Abstract

The limited mechanical properties of carbon nanofibers (CNFs) have become a severe problem hindering their wide range applications. The restricting issues are found in the whole fabrication process, including the precursor design, spinning and collection techniques, post treatments like stretching and aligning, and complicated thermal treatments involving stabilization and carbonization. Here we access the CNF development by focusing on the mechanical properties, and systematically discuss the strengthening strategies during the different fabrication stages.

Similar content being viewed by others

References

Rodriguez NM. A review of catalytically grown carbon nanoflbers. J Mater Res. 1993;8(12):3233–50. https://doi.org/10.1557/JMR.1993.3233.

de Jong KP, Geus JW. Carbon Nanofibers: Catalytic Synthesis and Applications. Catal Rev Sci Eng. 2000;42(4):481–510. https://doi.org/10.1081/CR-100101954.

Zou G, Zhang D, Dong C, Li H, Xiong K, Fei L, Qian Y. Carbon nanofibers: synthesis, characterization, and electrochemical properties. Carbon. 2006;44(5):828–32. https://doi.org/10.1016/j.carbon.2005.10.035.

Klein KL, Melechko AV, McKnight TE, Retterer ST, Rack PD, Fowlkes JD, Joy DC, Simpson ML. Surface characterization and functionalization of carbon nanofibers. J Appl Phys. 2008;103(6):061301. https://doi.org/10.1063/1.2840049.

Zhang L, Aboagye A, Kellar A, Lai C, Fong H. A review: carbon nanofibers from electrospun polyacrylonitrile and their applications. J Mater Sci. 2014;49(2):463–80. https://doi.org/10.1007/s10853-013-7705-y.

Lu W, He T, Xu B, He X, Adidharma H, Radosz M, Gasem K, Fan M. Progress in catalytic synthesis of advanced carbon nanofibers. J Mater Chem A. 2017;5(27):13863–81. https://doi.org/10.1039/c7ta02007d.

Chen LF, Feng Y, Liang HW, Wu ZY, Yu SH. Macroscopic-scale three-dimensional carbon nanofiber architectures for electrochemical energy storage devices. Adv Energy Mater. 2017;7(23):1700826. https://doi.org/10.1002/aenm.201700826.

de Oliveira JB, Guerrini LM, Oishi SS, de Oliveira Hein LR, dos Santos Conejo L, Rezende MC, Botelho EC. Carbon nanofibers obtained from electrospinning process. Mater Res Express. 2018;5(2):025602. https://doi.org/10.1088/2053-1591/aaa467.

Ruiz-Cornejo JC, Sebastián D, Lázaro MJ. Synthesis and applications of carbon nanofibers: a review. Rev Chem Eng. 2019. https://doi.org/10.1515/revce-2018-0021.

Jadhav SA, Dhavale SB, Patil AH, Patil PS. Brief overview of electrospun polyacrylonitrile carbon nanofibers: Preparation process with applications and recent trends. Mater Des Process Comm. 2019;1(5):e83. https://doi.org/10.1002/mdp2.83.

Miyagawa H, Rich MJ, Drzal LT. Thermo-physical properties of epoxy nanocomposites reinforced by carbon nanotubes and vapor grown carbon fibers. Thermochim Acta. 2006;442(1–2):67–73. https://doi.org/10.1016/j.tca.2006.01.016.

Al-Saleh MH, Sundararaj U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos Part A. 2011;42(12):2126–42. https://doi.org/10.1016/j.compositesa.2011.08.005.

Feng L, Xie N, Zhong J. Carbon nanofibers and their composites: a review of synthesizing. Properties Appl Mater. 2014;7:3919–45. https://doi.org/10.3390/ma7053919.

Zhuang X, Jia K, Cheng B, Feng X, Shi S, Zhang B. Solution blowing of continuous carbon nanofiber yarn and its electrochemical performance for supercapacitors. Chem Eng J. 2014;237:308–11. https://doi.org/10.1016/j.cej.2013.10.038.

Wang H, Wang W, Wang H, Jin X, Niu H, Wang H, Zhou H, Lin T. High performance supercapacitor electrode materials from electrospun carbon nanofibers in situ activated by high decomposition temperature polymer. ACS Appl Energy Mater. 2018;1(2):431–9. https://doi.org/10.1021/acsaem.7b00083.

Azwar E, Mahari WAW, Chuah JH, Vo DVN, Ma NL, Lam WH, Lam SS. Transformation of biomass into carbon nanofiber for supercapacitor application—a review. Int J Hydrogen Energy. 2018;43(45):20811–21. https://doi.org/10.1016/j.ijhydene.2018.09.111.

Yu S, Yang N, Vogel M, Mandal S, Williams OA, Jiang S, Schönherr H, Yang B, Jiang X. Battery-like supercapacitors from vertically aligned carbon nanofiber coated diamond: design and demonstrator. Adv Energy Mater. 2018;8(12):1702947. https://doi.org/10.1002/aenm.201702947.

Steigerwalt ES, Deluga GA, Cliffel DE, Lukehart CM. A Pt-Ru/Graphitic carbon nanofiber nanocomposite exhibiting high relative performance as a direct-methanol fuel cell anode catalyst. J Phys Chem B. 2001;105(34):8097–101. https://doi.org/10.1021/jp011633i.

