Abstract

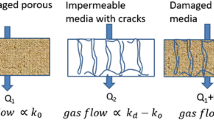

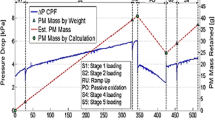

The objective of the current study is to numerically predict the collection efficiency, particulate matter (PM) loading, pressure drop, and flow characteristics in partially damaged or unplugged filters. Five different PM size classes with mean particle diameters ranging from 25 to 300 nm are considered for loading the filter. These PM classes are transported in the computational domain as scalars and collected in the filter through Brownian diffusion and interception mechanisms. Four different partially damaged filters with varying damaged cross-sections in the outlet face of the filter are considered. Five different exhaust gas flow rates from 50 to 300 kg/h with a transient soot loading condition are considered, which leads to different temporal and spatial soot cake evolutions as well as a different total soot mass in the filter. As expected, plugged filter sections have higher filtration efficiencies which increases monotonically with soot accumulation. For damaged segment, however, efficiency is nonmonotonic and depends strongly on particle size, loading, and prevailing flow conditions. The collection efficiency of damaged segments is less than 40% at all flow rates and damaged cross-sections considered in this study. The overall filter efficiency is evaluated as the sum of flow averaged filtration efficiencies of both plugged and unplugged sections. The overall filter efficiency is less than 100% and this efficiency decreases from filter-1 to filter-4 as the damaged filter section contributes to the efficiency loss. Spatial and temporal evolution of soot cake is different in damaged and undamaged sections. Strong nonuniform soot distribution is observed in the partially damaged filters in both the axial and radial direction. One objective of the current study is to analyze the overall filter collection efficiency with respect to the percentage of damage, which as a result will assist in the roadworthiness studies, on-board diagnostic studies, or periodic technical inspection of the filters or damaged filters.

Similar content being viewed by others

Abbreviations

- CFD:

-

Computational fluid dynamics

- CPSI:

-

Channels per square inch (1/in2)

- DPF:

-

Diesel particulate filter

- GHSV:

-

Gas hourly space velocity (1/s)

- GPF:

-

Gasoline particulate filter

- PM:

-

Particulate matter (soot)

- PN:

-

Particulate number (soot, #/m3)

- PM1:

-

Particulate matter 1 with size class 25 nm

- PM2:

-

Particulate matter 2 with size class 50 nm

- PM3:

-

Particulate matter 3 with size class 100 nm

- PM4:

-

Particulate matter 4 with size class 200 nm

- PM5:

-

Particulate matter 5 with size class 300 nm

- A :

-

Cross-sectional area (m2)

- D p :

-

Particle diffusion coefficient

- d :

-

Diameter (m)

- d c :

-

Unit collector diameter

- d p :

-

Mean particle diameter

- E :

-

Total filtration efficiency

- F :

-

Friction coefficient ( −)

- f :

-

Fraction of the flow going into plugged filter segment ( −)

- \(g\left(\varepsilon \right)\) :

-

Kuwabara flow field function

- Kn :

-

Knudsen number

- k :

-

Permeability (1/m2)

- m :

-

Mass (kg)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- l :

-

Length (channel) (m)

- \({N}_{R}\) :

-

Interception parameter

- p :

-

Pressure (Pa)

- Pe :

-

Peclet number

- t:

-

Time (s)

- u i :

-

Interstitial or pore velocity

- u w :

-

Approach velocity

- v :

-

Velocity (m/s)

- w s :

-

Wall thickness

- z :

-

Coordinate in axial direction (m

- δ :

-

Thickness (m)

- \(\varepsilon\) :

-

Porosity of the

- μ :

-

Dynamic viscosity of the gas (kg/(m s))

- η :

-

Efficiency ( −)

- ρ :

-

Density (kg/(m3))

- \(\varnothing\) :

-

Transported scalar value

- bnd:

-

Boundary (filter inlet, outlet)

- C:

-

Cross-section

- c:

-

Cake

- D:

-

Brownian diffusion efficiency

- d:

-

Damaged filter segment

- eff:

-

Effective (length)

- i:

-

Inlet (channel)

- in:

-

Inlet (face)

- iw:

-

Inlet-wall

- o:

-

Outlet (channel)

- out:

-

Outlet (filter)

- ow:

-

Outlet-wall

- over:

-

Overall filtration efficiency

- p:

-

Plugged filter segment

- R:

-

Interception efficiency

- r:

-

Regular filter segment

- s:

-

Dimensionless parameter

- w:

-

Wall

References

Kittelson, D.B.: Engines and nanoparticles: a review. J. Aerosol. Sci. 29(5–6), 575–588 (1998). https://doi.org/10.1016/S0021-8502(97)10037-4

Cohen, A.J., Pope, C.A.: Lung cancer and air pollution. In: Environmental health perspectives (1995)

Sauvain, J.J., Vu Duc, T., Guillemin, M.: Exposure to carcinogenic polycyclic aromatic compounds and health risk assessment for diesel-exhaust exposed workers. Int. Arch. Occup. Environ. Health. (2003). https://doi.org/10.1007/s00420-003-0439-4

Menon, S., Hansen, J., Nazarenko, L., Luo, Y.: Climate effects of black carbon aerosols in China and India. Science (80-. ). (2002). https://doi.org/10.1126/science.1075159

Ramanathan, V., Carmichael, G.: Global and regional climate changes due to black carbon. (2008)

Tzamkiozis, T., Ntziachristos, L., Samaras, Z.: Diesel passenger car PM emissions: from Euro 1 to Euro 4 with particle filter. Atmos. Environ. 44, 909–916 (2010). https://doi.org/10.1016/j.atmosenv.2009.12.003

Ing. G. Kadijk, Mayer, D.A.: White paper NPTI – the new periodic technical inspection emission test procedure for vehicles with emission control systems . In: ETH Conference, Zürich. pp. 1–12 (2017)

Schriefl, M.A., Nishida, R.T., Knoll, M., Boies, A.M., Bergmann, A.: Characterization of particle number counters based on pulsed-mode diffusion charging. Aerosol Sci. Technol. 54(7), 772–789 (2020). https://doi.org/10.1080/02786826.2020.1724257

Konstandopoulos, A.G., Kostoglou, M., Skaperdas, E., Papaioannou, E., Zarvalis, D., Kladopoulou, E.: Fundamental studies of diesel particulate filters: transient loading, regeneration and aging. In: SAE Technical Papers (2000)

Konstandopoulos, A.G., Kostoglou, M., Vlachos, N., Kladopoulou, E.: Progress in diesel particulate filter simulation. SAE Tech. Pap. (2005). https://doi.org/10.4271/2005-01-0946

Konstandopoulos, A.G., Johnson, J.H.: Wall-flow diesel particulate filters-their pressure drop and collection efficiency. In: SAE Technical Papers. pp. 99–123. SAE International (1989)

Koltsakis, G., Haralampous, O., Depcik, C., Ragone, J.C.: Catalyzed diesel particulate filter modeling. (2013)

Wurzenberger, J.C., Kutschi, S.: Advanced simulation technologies for diesel particulate filters, a fundamental study on asymmetric channel geometries. In: SAE Technical Paper Series (2010)

Koltsakis, G.: Catalytic automotive exhaust aftertreatment. Prog. Energy Combust. Sci. (2002). https://doi.org/10.1016/s0360-1285(97)00003-8

Charles, E., Sprouse III, Michael, D., Mangus, Christopher, D., D.: Diesel particulate filter model with detailed permeability analysis. Proc. 2011 Fall Conf. ASME Energy Water Scarcity Div. IMECE. 1–8 (2011)

Chiavola, O., Chiatti, G., Sirhan, N.: Impact of particulate size during deep loading on DPF management. Appl. Sci. 9, 3075 (2019). https://doi.org/10.3390/app9153075

Darcy, P., Guerry, S., Latouchent, G., Barbier, P., Fasolo, B.: Improvement of SiC DPF control strategies for uncontrolled regenerations with the aid of quasi 3d DPF model. SAE Int. J. Fuels Lubr. 1, 1362–1372 (2009). https://doi.org/10.4271/2008-01-1753

