Abstract

Low-activation vanadium alloys, with the reference composition of V–4Cr–4Ti have been considered as one of the most promising candidate materials for structural components such as the blanket in future fusion reactors, thanks to their excellent neutron irradiation resistance, superior high-temperature mechanical properties, and high compatibility with liquid lithium blankets. The self-cooled liquid lithium blanket using structural materials of vanadium alloys is an attractive concept because of the high heat transfer and high tritium breeding capability. After more than 2 decades of research, technological progress has been made in reducing the number of critical issues for application of vanadium alloys to fusion reactors. In this paper, the recent research and development activities of vanadium alloys are summarized, including significant progress achieved on fabrication technology and composition optimization, coating and corrosion, improved understanding of irradiation effects upon microstructure and material properties, retention of hydrogen isotopes, as well as advancements in joining and welding. In particular, the fact that recent products from China, Japan, US and France showed similar properties which meant the fabrication technology has been almost standardized.

Reproduced with permission from Ref. [19]. Copyright 2012 Elsevier

Reproduced with permission from Ref. [27]. Copyright 2002 Elsevier

Reproduced with permission from Ref. [50]. Copyright 2009 Elsevier

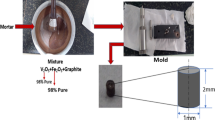

Reproduced with permission from Ref. [54]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [58]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [67]. Copyright 2016 Elsevier

Reproduced with permission from Ref. [87]. Copyright 2013 Elsevier

Reproduced with permission from Ref. [11]. Copyright 2011 Elsevier

Similar content being viewed by others

References

Kembleton R. 5-Nuclear fusion: what of the future? Managing global warming an interface of technology and human issues. New York: Elsevier Inc; 2019. p. 199.

Someya Y, Tobita K, Hiwatari R, Sakamoto Y, Joint Special Design Team for Fusion DEMO. Fusion DEMO reactor design based on nuclear analysis. Fusion Eng Des. 2018;136:1306.

Ihli T, Basu TK, Giancarli LM, Konishi S, Malang S, Najmabadi F, Nishio S, Raffray AR, Rao CV, Sagara A, Wu Y. Review of blanket designs for advanced fusion reactors. Fusion Eng Des. 2008;83:912.

Rowcliffe AF, Garrison LM, Yamamoto Y, Tan L, Katoh Y. Materials challenges for the fusion nuclear science facility. Fusion Eng Des. 2018;135:290.

Xu YP, Liu YM, Zhou HS, Luo GN. A review on the development of the structural materials of the fusion blanket. Mater Rev A. 2018;32(9):2897 (In Chinese).

Muroga T, Chen JM, Chernov VM, Fukumoto K, Hoelzer DT, Kurtz RJ, Nagasaka T, Pint BA, Satou M, Suzuki A, Watanabe H. Review of advances in development of vanadium alloys and MHD insulator coatings. J Nucl Mater. 2007;367–37:780.

Sadeghi H, Amrollahi R, Zare M, Fazelpour S. Design and simulation of a blanket module with high efficiency cooling system of tokamak focused on DEMO reactor. Nucl Eng Technol. 2020;52:323.

Raffray AR, Akiba M, Chuyanov V, Giancarli L, Malang S. Breeding blanket concepts for fusion and materials requirements. J Nucl Mater. 2002;307–311:21.

Tanaka T, Muroga T, Sagara A. Tritium self-sufficiency and neutron shielding performance of self-cooled liquid blanket system for helical reactor. Fusion Sci Technol. 2005;47:530.

Muroga T, Tanaka T, Sagara A. Blanket neutronics of Li/vanadium-alloy and Flibe/vanadium-alloy systems for FFHR. Fusion Eng Des. 2006;81:1203.

Chen JM, Chernov VM, Kurtz RJ. Overview of the vanadium alloy researches for fusion reactors. J Nucl Mater. 2011;417:289.

