Abstract

Ultrastable glasses (mostly prepared from the vapor phase under optimized deposition conditions) represent a unique class of materials with low enthalpies and high kinetic stabilities. These highly stable and dense glasses show unique physicochemical properties, such as high thermal stability, improved mechanical properties or anomalous transitions into the supercooled liquid, offering unprecedented opportunities to understand many aspects of the glassy state. Their improved properties with respect to liquid-cooled glasses also open new prospects to their use in applications where liquid-cooled glasses failed or where not considered as usable materials. In this review article we summarize the state of the art of vapor-deposited (and other) ultrastable glasses with a focus on the mechanism of equilibration, the transformation to the liquid state and the low temperature properties. The review contains information on organic, metallic, polymeric and chalcogenide glasses and an updated list with relevant properties of all materials known today to form a stable glass.

Similar content being viewed by others

Since their discovery in 2007 by Mark Ediger and his group at the university of Wisconsin [1], Madison, vapor-deposited stable glasses have become an important area of research within the glass community due to their remarkable properties that facilitate new approaches to the exploration of some long-standing problems in glass science, such as the glass transition phenomenology and the existence or not of an ideal glass that is hidden by the kinetic glass transition observed in the laboratory. At the same time, vapor-deposition offers a versatile route to produce organic thin film glasses with enhanced kinetic and thermodynamic stability, as well as tailored molecular orientation, opening new possibilities to improve the efficiency and lifetime of organic optoelectronic devices [2]. While much research has focused on organic glasses, a new burst of activity is related now to ultrastability in metallic glasses and polymers, two families of materials with many relevant industrial applications. We note that several excellent reviews have been recently published covering aspects related to the origin of ultrastability, their packing anisotropy and tuning of the molecular orientation, as well as structure–property relationships of stable organic glasses [3,4,5]. Here, we intend to give a broader description that provides updated information on the different materials that have been grown from the vapor as ultrastable glasses including metallic, organic, polymeric, and chalcogenides. Although during the 14 years of activity in this field most of the work has involved organic glasses, we incorporate whenever possible data from metallic glasses and polymers. From this diverse perspective we focus on the mechanism of formation of stable glasses and on their low-temperature properties, their transformation into the supercooled liquid, the role of fragility in stable glass formation and some potential applications of these materials. The review is organized as follows. The first section provides a general introduction of the main characteristics of stable glasses and some common properties and distinctions between stable glasses of different families and prepared by different routes. It includes organic, metallic, polymer and chalcogenide glasses and a comprehensive up-to-date list/table of most materials prepared from the vapor as stable glasses. The second section covers the mechanism of formation of low enthalpy glasses by vapor deposition. Section 3 deals with the transformation mechanism of organic stable glasses into the supercooled liquid. It covers two scenarios: in very thin films propagation fronts parallel to the film surface (or interfaces) dominate the transformation and, in much thicker films, the transformation proceeds through a bulk process that resembles nucleation and growth in the melting of polycrystalline solids. Section 4 describes some of the remarkable features of the low-temperature properties of glasses and the exceptional properties of vapor-deposited stable glasses. Finally, Sect. 5 summarizes some interesting (opto)electronic and thermal transport properties of vapor-deposited stable glasses in relation to present or potential applications.

