Abstract

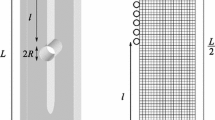

The three-point loading method is used to the measure the fracture strength σ f of polycrystalline CVD diamond plates with thickness in the range of h = 0.06–1.0 mm. Optical quality samples grown in a microwave plasma using CH4-H2 gas mixtures show an inherently nonuniform structure, the crystallite size varying (increasing) by 1–2 orders of magnitude in traversing from the substrate side to growth side. The value of σ f approaches ≈ 2200 MPa for the thinnest film when the fine-grained (substrate) side is under tensile stress, reducing with plate thickness down to ≈ 600 MPa at h ≈1000 μm. The strength is approximately a factor of two lower for the substrate side under tensile stress. In general, the material tested follows Hall-Petch relationship—a stress increase with grain size reduction. The fracture statistics are analyzed using a Weibull distribution, and a Weibull modulus m of 6.4 and 4.5 is found for the growth and substrate side under tension, respectively. Young’s modulus E = 1072 ± 153 GPa for polycrystalline diamond is evaluated from the same tests.

Similar content being viewed by others

References

CVD Diamond for Electronic Devices and Sensors, Sussmann, R.S., Ed., Chichester: Wiley, 2009.

Ral’chenko, V. and Konov, V., CVD Diamonds: Application in Electronic, Elektronika: Nauka, Tekhnologiya, Biznes, 2007, no. 4, pp. 58–67.

Pickles, C.S.J., Madgwick, T.D., Sussmann, R.S., et al., Optical Performance of Chemically Vapor-Deposited Diamond at Infrared Wavelengths, Diamond Relat. Mater., 2000, vol. 9, pp. 916–920.

Rogalin, V.E., Ashkinazi, E.E., Popovich, A.F., et al., Durability of Diamond Optics in the Beam of Powerful Fibrous Laser, Tez. dokl. XIV Nats. konf. po rostu kristallov, IV Mezhd. konf. “Kristallofizika XXI veka”. T. 2, (Proc. 14th Nat. Conf. on Crystal Growth; Proc. 4th Int. Conf. “Crystallophysics of XXI Century”), Moscow, 2010, pp. 307–308.

Thumm, M., MPACVD-Diamond Windows for High-Power and Long-Pulse Millimeter Wave Transmission, Diamond Relat. Mater., 2001, vol. 10, pp. 1692–1699.

Hanyu, H., Kamiya, S., Murakami, Y., et al., Dry and Semidry Machining Using Finely Crystallized Diamond Coating Cutting Tools, Surface Coat. Techn., 2003, vol. 174–175, pp. 992–995.

Balmer, R.S., Brandon, J.R., Clewes, S.L., et al., Chemical Vapor Deposition Synthetic Diamond: Materials, Technology and Applications, J. Physics: Cond. Matter, 2009, vol. 21, no. 36, p. 364221.

Luk’yanov, A.Yu., Ral’chenko, V.G., Khomich, A.V., Serdtsev, E.V., Volkov, P.V., Savel’ev, A.V., and Konov, V.I., Measurement of Optical Absorption in Polycrystalline CVD Diamond Plates by the Phase Photothermal Method at a Wavelength of 10.6 mcm, Quantum Electron., 2008, vol. 38, no. 12, pp. 1171–1178.

Inyushkin, A.V., Taldenkov, A.N., Ral’chenko, V.G., Konov, V.I., Khomich, A.V., and Khmel’nitski, R.A., Thermal Conductivity of Polycrystalline CVD Diamond: Experiment and Theory, J. Exp. Theor. Phys., 2008, vol. 1o7, no. 3, pp. 462–472.

Sumant, A.V., Auciello, O., Carpick, R.W., et al., Ultrananocrystalline and Nanocrystalline Diamond Thin Films for MEMS/NEMS Applications, MRS Bulletin, 2010, vol. 35, no. 4, pp. 281–288.

Pickles, C.S.J., The Fracture Stress of Chemical Vapor Deposited Diamond, Diamond Relat. Mater., 2002, vol. 11, pp. 1913–1922.