Nagasaka T, Muroga T. Vanadium for nuclear systems. Compr Nucl Mater (Second Edition). 2020;6:1.

Muroga T, Nagasaka T, Abe K, Chernov VM, Matsui H, Smith DL, Xu ZY, Zinkle SJ. Vanadium alloys’ overview and recent results. J Nucl Mater. 2002;307–311:547.

Nagasaka T, Muroga T, Hino T, Satou M, Abe K, Chuto T, Iikubo T. Impurity behavior in V–4Cr–4Ti–Y alloys produced by levitation melting. J Nucl Mater. 2007;367–370:823.

Johnson WR, Smith JP. Fabrication of a 1200 kg ingot of V–4Cr–4Ti alloy for the DIII–D radiative divertor program. J Nucl Mater. 1998;258–263:1425.

Nagasaka T, Muroga T, Wu YC, Xu ZY, Imamura M. Low activation characteristics of several heats of V-4Cr-4Ti ingot. J Plasma Fusior Res. 2002;5:545.

Flem ML, Gentzbittel JM, Wident P. Assessment of a European V–4Cr–4Ti alloy-CEA-J57. J Nucl Mater. 2013;442:S325.

Fu HY, Chen JM, Zheng PF, Nagasaka T, Muroga T, Li ZD, Cui S, Xu ZY. Fabrication using electron beam melting of a V–4Cr–4Ti alloy and its thermo-mechanical strengthening study. J Nucl Mater. 2013;442(1–3):S336.

Muroga T. Vanadium for nuclear systems. Compr Nucl Mater. 2012;4:391.

Ding JW, Yang SW, Liu GL, Li QF, Zhu BL, Zhang MQ, Zhou LJ, Shang CJ, Zhan Q, Wan FR. Recrystallization nucleation in V-4Cr-4Ti alloy. J Alloys Compd. 2019;777:663.

Zhu BL, Yang SW, Zhang MQ, Ding JW, Long Y, Wan FR. Formation and evolution of platelet-like Ti-rich precipitates in the V–4Cr–4Ti alloy. Mater Charact. 2016;111:60.

Impagnatiello A, Toyama T, Jimenez-Melero E. Ti-rich precipitate evolution in vanadium-based alloys during annealing above 400°C. J Nucl Mater. 2017;485:122.

Jiang SN, Xu LQ, Wan FR. Effect of precipitates on high-temperature strength and irradiation behavior of vanadium-based alloys. J Iron Steel Res Int. 2018;25:1270.

Tougou K, Nogiwa K, Tachikawa K, Fukumoto K. Tensile testing study of dynamic interactions between dislocations and precipitate in vanadium alloys. J Nucl Mater. 2013;442:S350.

Zheng PF, Nagasaka T, Muroga T, Chen JM, Li YF. Creep properties of V–4Cr–4Ti strengthened by cold working and aging. Fusion Eng Des. 2011;86:2561.

Chen JM, Nagasaka T, Muroga T, Qiu SY, Li C, Nita N. Mechanical properties of V–4Cr–4Ti strengthened by precipitation and cold rolling. J Nucl Mater. 2008;374:298.

Heo NJ, Nagasaka T, Muroga T, Matsui H. Effect of impurity levels on precipitation behavior in the low-activation V–4Cr–4Ti alloys. J Nucl Mater. 2002;307–311:620.

Zheng PF, Nagasaka T, Muroga T, Chen JM. Microstructures and mechanical properties of mechanically alloyed V–4Cr–4Ti alloy dispersion strengthened by nano-particles. Fusion Eng Des. 2014;89(7–8):1648.

Peng LX, Jiang CL, Li XW, Zhou P, Li YF, Lai XC. The formation of precipitates and its effect on grain structure in V-4Cr-4Ti alloys with yttrium addition. J Alloys Compd. 2017;694:1165.

