloying of melt-quenched Nd7.4Pr2.0Fe76.6Co4.2Zr3.4B6.4 and Nd5.8Fe80Co4.9Ti1.5Si2.5B5.3 alloys taken in mass proportions of 90/10 and 70/30. It is found that, after mechanical alloying, an amorphous–crystalline structure is formed; it consists of the hard magnetic Nd2Fe14B and soft magnetic (amorphous and α-Fe) phases. Subsequent annealing at ~500°C initiates the decomposition of the amorphous phase and the formation of the nanocrystalline Nd2Fe14B and α-Fe phases. This leads to an increase in the coercivity and the residual magnetization-to-saturation magnetization ratio (σr/σs ≥ 0.5). It is assumed that the magnetic hardening of powders is due to the formation of an exchange-coupled state, which results from the exchange interaction between α-Fe nanocrystals and the Nd2Fe14B phase.

Similar content being viewed by others

References

K. Guth, J. Lyubina, B. Gebel, L. Schultz, and O. Gutfleisch, “Ultra-fine grained Nd–Fe–B by high pressure reactive milling and desorption,” J. Magn. Magn. Mater. 324, 2731–2735 (2012).

E. F. Kneller and R. Hawig, “The exchange-spring magnet: a new material principle for permanent magnets,” IEEE Trans. Magn. 27, 3588–3600 (1991).

J. Ljubina, B. Rellinghaus, O. Gutfleisch, and M. Albrecht, “Structure and magnetic properties of L10-ordered Fe–Pt alloys and nanoparticles,” Handbook of Magnetic Materials 19, 291–407 (2011).

F. Liu, Y. L. Hou, and S. Gao, “Exchange-coupled nanocomposites: chemical synthesis, characterization and applications,” Chem. Soc. Rev. 43, 8098–8113 (2014).

I. B. Kekalo and V. P. Menushenkov, Melt-Quenched Hard Magnetic Nd–Fe–B Materials (MISiS, Moscow, 2000).

E. C. Stoner and E. P. Wohlfarth, “A mechanism of magnetic hysteresis in heterogeneous alloys,” Philos. Trans. Roy. Soc. A 240, 599–642 (1948). doi 10.1098/rsta.1948.0007

J. M.D. Coey, “Hard magnetic materials: a perspective,” IEEE Trans. Magn. 47, 4671–6481 (2011).

R. Skomski, “Predicting the future of permanent-magnet materials,” IEEE Trans. Magn. 49, 3215–3220 (2013).

P. K. Sahota, Y. Liu, R. Skomski, M. Manchanda, R. Zhang, M. Franchin, H. Fangohr, G. C. Hadjipanayis, A. Kashyap, and D. J. Sellmyer, “Ultrahard magnetic nanostructures,” J. Appl. Phys. 111, 07E–345 (2012).

V. Pop, S. Gutoiu, E. Dorolti, O. Isnard, and I. Chicinas, “The influence of short time heat treatment on the structural and magnetic behavior of Nd2Fe14B/a-Fe nanocomposite obtained by mechanical milling,” J. Alloys Compd. 509, 9964 (2011).

R. Hirian, S. Mican, O. Isnard, L. Barbu-Tudoran, and V. Pop, “Influence of microstructure on the interphase exchange coupling of Nd2Fe14B + 10 wt % a-Fe nanocomposites obtained at different milling energies,” J. Alloys Compd. 697, 19–24 (2017).

X. Tang, X. Chen, R. Chen, and A. Yan, “Polycrystalline Nd2Fe14B/a-Fe nanocomposite flakes with a submicro/nanometre thickness prepared by surfactantassisted high-energy ball milling,” J. Alloys Compd. 644, 562–569 (2015).

W.-L. Zuo, M. Zhang, E. Niu, X.-P. Shao, F.-X. Hu, J.-R. Sun, and B.-G. Shen, “The coercivity mechanism of Pr–Fe–B nanoflakes prepared by surfactantassisted ball milling,” J. Magn. Magn. Mater, 390, 15–19 (2015).

E. V. Shelekhov and T. A. Sviridova, “Software for X-ray analysis of polycrystals,” Met. Sci. Heat Treat. 42, 309–313 (2002).

Yu. D. Yagodkin, C. M. Minakova, S. V. Ketov, and A. S. Lileev, “X-ray procedure for the study of phase composition of amorphous–crystalline Nd–Fe–B alloys,” Zavod. Lab. 70 (8), 34–37 (2004).

W. Zhanyong, L. Wenqing, and S. Yanli, “Effects of magnetic annealing on crystallization and magnetic properties of Nd2Fe14B/a-Fe nanocomposite magnets,” J. Rare Earths 28, 417–419 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.G. Savchenko, V.P. Menushenkov, A.Yu. Plastinin, I.V. Shchetinin, A.I. Rafal’skii, I.G. Bordyuzhin, V.A. Ryazantsev, V.N. Verbetskii, 2017, published in Deformatsiya i Razrushenie Materialov, 2017, No. 10, pp. 30–34.

Rights and permissions

About this article

Cite this article

Savchenko, A.G., Menushenkov, V.P., Plastinin, A.Y. et al. Phase Composition and Magnetic Properties of Nd2Fe14B/α-Fe Nanocomposites Prepared by Mechanical Alloying. Russ. Metall. 2018, 354–358 (2018). https://doi.org/10.1134/S0036029518040134

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518040134