Abstract

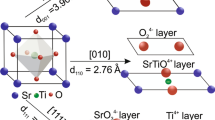

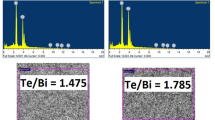

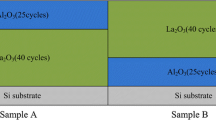

The possibility of synthesizing textured barium hexaferrite films on silicon wafers with Ti, Al2O3/Ti, or Al2O3/TiO2 barrier layers was studied. X-ray diffraction (XRD) showed that, after crystallization annealing, the hexaferrite phase with the (00l) preferred orientation was formed only when there was contact between BaFe12O19 and Al2O3. The hexaferrite microstructure in these samples, according to atomic force microscopy (AFM), is represented by rounded grains, which are typical of films where the hexagonal axis is perpendicular to the surface plane. Titanium in a BaFe12O19/Al2O3/Ti sample was partially oxidized during the synthesis. This process and the associated phase transformations in TiO2 are assumed to induce mechanical stress in the structure and, as a consequence, the formation of macroscopic defects (bulges). Complete pre-oxidation of the titanium film produced a textured BaFe12O19 structure without macroscopic defects.

Similar content being viewed by others

REFERENCES

R. C. Pullar, Prog. Mater. Sci. 57, 1191 (2012). https://doi.org/10.1016/j.pmatsci.2012.04.001

C. Fernandez De Julian, C. Sangregorio, J. de la Figuera, et al., J. Phys. D: Appl. Phys. 54, 153001 (2021). https://doi.org/10.1088/1361-6463/abd272

R. Jotania, AIP. Conf. Proc. 1621, 596 (2014). https://doi.org/10.1063/1.4898528

V. G. Kostishin, D. N. Chitanov, A. G. Nalogin, et al., Russ. J. Inorg. Chem. 61, 279 (2016). https://doi.org/10.1134/S0036023616030116

V. V. Korovushkin, A. V. Trukhanov, M. N. Shipko, et al., Russ. J. Inorg. Chem. 64, 574 (2019). https://doi.org/10.1134/S0036023619050115

V. V. Korovushkin, A. V. Trukhanov, V. G. Kostishin, et al., Phys. Solid State 62, 891 (2020). https://doi.org/10.1134/S1063783420050145

H. Li, L. Zheng, D. Deng, et al., J. Alloys Compd. 862, 158638 (2021). https://doi.org/10.1016/j.jallcom.2021.158638

H. K. Satyapal, R. K. Singh, S. S. Kumar, et al., Mater. Today Proc. 44, 1833 (2021).

K. S. Martirosyan, E. Galstyan, S. M. Hossain, et al., Mater. Sci. Eng. B 176, 8 (2011). https://doi.org/10.1016/j.mseb.2010.08.005

V. K. Chakradhary and M. J. Akhtar, Composites B 183, 107667 (2020). https://doi.org/10.1016/j.compositesb.2019.107667

X. Zhang, Y. Zhang, S. Cao, et al., Mater. Lett. 248, 24 (2019). https://doi.org/10.1016/j.matlet.2019.03.139

B. K. O’Neil and J. L. Young, IEEE Antennas and Propagation Society International Symposium, San Diego, 2008. https://doi.org/10.1109/APS.2008.4619493

S. G. Wang, S. D. Yoon, and C. Vittoria, J. Appl. Phys. 92, 6728 (2002). https://doi.org/10.1063/1.1517749

E. D. Solovyova, M. L. Calzada, and A. G. Belous, J. Sol-Gel Sci. Technol. 75, 215 (2015). https://doi.org/10.1007/s10971-015-3692-6

H. Tang, W. Zhang, B. Peng, and W. Zhang, Thin Solid Films 518, 3342 (2010). https://doi.org/10.1016/j.tsf.2010.01.038

S. Yong An, S. Won Lee, I.-B. Shim, and C. Sung Kim, Phys. Status Solidi A 189, 893 (2002). https://doi.org/10.1002/1521-396X(200202)189:3<893::AID-PSSA893>3.0.CO;2-O

S. Verma, S. Mahadevan, C. Pahwa, et al., J. Supercond. Nov. Magn. 33, 2507 (2020). https://doi.org/10.1007/s10948-020-05494-2

C. Velez, J. Ewing, S. Hwangbo, et al., EEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Ann Arbor. Michigan, 16–18 July 2018.https://doi.org/10.1109/IMWS-AMP.2018.8457152

S. M. Masoudpanah, S. A. Seyyed Ebrahimi, and C. K. Ong, J. Magn. Magn. Mater. 324, 2894 (2012). https://doi.org/10.1016/j.jmmm.2012.04.034

Z. Xu, Z. Lan, K. Sun, et al., J. Alloys Compd. 575, 257 (2013). https://doi.org/10.1016/j.jallcom.2013.04.084

V. G. Kostishin, A. Yu. Mironovich, R. I. Shakirzyanov, et al., Usp. Prikl. Fis. 8, 370 (2020).

S. M. Masoudpanah, S. A. Seyyed Ebrahimi, and C. K. Ong, J. Magn. Magn. Mater. 324, 2654 (2012). https://doi.org/10.1016/j.jmmm.2012.03.040