Chinthaginjala JK, Seshan K, Lefferts L. Preparation and application of carbon-nanofiber based microstructured materials as catalyst supports. Ind Eng Chem Res. 2007;46(12):3968–78. https://doi.org/10.1021/ie061394r.

Kim IT, Song MJ, Shin S, Shin MW. Co- and defect-rich carbon nanofiber films as a highly efficient electrocatalyst for oxygen reduction. Appl Surf Sci. 2018;435:1159–67. https://doi.org/10.1016/j.apsusc.2017.11.228.

Park SH, Jung HR, Kim BK, Lee WJ. MWCNT/mesoporous carbon nanofibers composites prepared by electrospinning and silica template as counter electrodes for dye-sensitized solar cells. J Photochem Photobiol A. 2012;246:45–9. https://doi.org/10.1016/j.jphotochem.2012.07.013.

Han Z, Cheng Z, Chen Y, Li B, Liang Z, Li H, Ma Y, Feng X. Fabrication of highly pressure-sensitive, hydrophobic, and flexible 3D carbon nanofiber networks by electrospinning for human physiological signal monitoring. Nanoscale. 2019;11(13):5942–50. https://doi.org/10.1039/c8nr08341j.

Wang Z, Wu S, Wang J, Yu A, Wei G. Carbon nanofiber-based functional nanomaterials for sensor applications. Nanomaterials. 2019;9(7):1045. https://doi.org/10.3390/nano9071045.

Aliev AE, Perananthan S, Ferraris JP. Carbonized electrospun nanofiber sheets for thermophones. ACS Appl Mater Interfaces. 2016;8(45):31192–201. https://doi.org/10.1021/acsami.6b08717.

Fang SP, Colon-Perez L, Zhou J, DeMarse TB, Febo M, Carney PR, Yoon YK. High magnetic field fmri compliant carbon nanofiber neural probes. In: 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS). 2017, p. 1707–1710. https://doi.org/10.1109/TRANSDUCERS.2017.7994395.

Stout DA, Basu B, Webster TJ. Poly(lactic-co-glycolic acid): carbon nanofiber composites for myocardial tissue engineering applications. Acta Biomater. 2011;7(8):3101–12. https://doi.org/10.1016/j.actbio.2011.04.028.

Zhang S, Liu H, Tang N, Ge J, Yu J, Ding B. Direct electronetting of high-performance membranes based on self-assembled 2D nanoarchitectured networks. Nat Commun. 2019;10:1458. https://doi.org/10.1038/s41467-019-09444-y.

Iqbal N, Wang X, Babar AA, Yan J, Yu J, Park SJ, Ding B. Polyaniline enriched flexible carbon nanofibers with core-shell structure for high-performance wearable supercapacitors. Adv Mater Interfaces. 2017;4(24):1700855. https://doi.org/10.1002/admi.201700855.

Aboalhassan AA, Yan J, Zhao Y, Dong K, Wang X, Yu J, Ding B. Self-assembled porous-silica within N-doped carbon nanofibers as ultra-flexible anodes for soft lithium batteries. iScience. 2019;16:122–32. https://doi.org/10.1016/j.isci.2019.05.023.

Kim H, Lee S. Characterization of carbon nanofiber (CNF)/polymer composite coated on cotton fabrics prepared with various circuit patterns. Fashion Text. 2018;5:7. https://doi.org/10.1186/s40691-017-0120-2.

Park C, Engel ES, Crowe A, Gilbert TR, Rodriguez NM. Use of carbon nanofibers in the removal of organic solvents from water. Langmuir. 2000;16(21):8050–6. https://doi.org/10.1021/la9916068.

Si Y, Ren T, Li Y, Ding B, Yu J. Fabrication of magnetic polybenzoxazine-based carbon nanofibers with \(\text{Fe}_{3}\text{O}_{4}\) inclusions with a hierarchical porous structure for water treatment. Carbon. 2012;50(14):5176–85. https://doi.org/10.1016/j.carbon.2012.06.059.

Huang B, Yue J, Wei Y, Huang X, Tang X, Du Z. Enhanced microwave absorption properties of carbon nanofibers functionalized by FeCo coatings. Appl Surf Sci. 2019;483:98–105. https://doi.org/10.1016/j.apsusc.2019.03.301.

Liu M, Zhang P, Qu Z, Yan Y, Lai C, Liu T, Zhang S. Conductive carbon nanofiber interpenetrated graphene architecture for ultra-stable sodium ion battery. Nat Commun. 2019;10:3917. https://doi.org/10.1038/s41467-019-11925-z.

Zussman E, Chen X, Ding W, Calabri L, Dikin DA, Quintana JP, Ruoff RS. Mechanical and structural characterization of electrospun PAN-derived carbon nanofibers. Carbon. 2005;43(10):2175–85. https://doi.org/10.1016/j.carbon.2005.03.031.

History of Carbon Fiber. 2019. http://www.torayca.com/en/aboutus/abo_002.html. Accessed Sept 2019.

Fitzer E. Pan-based carbon fibers—-present state and trend of the technology from the viewpoint of possibilities and limits to influence and to control the fiber properties by the process parameters. Carbon. 1989;27(5):621–45. https://doi.org/10.1016/0008-6223(89)90197-8.

Reneker DH, Yarin AL, Fong H, Koombhongse S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J Appl Phys. 2000;87(9):4531–47. https://doi.org/10.1063/1.373532.

