Abstract

An experiment to investigate the effect of preloading on bone impacts by projectiles was undertaken. During this experiment, a total of 59 bones were impacted. Red deer tibias were used, with impacts to the shaft under three different loading conditions. The purpose of the trial was to provide an indication on whether preloading a bone has an effect on chance of perforation, or type and level of fracture sustained. This is important because the United Kingdom (UK) Ministry of Defence (MOD) requires accurate injury models to aid with decision-making and risk analyses.

Similar content being viewed by others

Introduction

The United Kingdom (UK) Ministry of Defence (MOD) requires accurate injury models to aid with decision-making and risk analyses. These decisions include what protective equipment to use and to what specification. Generally, to make a piece of protective equipment more effective, you add more material (weight). Adding weight could make the soldier less effective in different situations or have an effect on a soldier’s long-term wellbeing. Understanding what variables are involved and what effect each has allowed the UK MOD to make informed decisions.

One of these injury models requires an estimation of the effect of projectile impact on a bone. A literature search conducted by Dstl determined the state of the art in this field. All reviewed experiments that investigated the ballistic performance of bones were conducted unloaded and the bones were held in place by a clamp or a block of gelatin [1,2,3,4,5]. This is not representative of real-world conditions as performing activities will place stresses within the bone. Because of the fact that during some activities a leg bone can be loaded up to five times body weight, such as when jumping or climbing stairs [6] (this will increase with a full burden of equipment), an experiment for assessing the effect of prestressed bones on ballistic performance is required.

The aim of this experiment was to identify whether there is evidence that a preloaded tibia has different damage thresholds to an unloaded tibia when impacted by a projectile against the parameters: likelihood of perforation, level of damage and type of fracture. The assessment was achieved through the analysis of high-speed video (HSV) of the projectile to collect projectile velocity pre-impact and a record of the projectile impacting the bone; a visual assessment of the bone post-impact was also conducted. For this experiment, red deer tibias were used because of their likeness to human tibias.Footnote 1

Method

Target Details

Red deer hind legs were purchased from the food chainFootnote 2 sealed within vacuum packs and stored frozen at − 20 °C for a minimum of 2 weeks and a maximum of 6 weeks prior to the commencement of the experiment. This was necessary because the quantity of bones required, and time needed to plan the experiment meant that the bones could not be supplied fresh. The age of the deer at the time of slaughter was between 12 and 24 months. The average time delay between slaughter and freezer was 1 week and were transported to Dstl in a cold box and placed straight in a freezer. The bones were defrosted by immersion in room temperature Hartmann’s solutionFootnote 3 for a minimum of 12 h and a maximum of 36 h. Hartmann’s solution is used because it is electrolytically balanced and is designed for rehydration.

The hind legs were supplied whole following the butchering process; prior to immersion, the tibia had to be isolated from the remainder of the leg and cleaned to remove any excess tissue. The tibias were removed from the ankle and knee joint, and then, any tissue was stripped away on the impact area. Efforts were made to remove tissue at the top and bottom of the bone to improve how the bone would fit in the frame, but after the first few firings, this was deemed unnecessary. Once the bone was cleaned, it was placed in Hartmann’s solution ready for shooting the next day. Each target was inspected for surface damage prior to firing and only impacted once.

The bones were preloaded with the use of a loading frame specifically designed for this experiment. The loading arm on the frame was used to transfer the moment from the hydraulic pump to the bone.

The frame in use is shown in Fig. 1. Before any tests were conducted, a bone was loaded to + 25% of the highest intended experimental load (i.e. 500 pounds per square inch (psi) rather than 400 psi) to ensure that there was no risk of the bone fracturing as a result of the loading strain. The bone compacted under this initial loading. This meant that when a load was applied to a bone, the user had to ensure the load stayed constant and the bone was not still yielding under the stress as this would, over time, reduce the load on the bone for firing.

The average muzzle to target distance was 1.06 m, with a range of ± 0.01 m. The impact point was the middle of the diaphysis and kept the same with all tests. Efforts were made to keep variables the same between test groups, e.g. all groups contained a similar variety of bone masses and diameters at the impact point. The bones either broke or remained intact when impacted by the 6-mm diameter steel ball bearing projectile fired from the gas gun; on one occasion, the bone broke under the load beyond the recording timespan of the HSV (0.5 s).

The maximum velocity was 323 m s−1 and the minimum velocity was 173 m s−1.

To achieve the originally intended loads of 1 × body weight and 5 × body weight, the pressure on the pump would have to be 69 and 342 psi; this was not marked on the pressure gauge. Therefore, 100 psi was chosen because 100 psi is closest to 1 × body weight and 400 psi was chosen because although 300 psi was slightly closer to 5 × body weight, a larger difference in test cases (while still being relevant) was seen as beneficial for a comparative study (the 400 psi load case was therefore close to 6 × body weight). The accuracy of the user was deemed to be ± 25 psi for each firing. From here forward, the different test groups will be known as no load, 100 psi and 400 psi (Table 1).

Instrumentation Setup

The experiment setup is shown in Fig. 2.

