Abstract

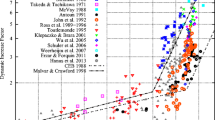

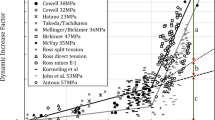

The spalling technique based on the use of a single Hopkinson bar put in contact with the tested sample has been widely adopted as a reliable method for obtaining the tensile response of concrete and rock-like materials at strain rates up-to 200 s− 1. However, the traditional processing method, based on the use of Novikov acoustic approach and the rear face velocity measurement, remains quite questionable due to strong approximations of this data processing method. Recently a new technique for deriving cross-sectional stress fields of a spalling sample filmed with an ultra-high speed camera and based on using the full field measurements and the virtual fields method (VFM) was proposed. In the present work, this topic is perused by performing several spalling tests on ordinary concrete at high acquisition speed of 1Mfps to accurately measure the tensile strength, Young’s modulus, strain-rate at failure and stress–strain response of concrete at high strain-rate. The stress–strain curves contain more measurement points for a more reliable identification. The observed tensile stiffness is up-to 50% lower than the initial compressive stiffness and the obtained peak stress was about 20% lower than the one obtained by applying the Novikov method. In order to support this claim, numerical simulations were performed to show that the change of stiffness between compression and tension highly affects the rear-face velocity profile. This further suggests that the processing based only on the velocity “pullback” is quite sensitive and can produce an overestimate of the tensile strength in concrete and rock-like materials.

Similar content being viewed by others

References

Li QM, Reid SR, Wen HM, Telford AR (2005) Local impact effects of hard missiles on concrete targets. Int J Impact Eng 32:224–284. doi:10.1016/j.ijimpeng.2005.04.005

Wen HM, Xian YX (2015) A unified approach for concrete impact. Int J Impact Eng 77:84–96. doi:10.1016/j.ijimpeng.2014.11.015

Kanel GI (2010) Spall fracture: methodological aspects, mechanisms and governing factors. Int J Fract 163:173–191. doi:10.1007/s10704-009-9438-0

Malvar LJ, Crawford JE (1998) Dynamic Increase Factors. In: 28th Department of defense explosives safety seminar. Orlando, Florida, pp 1–17

Weerheijm J. 2013 Understanding the tensile properties of concrete. Woodhead Publishing Limited, Cambridge

Zielinski AJ, Reinhard HW, Körmeling HA (1981) Experiments on concrete under uniaxial impact tensile loading. Matériaux Constr 14:163–169. doi:10.1007/BF02473920

Zielinski AJ, Reinhardt HW (1982) Stress-strain behaviour of concrete and mortar at high rates of tensile loading. Cem Concr Res 12:309–319

Rossi P, Mier JGM., Toutlemonde F, Maou F, Boulay C (1994) Effect of loading rate on the strength of concrete subjected to uniaxial tension. Mater Struct 27:260–264. doi:10.1007/BF02473042

Toutlemonde F, Boulay C, Rossi P (1995) High strain rate tensile behaviour of concrete: significan parameters. In Fracture mechanics of concrete structures, Proceedings of FRAMCOS-2. Wittmann FH (ed) pp. 709–718. AEDIFICATIO, Freiburg

Weerheijm J. 1992 Concrete under impact tensile loading and lateral compression. PhD thesis, TU Delft

Reinhardt HW, Körmeling HA, Zielinski AJ (1986) The split Hopkinson bar, a versatile tool for the impact testing of concrete. Mater Struct 19:55–63. doi:10.1007/BF02472311

Asprone D, Cadoni E, Prota A, Manfredi G (2009) Dynamic behavior of a mediterranean natural stone under tensile loading. Int J Rock Mech Min Sci 46:514–520. doi:10.1016/j.ijrmms.2008.09.010

Cadoni E, Solomos G, Albertini C (2013) Concrete behaviour in direct tension tests at high strain rates. Mag Concr Res 65:660–672. doi:10.1680/macr.12.00175

Cadoni E, Labibes K, Albertini C, Berra M, Giangrasso M (2001) Strain-rate effect on the tensile behaviour of concrete at different relative humidity levels. Mater Struct 34:21–26