1 Introduction

Glasses can be broadly defined as non-equilibrium solids lacking long-range order. The absence of periodicity provides exceptional attributes to these materials. In particular, they can be made more homogeneous on larger scales than crystals due to the absence of grain boundaries and there is a large flexibility in tuning their composition and properties without entering well-defined thermodynamic states. They exhibit a reversible transition between the glass and the supercooled liquid that is termed glass transition. Consequently, a good understanding of the dynamical behavior of supercooled liquids is crucial for a precise knowledge of the formation of the glass. The reader is referred to several reviews covering the supercooled liquid state [6, 7], here we briefly introduce some ideas that we consider relevant for the discussion below. The glass is usually obtained by cooling the liquid from above the melting temperature of the material, bypassing crystallization, to low temperature regions where viscosity is high enough to consider the material a solid in observational time scales.Footnote 1 In the glass state, molecular motion almost ceases, except for thermal vibrations. A similar statement can be formulated in terms of the structural relaxation time, τ (also called alpha relaxation), considering the Maxwell equation [8] that relates the relaxation time of the supercooled liquid and the shear viscosity through \(\tau ={G}_{\infty }\cdot \eta \), where \({G}_{\infty }\) is the shear modulus measured at high frequency. The relaxation time of the liquid is proportional to the viscosity and roughly follows its same temperature dependence, since the variation of \({G}_{\infty }\) with temperature is much less dramatic than that of the viscosity. Therefore, similarly to viscosity, \(\tau \) of the supercooled liquid grows abruptly close to the glass transition, although this dynamical change is not associated to a structural variation. The relaxation time can be considered as a characteristic time associated to the rearrangement of a system once it has been externally altered and moved out from equilibrium. It can also be associated to the dissipation of spontaneous density fluctuations occurring in the liquid structure. Both characteristic times are related by the fluctuation–dissipation theorem. For example, when reducing the temperature of a liquid by a small value, its volume (or enthalpy) does not change immediately, but the process requires a certain amount of time to reach equilibrium. This equilibration time (or relaxation time), which is temperature dependent, governs the dynamics of such a change. The temperature at which the relaxation time of the material exceeds standard laboratory time scales (by convention chosen at around 100 s) is considered as the standard glass transition temperature, Tg, (Fig. 1a). This temperature marks the transition from the supercooled liquid to the glass state [6]. The glass transition temperature can be defined in many other alternative ways: for instance, in calorimetry experiments, its value for a given substance is defined by a finite discontinuity of the heat capacity when cooling from the liquid at − 10 K/min [9] (see Fig. 2). Throughout this review, we will refer to a conventional glass as one that has been cooled from the liquid at − 10 K/min, and its Tg is measured on cooling or at the subsequent heating at + 10 K/min. However, the temperature associated to the atomic/molecular arrest depends on the thermal history of the material, that is, for instance, on its cooling rate. The lower the cooling rate, the lower the glass transition temperature, if crystallization can be avoided. In other words, the glass can be made more stable (lower Tg on cooling) by simply decreasing the cooling rate. Of course, besides the risk of crystallization that is a handicap for many families of glasses, there is a practical obstacle to this processing route since, roughly speaking, temperature excursions of tens/hundreds of degrees from the liquid state are typically required to produce a glass. That is, cooling at 0.01 K/min for 100 K will require around 10 days. Further lowering two orders of magnitude, the cooling rate to obtain a glass with higher thermodynamic stability (lower Tg) will raise this number to 3 years. The amount of stability enhancement upon lowering the cooling rate will ultimately depend on the fragility of the supercooled liquid. The kinetic fragility is a measure of the non-Arrhenius character of the change of viscosity (or relaxation time) of the supercooled liquid when approaching the glass transition temperature. Strong liquids display an Arrhenius temperature dependence, while fragile liquids are highly non-Arrhenius [10, 11]. The larger the deviation from Arrhenius, the higher the fragility, as schematically shown in Fig. 1b. An indicator of the kinetic fragility of the liquid is the parameter m, that is obtained through the Angell plot [12] (log (η) vs Tg/T, as in Fig. 1b), using the following expression, \(m={\left.\frac{d\mathrm{log}\left[\tau \left(T\right)\right]}{d\left(\frac{{T}_{\mathrm{g}}}{T}\right)}\right]}_{T={T}_{\mathrm{g}}}\). Low and large m values mean strong and fragile liquids, respectively.

Representation of the dynamics of typical glass-forming liquids: a logarithm of the structural (alpha) relaxation time of glycerol as a function of 1000/T, showing the exponential growth of relaxation dynamics as the temperature is lowered, and b logarithm of the viscosity as a function of the normalized inverse of temperature for materials with different fragility. Strong materials, such as silicon dioxide, follow an Arrhenius expression, while fragile glass formers, such as o-terphenyl, follow a super Arrhenius expression. Data obtained from [13, 14]

Representation of the typical specific heat trace of a glass transition during cooling (dashed red line) and the subsequent heating, at a faster pace than the previous cooling (blue line). The beginning of the glass transition peak on heating corresponds to the onset temperature (Ton). The integration of the specific heat trace yields the enthalpy curve. The limiting fictive temperature can be calculated as the intersection between the enthalpy curve and the extrapolation of the supercooled liquid enthalpy line

The stability of a glass can also be improved by annealing the glass below the glass transition temperature, a process often termed aging. Aging, in a structural sense, is a very slow relaxation process because it relies on the bulk structural relaxation, that has a sharp exponential behavior below Tg (see Fig. 1a). Therefore, unreachable time scales are often needed to prepare a glass with very high thermal stability. This is the main drawback of liquid-cooled glasses, because if the glass is not stable enough at the working temperatures it may undergo changes during its lifetime operation in many practical applications.

