Abstract

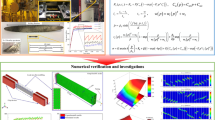

Evaluation of the possibility of substitution of steel part in the car body by the one made of AZ31 alloy was the main objective of the whole project. The objective of this paper was to determine the flow stress model, which accounts for the difference in the behavior of magnesium alloys during tension and compression. Tension tests on Zwick machine and compression tests on Gleeble 3800 were performed. Inverse analysis was applied to interpretation of the results of the tests. Separate numerical models for tension and compression were implemented into Abaqus software and simulations of the stamping were performed. Sensitivity of the results to the flow stress model was evaluated.

Similar content being viewed by others

References

Blawert C, Hort N, Kainer KU. Automotive applications of magnesium and its alloys. Trans Indian Inst Met. 2004;57:397–408.

Kawalla R, Lehmann G, Ullmann M, Vogt H-P. Magnesium semi-finished products for vehicle construction. Int J Adv Manuf Technol. 2008;8:93–101.

Kumar DS, Sasanka CT, Ravindra K, Suman KNS. Magnesium and its alloys in automotive applications. Am J Mater Sci Technol. 2015;4:12–30.

Musfirah AH, Jaharah AG. Magnesium and aluminum alloys in automotive industry. J Appl Sci Res. 2012;8:4865–75.

Ambroziński M, Rauch Ł, Paćko M, Gronostajski Z, Jaśkiewicz K, Chorzępa W. Computer aided design of manufacturing of automotive part made of magnesium alloy. Comput Methods Mater Sci. 2016;16(4):177–85.

Gzyl M, Rosochowski A, Pesci R, Olejnik L, Yakushina E, Wood P. Mechanical properties and microstructure of AZ31B magnesium alloy processed by I-ECAP. Metall Mater Trans A. 2014;45A:1609–20.

Kawalla R, Ullmann M, Oswald M, Schmidt C. Properties of strips and sheets of magnesium alloy produced by casting-rolling technology. In: Kainer KU, Dresden, (eds). Proc. 7th int. conf. on magnesium alloys and their applications. 2006, pp. 364–369.

Ullmann M, Oswald M, Gorelova S, Kawalla R, Vogt HP. Strip rolling technology of magnesium alloys. In: Steel Research International, Spec. issue 14th Metal Forming Conf., 2012, pp. 855–858.

Kuc D, Hadasik E, Schindler I, Kawulok P, Sliwa R. Characteristics of plasticity and microstructure of hot forming magnesium alloys Mg–Al–Zn type. Arch Metall Mater. 2013;58:151–6.

El-Morsy A, Ismail A, Waly M. Microstructural and mechanical properties evolution of magnesium AZ61 alloy processed through a combination of extrusion and thermomechanical processes. Mater Sci Eng A. 2008;486:528–33.

Qin Y-J, Pan Q-L, He Y-B, Li W-B, Liu X-Y, Fan X. Modeling of flow stress for magnesium alloy during hot deformation. Mater Sci Eng A. 2010;527:2790–7.

Raghunath BK, Raghukandan K, Karthikeyan R, Palanikumar K, Pillai UTS, Gandhi RA. Flow stress modeling of AZ91 magnesium alloys at elevated temperature. J Alloys Compd. 2011;509:4992–8.

Sheng ZQ, Shivpuri R. Modeling flow stress of magnesium alloys at elevated temperature. Mater Sci Eng, A. 2006;419:202–8.

Xu Y, Hu L-X, Sun Y. Hot deformation behavior and microstructure evolution of as-cast AZ91D magnesium alloy without pre-homogenization treatment. Rare Met. 2013;34:338–46.

Kuc D, Pietrzyk M. Physical and numerical modelling of plastic deformation of magnesium alloys. Comput Methods Mater Sci. 2010;10:130–42.

Barnett MR, Davies CHJ, Ma X. An analytical constitutive law for twinning dominated flow in magnesium. Scr Mater. 2005;52:627–32.

Sellars CM, McTeggart G. Hot workability. Int Met Rev. 1972;17:1–24.

Szeliga D, Gawąd J, Pietrzyk M. Inverse analysis for identification of rheological and friction models in metal forming. Comput Methods Appl Mech Eng. 2006;195:6778–98.

Szeliga D, Gawąd J, Pietrzyk M, Kuziak R. Inverse analysis of tensile tests. Steel Res Int. 2005;76:807–14.

Gawąd J, Kuziak R, Madej Ł, Szeliga D, Pietrzyk M. Identification of rheological parameters on the basis of various types of compression and tension tests. Steel Res Int. 2005;76:131–7.

Lou XY, Li M, Boger RK, Agnew SR, Wagoner RH. Hardening evolution of AZ31B Mg sheet. Int J Plast. 2007;23:44–86.

Nguyen N-T, Seo OS, Lee CA, Lee M-G, Kim J-H, Kim HY. Mechanical behavior of AZ31B Mg alloy sheets under monotonic and cyclic loadings at room and moderately elevated temperatures. Materials. 2014;7:1271–95.

Chino Y, Kimura K, Mabuchi M. Twinning behavior and deformation mechanisms of extruded AZ31 Mg alloy. Mater Sci Eng A. 2008;486:481–8.

Acknowledgements

The research was financed by the NCBiR (the National Centre of Research and Development) within the frames of the research project no. PBS1/A5/29/2013.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declared that they have no conflict of interest.

Ethical approval

Research was done according to ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pietrzyk, M., Kuziak, R., Bzowski, K. et al. Material characterization for numerical simulation of manufacturing of automotive part made of magnesium alloy. Archiv.Civ.Mech.Eng 20, 6 (2020). https://doi.org/10.1007/s43452-019-0001-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-019-0001-0