Kontses, D., Geivanidis, S., Fragkiadoulakis, P., Samaras, Z.: Uncertainties in model-based diesel particulate filter diagnostics using a soot sensor. Sensors (Switzerland) 19, 3141 (2019). https://doi.org/10.3390/s19143141

Kadijk, G., Coordination, I.: Roadworthiness test investigations of diesel particulate filters. (2015)

Spielman, L., Goren, S.L.: Model for predicting pressure drop and filtration efficiency in fibrous media. Environ. Sci. Technol. 2, 279–287 (1968). https://doi.org/10.1021/es60016a003

Ström, H., Sasic, S.: The role of thermophoresis in trapping of diesel and gasoline particulate matter. Catal. Today. 188, 14–23 (2012). https://doi.org/10.1016/j.cattod.2012.02.023

Tandon, P., Heibel, A., Whitmore, J., Kekre, N., Chithapragada, K.: Measurement and prediction of filtration efficiency evolution of soot loaded diesel particulate filters. Chem. Eng. Sci. (2010). https://doi.org/10.1016/j.ces.2010.05.020

Foley, R., Johnson, J., Naber, J., Rogoski, L.: Experimental measurements of particulate matter distribution in a catalyzed particulate filter. Emiss. Control Sci. Technol. 1, 32–48 (2015). https://doi.org/10.1007/s40825-014-0005-4

Bensaid, S., Marchisio, D.L., Fino, D., Saracco, G., Specchia, V.: Modelling of diesel particulate filtration in wall-flow traps. Chem. Eng. J. 154, 211–218 (2009). https://doi.org/10.1016/j.cej.2009.03.043

Turner, C., Thornhill, D., McCullough, G., Patel, S.: Comparison of experimental PIV data and CFD simulations for flow in a diesel particulate filter inlet diffuser. In: SAE Technical Papers. SAE International (2011)

Chittipotula, T., Kutschi, S., Wurzenberger, J.C.: Performance of broken particulate filters—a 1D and 3D simulation study. Emiss. Control Sci. Technol. 6, 186–194 (2020). https://doi.org/10.1007/s40825-020-00160-4

Dritselis, C.D., Tzorbatzoglou, F., Mastrokalos, M., Haralampous, O.: Numerical study of flow and particle deposition in wall-flow filters with intact or damaged exit. Fluids. 4, 201 (2019). https://doi.org/10.3390/fluids4040201

Bémer, D., Thomas, D., Pacault, S.: Performance of a diesel particle filter damaged by drilling holes in the filter walls to simulate internal micro-cracks. Emiss. Control Sci. Technol. 6, 442–449 (2020). https://doi.org/10.1007/s40825-020-00172-0

Basu, S., Henrichsen, M., Tandon, P., He, S., Heibel, A.: Filtration efficiency and pressure drop performance of ceramic partial wall flow diesel particulate filters. SAE Int. J. Fuels Lubr. (2013). https://doi.org/10.4271/2013-01-9072

Hinterberger, C., Kaiser, R., Olesen, M.: 3D-simulation of soot loading and DPF regeneration. MTZ Worldw 67, 2–5 (2006). https://doi.org/10.1007/BF03227832

Rissler, J., Messing, M.E., Malik, A.I., Nilsson, P.T., Nordin, E.Z., Bohgard, M., Sanati, M., Pagels, J.H.: Effective density characterization of soot agglomerates from various sources and comparison to aggregation theory. Aerosol Science and Technology 47(7), 792–805 (2013). https://doi.org/10.1080/02786826.2013.791381

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chittipotula, T. Numerical Prediction of Particulate Matter (PM) Collection Efficiency, Loading, and Flow Characteristics in Partially Damaged Particulate Filters with Different PM Size Classes. Emiss. Control Sci. Technol. 7, 302–320 (2021). https://doi.org/10.1007/s40825-021-00195-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-021-00195-1