Abstract

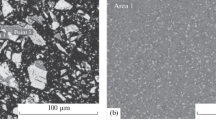

The possibility of obtaining gray, pink, light brown, crimson, olive green pigments based on blast-furnace slag is substantiated. Blast-furnace slag was studied using X-ray analysis, energy-dispersive X-ray microanalysis, and digital electronic microscope. The high efficiency of the low-temperature process for obtaining pigments is shown. It has been established that a high degree of conversion is provided by chemical interaction. The technological properties of the pigment are determined. To determine the optimal synthesis conditions, the influence of several variables, such as temperature, contact time, and adsorbent mass, was studied. Quadratic models were also obtained. Statistical processing was carried out. The central composite rotatable experimental design was used to determine the optimal conditions for obtaining pigments using different chromophore cations (chromium, iron, zinc, nickel). The experimental plan was carried out at two levels of three operating parameters, which were the mass of slag, the time of synthesis, and temperature. Four quadratic mathematical models have been obtained that describe the dependence of the degree of transformation on parameters. The models are adequate. The maximum conversions for chromium, iron, zinc, and nickel are 96.3%, 94.11% 33.7%, and 99.91%, respectively.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data available within the article.

References

Sun J, Na H, Yan T, Qiu Z, Yuan Y, He J, Du T (2021) A comprehensive assessment on material, exergy and emission networks for the integrated iron and steel industry. Energy 235:121429. https://doi.org/10.1016/j.energy.2021.121429

Schoeman Y, Oberholster P, Somerset V (2021) A decision-support framework for industrial waste management in the iron and steel industry: a case study in Southern Africa. CSCEE 3:100097. https://doi.org/10.1016/j.cscee.2021.100097

Petrík J, Blaško P, Mikloš V, Pribulová A, Futaš P, Vasilňková A, Šolc M (2020) The load dependence of the micro-hardness of the blast furnace slag. Int J Mater Eng 26(3):329–340. https://doi.org/10.30544/512

Yi H, Xu G, Cheng H, Wang J, Wan Y, Chen H (2012) An overview of utilization of steel slag. Procedia Environ Sci. 16:791–801. https://doi.org/10.1016/j.proenv.2012.10.108

Shi J, Qiu Y, Yu B, Xie X, Dong J, Hou C, Liu C (2022) Titanium extraction from titania-bearing blast furnace slag: a review. JOM. https://doi.org/10.1007/s11837-021-05040-y

Song Q, Guo MZ, Wang L, Ling TC (2021) Use of steel slag as sustainable construction materials: a review of accelerated carbonation treatment. Resour Conserv Recycl 173:105740. https://doi.org/10.1016/j.resconrec.2021.105740

Li ZH, Zhang YJ, Zhang YZ, Du PP, Ren QQ (2018) Effect of content of Al2O3 and MgO on crystallization of blast furnace slag during fiber formation. J Cent South Univ 25(10):2373–2379. https://doi.org/10.1007/s11771-018-3921-6

Wu M, Huang A, Chen D, Fu L, Gu H (2022) Effect of carbon black on corrosion resistance of Al2O3–SiC–C castables to SiO2–MgO slag. Ceram Int 48(10):13659–13664. https://doi.org/10.1016/j.ceramint.2022.01.245

Aziz IH, Abdullah MMAB, Salleh MM, Azimi EA, Chaiprapa J, Sandu AV (2020) Strength development of solely ground granulated blast furnace slag geopolymers. Constr Build Mater 250:118720. https://doi.org/10.1016/j.conbuildmat.2020.118720

Dong Q, Wang G, Chen X, Tan J, Gu X (2021) Recycling of steel slag aggregate in portland cement concrete: an overview. J Clean Prod 282:124447. https://doi.org/10.1016/j.jclepro.2020.124447

Aydin T, Casin E (2021) Mixed alkali and mixed alkaline-earth effect in ceramic sanitaryware bodies incorporated with blast furnace slag. Waste Biomass Valorization 12(5):2685–2702. https://doi.org/10.1007/s12649-020-01187-y

Paixao A, Fortunato E (2021) Abrasion evolution of steel furnace slag aggregate for railway ballast: 3D morphology analysis of scanned particles by close-range photogrammetry. Constr Build Mater 267:121225. https://doi.org/10.1016/j.conbuildmat.2020.121225

Jing G, Wang J, Wang H, Siahkouhi M (2020) Numerical investigation of the behavior of stone ballast mixed by steel slag in ballasted railway track. Constr Build Mater 262:120015. https://doi.org/10.1016/j.conbuildmat.2020.120015

Jia R, Deng L, Yun F, Li H, Zhang X, Jia X (2019) Effects of SiO2/CaO ratio on viscosity, structure, and mechanical properties of blast furnace slag glass ceramics. Mater Chem Phys 233:155–162. https://doi.org/10.1016/j.matchemphys.2019.05.065

Khlopytskyi A, Savenkov A (2020) Prospects of the application of coal ash materials to produce construction heat-insulation ceramics. Vopr Khimii i Khimicheskoi Tekhnologii 4:215–224. https://doi.org/10.32434/0321-4095-2020-130-3-215-224

Zhang J, Tan H, He X, Yang W, Deng X (2020) Utilization of carbide slag-granulated blast furnace slag system by wet grinding as low carbon cementitious materials. Constr Build Mater 249:118763. https://doi.org/10.1016/j.conbuildmat.2020.118763