Klein, C.A., Diamond Windows and Domes: Flexural Strength and Thermal Shock, Diamond Relat. Mater., 2002, vol. 11, no. 2, pp. 218–227.

Lu, F.X., Jiang, Z., Tang, W.Z., et al., Accurate Measurement of Strength and Fracture Toughness for Miniature-Size Thick Diamond-Film Samples by Three-Point Bending at Constant Loading Rate, Diamond Relat. Mater., 2001, vol. 10, pp. 770–774.

Yang, J.X., Li, C.M., Lu, F.X., et al., Microstructure and Fracture Strength of Different Grades of Freestanding Diamond Films Deposited by a DC Arc Plasma Jet Process, Surf. Coat. Technol., 2005, vol. 192, nos. 2–3, pp. 171–176.

Davies, A.R., Field, J.E., and Pickles, C.S.J., Strength of Free-Standing Chemically Vapor-Deposited Diamond Measured by a Range of Techniques, Philos. Mag., 2003, vol. 83, no. 36, pp. 4059–4070.

Gray, K.J. and Windischmann, H., Free-Standing CVD Diamond Wafers for Thermal Management by DC Arc Jet Technology, Diamond Relat. Mater., 1999, vol. 8, pp. 903–908.

Sporl, R, Heidinger, R, Kennedy, G.R, et al., Proc. 9th CIMTEC-98—Forum on New Materials, Symp. IV—Diamond Films, Vincenzini, P., Ed., Techna Srl, 1999, pp. 335–342.

Ral’chenko, V.G., Savel’ev, A.V., Popovich, A.F., et al., Two-Layered Diamond-Aluminum Nitride Heat-Removing Dielectric Wafers, Mikroelektronika, 2006, vol. 35, no. 4, pp. 243–248.

Ralchenko, V., Sychov, I., and Vlasov, I., Quality of Diamond Wafers Grown by Microwave Plasma CVD: Effects of Gas Flow Rate, Diamond Relat. Mater., 1999, vol. 8, pp. 189–193.

Vlasov, I.I., Ralchenko, V.G., Obraztsova, E.D., et al., Stress Mapping of Chemical-Vapor-Deposited Diamond Film Surface by Micro-Raman Spectroscopy, Appl. Phys. Lett., 1997, vol. 71, no. 13, pp. 1789–1791.

Fodchuk, I.M., Tkach, V.M., Ralchenko, V.G., et al., Distribution in Angular Mismatch between Crystallites in Diamond Films Grown in Microwave Plasma, Diamond Relat. Mater., 2010, vol. 19, pp. 409–412.

Wachtman, J.B., Mechanical Properties of Ceramics, New York: Wiley, 1996.

Burton, N.C., Steeds, J.W., Meaden, G.M., et al., Strain and Microstructure Variation in Grains of CVD Diamond Film, Diamond Relat. Mater., 1995, vol. 4, pp. 1222–1234.

Espinosa, H.D., Peng, B., Prorok, B.C., et al., Fracture Strength of Ultrananocrystalline Diamond Thin Films—Identification of Weibull Parameters, J. Appl. Phys., 2003, vol. 94, no. 9, pp. 6076–6084.

Ralchenko, V., Nistor, L., Pleuler, E., et al., Structure and Properties of High-Temperature Annealed CVD Diamond, Diamond Relat. Mater., 2003, vol. 12, pp. 1964–1970.

Klein, C.A. and Cardinale, G.F., Young’s Modulus and Poisson’s Ratio of CVD Diamond, Diamond Relat. Mater., 1993, vol. 2, nos. 5–7, pp. 918–923.

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.G. Ralchenko, E. Pleiler, D.N. Sovyk, V.I. Konov, 2011, published in Perspektivnye Materialy, 2011, No. 3, pp. 33–39.

The article was translated by the authors.

Rights and permissions

About this article

Cite this article

Ralchenko, V.G., Pleiler, E., Sovyk, D.N. et al. Strength of optical quality polycrystalline CVD diamond. Inorg. Mater. Appl. Res. 2, 439–444 (2011). https://doi.org/10.1134/S2075113311050273

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113311050273