Liu J, Yue Z, Fong H. Continuous nanoscale carbon fibers with superior mechanical strength. Small. 2009;5(5):536–42. https://doi.org/10.1002/smll.200801440.

Liu C, Cheng HM. Carbon nanotubes: controlled growth and application. Mater Today. 2013;16(1–2):19–28. https://doi.org/10.1016/j.mattod.2013.01.019.

Tibbetts GG, Lake ML, Strong KL, Rice BP. A review of the fabrication and properties of vapor-grown carbon nanofiber/polymer composites. Compos Sci Technol. 2007;67(7–8):1709–18. https://doi.org/10.1016/j.compscitech.2006.06.015.

Linares A, Canalda JC, Cagiao ME, García-Gutiérrez MC, Nogales A, Martín-Gullón I, Vera J, Ezquerra TA. Broad-band electrical conductivity of high density polyethylene nanocomposites with carbon nanoadditives: multiwall carbon nanotubes and carbon nanofibers. Macromolecules. 2008;41(19):7090–7. https://doi.org/10.1021/ma801410j.

van der Lee MK, van Dillen AJ, Geus JW, de Jong KP, Bitter JH. Catalytic growth of macroscopic carbon nanofiber bodies with high bulk density and high mechanical strength. Carbon. 2006;44(4):629–37. https://doi.org/10.1016/j.carbon.2005.09.031.

Martin-Gullon I, Vera J, Conesa JA, González JL, Merino C. Differences between carbon nanofibers produced using Fe and Ni catalysts in a floating catalyst reactor. Carbon. 2006;44(8):1572–80. https://doi.org/10.1016/j.carbon.2005.12.027.

Al-Saleh MH, Sundararaj U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon. 2009;47(1):2–22. https://doi.org/10.1016/j.carbon.2008.09.039.

Guadagno L, Raimondo M, Vittoria V, Vertuccio L, Lafdi K, De Vivo B, Lamberti P, Spinelli G, Tucci V. The role of carbon nanofiber defects on the electrical and mechanical properties of CNF-based resins. Nanotechnology. 2013;24(30):305704. https://doi.org/10.1088/0957-4484/24/30/305704.

Uchida T, Anderson DP, Minus ML, Kumar S. Morphology and modulus of vapor grown carbon nano fibers. J Mater Sci. 2006;41(18):5851–6. https://doi.org/10.1007/s10853-006-0324-0.

Yao Y, Xu R, Chen M, Cheng X, Zeng S, Li D, Zhou X, Wu X, Yu Y. Encapsulation of \(\text{SeS}_{2}\) into nitrogen-doped free-standing carbon nanofiber film enabling long cycle life and high energy density \(\text{K-SeS}_{2}\) battery. ACS Nano. 2019;13(4):4695–704. https://doi.org/10.1021/acsnano.9b00980.

Arshad SN, Naraghi M, Chasiotis I. Strong carbon nanofibers from electrospun polyacrylonitrile. Carbon. 2011;49(5):1710–9. https://doi.org/10.1016/j.carbon.2010.12.056.

Wang C, Kim J, Kim M, Lim H, Zhang M, You J, Yun JH, Bando Y, Li J, Yamauchi Y. Nanoarchitectured metal-organic framework-derived hollow carbon nanofiber filters for advanced oxidation processes. J Mater Chem A. 2019;7(22):13743–50. https://doi.org/10.1039/c9ta03128f.

Ma S, Wang Y, Liu Z, Huang M, Yang H, Xu Zl. Preparation of carbon nanofiber with multilevel gradient porous structure for supercapacitor and \(\text{CO}_{2}\) adsorption. Chem Eng Sci. 2019;205:181–9. https://doi.org/10.1016/j.ces.2019.05.001.

Merkulov VI, Lowndes DH, Wei YY, Eres G, Voelkl E. Patterned growth of individual and multiple vertically aligned carbon nanofibers. Appl Phys Lett. 2000;76(24):3555–7. https://doi.org/10.1063/1.126705.

Endo M, Kim YA, Ezaka M, Osada K, Yanagisawa T, Hayashi T, Terrones M, Dresselhaus MS. Selective and efficient impregnation of metal nanoparticles on cup-stacked-type carbon nanofibers. Nano Lett. 2003;3(6):723–6. https://doi.org/10.1021/nl034136h.

Qin Y, Zhang Z, Cui Z. Helical carbon nanofibers with a symmetric growth mode. Carbon. 2004;42(10):1917–22. https://doi.org/10.1016/j.carbon.2004.03.020.

Jian X, Chen X, Zhou Z, Li G, Jiang M, Xu X, Lu J, Li Q, Wang Y, Gou J, Hui D. Remarkable improvement in microwave absorption by cloaking a micro-scaled tetrapod hollow with helical carbon nanofibers. Phys Chem Chem Phys. 2015;17(5):3024–31. https://doi.org/10.1039/c4cp04849k.

Li D, Xia Y. Electrospinning of nanofibers: reinventing the wheel? Adv Mater. 2004;16(14):1151–70. https://doi.org/10.1002/adma.200400719.

Reneker DH, Yarin AL. Electrospinning jets and polymer nanofibers. Polymer. 2008;49(10):2387–425. https://doi.org/10.1016/j.polymer.2008.02.002.

Rahaman MSA, Ismail AF, Mustafa A. A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab. 2007;92(8):1421–32. https://doi.org/10.1016/j.polymdegradstab.2007.03.023.