Lambert DE, Ross CA 2000 Strain rate effects on dynamic fracture and strength. Int J Impact Eng 24, 985–998. doi:10.1016/S0734-743X(00)00027-0

Wang QZ, Li W, Xie HP (2009) Dynamic split tensile test of flattened Brazilian disc of rock with SHPB setup. Mech Mater 41:252–260. doi:10.1016/j.mechmat.2008.10.004

Chen R, Xia K, Dai F, Lu F, Luo SN (2009) Determination of dynamic fracture parameters using a semi-circular bend technique in split Hopkinson pressure bar testing. Eng Fract Mech 76:1268–1276. doi:10.1016/j.engfracmech.2009.02.001

Dai F, Xia K, Zheng H, Wang YX (2011) Determination of dynamic rock Mode-I fracture parameters using cracked chevron notched semi-circular bend specimen. Eng Fract Mech 78:2633–2644. doi:10.1016/j.engfracmech.2011.06.022

Delvare F, Hanus JL, Bailly P (2010) A non-equilibrium approach to processing Hopkinson Bar bending test data: Application to quasi-brittle materials. Int J Impact Eng 37:1170–1179. doi:10.1016/j.ijimpeng.2010.07.001

Zhao J, Li H (2000) Experimental determination of dynamic tensile properties of a granite. Int J Rock Mech Min Sci 37:861–866. doi:10.1016/S1365-1609(00)00015-0

Bragov AM, Petrov YV, Karihaloo BL, Konstantinov AY, Lamzin DA, Lomunov AK, Smirnov, IV (2013) Dynamic strengths and toughness of an ultra high performance fibre reinforced concrete. Eng Fract Mech 110:477–488. doi:10.1016/j.engfracmech.2012.12.019

Lu YB, Li QM (2011) About the dynamic uniaxial tensile strength of concrete-like materials. Int J Impact Eng 38:171–180. doi:10.1016/j.ijimpeng.2010.10.028

Forquin P, Riedel W, Weerheijm J (2013) Dynamic test devices for analyzing the tensile properties of concrete. In Understanding the tensile properties of concrete, pp 137e–181e. Elsevier, Amsterdam. doi:10.1533/9780857097538.2.137

Klepaczko JRR, Brara A (2001) An experimental method for dynamic tensile testing of concrete by spalling. Int J Impact Eng 25:387–409. doi:10.1016/S0734-743X(00)00050-6

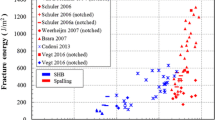

Schuler H, Mayrhofer C, Thoma K (2006) Spall experiments for the measurement of the tensile strength and fracture energy of concrete at high strain rates. Int J Impact Eng 32:1635–1650. doi:10.1016/j.ijimpeng.2005.01.010

Weerheijm J, Van Doormaal, JC (2007) Tensile failure of concrete at high loading rates: new test data on strength and fracture energy from instrumented spalling tests. Int J Impact Eng 34:609–626. doi:10.1016/j.ijimpeng.2006.01.005

Kubota S, Ogata Y, Wada Y, Simangunsong G, Shimada H, Matsui K (2008) Estimation of dynamic tensile strength of sandstone. Int J Rock Mech Min Sci 45:397–406. doi:10.1016/j.ijrmms.2007.07.003

Zhu J, Sun C, Qian Z, Chen J (2011) The spalling strength of ultra-fiber reinforced cement mortar. Eng Fail Anal 18:1808–1817. doi:10.1016/j.engfailanal.2011.05.001

Zhang QB, Zhao J (2014) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47:1411–1478. doi:10.1007/s00603-013-0463-y

Erzar B, Forquin P (2010) An experimental method to determine the tensile strength of concrete at high rates of strain. Exp Mech 50:941–955. doi:10.1007/s11340-009-9284-z

Novikov SA, Ivanov AG (1966) Failure of steel, aluminium and copper under explosive shock loading. Fiz Met i Metalloved 21:608–615