One of the most relevant attributes of vapor-deposited stable glasses is that they can be prepared in thermodynamic states comparable to glasses that have been cooled (or equivalently aged) for hundreds/thousands of years. This property brings unusual opportunities to prepare, in just a few hours, glasses that may take unattainable waiting times by conventional liquid-cooled protocols. This correspondence between vapor-deposited and conventional glasses is always established upon extrapolation of the properties of the liquid-cooled glass towards extremely low cooling rates or geological timescales of aging. In addition, vapor-deposited glasses often exhibit molecular packing anisotropy [15, 16] which adds another degree of freedom to tune the properties of the material, but at the same time hinders a direct correlation of some of their properties with respect to isotropic liquid-cooled glasses. Therefore, one of the relevant questions in the field of vapor-deposited stable glasses is whether they would be comparable to glasses prepared by conventional means in unreachable timescales, or they correspond to unique configurations that are a particularity of the preparation method.

Probably, the most prominent characteristics of vapor-deposited glasses are related to their kinetic and thermodynamic stabilities. The kinetic stability is typically measured through the shift of the onset of devitrification (Ton), defined as the temperature at which the glass starts to transform into the supercooled liquid on heating. Since stable glasses are prepared from the vapor as films, the variation of Ton is typically measured either with calorimetry (by standard calorimetry for micron-thick films or chip-based calorimetry for thinner ones) or with ellipsometry, measuring the thickness change as a function of temperature. Ton is evaluated at the crossing point between the heat capacity of the glass and the rapidly increasing heat capacity line. This temperature coincides with the inflection point of the Cp line during cooling when \(\left|{q}_{\mathrm{c}}\right|=\left|{q}_{\mathrm{h}}\right|\). If heating is faster than cooling, Ton is right shifted compared to the inflection point of the heat capacity on cooling (Tg), as shown in Fig. 2. This is the situation for vapor-deposited glasses: since they are in thermodynamic states equivalent to glasses cooled at extremely small cooling rates, but Ton is measured on heating at rates around 10 K/min. Therefore, Ton is shifted to high temperatures with respect to Tg, the larger the shift the higher the kinetic stability of the glass. An alternative (but closely related) quantification of the kinetic stability can be obtained by comparing the time needed to transform a material to its supercooled liquid state during an isotherm at T > Tg with the alpha relaxation time at that temperature. This time is referred to as transformation time. For instance, if a glass takes 1000 s to become a liquid at T1 > Tg and τα is 0.1 s at T1, then the ratio ttrans/τα is 104. Another signature of the high stability of ultrastable glasses is the thermodynamic stability, which is measured by the decrease of a state variable (enthalpy, volume) with respect to the liquid-cooled glass. Enthalpy reductions around 5–10 J/g are typically reached in ultrastable glasses (Table I). The thermodynamic stability is described through the concept of the fictive temperature (Tf), defined as the temperature at which the state variable (enthalpy or density) has the same value for the glass and for the extrapolated equilibrium liquid [9, 17] (see Fig. 2). While it has been recognized that glasses do not show a unique, macroscopic, Tf, but rather a microscopic dispersion of fictive temperatures [18], it is a useful parameter to globally define the stability of a glass and we will use it this way throughout this review. The evaluation of Tf can be done in several ways: using calorimetric data, the integration of heat capacity yields the enthalpy as a function of temperature and the extrapolation of the enthalpy of the supercooled liquid line to low temperatures provides Tf at the crossing point between the liquid and the glass lines (see Fig. 2).