Taylor GI. Electrically driven jets. Proc R Soc Lond A. 1969;313(1515):453–75. https://doi.org/10.1098/rspa.1969.0205.

Barua B, Saha MC. Studies of reaction mechanisms during stabilization of electrospun polyacrylonitrile carbon nanofibers. Polym Eng Sci. 2018;58(8):1315–21. https://doi.org/10.1002/pen.24708.

Ouyang Q, Cheng L, Wang H, Li K. Mechanism and kinetics of the stabilization reactions of itaconic acid-modified polyacrylonitrile. Polym Degrad Stab. 2008;93(8):1415–21. https://doi.org/10.1016/j.polymdegradstab.2008.05.021.

Belyaev SS, Arkhangelsky IV, Makarenko IV. Non-isothermal kinetic analysis of oxidative stabilization processes in PAN fibers. Thermochim Acta. 2010;507–508:9–14. https://doi.org/10.1016/j.tca.2010.04.022.

Xue Y, Liu J, Liang J. Correlative study of critical reactions in polyacrylonitrile based carbon fiber precursors during thermal-oxidative stabilization. Polym Degrad Stab. 2013;98(1):219–29. https://doi.org/10.1016/j.polymdegradstab.2012.10.018.

Xue Y, Liu J, Liang J. Kinetic study of the dehydrogenation reaction in polyacrylonitrile-based carbon fiber precursors during thermal stabilization. J Appl Polym Sci. 2013;127(1):237–45. https://doi.org/10.1002/app.37878.

Zhang BT, Zhang Y, Teng Y. Electrospun magnetic cobalt-carbon nanofiber composites with axis-sheath structure for efficient peroxymonosulfate activation. Appl Surf Sci. 2018;452:443–50. https://doi.org/10.1016/j.apsusc.2018.05.065.

Iqbal N, Wang X, Babar AA, Yu J, Ding B. Highly flexible \(\text{NiCo}_{2}\text{O}_{4}\)/CNTs doped carbon nanofibers for \(\text{CO}_{2}\) adsorption and supercapacitor electrodes. J Colloid Interface Sci. 2016;476:87–93. https://doi.org/10.1016/j.jcis.2016.05.010.

Ge J, Fan G, Si Y, He J, Kim HY, Ding B, Al-Deyab SS, El-Newehy M, Yu J. Elastic and hierarchical porous carbon nanofibrous membranes incorporated with NiFe2O4 nanocrystals for highly efficient capacitive energy storage. Nanoscale. 2016;8(4):2195–204. https://doi.org/10.1039/c5nr07368e.

Si Y, Yu J, Tang X, Ge J, Ding B. Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality. Nat Commun. 2014;5:5802. https://doi.org/10.1038/ncomms6802.

Fennessey SF, Farris RJ. Fabrication of aligned and molecularly oriented electrospun polyacrylonitrile nanofibers and the mechanical behavior of their twisted yarns. Polymer. 2004;45(12):4217–25. https://doi.org/10.1016/j.polymer.2004.04.001.

Zhou Z, Liu K, Lai C, Zhang L, Li J, Hou H, Reneker DH, Fong H. Graphitic carbon nanofibers developed from bundles of aligned electrospun polyacrylonitrile nanofibers containing phosphoric acid. Polymer. 2010;51(11):2360–7. https://doi.org/10.1016/j.polymer.2010.03.044.

Li D, Wang Y, Xia Y. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays. Nano Lett. 2003;3(8):1167–71. https://doi.org/10.1021/nl0344256.

Deitzel JM, Kleinmeyer JD, Hirvonen JK, Tan Beck NC. Controlled deposition of electrospun poly(ethylene oxide) fibers. Polymer. 2001;42(19):8163–70. https://doi.org/10.1016/S0032-3861(01)00336-6.

Smit E, Bűttner U, Sanderson RD. Continuous yarns from electrospun fibers. Polymer. 2005;46(8):2419–23. https://doi.org/10.1016/j.polymer.2005.02.002.

Pan H, Li L, Hu L, Cui X. Continuous aligned polymer fibers produced by a modified electrospinning method. Polymer. 2006;47(14):4901–4. https://doi.org/10.1016/j.polymer.2006.05.012.

Xie Z, Niu H, Lin T. Continuous polyacrylonitrile nanofiber yarns: preparation and dry-drawing treatment for carbon nanofiber production. RSC Adv. 2015;5(20):15147–53. https://doi.org/10.1039/c4ra16247a.

Ali U, Niu H, Abbas A, Shao H, Lin T. Online stretching of directly electrospun nanofiber yarns. RSC Adv. 2016;6(36):30564–9. https://doi.org/10.1039/C6RA01856D.

Krauß P, Wombacher T, Schneider JJ. Synthesis of carbon nanofibers by thermal conversion of the molecular precursor 5,6;11,12-di-\(o\)-phenylenetetracene and its application in a chemiresistive gas sensor. RSC Adv. 2017;7(71):45185–94. https://doi.org/10.1039/c7ra08257f.

Wen Y, Jiang M, Kitchens CL, Chumanov G. Synthesis of carbon nanofibers via hydrothermal conversion of cellulose nanocrystals. Cellulose. 2017;24(11):4599–604. https://doi.org/10.1007/s10570-017-1464-x.

