Abstract

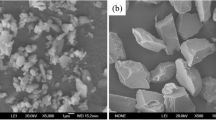

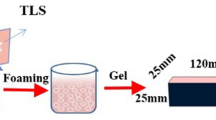

Hierarchical porous ZrO2/Al2O3 ceramics with controllable pore structure were fabricated by gel-foaming method using nontoxic sodium alginate as gelling agent. Both the rheological property of ceramic slurry and the curing mechanism of gelatin system were studied. The effects of ZrO2 content and sintering temperature on the pore structure and properties were also investigated. The three-dimensional net structure forms between calcium ion and sodium alginate molecule; then, the ceramic powder can realize in situ solidification. The porosity changes from 33 to 74% with different ZrO2 content and sintering temperature. The macropores can be controlled through adjusting the foaming agent and ZrO2 contents. The mesopores are mainly regulated by sintering temperature. The porosity and pore structure can be tailored through optimizing the gel-foaming and sintering process parameters. The sintering temperature has important influence on the mechanical properties. The porous ceramics with 25% ZrO2 content sintered at 1550°C shows the highest compressive strength of 130MPa. The mechanical properties are improved with the micro-crack toughening and phase transformation mechanisms of ZrO2 phases. Hierarchical porous ceramics with more inter-connective pores, high specific surface area, and suitable strength are promising for filtration and catalyst support applications.

Similar content being viewed by others

References

Hou, C.B., Tian, X.Y., Nan, Y.: Hierarchically porous alumina ceramic catalyst carrier prepared by powder bed fusion. J. Eur. Ceram. Soc. 40(12), 4253–4264 (2020)

Pabst, W., Gregorová, E., Černý, M., Sedlářová, I.: Preparation and characterization of porous alumina–zirconia composite ceramics. J. Eur. Ceram. Soc. 31(14), 2721–2731 (2011)

Ahmad, R., Ha, J.H., Song, I.H.: Particle-stabilized ultra-low density zirconia toughened alumina foams. J. Eur. Ceram. Soc. 31(13-14), 2559–2564 (2013)

Wiecinska, P., Skrzos, L., Prokurat, N.: New route for processing of multilayer Al2O3-Co3O4 materials through gelcasting. J. Eur. Ceram. Soc. 37(4), 1627–1634 (2017)

Qiao, J., Wen, Y.B.: Preparation and characterization of magnesium aluminate (MgAl2O4) spinel ceramic foams via direct foam-gelcasting. Ceram. Int. 46(1), 678–684 (2020)

Han, L., Li, F.L., Deng, X.G., Wang, J.K., Zhang, H.J., Zhang, S.W.: Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures. J. Eur. Ceram. Soc. 37(7), 2717–2725 (2017)

Potoczek, M.: Hydroxyapatite foams produced by gelcasting using agarose. Mater. Lett. 62(6-7), 1055–1057 (2008)

Xue, W.J., Huang, Y., Xie, Z.P., Liu, W.: Al2O3 ceramics with well-oriented and hexagonally ordered pores: the formation of microstructures and the control of properties. J. Eur. Ceram. Soc. 32(12), 3151–3159 (2012)

Du, L.J., Liu, W., Hu, S.L., Wang, Y.Z., Yang, J.L.: Preparation and photocatalytic properties of macroporous honeycomb alumina ceramics used for water purification. J. Eur. Ceram. Soc. 34(3), 731–738 (2014)

Santos, C.J.E., Wei, T., Cho, B., Kriven, W.M.: A forming technique to produce spherical ceramic beads using sodium alginate as a precursor binder phase. J. Am. Ceram. Soc. 96(11), 3379–3388 (2013)

Chen, R.Y., Jia, W.B., Shan, Q., Ling, Y.S., Lao, D., Wang, Y.F., Li, S.J., Hei, D.Q.: A novel design of Al2O3-ZrO2 reticulated porous ceramics with hierarchical pore structures and excellent properties. J. Eur. Ceram. Soc. 39(5), 1877–1886 (2019)

Hojjat, M., Nayebzadeh, H., Khadangi-Mahrood, M., Rahmani-Vahid, B.: Optimization of process conditions for biodiesel production over CaO-Al2O3/ZrO2 catalyst using response surface methodology. Chem. Pap. 71(3), 689–698 (2017)