Tf can also be evaluated from the specific heat data using the area matching method of Moynihan et al. [17]. A different approach is to use ellipsometric data and extract Tf as the intersection between the thickness of the glass and the extrapolation to lower temperatures of the thickness of the liquid. In view of the above, though ultrastability is a tunable quantity, an ultrastable glass could be defined as a glass that simultaneously exhibits: (i) transformation times when annealed above Tg that are orders of magnitude larger than the alpha relaxation times at that temperature (typical values in organic glasses are 103–106) or equivalently shifts in Ton (during a heating scan) by some important fraction (around 5% or more) relative to Tg. ΔTon (%) is defined as ((Ton(stable)-Tg(conventional))/Tg(conventional)) × 100, and (ii) a fictive temperature evaluated through any relevant macroscopic property (enthalpy, density, hardness) that approaches the ideal glass state beyond what can be achieved by cooling the liquid in reasonable time scales. As will be shown below, not all materials termed ultrastable glasses in the literature comply with the same characteristics. Organic glasses show low enthalpic fictive temperatures while in metallic glasses, due to the difficulty of measuring in a sufficiently large temperature interval the heat capacity of the liquid because of crystallization, it is best to correlate the stability with respect to the mechanical properties.

At this point, we introduce the potential energy landscape (PEL) paradigm, which is so widely employed to visualize and discuss the dynamic and thermodynamic behavior of glasses and viscous liquids. As depicted in Fig. 3, the PEL of an ensemble of N particles is essentially a topographic view of the (3N + 1) potential-energy hypersurface of any glass-forming substance [19,20,21], though it is schematically projected on two dimensions for sake of convenience. Even a small portion of this energy diagram is plenty of local minima and saddle points for thermal energies below kBTm (where Tm stands for the melting temperature of the stable crystalline state, when it exists). When a liquid is supercooled bypassing the crystallization down to the glass-transition temperature Tg, it becomes a glass getting trapped in one of the many possible local minima or metastable states, depending on the thermal history followed. Furthermore, many authors have speculated on the possible existence of an “ideal glass” which should correspond to the best and most stable possible glass achievable, associated with the lowest relative minimum. This ideal glass would have zero configurational entropy, equal to that of crystals, and has been associated to the possible existence of an underlying, likely second order, thermodynamic glass transition occurring at the so-called Kauzmann temperature TK [22].

Schematic potential energy landscape (PEL) for supercooled liquids and glasses, including the hypothetical absolute minimum for a glass state. An ideal glass would be obtained after an infinitely long aging at the Kauzmann temperature TK. Double-well (DWP) and single-well (SWP) potentials are also suggested (see Sect. 4 for a detailed discussion). A glass could evolve by aging, exploring lower energy states, or by rejuvenation, moving towards higher energy states. A vapor deposited ultrastable glass can access low energy states, close to the ideal glass

Interestingly, a few experiments in the last decade have addressed more directly this question, by trying to get very deep in the energy landscape, approaching the ideal glass state, as illustrated in Fig. 3. The recent emergence of highly stable glasses has opened an appealing and timely window to investigate these issues in a real, not speculative way [23,24,25]. In a PEL view the kinetic stability can be seen as the height of the barriers that need to be overcome to attain another, more equilibrated, metastable state. Hence the thermodynamic stability is pictured by a deep position in the PEL. The lower the value of Tf, the higher is the stability of the glass or, to put it another way, the lower is the position of the glass in the PEL.

1.1 Organic glasses

Most of the work on ultrastable glasses has involved molecular glasses. Since the first measurements in 2007 [1] with 1,3-bis-(1-naphthyl)-5-(2-naphthyl)benzene (TNB) (Tg = 347 K) and indomethacin (IMC) (Tg = 315 K), more than 45 different organic molecules, ranging from small molecules such as toluene [26,27,28] and ethylbenzene [28] to pharmaceuticals such as IMC and TNB and more recently to organic semiconductors like TPD [29, 30], NPD [31, 32] and TPBi [2], have shown their ability to form highly stable glasses upon growth by physical vapor deposition at the right processing conditions. Table 1 shows a comprehensive list of molecules and some of the outstanding properties of the vapor-deposited thin film ultrastable glasses obtained from them. As a general trend, vapor-deposited organic glasses show a substantial increase of Ton compared to a conventional glass prepared by cooling the liquid at − 10 K/min. ΔTon roughly varies from 2 to 10% (see Table 1) depending on the molecular system and growth conditions.

