Abstract

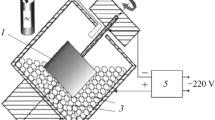

The method of Thermoreactive Electrospark Surface Strengthening (TRESS) is presented in this work. Thus the process of coating formation becomes a less energy consuming one as compared to the basic technology of the electrospark alloying. The additional heat of the chemical reaction of the synthesis final products formation on the substrate contribute to the increase of thickness and continuity of the coating, to the diminution of the inner tension due to the smoother concentration gradients through the coating thickness. The opportunities of TRESS method are exposed with the example of the FGM wear- and heat-resistant coating formation on the base of NiAl, TiAl. FGM diamond containing coatings production by the said method is presented. Optimal conditions and technological parameters for diamond containing coatings deposition is found. The masstransfer kinetics, the coating structure and properties were studied.

Similar content being viewed by others

REFERENCES

A. D. Verkhoturov and I. A. Podchernyaeva, L. Ph. Pryadko, Electrode materials for the electrospark alloying. (M., Nauka, p. 224, 1998.)

A. Ye. Hitlevitch, V. V. Mikhailov, and N. Ya. Parkanskii. Electrospark alloying of metal coatings. (Kishinev, Shtiintsa, p. 195, 1985).

V. V. Podlesov, T. A. Shevelyova, and A. Ye. Kudryashov, Investigation of the ESA Process and Properties of the TiC-TaC-H18N9T coatings, Elektronnaya Obrabotka Materialov, 165, 16 (1992).

A. E. Kudryashov, E. A. Levashov, and Abdul-Fattah O. Ali, On the perspectives of application of new SHS materials to the technology of Electrospark Alloying die steels, Int. Journal of SHS, 6, 445 (1997).

T. N. Shishkina, V. V. Podlesov, and A. M. Stolin, Microstructure and properties of extruded SHS-materials, Journal of Engineering Physics and Thermophysics, 63, 547 (1993).

E. A. Levashov, Yu. V. Bogatov, and A. S. Rogachev, Specific features of structure formation of synthetic hard-tool materials in the SHS-compacting process. Journal of Engineering Physics and Thermophysics, 63, 1091 (1993).

E. A. Levashov, A. E. Kudryashov, and A. G. Nikolaev, About the combination of the SHS and Electrospark alloying processes for the thick film coating production Abstracts 4th International Symposium on Self-Propagating High-Temperature Synthesis, Toledo, Spain, 150 (1997).

A. Satuvaldiyev, and E. O. Dronov. Synthesis of complex carbides of W-V system in the conditions of electroerosion process. Physica i khimiya obrabotki materialov, 2, 85 (1996).

T. A. Sviridova, E. V. Shelekhov, and A. A. Reznikov, Quantitative X-ray phase analysis of easytexture objects. Zavodscaya laboratorya, 10, 17 (1997).

A. S. Rogachev, A. Varma, and A. G. Merzhanov. The mechanism of self-propagating high-temperature synthesis of nickel aluminides, part 1: Formation of the product microstructure in a combustion wave. Int. Journal of SHS, 2, 25 (1993).

V. M. Shkiro and I. P. Borovinskaya. Studying the combustion regularities of titanium and carbon mixture. Combustion processes in chemical technology and in metallurgy. Chernogolovka, 253, (1975).

A. I. Kirdyashkin, Yu. M. Maksimov, and A. G. Merzhanov. About the influence of capillary impregnation on the process of gasless system combustion. Physica goreniya i vzruva, 17, 10 (1981).

Yu. V. Bogatov and E. A. Levashov, Pitulin, A. N. Effect of the SHS process peculiarities on compact titanium carbide structure. Poroshkovaya metallurgiya, 7, 76, (1991).

V. I. Itin and Yu. N. Naiborodinko. High-temperature synthesis of intermetallide compounds. Edit by prof. Korotayev A. D., Tomsk, 68, (1989).

E. A. Levashov, I. P. Borovinskaya, A. S. Rogachov, M. Koizumi, M. Ohyanagi, and S. Hosomi, SHS: A new method for production of diamond-containing ceramics. Intern. Journal of Self-Propagating High-Temperature Synthesis, 2, 189, (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Levashov, E.A., Kharlamov, E.I., Kudryashov, A.E. et al. About the Method of Thermoreactive Electrospark Surface Strengthening. Journal of Materials Synthesis and Processing 7, 23–33 (1999). https://doi.org/10.1023/A:1021873030369

Issue Date:

DOI: https://doi.org/10.1023/A:1021873030369