Erzar B, Forquin P (2014) Analysis and modelling of the cohesion strength of concrete at high strain-rates. Int J Solids Struct 51:2559–2574. doi:10.1016/j.ijsolstr.2014.01.023

Li X, Tao M, Wu C, Du K, Wu Q (2017) Spalling strength of rock under different static pre-confining pressures. Int J Impact Eng 99:69–74. doi:10.1016/j.ijimpeng.2016.10.001

Snozzi L, Gatuingt F, Molinari JF (2012) A meso-mechanical model for concrete under dynamic tensile and compressive loading. Int J Fract 178:179–194. doi:10.1007/s10704-012-9778-z

Xu PB, Xu H, Wen HM 2016 3D meso-mechanical modeling of concrete spall tests. Int J Impact Eng. 97, 46–56. doi:10.1016/j.ijimpeng.2016.06.005

Zhou W, Tang L, Liu X, Ma G, Chen M (2016) Mesoscopic simulation of the dynamic tensile behaviour of concrete based on a rate-dependent cohesive model. Int J Impact Eng 95:165–175. doi:10.1016/j.ijimpeng.2016.05.003

Pedersen RR, Simone A, Sluys LJ (2013) Mesoscopic modeling and simulation of the dynamic tensile behavior of concrete. Cem Concr Res 50:74–87. doi:10.1016/j.cemconres.2013.03.021

Erzar B, Forquin P (2011) Experiments and mesoscopic modelling of dynamic testing of concrete. Mech Mater 43:505–527. doi:10.1016/j.mechmat.2011.05.002

Pierron F, Forquin P (2012) Ultra-high-speed full-field deformation measurements on concrete spalling specimens and stiffness identification with the virtual fields method. Strain 48:388–405. doi:10.1111/j.1475-1305.2012.00835.x

Mazars J (1986) A description of micro- and macroscale damage of concrete structures. Eng Fract Mech 25:729–737. doi:10.1016/0013-7944(86)90036-6

Sallier L, Forquin P (2012) On the use of Hillerborg regularization method to model the softening behaviour of concrete subjected to dynamic tensile loading. Eur Phys J Spec Top 206:97–105. doi:10.1140/epjst/e2012-01591-5

Hentz S, Donzé FV, Daudeville L (2004) Discrete element modelling of concrete submitted to dynamic loading at high strain rates. Comput Struct 82:2509–2524. doi:10.1016/j.compstruc.2004.05.016

Weerheijm J, Van Doormaal A (2004) Tensile fracture of concrete at high loading rates. FRAMCOS – 5, Vail

Wu H, Zhang Q, Huang F, Jin Q (2005) Experimental and numerical investigation on the dynamic tensile strength of concrete. Int J Impact Eng 32:605–617. doi:10.1016/j.ijimpeng.2005.05.008

Brara a., Klepaczko JR (2006) Experimental characterization of concrete in dynamic tension. Mech Mater 38:253–267. doi:10.1016/j.mechmat.2005.06.004

Gabet T, Malécot Y, Daudeville L (2008) Triaxial behaviour of concrete under high stresses: influence of the loading path on compaction and limit states. Cem Concr Res 38:403–412. doi:10.1016/j.cemconres.2007.09.029

Piotrowska E, Forquin P (2015) Experimental investigation of the confined behavior of dry and wet high-strength concrete: quasi static versus dynamic loading. J Dyn Behav Mater 1:191–200. doi:10.1007/s40870-015-0017-3

Zingg L, Briffaut M, Baroth J, Malecot Y (2016) Influence of cement matrix porosity on the triaxial behaviour of concrete. Cem Concr Res 80:52–59. doi:10.1016/j.cemconres.2015.10.005

Poinard C, Piotrowska E, Malecot Y, Daudeville L, Landis EN (2012) Compression triaxial behavior of concrete: the role of the mesostructure by analysis of X-ray tomographic images. Eur J Environ Civ Eng 16:s115–s136. doi:10.1080/19648189.2012.682458

Parks VJ (1989) Geometrie Moire. In: Pendleton RL, Tuttle ME (eds) Manual on experimental methods for mechanical testing of composites. Springer, Dordrecht, pp 57–65. doi:10.1007/978-94-009-1129-1_11