Kaerkitcha N, Chuangchote S, Sagawa T. Control of physical properties of carbon nanofibers obtained from coaxial electrospinning of PMMA and PAN with adjustable inner/outer nozzle-ends. Nanoscale Res Lett. 2016;11:186. https://doi.org/10.1186/s11671-016-1416-7.

Hulteen JC, Chen HX, Chambliss CK, Martin CR. Template synthesis of carbon nanotubule and nanofiber arrays. Nanostruct Mater. 1997;9(1–8):133–6. https://doi.org/10.1016/S0965-9773(97)00036-6.

Fernández-Saavedra R, Aranda P, Ruiz-Hitzky E. Templated synthesis of carbon nanofibers from polyacrylonitrile using sepiolite. Adv Funct Mater. 2004;14(1):77–82. https://doi.org/10.1002/adfm.200305514.

Wang Y, Zheng M, Lu H, Feng S, Ji G, Cao J. Template synthesis of carbon nanofibers containing linear mesocage arrays. Nanoscale Res Lett. 2010;5:913–6. https://doi.org/10.1007/s11671-010-9562-9.

Ramachandramoorthy R, Beese A, Espinosa H. In situ electron microscopy tensile testing of constrained carbon nanofibers. Int J Mech Sci. 2018;149:452–8. https://doi.org/10.1016/j.ijmecsci.2017.09.028.

Beese AM, Papkov D, Li S, Dzenis Y, Espinosa HD. In situ transmission electron microscope tensile testing reveals structure-property relationships in carbon nanofibers. Carbon. 2013;60:246–53. https://doi.org/10.1016/j.carbon.2013.04.018.

Chawla S, Cai J, Naraghi M. Mechanical tests on individual carbon nanofibers reveals the strong effect of graphitic alignment achieved via precursor hot-drawing. Carbon. 2017;117:208–19. https://doi.org/10.1016/j.carbon.2017.02.095.

Ozkan T, Naraghi M, Chasiotis I. Mechanical properties of vapor grown carbon nanofibers. Carbon. 2010;48(1):239–44. https://doi.org/10.1016/j.carbon.2009.09.011.

Li X, Yang Y, Zhao Y, Lou J, Zhao X, Wang R, Liang Q, Huang Z. Electrospinning fabrication and in situ mechanical investigation of individual graphene nanoribbon reinforced carbon nanofiber. Carbon. 2017;114:717–23. https://doi.org/10.1016/j.carbon.2016.12.082.

Papkov D, Zou Y, Andalib MN, Goponenko A, Cheng SZD, Dzenis YA. Simultaneously strong and tough ultrafine continuous nanofibers. ACS Nano. 2013;7(4):3324–31. https://doi.org/10.1021/nn400028p.

Naraghi M, Chasiotis I, Kahn H, Wen Y, Dzenis Y. Mechanical deformation and failure of electrospun polyacrylonitrile nanofibers as a function of strain rate. Appl Phys Lett. 2007;91(15):151901. https://doi.org/10.1063/1.2795799.

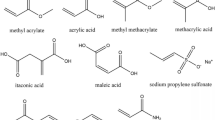

Duan G, Zhang H, Jiang S, Xie M, Peng X, Chen S, Hanif M, Hou H. Modification of precursor polymer using co-polymerization: a good way to high performance electrospun carbon nanofiber bundles. Mater Lett. 2014;122:178–81. https://doi.org/10.1016/j.matlet.2014.02.023.

Moon S, Farris RJ. Strong electrospun nanometer-diameter polyacrylonitrile carbon fiber yarns. Carbon. 2009;47(12):2829–39. https://doi.org/10.1016/j.carbon.2009.06.027.

Liao X, Dulle M, Silva dSeJM, Wehrspohn RB, Agarwal S, Förster S, Hou H, Smith P, Greiner A. High strength in combination with high toughness in robust and sustainable polymeric materials. Science. 2019;366(6471):1376–9. https://doi.org/10.1126/science.aay9033.

Ma S, Liu J, Qu M, Wang X, Huang R, Liang J. Effects of carbonization tension on the structural and tensile properties of continuous bundles of highly aligned electrospun carbon nanofibers. Mater Lett. 2016;183:369–73. https://doi.org/10.1016/j.matlet.2016.07.144.

Zhou Z, Lai C, Zhang L, Qian Y, Hou H, Reneker DH, Fong H. Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer. 2009;50(13):2999–3006. https://doi.org/10.1016/j.polymer.2009.04.058.

Youm JS, Kim JH, Kim CH, Kim JC, Kim YA, Yang KS. Densifying and strengthening of electrospun polyacrylonitrile-based nanofibers by uniaxial two-step stretching. J Appl Polym Sci. 2016;133(37):43945. https://doi.org/10.1002/app.43945.

Liu CK, Feng Y, He HJ, Zhang J, Sun RJ, Chen MY. Effect of carbonization temperature on properties of aligned electrospun polyacrylonitrile carbon nanofibers. Mater Des. 2015;85:483–6. https://doi.org/10.1016/j.matdes.2015.07.021.

Alarifi IM, Khan WS, Asmatulu R. Synthesis of electrospun polyacrylonitrile-derived carbon fibers and comparison of properties with bulk form. PLoS One. 2018;13(8):e0201345. https://doi.org/10.1371/journal.pone.0201345.

