Abstract

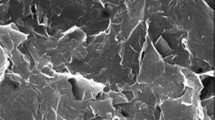

CoFe2O4-reduced graphene oxide (CoFe2O4-rGO) composites were synthesized by one-pot solvothermal technique. Different amount of well-dispersed nanosized cubical grains of CoFe2O4-rGO were incorporated into the epoxy resin for the preparation of fluid composite samples. The magnetorheological properties of the prepared samples showed significant enhancement in yield strength as well as viscoelastic properties. The flow curves of the samples showed non-Newtonian behavior at lower strain rate (γ˙ < 10 s−1) under high magnetic field strength, thereafter with increasing the value of γ˙, the flow curves shifted Newtonian regime. The composite samples also possessed a yield stress (τy) under a magnetic field at adequately high strain rates and followed Bingham relation \( \tau ={\tau}_{\mathrm{y}}+\overset{\hbox{'}}{\gamma }{\eta}_0 \), where, τ is shear stress perpendicular to the applied magnetic field and η0 is the plastic viscosity. The experimentally obtained values of τy for different values of B0 and φ correspond well to the values predicted theoretically by Rosensweig.

Magnetorheological properties of CoFe2O4-rGO/epoxy epoxy composite prepared by mechanical mixing are superior to that of neat epoxy.

Similar content being viewed by others

References

Pickering KL, Khimi SR, Ilanko S (2015) The effect of silane coupling agent on iron sand for use in magnetorheological elastomers part 1: surface chemical modification and characterization. Compos Part A :Appl Sci Manuf 68:377–386

Sun S, Deng H, Yang J, Li W, Du H, Alici J, Nakano M (2015) An adaptive tuned vibration absorber based on multilayered MR elastomers. Smart Mater Struct 24:045045

Deng HX, Gong XL (2008) Application of magnetorheological elastomer to vibration absorber. Commun Nonlinear Sci Numer Simul 13:1938–1947

Shen Y, Golnaraghi MF, Heppler GR (2004) Experimental research and modeling of magnetorheological elastomers. J Intell Mater Syst Struct 15:27–35

Sedlacik M, Mrlik M, Babayan V, Pavlinek V (2016) Magnetorheological elastomers with efficient electromagnetic shielding. Compos Struct 135:199–204

Demchuk SA, Kuz’min VA (2002) Viscoelastic properties of magnetorheological elastomers in the regime of dynamic deformation. J Eng Phys Thermophys 75:396–400

Ju B, Tang R, Zhang D, Yang B, Yu M, Liao C, Yuan X, Zhang L, Liu J (2016) Dynamic mechanical properties of magnetorheological elastomers based on polyurethane matrix. Polym Compos 37:1587–1595

Wang YL, Hu YA, Chen L, Gong XL, Jiang WQ, Zhang PQ (2006) Effects of rubber/magnetic particle interactions on the performance of magnetorheological elastomers. Polym Test 25:262–267

Jolly MR, Carlson JD, Munoz BC (1996) The Magnetoviscoelastic response of elastomer composites consisting of ferrous particles embedded in a polymer matrix. J Intell Mater Syst Struct 7:613–622

Xia M, Yang H, Ling J, Yao Q, Li G, Luo Y (2018) The mechanical behaviors of epoxy-terminated hyperbranched polyester (E-HBP) as toughener in different epoxy resins. Adv Compos Hybrid Mater 1:310–319

Yang X, Guo Y, Luo X, Zheng N, Ma T, Tan J, Li C, Zhang Q, Gu J (2018) Self-healing, recoverable epoxy elastomers and their composites with desirable thermal conductivities by incorporating BN fillers via in-situ polymerization. Compos Sci Technol 164:59–64

Chhetri S, Adak NC, Samanta P, Mallisetty PK, Murmu NC, Kuila T (2018) Interface engineering for the improvement of mechanical and thermal properties of covalent functionalized graphene/epoxy composites. J Appl Polym Sci 135:1–10

Adak NC, Chhetri S, Kim NH, Murmu NC, Samanta P, Kuila T (2018) Static and dynamic mechanical properties of graphene oxide-incorporated woven carbon fiber/epoxy composite. J Mater Eng Perform 27:1138–1147

Ahmed J (2018) In-situ synthesis of visible-light responsive Ag2O/graphene oxide nanocomposites and effect of graphene oxide content on its photocatalytic activity. Adv Compos Hybrid Mater 1:374–388

Yu G, Lu Y, Guo J, Patel M, Bafana A, Wang X, Qiu B, Jeffryes C, Wei S (2018) Carbon nanotubes, graphene, and their derivatives for heavy metal removal. Adv Compos Hybrid Mater 1:56–78

Huangfu Y, Liang C, Han Y, Qiu H, Song P, Wang L, Kong J, Gu J (2019) Fabrication and investigation on the Fe3O4/thermally annealed graphene aerogel/epoxy electromagnetic interference shielding nanocomposites. Compos Sci Technol 169:70–75

Guo Y, Xu G, Yang X, Ruan K, Ma T, Zhang Q, Gu J, Wu Y, Liu H, Guo Z (2018) Significantly enhanced and precisely modeled thermal conductivity in polyimide nanocomposites with chemically modified graphene via in situ polymerization and electrospinning-hot press technology. J Mater ChemC 6:3004–3015

Vicentea JD, Vereda F, Gutiérrez JPS (2010) Effect of particle shape in magnetorheology. J Rheol 54:1337–1362