The experiment used two high-speed video cameras, one to measure projectile velocity and one to record footage of the impact. Both cameras were triggered with an audio trigger box located near the muzzle of the gas gun. The video measuring the projectile velocity was positioned perpendicular to the shot line, measured to within 0.1° of the gun barrel; this was measured by taking two points along the long-axis of the gun and along the width of the camera to measure the angle with reference to the wall of the firing chamber. The camera settings were 100,000 frames per second (FPS), a shutter speed of 1/800,000 s and a resolution of 896 × 208 pixels. These settings were chosen to maximise the number of frames in which the projectile flight would be in view while reducing image blur as much as possible. Image quality using HSV is directly affected by light intensity; image clarity was therefore constrained by the lighting available within the fragment firing chamber.Footnote 4 A 1-m steel rule was used to take a calibration image at the start of each day, and any time the setup was changed. The accuracy of the camera timing unit is either ± 1.25 ns or ± 0.005% of frame rate, whichever is greater. To quantify motion blur, the projectile diameter of the ball bearing was measured to within 0.1 mm of 6 mm over several measurements on the video. With these values and others taken into account, the velocity error measurement was calculated as ± 1%. The error bars were calculated by accumulating the ± error at each set in the velocity calculation then comparing the maximum and minimum final values.

The camera recording the projectile/bone impact had a frame rate of 42,000 FPS, a shutter speed of 1/200,000 s and a resolution of 896 × 544 pixels. Due to limited space, this camera had to be outside the fragment firing chamber (see Fig. 2); however, this had minimal effect on the quality of results.

Firing Schedule

In total, 59 shots were fired on tibia targets. Of these, seven shots were deemed not fair and one shot was discounted following trigger failure of the camera used to record velocity. Over the course of the trial, the temperature range was 23 to 28 °C,Footnote 5 the ambient pressure range was 1032 to 1043 mbar and the humidity range was 42 to 60%.Footnote 6 These readings were taken inside the fragment firing chamber where it was frequently warmer than the surrounding room.

Statistical Analysis of Results

During the experiment, steps were taken to ensure that non-test variables were not influencing the results; therefore, two-tailed t tests were performed (Table 2) to check for statistically significant differences in the variables (bone diameter, bone mass and projectile impact velocity) between the three groups: No load, 100 psi and 400 psi. The mean mass values for the loading cases are 0.42, 0.40 and 0.4 kg for no load, 100 psi and 400 psi, respectively. The mean bone diameter values for the loading cases are 23.6, 22.5 and 23.1 mm for no load, 100 psi and 400 psi, respectively. Unfair shots were excluded from the analysis.

The results show that there are no significant differences between groups (p < 0.05). This means that none of these variables produced confounding effects, which confirms that statistical comparisons between groups can be made for the outcomes: perforation, broken bone and rear damage.

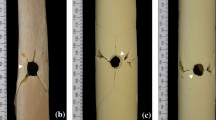

Perforation occurred when a projectile had the energy to enter the front surface of the bone, passed through and exit through the rear face of the bone. Impacts that struck the bone but passed along its side (glancing blows) were not counted as perforations. An example of a perforation is shown in Fig. 3.

Broken bone occurred when the bone was no longer intact from one end to another. If fragments or large chunks of the bone were removed but the two ends were still connected, the bone was not classified as broken. (Shown in Fig. 4.)

Rear damage occurred when there were cracks, fractures, delamination, fragments or swarf on the outer rear face of the bone (not the inside face of the rear compactFootnote 7 bone) as well as broken bones. Examples of rear damage are shown in Figs. 5 and 6.

Two-sample proportions tests were performed to check for statistically significant differences in the proportions of perforations, broken bones and rear damage between the three groups: No load, 100 psi and 400 psi.

Results show that there are no significant differences (where p < 0.05) in the proportions of perforations, broken bones or rear damage between groups (no load, 100 psi, 400 psi) as shown in Tables 3 and 4.

One possible explanation for the lack of significant results is the small sample sizes, n = 20, n = 14 and n = 17 for the groups no load, 100 psi and 400 psi, respectively, which results in low levels of confidence and low statistical power. To check for the possibility of a combined effect between projectile impact velocity and the three load types, bias-reduced generalised linear models were fitted using the statistical package, R.Footnote 8 Three models—for perforation, broken bone and rear damage—were created. Specifically, the models considered the following:

-

Model 1: Effects of load, velocity and load × velocity on perforation (baseline = no load)

-

Model 2: Effects of load, velocity and load × velocity on broken bones (baseline = no load)

-

Model 3: Effects of load, velocity and load × velocity on rear damage (baseline = no load)

Results from model 1 show that there is a statistically significant positive effect of projectile impact velocity on the probability of perforation (p = 0.05). No significant effects are found for either of the two loaded conditions (100 psi, 400 psi) compared to the baseline (no load), and no significant effects are found to suggest that there is an interactive effect between load and velocity.