Ge JJ, Hou H, Li Q, Graham MJ, Greiner A, Reneker DH, Harris FW, Cheng SZD. Assembly of well-aligned multiwalled carbon nanotubes in confined polyacrylonitrile environments: electrospun composite nanofiber sheets. J Am Chem Soc. 2004;126(48):15754–61. https://doi.org/10.1021/ja048648p.

Hou H, Ge JJ, Zeng J, Li Q, Reneker DH, Greiner A, Cheng SZD. Electrospun polyacrylonitrile nanofibers containing a high concentration of well-aligned multiwall carbon nanotubes. Chem Mater. 2005;17(5):967–73. https://doi.org/10.1021/cm0484955.

Song Z, Hou X, Zhang L, Wu S. Enhancing crystallinity and orientation by hot-stretching to improve the mechanical properties of electrospun partially aligned polyacrylonitrile (PAN) nanocomposites. Materials. 2011;4(4):621–32. https://doi.org/10.3390/ma4040621.

Deng S, Liu X, Liao J, Lin H, Liu F. PEI modified multiwalled carbon nanotube as a novel additive in PAN nanofiber membrane for enhanced removal of heavy metal ions. Chem Eng J. 2019;375:122086. https://doi.org/10.1016/j.cej.2019.122086.

Ma S, Liu J, Liu Q, Liang J, Zhao Y, Fong H. Investigation of structural conversion and size effect from stretched bundle of electrospun polyacrylonitrile copolymer nanofibers during oxidative stabilization. Mater Des. 2016;95:387–97. https://doi.org/10.1016/j.matdes.2016.01.134.

Fatema UK, Uddin AJ, Uemura K, Gotoh Y. Fabrication of carbon fibers from electrospun poly(vinyl alcohol) nanofibers. Text Res J. 2011;81(7):659–72. https://doi.org/10.1177/0040517510385175.

Kawase J, Abe K, Tachikawa N, Katayama Y, Shiratori S. Influence of carbonization temperature and press processing on the electrochemical characteristics of self-standing iron oxide/carbon composite electrospun nanofibers. RSC Adv. 2017;7(52):32812–8. https://doi.org/10.1039/c7ra05301k.

Yarova S, Jones D, Jaouen F, Cavaliere S. Strategies to hierarchical porosity in carbon nanofiber webs for electrochemical applications. Surfaces. 2019;2(1):159–76. https://doi.org/10.3390/surfaces2010013.

Hu W, Zhang Z, Li L, Ding Y, An J. Preparation of electrospun \(\text{SnO}_{2}\) carbon nanofiber composite for ultra- sensitive detection of APAP and p-Hydroxyacetophenone. Sens Actuators B. 2019;299:127003. https://doi.org/10.1016/j.snb.2019.127003.

Sokolowski K, Palka P, Blazewicz S, Fraczek-Szczypta A. Carbon nanofibers-based nanocomposites with silicon oxy-carbide matrix. Ceram Int. 2020;46:1040–51. https://doi.org/10.1016/j.ceramint.2019.09.069.

de Oliveira JB, Guerrini LM, Conejo LdS, Rezende MC, Botelho EC. Viscoelastic evaluation of epoxy nanocomposite based on carbon nanofiber obtained from electrospinning processing. Polym Bull. 2019;76(12):6063–76. https://doi.org/10.1007/s00289-019-02707-0.

Gergin I, Ismar E, Sarac AS. Oxidative stabilization of polyacrylonitrile nanofibers and carbon nanofibers containing graphene oxide (GO): a spectroscopic and electrochemical study. Beilstein J Nanotechnol. 2017;8:1616–28. https://doi.org/10.3762/bjnano.8.161.

Cai J, Naraghi M. Effect of templating graphitization on electrical conductivity of electrospun CNTs reinforced carbon nanofiber. In: 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Grapevine, Texas, USA; 2017, p. 796. https://doi.org/10.2514/6.2017-0796.

Fox B. Making stronger carbon-fiber precursors. Science. 2019;366(6471):1314–5. https://doi.org/10.1126/science.aaz7928.

Damodaran S, Desai P, Abhiraman AS. Chemical and physical aspects of the formation of carbon fibres from PAN-based precursors. J Text Inst. 1990;81(4):384–420. https://doi.org/10.1080/00405009008658719.

Gu SY, Ren J, Vancso GJ. Process optimization and empirical modeling for electrospun polyacrylonitrile (PAN) nanofiber precursor of carbon nanofibers. Eur Polym J. 2005;41(11):2559–68. https://doi.org/10.1016/j.eurpolymj.2005.05.008.

Wang J, Hu L, Yang C, Zhao W, Lu Y. Effects of oxygen content in the atmosphere on thermal oxidative stabilization of polyacrylonitrile fibers. RSC Adv. 2016;6(77):73404–11. https://doi.org/10.1039/c6ra15308a.

Qin X, Lu Y, Xiao H, Song Y. Improving stabilization degree of stabilized fibers by pretreating polyacrylonitrile precursor fibers in nitrogen. Mater Lett. 2012;76:162–4. https://doi.org/10.1016/j.matlet.2012.02.103.

Duan G, Fang H, Huang C, Jiang S, Hou H. Microstructures and mechanical properties of aligned electrospun carbon nanofibers from binary composites of polyacrylonitrile and polyamic acid. J Mater Sci. 2018;53(21):15096–106. https://doi.org/10.1007/s10853-018-2700-y.

