Abstract

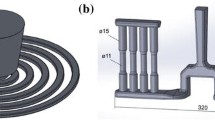

Qualiflash is a quick method of assessing the melt cleanliness of foundry Al–Si alloys over a wide range of Si contents up to 17 wt%. It has an immediate response in measuring the quantity of oxides and non-metallic inclusions. Improving the melt cleanliness moves the Quality Temperature Index line toward lower Q values. Prefil curves demonstrate very good sensitivities to the variations in the melt treatment conditions. The filtration rate is greatly affected by grain refiner addition. The highest curve is displayed by the alloy without grain refiner addition. The filtration rate progressively decreases with increasing amount of grain refiner. When the total amount of boron in the grain refiner added to the melt reaches 60 ppm, the filtration rate is approximately nil. The overall error on the Prefil curve is ± 9% at a level of confidence of 95% at any time during the filtration.

Similar content being viewed by others

References

J.E. Gruzleski, B.M. Closset (eds.), The Treatment of Liquid Aluminum–Silicon Alloys (American Foundrymen’s Society, Inc., Des Plaines, IL, 1990), pp. 186–189

S. Shivkumar, D. Apelian, H. Bracher, Melt cleanliness in die cast aluminum alloys, in Transactions of the 16th International Die Casting Congress and Exposition, Detroit, Michigan, USA. 30 Sept–3 Oct (1991), pp. 143–152

P.S. Mohanty, F.H. Samuel, J.E. Grazleski, Studies on addition of inclusions to molten aluminum using a novel technique. Metall. Mater. Trans. B 26B, 103–109 (1995)

J. Langerweger, Non-metallic inclusions as the cause of structural porosity, heterogeneous cell structure and surface cracks in DC cast Al products. Swiss Alum. Ltd. J. 4, 685–705 (1980)

M.J. Lessiter, Understanding inclusions in aluminum casting. Modern Cast. 83, 29–31 (1993)

D. Doutre, B. Gariépy, J.P. Martin, G. Dubé, Aluminum cleanliness monitoring: methods and applications in process development and quality control. Light Met. 1179–1189 (1985)

K. Strauss (ed.), Applied Science in the Casting of Metals (Pergamum Press, Oxford, 1970), pp. 241–293

M.A. Easton, D.H. St John, The effect of grain refinement on the formation of casting defects in alloy 356 casting. Int. J. Cast Met. Res. 12, 393–408 (2000)

L. Liu, F.H. Samuel, Assessment of melt cleanliness in A356.2 aluminum casting alloys using the porous disc filtration apparatus technique. J. Mater. Sci. 32, 5927–5944 (1997)

N. Habibi, A.M. Samuel, F.H. Samuel, P. Rochette, D. Paquin, Effect of grain refining and Sr modification on Prefil measurement sensitivity in 356 alloys using electron probe microanalysis technique. Int. J. Cast Met. Res. 17(2), 79–87 (2004)

F.H. Samuel, P. Ouellet, A.A. Simard, Measurements of oxide films in Al-(6–17) wt% Si foundry alloys using the qualiflash filtration technique. Int. J. Cast Met. Res. 12(1), 49–65 (1999)

P.K. Singh, D.J. Mitchell, Analysis of metal quality in a low pressure permanent mold foundry, in 105th AFS Casting Congress, Dallas Texas, April 28–May 1 (2001), pp. 88–102

D. Apelian, S. Shivkumar, Molten metal filtration—past, present and future trends, in Proceedings of the 2nd International Conference on Molten Aluminum Processing, Orlando, Florida, Nov 6–7, (AFS, Des Plaines, IL, 1989), pp. 1–36

A. Simard, F. Dallaire, J. Proulx, P. Rochette, Cleanliness measurement benchmarks of aluminum alloys obtained directly on—line using the prefil footprinter instrument, Light Met. 379–385 (2000)

P.G. Enright, I.R. Hughes, in Proceedings of the 4th International Conference on Molten Aluminum Processing, Orlando, Florida, Nov 12–14, (American Foundrymen’s Society, Des Plaines, IL, 1995), p. 431

A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, A metallographic study of grain refining of Sr-modified 356 alloy. Int. J. Metalcast. 11(2), 305–320 (2017)

A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Influence of oxides on porosity formation in Sr-treated alloys. Int. J. Metalcast. 11(4), 729–742 (2017)

K. Dennis, R.A.L. Drew, J.E. Gruzleski, Effect of strontium on the oxidation behavior of an A356 alloy. Alum. Trans. 3, 31–39 (2000)

P. Sandford, Getting the junk out of the molten aluminum. AFS Trans. 105, 95–153 (1995)

M. Maniruzzaman, M. Makhlouf, The removal of solid inclusions from aluminum alloys melts by flotation, in 5th International AFS Conference on Molten Aluminum Processing, Nov 8–10, Orlando (1998), pp. 61–67

L. Liu, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, Influence of oxides on porosity formation in Sr-treated Al–Si casting alloys. J. Mater. Sci. 36, 1255–1267 (2003)

Acknowledgements

The authors would like to thank Amal Samuel for enhancing the images presented in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samuel, A.M., Doty, H.W., Valtierra, S. et al. Inclusion Measurements in Al–Si Foundry Alloys Using Qualiflash and Prefil Filtration Techniques. Inter Metalcast 12, 625–642 (2018). https://doi.org/10.1007/s40962-017-0185-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0185-0