The two most relevant external parameters influencing the kinetic and thermodynamic stability of vapor-deposited organic glasses are the substrate temperature during growth from the vapor, Tsub, and the growth rate, g [33,34,35]. In most cases, stable organic glasses are deposited using g values around 0.1–1 nm/s. Lower (higher) rates can be used to prepare glasses with higher(lower) stability. The influence of these parameters on glass stability can be understood through the concept of surface equilibration and will be deeply discussed in Sect. 2. Figure 4 shows typical trends for Ton and Tf as a function of the substrate temperature (for g ≈ 0.1–1 nm/s). The region of maximum stability (both kinetic and thermodynamic) is broadly located between 0.8 and 0.9 Tg, being Tg the glass transition temperature of the conventional glass. In the region close to Tg the glass can be grown in equilibrium with the liquid at the deposition temperature if the growth rate is low enough [36]. That is, in these conditions, a glass grown at a substrate temperature of, for example, 0.95 Tg, will have a fictive temperature that equals 0.95 Tg. Figure 4 also shows that as we lower Tsub we get to a temperature at which the glass falls out of equilibrium, i.e. does not follow the extrapolation line of the supercooled liquid. This has been explored in detail by Beasley et al. [25] and brings the interesting issue as to how low can we reduce the substrate temperature (and, concomitantly, the growth rate) to obtain glasses in equilibrium with the supercooled liquid. The fundamental and relevant question would be: How far an ultrastable glass can go down in the energy landscape? That is, can we reach an enthalpy state close to the one theoretically predicted for the ideal glass? This relevant issue is further discussed in Sect. 2.5.

Onset temperature of devitrification (bottom) and fictive temperature (top) of several organic thin films: a Toluene; b Tris(4-carbazoyl-9-ylphenyl)amine (TCTA), c Celecoxib. Lines are a guide to the eye. The devitrification was measured by quasi-adiabatic membrane-based nanocalorimetry, at heating rates of the order of 3 × 104 K/s for films of equal thickness. Data extracted from different sources [37,38,39]

In practical experiments, lowering the value of g even further is experimentally challenging, and at some point when the substrate temperature decreases the vapor-deposited glass will fall out of equilibrium, i.e. its average fictive temperature will be higher than Tsub. This is the shadow region in Fig. 4a. The properties of vapor-deposited glasses grown at low substrate temperatures, below 0.75 Tg, have not been explored in detail and it is too early to draw conclusions about the mechanism of stabilization in this temperature regime, at least for organic glasses. Recent experiments from Fakhraai and coworkers [40] show that at temperatures around and below 0.85 Tg it is possible to access to a different phase in TPD vapor deposited glasses but only for very thin films, below 70 nm. This is a clear example showing how complex can become the relaxation mechanisms that take place during the deposition process.

The role other external variables can play in the properties of the glass is much less explored compared to temperature and growth rate. Below, we describe several ways one could think to modify the energy of the incoming molecules or their arrangement/packing within a glass. For instance, ion-beam-assisted deposition (IBAD) irradiating the substrate surface with a low-energy ion beam during growth could be used to enhance surface diffusion. If crystals can be avoided during thin film growth, this deposition technique may enable highly stable glasses at lower deposition temperatures compared to standard physical vapor deposition. Other external variables such as electric/magnetic fields or light during thin film growth may have some impact on the formation of stable glasses depending on the nature of the organic molecule. For example, organic molecules with large intrinsic electric dipolar moments could be orientationally tuned by high external electric fields while keeping a high thermodynamic stability. The presence of magnetic fields during deposition may also play a role in molecules containing magnetic atoms. Or illumination of the substrate during growth may affect the formation of semiconductor molecules with homo–lumo levels lower than the energy of the incident light [41].

Another property that is very useful in understanding some of the unusual properties of stable organic glasses is density. Ellipsometry data are employed to infer the density of the films and highly stable organic glasses are consistently more dense than conventional liquid-cooled glasses by around 1–2% depending on the organic molecule and the deposition conditions (see Table 1). The increased density of the glass correlates relatively well with the enhanced thermodynamic stability, i.e. fictive temperature [37, 38]. The high packing density of stable glasses is often invoked to explain the heterogenous nature of the transformation of the stable glass into the supercooled liquid, that starts in regions of high mobility at the surface of the glass, where mobility is orders of magnitude higher than in the bulk. The observation of propagation fronts that start at surfaces/interfaces has already been observed and analyzed in many organic glasses. Section 3 gives a detailed overview of this mechanism.