Lee J, Choi JI, Cho AE, Kumar S, Jang SS, Kim YH. Origin and control of polyacrylonitrile alignments on carbon nanotubes and graphene nanoribbons. Adv Funct Mater. 2018;28(15):1706970. https://doi.org/10.1002/adfm.201706970.

Maitra T, Sharma S, Srivastava A, Cho YK, Madou M, Sharma A. Improved graphitization and electrical conductivity of suspended carbon nanofibers derived from carbon nanotube/ polyacrylonitrile composites by directed electrospinning. Carbon. 2012;50(5):1753–61. https://doi.org/10.1016/j.carbon.2011.12.021.

Dror Y, Salalha W, Khalfin RL, Cohen Y, Yarin AL, Zussman E. Carbon nanotubes embedded in oriented polymer nanofibers by electrospinning. Langmuir. 2003;19(17):7012–20. https://doi.org/10.1021/la034234i.

Ko F, Gogotsi Y, Ali A, Naguib N, Ye H, Yang GL, Li C, Willis P. Electrospinning of continuous carbon nanotube-filled nanofiber yarns. Adv Mater. 2003;15(14):1161–5. https://doi.org/10.1002/adma.200304955.

Ghobadi S, Sadighikia S, Papila M, Cebeci FÇ, Gürsel SA. Graphene-reinforced poly(vinyl alcohol) electrospun fibers as building blocks for high performance nanocomposites. RSC Adv. 2015;5(103):85009–18. https://doi.org/10.1039/c5ra15689k.

Chee WK, Lim HN, Andou Y, Zainal Z, Hamra AAB, Harrison I, Altarawneh M, Jiang ZT, Huang NM. Functionalized graphene oxide-reinforced electrospun carbon nanofibers as ultrathin supercapacitor electrode. J Energy Chem. 2017;26(4):790–8. https://doi.org/10.1016/j.jechem.2017.04.007.

Nain R, Singh D, Jassal M, Agrawal AK. Zinc oxide nanorod assisted rapid single-step process for the conversion of electrospun poly(acrylonitrile) nanofibers to carbon nanofibers with a high graphitic content. Nanoscale. 2016;8(7):4360–72. https://doi.org/10.1039/c5nr06809f.

Prasad JV, Satpathy US, Jassal M, Pantar A, Satish S. Studies of the effect of comonomers on the microstructure of polyacrylonitrile in radical polymerization using NMR spectroscopy. Int J Polym Mater. 1992;18(1–2):105–15. https://doi.org/10.1080/00914039208034817.

Devasia R, Reghunadhan Nair CP, Sivadasan P, Ninan KN. High char-yielding poly[acrylonitrile-\(co\)-(itaconic acid)-\(co\)-(methyl acrylate)]: synthesis and properties. Polym Int. 2005;54(8):1110–8. https://doi.org/10.1002/pi.1811.

Nguyen-Thai NU, Hong SC. Structural evolution of poly(acrylonitrile-\(co\)-itaconic acid) during thermal oxidative stabilization for carbon materials. Macromolecules. 2013;46(15):5882–9. https://doi.org/10.1021/ma401003g.

Ju A, Yan Y, Wang D, Luo J, Ge M, Li M. A high molecular weight acrylonitrile copolymer prepared by mixed solvent polymerization: I. Effect of monomer feed ratios on polymerization and stabilization. RSC Adv. 2014;4(109):64043–52. https://doi.org/10.1039/c4ra10779a.

Loginova EV, Mikheev IV, Volkov DS, Proskurnin MA. Quantification of copolymer composition (methyl acrylate and itaconic acid) in polyacrylonitrile carbon-fiber precursors by FTIR-spectroscopy. Anal Methods. 2016;8(2):371–80. https://doi.org/10.1039/c5ay02264a.

Faraji S, Yardim MF, Can DS, Sarac AS. Characterization of polyacrylonitrile, poly(acrylonitrile-\(co\)-vinyl acetate), and poly(acrylonitrile-\(co\)-itaconic acid) based activated carbon nanofibers. J Appl Polym Sci. 2017;134(2):44381. https://doi.org/10.1002/app.44381.

Hosseini SA, Pan N, Ko F. Dynamic mechanical relaxations of electrospun poly(acrylonitrile-co-methyl acrylate) nanofibrous yarn. Text Res J. 2017;87(18):2193–203. https://doi.org/10.1177/0040517516665265.

Moskowitz JD, Wiggins JS. Semibatch RAFT copolymerization of acrylonitrile and N-isopropylacrylamide: effect of comonomer distribution on cyclization and thermal stability. Polymer. 2016;84:311–8. https://doi.org/10.1016/j.polymer.2015.12.035.

Kaur J, Millington K, Cai JY. Rheology of polyacrylonitrile-based precursor polymers produced from controlled (RAFT) and conventional polymerization: Its role in solution spinning. J Appl Polym Sci. 2016;133(48):44273. https://doi.org/10.1002/app.44273.

Cai JY, McDonnell J, Brackley C, O’Brien L, Church JS, Millington K, Smith S, Phair-Sorensen N. Polyacrylonitrile-based precursors and carbon fibers derived from advanced RAFT technology and conventional methods—the 1st comparative study. Mater Today Commun. 2016;9:22–9. https://doi.org/10.1016/j.mtcomm.2016.09.001.