Ríos JD, Vahí A, Leiva C, Martínez-De la Concha A, Cifuentes H (2019) Analysis of the utilization of air-cooled blast furnace slag as industrial waste aggregates in self-compacting concrete. Sustainability 11(6):1702. https://doi.org/10.3390/su11061702

Oge M, Ozkan D, Celik MB, Gok MS, Karaoglanli AC (2019) An overview of utilization of blast furnace and steelmaking slag in various applications. Mater Today Proc 11:516–525. https://doi.org/10.1016/j.matpr.2019.01.023

Duan W, Wu Q, Li P, Cheng P (2022) Techno-economic analysis of a novel full-chain blast furnace slag utilization system. Energy 242:123049. https://doi.org/10.1016/j.energy.2021.123049

Cheng X, Long D, Zhang C, Gao X, Yu Y, Mei K, Chen Z (2019) Utilization of red mud, slag and waste drilling fluid for the synthesis of slag-red mud cementitious material. J Clean Prod 238:117902. https://doi.org/10.1016/j.jclepro.2019.117902

Guo X, Xiong G (2021) Resistance of fiber-reinforced fly ash-steel slag based geopolymer mortar to sulfate attack and drying-wetting cycles. Constr Build Mater 269:121326. https://doi.org/10.1016/j.conbuildmat.2020.121326

Abdollahnejad Z, Mastali M, Falah M, Shaad KM, Luukkonen T, Illikainen M (2021) Durability of the reinforced one-part alkali-activated slag mortars with different fibers. Waste Biomass Valori 12(1):487–501. https://doi.org/10.1007/s12649-020-00958-x

Zaichuk AV, Amelina AA (2017) Production of uvarovite ceramic pigments using granulated blast-furnace slag. Glass Ceram 74(3):99–103. https://doi.org/10.1007/s10717-017-9937-9

Zaichuk AV, Amelina AA (2019) Blue-green spinel-type ceramic pigments prepared from the slag of aluminothermal production of ferrotitanium. Vopr Khimii i Khimicheskoi Tekhnologii 4:46–54

Maslennikova GN, Pishch IV, Gvozdeva NA (2009) Particularities of the synthesis of pigments with corundum–spinel structure. Glass Ceram 66(1):5–7. https://doi.org/10.1007/s10717-009-9108-8

Frolova LA, Pivovarov AA, Butyrina TE, Tsepich EG (2015) Purification of wastewaters, containing chromium, by a sorbent based on blast furnace slag. J Water Chem Technol 37(4):185–190. https://doi.org/10.3103/S1063455X15040062

Ozel E, Turan S, Coruh S, Ergun ON (2006) Production of brown and black pigments by using flotation waste from copper slag. Waste Manag Res 24(2):125–133. https://doi.org/10.1177/0734242X06062690

Ren G, Wang X, Zhang Z, Zhong B, Yang L, Yang X (2017) Characterization and synthesis of nanometer magnetite black pigment from titanium slag by microwave-assisted reduction method. Dyes Pigm 147:24–30. https://doi.org/10.1016/j.dyepig.2017.07.068

Frolova L, Shuvalov V (2013) The technology of obtaining complex anticorrosive pigments from zinc-containing waste water. Chem Chem Technol 7(2):1–5

Frolova LA (2014) Production conditions of iron oxide black from pickle liquors. Metall Min Ind 4:65–69

Sahu KK, Alex TC, Mishra D, Agrawal A (2006) An overview on the production of pigment grade titania from titania-rich slag. Waste Manag Res 24(1):74–79. https://doi.org/10.1177/0734242X06061016

Frolova L, Pivovarov A (2016) Obtaining of brown pigments from concentrated waste water containing nickel. Chem Chem Technol 10(2):209–211

Mason RL, Gunst RF, Hess JL (2003) Statistical design and analysis of experiments: with applications to engineering and science. Wiley, New York

Marinova Y, Hohemberger JM, Cordoncillo E, Escribano P, Carda JB (2003) Study of solid solutions, with perovskite structure, for application in the field of the ceramic pigments. J Eur Ceram Soc 23(2):213–220. https://doi.org/10.1016/S0955-2219(02)00182-6

Ogirigbo OR, Black L (2016) Influence of slag composition and temperature on the hydration and microstructure of slag blended cements. Constr Build Mater 126:496–507. https://doi.org/10.1016/j.conbuildmat.2016.09.057

Sun H, Nakashima K, Mori K (2006) Influence of slag composition on slag–iron interfacial tension. ISIJ Int 46(3):407–412. https://doi.org/10.2355/isijinternational.ISIJINT-2022-047

Novelty statement

The main goal of the work is to find out the possibility of using blast-furnace slags to obtain pigments by precipitation. While many researchers have worked on the use of blast-furnace slag, very few researchers have specifically reported on the production of pigments. In addition, their production by the ceramic process requires high temperatures and leads to agglomeration. The color characteristics of the resulting pigment were determined.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Sharif Jahanshahi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Frolova, L., Bluss, B., Ivanchenko, A. et al. Utilization of Furnace Slag for Pigments Production. J. Sustain. Metall. 8, 1892–1903 (2022). https://doi.org/10.1007/s40831-022-00613-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00613-w