Z. Xu, Z. Lan, K. Sun, et al., Appl. Surf. Sci. 271, 362 (2013). https://doi.org/10.1016/j.apsusc.2013.01.203

F. M. Mwema, O. P. Oladijo, S. A. Akinlabi, and E. T. Akinlabi, J. Alloys Compd. 747, 306 (2018). https://doi.org/10.1016/j.jallcom.2018.03.006

A. M. Glezer and N. A. Shurygina, Amorphous Nanocrystalline Alloys (Fizmatlit, Moscow, 2013) [in Russian].

N. N. Shams, M. Matsumoto, and A. Morisako, IEEE Trans. Magn. 40, 2955 (2004). https://doi.org/10.1109/TMAG.2004.829276

A. Morisako, N. N. Shams, Y. Miura, et al., J. Magn. Magn. Mater. 272–276, 2191 (2004). https://doi.org/10.1016/j.jmmm.2003.12.632

P. Kulik, C. Yu, and A. Sokolov, Scr. Mater. 188, 190 (2020). https://doi.org/10.1016/j.scriptamat.2020.07.041

V. V. Pan’kov, A. I. Stognii, V. D. Koshevar, and V. A. Ketsko, Inorg. Mater. 44, 1022 (2008). https://doi.org/10.1134/S0020168508090203

V. G. Kostishin, A. Y. Mironovich, A. V. Timofeev, et al., Russ. J. Inorg. Chem. 66, 603 (2021). https://doi.org/10.1134/S003602362104015X

G. Abadias, E. Chason, J. Keckes, et al., J. Vac. Sci. Technol. A 36, 020801 (2018). https://doi.org/10.1116/1.5011790

W. Jiang, D. Xu, S. Yao, et al., Mater. Sci. Semicond. Proc. 43, 222 (2016). https://doi.org/10.1016/j.mssp.2015.12.020

D. Dergez, J. Schalko, A. Bittner, and U. Schmid, Appl. Surf. Sci. 284, 348 (2013). https://doi.org/10.1016/j.apsusc.2013.07.104

V. Chawla, R. Jayaganthan, A. K. Chawla, and R. Chandra, Mater. Chem. Phys. 111, 414 (2008). https://doi.org/10.1016/j.matchemphys.2008.04.048

W. D. Townes, J. H. Fang, and A. J. Perrotta, Z. Kristallogr. 125, 437 (1967). https://doi.org/10.1524/ZKRI.1967.125.125.437

E. Gemelli and N. H. A. Camargo, Revista Materia 12, 525 (2007). https://doi.org/10.1590/S1517-70762007000300014

D. V. Pavlenko, D. V. Tkach, S. M. Danilova-Tretyak, and L. E. Evseeva, J. Eng. Phys. Thermophys. 90, 685 (2017). https://doi.org/10.1007/s10891-017-1616-8

R. K. Kirby, J. Res. Natl. Bur. Stand. A: Phys. Chem. 71, 363 (1967). https://dx.doi.org/10.6028%2Fjres.071A.041

V. A. Fedorov, A. D. Berezner, A. I. Beskrovnyi, et al., Phys. Solid State 60, 705 (2018). https://doi.org/10.1134/S1063783418040091

V. Yu. Kolosov, K. L. Shvamm, R. V. Gainutdinov, and A. L. Tolstikhina, Bull. Russ. Acad. Sci. Phys. 71, 1442 (2007). https://doi.org/10.3103/S1062873807100280

V. G. Kostishin, A. Yu. Mironovich, A. V. Timofeev, et al., Semiconductors 55, 308 (2021). https://doi.org/10.1134/S106378262103012X

E. P. Lokshin and T. A. Sednev, Russ. J. Gen. Chem. 81, 1749 (2011). https://doi.org/10.1134/S1070363211090015

J. Huberty and H. Xu, J. Solid State Chem. 181, 508 (2008). https://doi.org/10.1016/j.jssc.2007.12.015

M. P. Gonullu and H. Ates, Superlattices Microstruct. 147, 106699 (2020). https://doi.org/10.1016/j.spmi.2020.106699

J. S. Mangum, O. Agirseven, J. E. S. Haggerty, et al., J. Non-Cryst. Solids 505, 109 (2019). https://doi.org/10.1016/j.jnoncrysol.2018.10.049

A. Azarniya, A. Azarniya, H. R. M. Hosseini, and A. Simchi, Mater. Charact. 103, 125 (2015). https://doi.org/10.1016/j.matchar.2015.03.030

Y. Ohya, S. Yamamoto, T. Ban, et al., J. Eur. Ceram. Soc. 37, 1673 (2017). https://doi.org/10.1016/j.jeurceramsoc.2016.11.037

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interests.

Additional information

Translated by O. Fedorova

Rights and permissions

About this article

Cite this article

Kostishin, V.G., Mironovich, A.Y., Timofeev, A.V. et al. Textured Barium Hexaferrite Films on Silicon Substrates with Aluminum Oxide and Titanium Oxide Barrier Layers. Russ. J. Inorg. Chem. 66, 1802–1810 (2021). https://doi.org/10.1134/S0036023621120093

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023621120093