Duan XR, Chen JM, Feng KM, Liu X, Li B, Wu JH, Wang XY, Zheng PF, Wang YQ, Wang PH, Liu Y. Progress in fusion technology at SWIP. Fusion Eng Des. 2016;109:1022.

Muroga T, Pint BA. Progress in the development of insulator coating for liquid lithium blankets. Fusion Eng Des. 2010;85:1301.

Kurtz RJ, Odette GR. Structural alloys for nuclear energy applications. Amsterdam: Elsevier. 2019; p 51.

Pint BA, Tortorelli PF, Jankowski A, Hayer J, Muroga T, Suzuki A, Yeliseyeva OI, Chernov VM. Recent progress in the development of electrically insulating coatings for a liquid lithium blanket. J Nucl Mater. 2004;329–333:119.

Akamatsu H, Satou M, Sato T, Jain A, Gupta V, Hasegawa A. Evaluation of bonding strength between yttria coating and vanadium alloys for development of self-cooled blanket. J Nucl Mater. 2011;417:1253.

Eliseeva OI, Fedirko VN, Chernov VM, Zavialsky LP. Corrosion of V-Ti–Cr alloys in liquid lithium: influence of alloy composition and concentration of nitrogen in lithium. J Nucl Mater. 2000;283–287:1282.

Evtikhin VA, Lyublinski IE, Vertkov AV. Compatibility of vanadium alloys and its weld joints in homogeneous and heterogeneous liquid lithium systems. J Nucl Mater. 1998;258–263:1487.

Pint BA, Pawel SJ, Howell M, Moser JL, Garner GW, Santella ML, Tortorelli PF, Wiffen FW, DiStefano JR. Initial characterization of V–4Cr–4Ti and MHD coatings exposed to flowing Li. J Nucl Mater. 2009;386–388:712.

Fujiwara M, Natesan K, Satou M, Hasegawa A, Abe K. Effects of doping elements on oxidation properties of V-Cr–Ti type alloys in several environments. J Nucl Mater. 2002;307–311:601.

Sawan ME. Damage parameters of structural materials in fusion environment compared to fission reactor irradiation. Fusion Eng Des. 2012;87:551.

Wan FR. Clusters of point defects and one-dimensional motion of clusters during irradiation damage in materials. Chinese J Eng. 2020;42(12):1535 (in Chinese).

Gao J, Cui LJ, Wan FR. Characterization of microstructure in hydrogen ion irradiated vanadium at room temperature and the microstructural evolution during post-irradiation annealing. Mater Charact. 2016;111:1.

Impagnatiello A, Shubeita SM, Wady PT, Ipatova I, Dawson H, Barcellini C, Jimenez-Melero E. Monolayer-thick TiO precipitation in V-4Cr-4Ti alloy induced by proton irradiation. Scr Mater. 2017;130:174.

Xiao XZ, Song DK, Chu HHJ, Xue JJM, Duan HL. Irradiation hardening for metallic materials. Adv Mech. 2015;45:142.

Pei H, Yao WZ, Liu JM, Zhang XD. Evaluation of irradiation properties for fusion structural materials. J Mater Eng. 2018;46(6):19.

Spitsyn AV, Bobyr NP, Kulevoy TV, Fedin PA, Semennikov AI, Stolbunov VS. Use of MeV energy ion accelerators to simulate the neutron damage in fusion reactor materials. Fusion Eng Des. 2019;146:1313.

Stork D, Zinkle SJ. Introduction to the special issue on the technical status of materials for a fusion reactor. Nucl Fusion. 2017;57:092001.

Jaime M, Tuan H, Michael F, Hsiung LL. A review of helium–hydrogen synergistic effects in radiation damage observed in fusion energy steels and an interaction model to guide future understanding. J Nucl Mater. 2015;462:409.

Yang YC, Ding JH, Zhang HL, Zhang PB, Mei XX, Huang SS, Zhao JJ. Atomistic understanding of helium behaviors at grain boundaries in vanadium. Comp Mater Sci. 2019;158:296.