Results from model 2 show that there is a statistically significant positive effect of projectile impact velocity on the probability of broken bones (p = 0.04). There is some evidence to suggest that the probability of broken bones is lower for load 400 psi compared to no load (p = 0.08) for similar impact velocities. There is also some evidence to suggest that the interactive effect between load 400 and velocity is smaller than the interactive effect between no load and velocity (p = 0.07). There was no significant difference between no load and 100 psi.

Results from model 3 show some evidence to suggest that there is a statistically significant positive effect between velocity and rear damage (p = 0.08). No significant differences are found for either of the loads (100 psi, 400 psi) compared to the baseline (no load), and no significant effects are found for the interactive effects between load and velocity.

Owing to the small sample sizes in this study, it is believed that a p < 0.08 is evidence of correlation.

Discussion

Despite the small sample size, some statistically significant conclusions can be drawn. Both of the variables perforation and broken bone show a statistically significant positive correlation with projectile impact velocity irrespective of loading. There is also evidence that rear damage has a correlation with velocity irrespective of loading. These conclusions are not surprising and were expected.

If the bone is subjected to the higher loading case (400 psi, 476 kg, ~ 6 × body weight), and the impact velocity is at the higher range from this experiment (270 m s−1 or more), there is less chance of the bone breaking compared to the no load condition. This was unexpected but not scientifically unfounded. Ceramics can be subjected to compressive loading to improve their ballistic performance [7] and bones are often compared to ceramic materials. However, there are fundamental differences such as visco-elasticity, which would cause a change in stored strain energy over time and a difference in the failure load relating to the rate of loading.

The data also suggests that the chance of perforation is independent of level of loading. This, combined with decreased chance of breaking at higher loads, implies that although the bone’s ballistic performance does not improve when subjected to loading, it is stronger as a complete structure.

Conclusions

From this experiment, the following conclusions can be drawn:

-

There is evidence to suggest that preloading the bone to approximately 6 times body mass decreases the probability of breakage but does not affect the chance of rear damage or perforation;

-

When developing injury models for risk assessments and decision-making, the stresses applied to body parts before a kinetic assault need to be considered.

Notes

Red Deer tibia was identified as a result of a review on readily available animal bones of appropriate size and shape by surgical subject matter experts.

The Red deer legs were purchased from Holme Farmed Venison (Produce) Ltd. Holme Farmed Venison, 9 First Avenue, Aviation Road, Sherburn in Elmet, Leeds, LS25 6PD

To make 10 l of Hartmann’s solution requires 10 l deionised water, 1.7 g CaCl2.2H20, 3 g KC1, 60 g NaCl and 31.7 ml C3H5Na03.

Lights used were a mixture of standard LED lamps (to avoid 60 Hz flashing from AC lamps) and LED blast lamps that are high intensity but short duration due to overheating risk.

Temperature and pressure measured on Fisher Scientific Thermometer, Calibration due June 2018. S/N: 160556490.

Measured on Traceable Thermo-Hydro. Calibration due February 2018. S/N: 160259896.

Compact bone also known as cortical bone forms the outer shell of most bones. The impact location for the experiment would be comprised of compact bone with a marrow centre.

R version 2.15.2: R Core Team (2013). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. ISBN 3-900051-07-0, URL: http://www.R-project.org/.

References

Kneubuehl BP (Ed), Coupland RM, Rothschild MA, Thali MJ (2011) Wound ballistics—basics and applications. Translation of the revised third German edition (2008). Springer-Verlag Berlin Heidelberg, New York. ISBN 978–3–642-20355-8

Kieser DC, Riddel IR, Kieser JA, Theis JC, Swain MV (2014) Bone micro-fracture observations from direct impact of slow velocity projectiles. J Arch Mil Med 2(1)

Di Maio, V.J.M. Gunshot wounds—practical aspects of firearms, ballistics, and forensic techniques, Second Edition. ISBN 0-8493-8163-0. CRC Press LLC, Boca Raton. 1999

Grundfest H (1945) Penetration of steel spheres into bone. Nat Research Council, Missiles Casualty Report No 10

Huelke DF, Buege LJ, Harger JH (1967) Bone fracture produced by high velocity impacts. Am J Anat 120:123–131

Mundermann A, Dryby CO, D’Lima DD, Colwell CW Jr, Andriacchi TP (2008) In vivo knee loading characteristics during activities of daily living as measured by an instrumented total knee replacement. Wiley InterScience. doi: 10.1002

Holmquist TJ, Johnson GR (2005) Modeling prestressed ceramic and its effect on ballistic performance. Int J Impact Engineering 31(2):113–127 ISSN 0734-743X

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access Content includes material subject to © Crown copyright (2018), Dstl. This material is licensed under the terms of the Open Government Licence except where otherwise stated. To view this licence, visit http://www.nationalarchives.gov.uk/doc/open-government-licence/version/3 or write to the Information Policy Team, The National Archives, Kew, London TW9 4DU, or email: psi@nationalarchives.gsi.gov.uk.

About this article

Cite this article

Keirl, J.J., Burton, L., Waterworth, K. et al. Ballistic Impacts on Bone: Effect of Preloading. Hum Factors Mech Eng Def Saf 2, 4 (2018). https://doi.org/10.1007/s41314-018-0010-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41314-018-0010-4