Kashevskii BE, Kordonskii VI, Prokhorov IV (1988) Magnetohydrodynamics. Plenum, New York

Bossis G, Lemaire E (1991) Yield stresses in magnetic suspensions. J Rheol 35:1345–1354

Tang X, Zhang X, Tao R, Rong YM (2000) Structure-enhanced yield stress of magnetorheological fluids. J Appl Phys 87:2634–2638

Claracq J, Sarrazin J, Montfort JP (2004) Viscoelastic properties of magnetorheological fluids. Rheol Acta 43:38–49

Plachy T, Cvek M, Kozakova Z, Sedlacik M, Moucka R (2017) The enhanced MR performance of dimorphic MR suspensions containing either magnetic rods or their non-magnetic analogs. Smart Mater Struct 26:025026

Vicente DJ, Gutierrez SJP, Reyes AE, Vereda F, Alvarez HR (2009) Dynamic rheology of sphere and rod based magnetorheological fluids. J Chem Phys 131:194902

Vicente DJ, Klingenberg JD, Alvarez HR (2011) Magnetorheological fluids: a review. Soft Matter 7:3701–3710

Wang G, Ma Y, Cui G, Li N, Dong X (2018) Two-dimensional Fe3O4/MoS2 nanocomposites for a magnetorheological fluid with enhanced sedimentation stability. Sft Matr 14:1917–1924

Wang G, Zhao D, Maa Y, Zhang Z, Che H, Mu J, Zhang X, Tong Y, Dong X (2017) Synthesis of calcium ferrite nanocrystal clusters for magnetorheological fluid with enhanced sedimentation stability. Pwdr Technol 322:47–53

Wang G, Ma Y, Tong Y, Dong X (2017) Development of manganese ferrite/graphene oxide nanocomposites for magnetorheological fluid with enhanced sedimentation stability. J Ind Eng Chem 48:142–150

Nobile MR, Raimondo M, Lafdi K, Guadagno L (2016) Rheological and morphological properties of graphene-epoxy nanocomposites. AIP Conf Proc 1736:020143

Adak NC, Chhetri S, Kuila T, Murmu NC, Samanta P, Lee JH (2018) Effects of hydrazine reduced graphene oxide on the inter-laminar fracture toughness of woven carbon fiber/epoxy composite. Compos Part B: Engg 149:22–30

Rosensweig RE (1995) On magnetorheology and electrorheology as states of unsymmetric stress. J Rheol 39:179

Kuila T, Bose S, Khanra P, Mishra AK, Kim NH, Lee JH (2012) A green approach for the reduction of graphene oxide by wild carrot root. Carbon 50:914–921

Zheng L, Guan L, Yang G, Chenac S, Zheng H (2018) One-pot synthesis of CoFe2O4/rGO hybrid hydrogels with 3D networks for high capacity electrochemical energy storage devices. RSC Adv 8:8607–8614

Gao HC, Xiao F, Ching CB, Duan HW (2012) High-performance asymmetric supercapacitor based on graphene hydrogel and nanostructured MnO2. ACS Appl Mater Intfs 4:2801–2810

Xia H, Zhu DD, Fu YS, Wang X (2012) CoFe2O4-graphene nanocomposite as a high-capacity anode material for lithium-ion batteries. Electrochim Acta 83:166–174

Parvez K, Wu ZS, Li R, Liu X, Graf R, Feng X, Mullen K (2014) Exfoliation of graphite into graphene in aqueous solutions of inorganic salts. J Am Chem Soc 136:6083

Wereley NM, Chaudhuri A, Yoo JH, John S, Kotha S, Suggs A, Radhakrishnan R, Love BJ, Sudarshan TS (2006) Bidisperse magnetorheological fluids using Fe particles at nanometer and micron scale. J Intell Mater Syst Struct 17:393–401

Mehta RV, Patel R, Chudasama B, Upadhyay RV (2008) Experimental investigation of magnetically induced unusual emission of light from a ferrodispersion. Opt Lett 33:1987–1989

Patel R (2011) Mechanism of chain formation in nanofluid based MR fluids. J Magn Magn Mater 323:1360–1363

Lopez MTL, Ramirez AG, Arco LR, Duran JDG, Iskakova L, Zubarev A (2012) Colloids on the frontier of ferrofluids. Langmuir 28:6232–6245

Popplewelly J, Rosensweig RE (1996) Magnetorheological fluid composites. J Phys D Appl Phys 29:2297–2303

Kameda J, Hirauchi K (2018) Rheological properties of composite serpentine-brucite suspensions: implications for mudflow behavior on forearc seamounts. Mar Geol 403:191–196

Gast AP, Zukowski CF (1989) Electrorheological fluids as colloidal suspensions. Adv Colloid Interf Sci 30:153–202

Li SP, Zhao G, Chen HY (2005) The relationship between steady shear viscosity and complex viscosity. J Dispers Sci Technol 26:415–419

Acknowledgements

The authors are thankful to the Director of CSIR-CMERI. The authors are also thankful to the Council of Scientific and Industrial Research, New Delhi, India, for funding the Fast Track Translational Project (MLP218112).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1236 kb)

Rights and permissions

About this article

Cite this article

Adak, N.C., Chhetri, S., Murmu, N.C. et al. Analytical and experimental investigation on magnetorheological behavior of CoFe2O4-rGO-incorporated epoxy fluid composites. Adv Compos Hybrid Mater 2, 266–278 (2019). https://doi.org/10.1007/s42114-019-00086-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-019-00086-8