Wang YY, Ding JH, Huang SS, Zhao JJ, Wang YZ. Mesoscale modeling of irradiation damage evolution in bcc iron and vanadium: a comparative study. Fusion Eng Des. 2018;37:303.

Zinkle SJ, Busby JT. Structural materials for fission and fusion energy. Mater Today. 2009;12:12.

Fukumoto K, Matsui H, Chandra Y, Takahashi K, Sasanuma H, Nadata S, Takahiro K. Radiation-induced precipitation in V–(Cr, Fe)–Ti alloys irradiated at low temperature with low dose during neutron or ion irradiation. J Nucl Mater. 2000;535–540:283.

Hosemann P, Kiener D, Wang YQ, Maloy SA. Issues to consider using nano indentation on shallow ion beam irradiated materials. J Nucl Mater. 2012;425:136.

Kasada R, Konishia S, Yabuuchi K, Nogami S, Ando M, Hamaguchi D, Tanigawa H. Depth-dependent nanoindentation hardness of reduced-activation ferritic steels after MeV Fe-ion irradiation. Fusion Eng Des. 2014;89(7–8):1637.

Yang YT, Yan TX, Zhang CH, Fu X, Ma TD, Niu MK, Ding ZN, Gou J, Chen YG, Song Y. Irradiation hardening of pure vanadium and vanadium alloys due to helium ion implantation and displacement damage. J Nucl Mater. 2020;540:152381.

Zhang P, Li SX, Zhang ZF. General relationship between strength and hardness. Mater Sci Eng A. 2011;2011(529):62.

Sato S, Shobu T, Satoh K, Ogawa H, Wagatsuma K, Kumagai M, Imafuku M, Tashiro H, Suzuki S. Distribution and anisotropy of dislocations in cold-drawn pearlitic steel wires analyzed using micro-beam X-ray diffraction. ISIJ Int. 2015;55(7):1432.

Moon J, Kim SH, Jang J, Lee JB, Lee CH. Orowan strengthening effect on the nanoindentation hardness of the ferrite matrix in microalloyed steels. Mater Sci Eng A. 2008;487:552.

Jiang SN, Xu LQ, Zheng PF. Evaluation of hardening behavior under synergistic interaction of He and subsequent H ions irradiation in vanadium alloys. Nucl Mater Energy. 2018;16:19.

Jiang SN, Wang ZM. Effect of annealing on microstructures and hardening of helium- hydrogen-implanted sequentially vanadium alloys. Nanoscale Res Lett. 2018;13:72.

Zou TT, Zhang PB, Zhao JJ, Zheng PF, Chen JM. First principles study of vacancy-solute complexes in vanadium. J Alloy Compd. 2018;763:861.

Li BS, Wang ZG, Wei KF, Shen TL, Yao CF, Zhang HP, Sheng YB, Lu XR, Xiong AL, Han WT. Evaluation of helium effect on irradiation hardening in F82H, ODS, SIMP and T91 steels by nano-indentation method. Fusion Eng Des. 2019;142:6.

Jiang SN, Yu CW, Zheng PF, Guo LP, Zhou X, Rao WF. Bubbles and precipitates formation and effects on the hardening of irradiated vanadium alloys. J Nucl Mater. 2021;544:152712.

Shi JJ, Zhao WZ, Wu YC, Liu XB, Jiang J, Cao XZ, Wang BY. Evolution of microstructures and hardening property of initial irradiated, post-irradiation annealed and re-irradiated Chinese-type low-Cu reactor pressure vessel steel. J Nucl Mater. 2019;523:333.

Zhang J, Han WZ. Oxygen solutes induced anomalous hardening, toughening and embrittlement in body-centered cubic vanadium. Acta Mater. 2020;196:122.