Wen, T.P., Lei, Y.: Enhanced ionic conductivity and thermal shock resistance of MgO stabllized ZrO2 doped with Y2O3. Ceram. Int. 46(12), 19835–19842 (2020)

Song, I.G., Kim, T.S., Kang, K.M.: Influence of MgO additive and sintering temperature on mechanical strength for alumina ceramic anchor. Korean J. Met. Mater. 52(3), 181–186 (2014)

Zamorategui, A., Coreno, O., Angel, J.D.: Effect of kind of acid and the solid fraction on the viscosity by the gamma-Al2O3 nanofiber in the form of precursor slurry for the final ceramic. J. Ceram. Process. Res. 17(7), 727–731 (2016)

Zeng, J.Z., Yang, J., Wan, W., Liu, X.L., Qiu, T.: Effect of Al2O3 particle size on preparation and properties of ZTA ceramics formed by gelcasting. Ceram. Int. 5, 5333–5338 (2014)

Ying, L., Zhao, L., Dai, X., Wang, C.A.: Preparation of porous YSZ ceramics by ball milling foaming-freeze drying process. Ceram. Int. 46(7), 9834–9838 (2020)

Dong, B.B., Yang, M.Y., Wang, F.H.: Porous Al2O3 plates prepared by combing foaming and gel-tape casting methods for efficient collection of oil from water. Chem. Eng. J. 370, 658–665 (2019)

Vahid, B.R., Saghatoleslami, N., Nayebzadeh, H., Maskooki, A.: Preparation of nano-size Al-promoted sulfated zirconia and the impact of calcination temperature on its catalytic activity. Chem. Biochem. Eng. Q. 26(2), 71–77 (2012)

Surzhikov, A.P., Frangul’yan, T.S., Gyngazov, S.A., Vasil’ev, I.P.: Investigation of low-temperature aging of porous composite ceramic in the system ZrO2(Y)-Al2O3. Glass Ceram. 71(9-10), 373–376 (2015)

Vahid, B.R., Saghatoleslami, N., Nayebzadeh, H., Toghiani, J.: Effect of alumina loading on the properties and activity of SO42−/ZrO2 for biodiesel production: process optimization via response surface methodology. J. Taiwan Inst. Chem. Eng. 83, 115–123 (2018)

Chen, R.Y., Jia, W.B., Hei, D.Q., Wang, Y.F.: Toward excellent performance of Al2O3-ZrO2 reticulated porous ceramics: new insights based on residual stress. Ceram. Int. 44(17), 21478–21485 (2018)

Nayebzadeh, H., Saghatoleslami, N., Tabasizadeh, M.: Application of microwave irradiation for fabrication of sulfated ZrO2-Al2O3 nanocomposite via combustion method for esterification reaction: process condition evaluation. J. Nanostructure Chem. 9(2), 141–152 (2019)

Li, Y.J., Yang, X.F., Liu, D.H.: Permeability of the porous Al2O3 ceramic with bimodal pore size distribution-Science direct. Ceram. Int. 45(5), 5952–5957 (2019)

Fey, T., Zierath, B., Greil, P., Potoczek, M.: Microstructural, mechanical and thermal characterization of alumina gel-cast foams manufactured with the use of agarose as gelling agent. J. Porous Mater. 22(5), 1305–1312 (2015)

Colombo, P.: In praise of pores. Science. 322(5900), 381–383 (2008)

Liu, G., Zhang, D., Meggs, C., Button, T.W.: Porous Al2O3-ZrO2 composites fabricated by an ice template method. Scr. Mater. 62, 466–468 (2010)

Morozova, V.L., Vasil’eva, A.E., Kalinina, V.M., Khamova, V.T., Shilova, A.O.: Porous ceramics based on the ZrO2(Y2O3)-Al2O3 system for filtration membranes. Glass Phys. Chem. 42(4), 408–413 (2016)

Funding

This work was supported by the National Natural Science Foundation of China (NO.51302053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, X., Zhang, Z., Wang, S. et al. Microstructure and properties of hierarchical porous ZrO2/Al2O3 ceramics prepared by gel-foaming method. J Aust Ceram Soc 59, 905–914 (2023). https://doi.org/10.1007/s41779-023-00883-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00883-x