Abstract

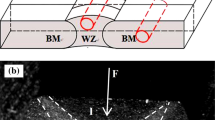

The effect of hydrogen addition on compression deformation behaviour of Ti–0.3Mo–0.8Ni alloy argon-arc welded joint has been investigated. Evolution mechanism of hydrogen-induced flow stress was discussed in detail. The results show that with increasing hydrogen content, the stretching and bending extent of fully lamellar microstructures including α lamellas and acicular hydride continued to increase, the morphology of dynamic recrystallization (DRX) grains tended to change from approximately equiaxed to large lamellar shape, and the quantity of DRX grains and recrystallization degree of grains increased obviously. A large number of dislocations concentrated in the vicinity of the hydride. Steady stress was decreased continuously with increasing hydrogen content, while peak stress of the hydrogenated 0.12 wt.% H weld zone was decreased to the minimum value and then increased slowly. A slight decrease in flow stress of the hydrogenated 0.05 wt.% H weld zone was caused by limited increase in the volume fraction of softer β phase. Hydrogen-induced DRX of α phase and improved dislocation movement by strong interaction between the hydride and dislocation directly resulted in a sharp drop in flow stress of the hydrogenated 0.12 and 0.21 wt.% H weld zone. Solute hydrogen also finitely contributed to a sharp drop in flow stress of the hydrogenated 0.12 and 0.21 wt.% H weld zone by promoted local softening, which induced continuous DRX and more movable dislocations to participate in slipping or climbing. The reinforcement effect and plastic deformation of the hydride and solution strengthening of β phase induced by solute hydrogen finally led to the increase in flow stress of the hydrogenated 0.21 wt.% H weld zone in its true strain range from 0 to 0.36.

Similar content being viewed by others

References

A. Karolczuk, H. Paul, Z. Szulc, K. Kluger, M. Najwer, G. Kwiatkowski, J. Mater. Eng. Perform. 27 (2018) 4571–4581.

P. Sengupta, G. Sharma, G.K. Dey, J. Nucl. Mater. 457 (2015) 205–208.

G.C. Li, X. Cheng, X.J. Tian, J. Iron Steel Res. Int. 25 (2018) 442–452.

H.M. Tawancy, J. Mater. Eng. Perform. 26 (2017) 504–513.

T.F. Song, X.S. Jiang, Z.Y. Shao, D.F. Mo, D.G. Zhu, M.H. Zhu, C.H. Young, Z.P. Luo, J. Iron Steel Res. Int. 24 (2017) 1023–1031.

R.R. Chen, T.F. Ma, J.J. Guo, H.S. Ding, Y.O. Su, H.Z. Fu, Mater. Des. 108 (2016) 259–268.

Y.Y. Zong, Y.C. Liang, Z.W. Yin, D.B. Shan, Int. J. Hydrogen Energy 37 (2012) 13631–13637.

C.C. Shen, C.Y. Yu, T.P. Perng, Acta Mater. 57 (2009) 868–874.

J.W. Zhao, H. Ding, H.L. Hou, Z.Q. Li, J. Alloy. Compd. 491 (2010) 673–678.

M.Q. Li, W.F. Zhang, Mater. Sci. Eng. A 502 (2009) 32–37.

S.M.J. Babu, B.P. Kashyap, N. Prabhu, R. Kapoor, R.N. Singh, J.K. Chakravartty, Mater. Sci. Eng. A 679 (2017) 75–86.

Z.G. Sun, G.Q. Chen, Y.Q. Wang, W.L. Zhou, H.L. Hou, Mater. Sci. Eng. A 527 (2010) 1003–1007.

L. Zhou, D. Liu, H.J. Liu, L.Z. Wu, Appl. Mech. Mater. 395–396 (2013) 243–250.

S.P Liu, Z. Zhang, S.F. Xiao, Y.G. Chen, J. Alloy. Compd. 781 (2019) 1139–1149.

Y. Zhang, S.Q. Zhang, C. Tao, Int. J. Hydrogen Energy 22 (1997) 125–129.

X. Wang, L. Wang, L.S. Luo, H. Yan, X.Z. Li, R.R. Chen, Y.Q. Su, Y.J. Guo, H.Z. Fu, Mater. Des. 121 (2017) 335–344.

J.Q. Lu, J.N. Qin, W.J. Lu, Y.F. Chen, D. Zhang, H.L. Hou, Int. J. Hydrogen Energy 34 (2009) 9266–9273.

X.J. Lin, F.Y. Dong, Y. Zhang, X.G. Yuan, H.J. Huang, B.W. Zheng, L.Wang, X. Wang, L.S. Luo, Y.Q. Su, Y.J. Xu, B.S. Han, Int. J. Hydrogen Energy 44 (2019) 8641–8649.

T.S. Balasubramanian, V. Balasubramanian, M.A. Muthu Manickam, Mater. Des. 32 (2011) 4509-4520.

J.H. Xiong, S.K. Li, F.Y. Gao, J.X. Zhang, Mater. Sci. Eng. A 640 (2015) 419–423.

O.N. Senkov, F.H. Froes, Int. J. Hydrogen Energy 24 (1999) 565–576.

H.F. Zhang, Research on high temperature deformation behaviors and application of BTi-62421S alloys, North University of China, Taiyuan, China, 2011.

Q.M. Liu, Z.H. Zhang, S.F. Liu, H.Y. Yang, Adv. Eng. Mater. 20 (2018) 1700679.

Z.H. Zhang, Q.M. Liu, S.F. Liu, H.Y. Yang, Rare Metal Mater. Eng. 48 (2019) 0104–0110.

J. Zhao, J. Zhong, F. Yan, F. Chai, M. Dargusch, J. Alloy. Compd. 710 (2017) 616–627.

K. Zhang, H.B. Wu, D. Tang, J. Iron Steel Res. Int. 19 (2012) No. 5, 58–62.

D.B. Shan, Y.Y. Zong, Y. Lv, B. Guo, Scripta Mater. 58 (2008) 449–452.

Y.Y. Zong, D.S. Wen, W.C. Xu, D.M. Yang, D.B. Shan, Z.Y. Liu, Proced. Eng. 81 (2014) 1420–1426.

X.M. Zhang, Y.Q. Zhao, W.D. Zeng, Mater. Sci. Technol. 27 (2011) 214–218.

O.N. Senkov, M. Dubois, J.J. Jonas, Metall. Mater. Trans. A 27 (1996) 3963–3970.

P.L. Martin, Mater. Sci. Eng. A 243 (1998) 25–31.

Acknowledgements

The authors would like to gratefully acknowledge that this work was supported by the China Postdoctoral Science Foundation (Grant No. 2020M672306) and National Natural Science Foundation of China (Grant Nos. 51874225 and 51671152). At the same time, the authors would also like to thank the researcher at China Aeronautical Manufacturing Technology Research Institute, Y.Q. Wang for hydrogen treatment and the researchers at Xi’an University of Architecture and Technology, M. Yang and X.S. Ding for fruitful discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Zh., Liu, Qm., Fu, L. et al. Effect of hydrogen addition on compression deformation behaviour of Ti–0.3Mo–0.8Ni alloy argon-arc welded joints. J. Iron Steel Res. Int. 28, 621–628 (2021). https://doi.org/10.1007/s42243-020-00509-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00509-7