Gui LJ, Liu YL. First-principles studying the properties of oxygen in vanadium: thermodynamics and tensile/shear behavior. Comput Condens Matter. 2016;7:7.

Zhang XM, Li YF, Tang JF, Deng L, Li W, Wang L, Deng HQ, Hu WY. Precipitate/vanadium interface and its strengthening on the vanadium alloys: a first-principles study. J Nucl Mater. 2019;527:151821.

Deng L, Zhang XM, Tang JF, Deng HQ, Xiao SF, Hu WY. First-principles study of the binding preferences and diffusion behaviors of solutes in vanadium alloys. J Alloy Compd. 2016;660:55.

Gong L, Su QL, Deng HQ, Xiao SF, Hu WY. The stability and diffusion properties of foreign impurity atoms on the surface and in the bulk of vanadium: a first-principles study. Comput Mater Sci. 2014;81:191.

Gusev AI. Ti5O5 superstructures of cubic titanium monoxide. J Exp Theor Phys. 2013;11:293.

Boev AO, Aksyonov D, Kartamyshev AI, Maksimenko VN, Nelasov IV, Lipnitskii AG. Interaction of Ti and Cr atoms with point defects in bcc vanadium: a DFT study. J Nucl Mater. 2017;492:14.

Zhang PB, Zou TT, Zhao JJ, Zheng PF, Chen JM. Effect of helium and vacancies in a vanadium grain boundary by first-principles. Nucl Instrum Method B. 2015;352:121.

Zou TT, Zhang PB, Zhao JJ, Zheng PF, Chen JM. Effect of Ti/Cr additive on helium diffusion and segregation in dilute vanadium alloys. Nucl Instrum Meth B. 2017;393:130.

Zhang PB, Zou TT, Feng SB, Zhao JJ. First principles investigations of hydrogen interaction with vacancy-oxygen complexes in vanadium alloys. Int J Hydrogen Energy. 2019;44:26637.

Zhang PB, Ding JH, Sun D, Yang YC, Huang SS, Zhao JJ. First-principles calculations of vacancy-O-He and vacancy-N-He complexes in vanadium. Comput Mater Sci. 2019;160:180.

Yukawa H, Nambu T, Matsumoto Y. Ta-W alloy for hydrogen permeable membranes. Mater Trans. 2011;52(4):610.

Cherkeza DI, Spitsyn AV, Golubeva AV, Chernov VM. Deuterium permeation through the low- activated V–4Cr–4Ti alloy under plasma irradiation. Nucl Mater Energy. 2020;23:100756.

Xu XP, Liu HD, Lyu YM, Zhou HS, Ding F, Li ZD, Li XC, Jing Wang J, Yuan XG, Wang XL, Xu Q, Lin CG, Cao XZ, Zhu T, Wang BY, Luo GN. Effects of high-energy C ions irradiation on the deuterium retention behavior in V-5Cr-5Ti. J Nucl Mater. 2018;509:513.

Sagara A, Tamura H, Tanaka T, Yanagi N, Miyazawa J, Goto T, Sakamoto R, Yagi J, Watanabe T, Takayama S, the FFHR design group. Helical reactor design FFHR-d1 and c1 for steady-state DEMO. Fusion Eng Des. 2014;89:2114.

Watanabe T, Sagara A, Yagi J, Tsujimura T, Yamazaki G, Kumagai K, Tanaka T. Hydrogen recovery from metal particle dispersed salt by selective microwave heating. Fusion Eng Des. 2018;36:1396.

Yagi J, Sagara A, Watanabe T, Tanaka T, Takayama S, Muroga T. Hydrogen solubility in FLiNaK mixed with titanium powder. Fusion Eng Des. 1907;92015:8.

Nishiumi R, Fukada S, Yamashita J, Katayama K, Sagara A, Yagi J. Hydrogen permeation through fluoride molten salt mixed with Ti powder. Fusion Sci Tech. 2017;72:747.