Zhou Z, Liu T, Khan AU, Liu G. Block copolymer-based porous carbon fibers. Sci Adv. 2019;5(2):eaau6852. https://doi.org/10.1126/sciadv.aau6852.

Kim DW, Kim CH, Yang CM, Ahn S, Kim YH, Hong SK, Kim KS, Hwang JY, Choi GB, Kim YA, Yang KS. Deriving structural perfection in the structure of polyacrylonitril-based electrospun carbon nanofibers. Carbon. 2019;147:612–5. https://doi.org/10.1016/j.carbon.2019.02.066.

Liu J, Chen G, Gao H, Zhang L, Ma S, Liang J, Fong H. Structure and thermo-chemical properties of continuous bundles of aligned and stretched electrospun polyacrylonitrile precursor nanofibers collected in a flowing water bath. Carbon. 2012;50(3):1262–70. https://doi.org/10.1016/j.carbon.2011.10.046.

Brennan DA, Jao D, Siracusa MC, Wilkinson AR, Hu X, Beachley VZ. Concurrent collection and post-drawing of individual electrospun polymer nanofibers to enhance macromolecular alignment and mechanical properties. Polymer. 2016;103:243–50. https://doi.org/10.1016/j.polymer.2016.09.061.

Doshi J, Reneker DH. Electrospinning process and applications of electrospun fibers. J Electrost. 1995;35(2–3):151–60. https://doi.org/10.1016/0304-3886(95)00041-8.

Theron A, Zussman E, Yarin AL. Electrostatic field-assisted alignment of electrospun nanofibres. Nanotechnology. 2001;12(3):384–90. https://doi.org/10.1088/0957-4484/12/3/329.

Zussman E, Theron A, Yarin AL. Formation of nanofiber crossbars in electrospinning. Appl Phys Lett. 2003;82(6):973–5. https://doi.org/10.1063/1.1544060.

Fong H, Liu W, Wang CS, Vaia RA. Generation of electrospun fibers of nylon 6 and nylon 6-montmorillonite nanocomposite. Polymer. 2002;43(3):775–80. https://doi.org/10.1016/S0032-3861(01)00665-6.

Dersch R, Liu T, Schaper AK, Greiner A, Wendorff JH. Electrospun nanofibers: Internal structure and intrinsic orientation. J Polym Sci Part A Polym Chem. 2003;41(4):545–53. https://doi.org/10.1002/pola.10609.

Katta P, Alessandro M, Ramsier RD, Chase GG. Continuous electrospinning of aligned polymer nanofibers onto a wire drum collector. Nano Lett. 2004;4(11):2215–8. https://doi.org/10.1021/nl0486158.

Brennan DA, Shirvani K, Rhoads CD, Lofland SE, Beachley VZ. Electrospinning and post-drawn processing effects on the molecular organization and mechanical properties of polyacrylonitrile (PAN) nanofibers. MRS Commun. 2019;9(2):764–72. https://doi.org/10.1557/mrc.2019.67.

Ali AB, Dreyer B, Renz F, Tegenkamp C, Sindelar R. Electrospun polyacrylonitrile based carbon nanofibers: the role of creep stress towards cyclization and graphitization. J Mater Sci Eng. 2018;7(5):1000493. https://doi.org/10.4172/2169-0022.1000493.

Wu M, Wang Q, Li K, Wu Y, Liu H. Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym Degrad Stab. 2012;97(8):1511–9. https://doi.org/10.1016/j.polymdegradstab.2012.05.001.

Gutmann P, Moosburger-Will J, Kurt S, Xu Y, Horn S. Carbonization of polyacrylonitrile-based fibers under defined tensile load: Influence on shrinkage behavior, microstructure, and mechanical properties. Polym Degrad Stab. 2019;163:174–84. https://doi.org/10.1016/j.polymdegradstab.2019.03.007.

Esrafilzadeh D, Morshed M, Tavanai H. An investigation on the stabilization of special polyacrylonitrile nanofibers as carbon or activated carbon nanofiber precursor. Synth Met. 2009;159(3):267–72. https://doi.org/10.1016/j.synthmet.2008.09.014.

Wu G, Lu C, Ling L, Hao A, He F. Influence of tension on the oxidative stabilization process of polyacrylonitrile fibers. J Appl Polym Sci. 2005;96(4):1029–34. https://doi.org/10.1002/app.21388.

Salim NV, Blight S, Creighton C, Nunna S, Atkiss S, Razal JM. The role of tension and temperature for efficient carbonization of polyacrylonitrile fibers: toward low cost carbon fibers. Ind Eng Chem Res. 2018;57(12):4268–76. https://doi.org/10.1021/acs.iecr.7b05336.

Schierholz R, Kröger D, Weinrich H, Gehring M, Tempel H, Kungl H, Mayer J, Eichel RA. The carbonization of polyacrylonitrile-derived electrospun carbon nanofibers studied by in situ transmission electron microscopy. RSC Adv. 2019;9(11):6267–77. https://doi.org/10.1039/c8ra10491c.

Acknowledgements

The authors thank financial supports from the National Natural Science Foundation of China (51925302, 51973028, 21961132024, and 51873029).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Hu, G., Zhang, X., Liu, X. et al. Strategies in Precursors and Post Treatments to Strengthen Carbon Nanofibers. Adv. Fiber Mater. 2, 46–63 (2020). https://doi.org/10.1007/s42765-020-00035-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-020-00035-x