Piro JL, Grediac M (2004) Producing and transferring low-spatial-frequency grids for measuring displacement fields with Moire and grid methods. Exp Tech 28:23–26

Pierron F, Grediac M 2012 The virtual fields method. 1st edn. Springer, New York. doi:10.1007/978-1-4614-1824-5

Giraudeau A, Pierron F (2005) Identification of stiffness and damping properties of thin isotropic vibrating plates using the virtual fields method: theory and simulations. J Sound Vib 284:757–781. doi:10.1016/j.jsv.2004.07.009

Giraudeau A, Guo B, Pierron F (2006) Stiffness and damping identification from full field measurements on vibrating plates. Exp Mech 46:777–787. doi:10.1007/s11340-006-9477-7

Moulart R, Pierron F, Hallett SR, Wisnom MR (2011) Full-field strain measurement and identification of composites moduli at high strain rate with the virtual fields method. Exp Mech 51:509–536. doi:10.1007/s11340-010-9433-4

Pierron F, Zhu H, Siviour C (2014) Beyond Hopkinson’s bar. Philos Trans A 372:20130195. doi:10.1098/rsta.2013.0195

Yoon S-H, Siviour CR (2017) Application of the virtual fields method to rubbers under medium strain rate deformation using both acceleration and traction force data. J Dyn Behav Mater 3:12–22. doi:10.1007/s40870-016-0090-2

Yoon S, Giannakopoulos I, Siviour CR (2015) Application of the virtual fields method to the uniaxial behavior of rubbers at medium strain rates. Int J Solids Struct 69–70:553–568. doi:10.1016/j.ijsolstr.2015.04.017

Wang D, Lucas M, Tanner KE (2013) Characterising the strain and temperature fields in a surrogate bone material subject to power ultrasonic excitation. Strain 49:409–419. doi:10.1111/str.12047

Pierron F (2016) Addendum to ‘characterising the strain and temperature fields in a surrogate bone material subject to power ultrasonic excitation’. Strain 52:186–190. doi:10.1111/str.12180

Surrel Y (1994) Moire and grid Methods: a ‘signal processing’ approach. Photomechanics 2342:118–127

Grédiac M, Blaysat B, Sur F (2017) A critical comparison of some metrological parameters characterizing local digital Image correlation and grid method. Exp Mech. doi:10.1007/s11340-017-0279-x

Zhu H, Pierron F (2016) Exploration of Saint-Venant’s principle in inertial high strain rate testing of materials. Exp Mech 56:3–23. doi:10.1007/s11340-015-0078-1

Zhao B, Asundi A (2001) Microscopic grid methods—resolution and sensitivity. Opt Lasers Eng 36:437–450. doi:10.1016/S0143-8166(01)00071-9

Saletti D, Forquin P (2015) A comparison of DIC and grid measurements for processing spalling tests with the VFM and an 80-kpixel ultra-high speed camera. Eur Phys J Spec Top 225:311–323. doi:10.1140/epjst/e2015-77777-x

Grédiac M, Sur F, Blaysat B (2016) The Grid method for in-plane displacement and strain measurement: a review and analysis. Strain 52:205–243. doi:10.1111/str.12182

Kosonocky WF, Yang G, Ye C, Kabra RK, Xie L, Lawrence JL, Mastrocolla V, Shallcross FV, Patel V (1996) 360/spl times/360-element very-high-frame-rate burst image sensor. Solid-state circuits conference, 1996. Digest of technical papers. 42nd ISSCC., 1996 IEEE international, pp 182–183. doi:10.1109/ISSCC.1996.488562

Etoh TG et al. (2003) An image sensor which captures 100 consecutive frames at 1,000,000 frames/s. IEEE Trans Electron Dev 50:144–151. doi:10.1109/TED.2002.806474

Etoh TG, Son DVT, Yamada T, Charbon E (2013) Toward one giga frames per second-evolution of in situ. Storage Image Sens 13:4640–4658. doi:10.3390/s130404640