Grossbeck ML, King JF, Hoelzer DT. Impurity effects on gas tungsten arc welds in V-Cr–Ti alloys. J Nucl Mater. 2000;283:1356.

Chung HM, Park JH, Strain RV, Leong KH, Smith DL. Mechanical properties and microstructural characteristics of laser and electron-beam welds in V–4Cr–4Ti. J Nucl Mater. 1998;258:1451.

Tsisar V, Nagasaka T, Le Flem M, Yeliseyeva O, Konys J, Muroga T. Impact properties of electron beam welds of V–4Ti–4Cr alloys NIFS-HEAT-2 and CEA-J57. Fusion Eng Des. 2014;89(7–8):1633.

Nagasaka T, Muroga T, Grossbeck ML, Miyazawa T, Yamazaki M, Shinozaki K. Effects of post-weld heat treatment conditions on hardness, microstructures and impact properties of vanadium alloys. J Nucl Mater. 2002;307(2):1595.

Heo NJ, Nagasaka T, Muroga T, Nishimura A, Shinozaki A, Watanabe H. Mechanical properties of laser weldment of V-4Cr-4Ti alloy. Fusion Sci Technol. 2003;44(2):470.

Nagasaka T, Muroga T, Watanabe H, Miyazawa T, Yamazaki M, Shinozaki K. Impact property of low-activation vanadium alloy after laser welding and heavy neutron irradiation. J Nucl Mater. 2013;442(1–3):S364.

Watanabe H, Yoshida N, Nagasaka T, Muroga T. The microstructure and hardness changes of neutron irradiated weld joint of vanadium alloy. J Nucl Mater. 2011;417(1–3):319.

Fu HY, Nagasaka T, Tanaka T, Sagara A, Serizawa H, Satou Y. Dissimilar-metals bonding between NIFS-HEAT-2 vanadium alloy and Hastelloy X nickel alloy by controlling intermetallics. Fusion Sci Technol. 2017;72(4):680.

Jiang SN, Shen JJ, Nagasaka T, Muroga T, Sagara A, Ohnuki S, Hokamoto K, Tanaka S, Inao D, Morizono Y, Kasada Y, Zheng PF. Interfacial characterization of dissimilar-metals bonding between vanadium alloy and Hastelloy X alloy by explosive welding. J Nucl Mater. 2020;539:152322.

Steward RV, Grossbeck ML, Chin BA, Aglan HA, Gan Y. Furnace brazing type 304 stainless steel to vanadium alloy (V–5Cr–5Ti). J Nucl Mater. 2000;283:1224.

Serizawa H, Ogura H, Morisada Y, Fujii H, Mori H, Nagasaka T. Influence of friction stir welding conditions on joinability of V-alloy/ SUS316L dissimilar joint. Nucl Mater Energy. 2018;15:43.

Zhang LW, Fu HY, Chai ZJ, Zheng PF, Wei R, Zhang M, Chen JM. Dissimilar-metal bonding of a carbide-dispersion strengthened vanadium alloy for V/Li fusion blanket application. Tungsten. 2020;2(1):101.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 11474167 and 51501097), the Natural Science Foundation of Shandong Province (Grant No. ZR2014EMP005), the Innovation Team of Jinan (Grant No. 2019GXRC035), and the Key R&D Program of Shandong Province of China (Grant No. 2019QYTPY057)

Author information

Authors and Affiliations

Contributions

Shao-Ning Jiang and Fu-Jie Zhou wrote the draft; Gao-Wei Zhang, Xiao-Ou Yi and Wei-Feng Rao contributed to conceiving the idea of the study; Chang-Wang Yu and Xiu-Jie Wang collected the data. All the authors contributed to the writing and revisions.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, SN., Zhou, FJ., Zhang, GW. et al. Recent progress of vanadium-based alloys for fusion application. Tungsten 3, 382–392 (2021). https://doi.org/10.1007/s42864-021-00107-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-021-00107-4