Badulescu C, Grediac M, Mathias JD (2009) Investigation of the grid method for accurate in-plane strain measurement. Meas Sci Technol 20:9

Rossi M, Pierron F, Forquin P (2014) Assessment of the metrological performance of an in situ storage image sensor ultra-high speed camera for full-field deformation measurements. Meas Sci Technol 25:25401. doi:10.1088/0957-0233/25/2/025401

Avril S, Feissel P, Pierron F, Villon, P (2008) Estimation of the strain field from full-field displacement noisy data. Comparing finite elements global least squares and polynomial diffuse approximation. Eur J Comput Mech 17:857–868. doi:10.3166/remn.17.857-868

Avril S, Feissel P, Pierron F, Villon P (2010) Comparison of two approaches for differentiating full-field data in solid mechanics. Meas Sci Technol 21:15703. doi:10.1088/0957-0233/21/1/015703

Savitzky A, Golay MJE (1964) Smoothing and differentiation of data by simplified least squares procedures. Anal Chem 36:1627–1639. doi:10.1021/ac60214a047

Saadati M, Forquin P, Weddfelt K, Larsson PL (2016) On the tensile strength of granite at high strain rates considering the influence from preexisting cracks. Adv Mater Sci Eng 2016. doi:10.1155/2016/6279571

Forquin P, Erzar B (2009) Dynamic fragmentation process in concrete under impact and spalling tests. Int J Fract 163:193–215. doi:10.1007/s10704-009-9419-3

Pierron F, Forquin P (2012) The virtual fields method applied to spalling tests on concrete. EPJ Web Conf 26:1054. doi:10.1051/epjconf/20122601054

Lukić B, Saletti D, Forquin P (2017) Use of simulated experiments for material characterization of brittle materials subjected to high strain rate dynamic tension. Philos Trans R Soc A Math Phys Eng Sci 375:20160168. doi:10.1098/rsta.2016.0168

Pontiroli C, Rouquand A, Mazars J (2010) Predicting concrete behaviour from quasi-static loading to hypervelocity impact. Eur J Environ Civ Eng 14:703–727. doi:10.1080/19648189.2010.9693259

Rouquand A, Pontiroli C, Mazars J 2007 Concrete structures under severe loading: a strategy to model the response for a large range of dynamic loads. In Fracture mechanics of concrete and concrete structures: proceedings of FraMCoS-6, Catania, Italy

Pontiroli C, Rouquand A, Daudeville L, Baroth J (2012) Soft projectile impacts analysis on thin reinforced concrete slabs: tests, modelling and simulations. Eur J Environ Civ Eng 16:1058–1073. doi:10.1080/19648189.2012.699745

Pontiroli C, Erzar B, Buzaud E (2014) Concrete behaviour under ballistic impacts: effects of materials parameters to penetration resistance and modeling with PRM model. Comput Model Concr Struct Proc EURO-C 2014 v2:685–693

Hillerborg A, Modéer M, Petersson P-E (1976) Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 6:773–781. doi:10.1016/0008-8846(76)90007-7

Lu Y, Xu J, Weerheijm J (2013) A mesoscale modeling perspective of cracking process and fracture energy under high strain rate tension. In 8th International Conference on Fracture Mechanics of Concrete and Concrete Structures - FraMCoS-8. Van Mier JGM, Ruiz G, Andrade C, Yu RC, Zhang XX (eds), pp. 942–952. Toledo, Spain

Acknowledgements

This research has been performed with the financial support of the CEA-Gramat Research Center (France). The provided support is gratefully acknowledged by the authors. The authors would like also to thank Laurent Sallier for assisting with the experimental work and Dr. Benjamin Erzar (CEA-Gramat) for fruitful discussions. This work has been partially financed by the LabEx Tec 21 (Investissements d’Avenir - Grant Agreement No. ANR-11-LABX-0030). The provided support is gratefully acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Forquin, P., Lukić, B. On the Processing of Spalling Experiments. Part I: Identification of the Dynamic Tensile Strength of Concrete. J. dynamic behavior mater. 4, 34–55 (2018). https://doi.org/10.1007/s40870-017-0135-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-017-0135-1