A remarkable characteristic of many vapor-deposited glasses is the existence of molecular anisotropy. An excellent review on this topic has appeared recently [5] and here we only give a short summary. While conventional glasses, those prepared by cooling from the melt, are completely isotropic, glasses prepared by physical deposition exhibit a particular molecular arrangement whose magnitude depends on deposition conditions (Tsub and growth rate) and on molecular shape. In general, glasses deposited below, and close to, Tg, exhibit an isotropic structure comparable to conventional glasses. Decreasing Tsub, the grown glass has an increasing tendency towards end-on packing (i.e. long axis of the molecule perpendicular to the substrate). Eventually, upon further decreasing of Tsub, the orientation of the molecule becomes more planar (parallel to the substrate), see Fig. 5. These observations have been experimentally determined using variable angle spectroscopic ellipsometry, X-ray diffraction, infrared/UV spectroscopy or absorption [3, 5, 42,43,44,45] and supported by a number of simulation works[29, 46]. The relation of molecular anisotropy with the mode of growth is described in Sect. 2 and the impact on the electronic and other properties considered in Sect. 5. To what extent molecular ordering and thermal stability are related is not well known, but several experiments point out that both properties are not correlated (see Sect. 2.5).

(Left) GIWAXS scattering patterns obtained from TPD glasses vapor deposited at substrate temperatures of 260 K and 315 K. The concentration of intensity observed along qz and qxy indicates anisotropic packing. These scattering patterns were obtained at an incidence angle of 0.14° and represent scattering from the entire thickness of the film. (Right) Schematic representing the microstructures of TPD glasses with the highest magnitude positive and negative order parameters in this study corresponding to sample prepared at 260 K and 315 K. For illustrative purposes, the degree of order has been enhanced in the schematics. Reprinted with permission from A. Gujral et al. Chem. Mater. 2015, 27, 9, 3341–3348 [47].

1.2 Metallic glasses

Metallic glasses, MG, are a family of remarkably important materials that share the properties of both metals and glasses giving rise to unique mechanical and functional properties, key to their use in many applications, such as computer memories and magnetic resistance sensors in electronics, surgical tools in the bio-medical industry, nuclear waste disposal reservoirs due to their resistance to irradiation or as the core of high-power transformers based on the soft magnetic properties of some metallic alloys [48]. However, their applicability is often limited by their tendency to exhibit low thermal stability and crystallization. Therefore, one of the main goals in the metallic glass community over the years has been to enhance the glass forming ability and to improve the thermal stability and mechanical strength of glasses.

While most of the studies are devoted to bulk metallic glasses (BMG) and the emphasis is placed on obtaining large-size disordered materials from the liquid using low cooling rates avoiding crystallization, recent efforts are also directed towards the preparation of thin film metallic glasses (TFMG) because of their potential use in specific areas such as biomedical and optical components [49]. Recent work on thin film metallic glasses prepared by magnetron sputtering has shown the feasibility of obtaining ultrastable metallic glasses in a broader range of deposition conditions (Tsub and g) compared to organic glasses [35, 50, 51].

In contrast to the behavior of organic vapor-deposited glasses where both kinetic and thermodynamic stability appear to be correlated and are always enhanced in highly stable glassy materials, the observation of high kinetic stability in TFMG, typically identified by a shift in Ton to higher temperatures during heating, has not always been accompanied by an enhancement of the thermodynamic stability (we note that in the metallic glass community Tg refers to the onset of the devitrification temperature measured by calorimetry at heating rates of around 10 to 20 K/min). That is, some stable MG exhibit simultaneously a higher onset of devitrification temperature and, apparently, a high position in the potential energy landscape, quantified through enthalpy plots or through the enthalpic fictive temperature. It seems that in metallic glasses the presence of large energy barriers to change the inner energy of the system also appear in states that are located high in the potential energy landscape, i.e. states with low thermodynamic stability. This is a distinct, and still not well understood, variation between vapor-deposited metallic and organic glasses. We note, however, that it is often difficult to evaluate with enough accuracy the enthalpic fictive temperature in thin film metallic glasses because of the presence of crystallization close to the glass transition.

Two reports in 2013 [50, 51] were the first observation of ultrastability in metallic glasses and since then many others have been published, most of them within the Zr-based family [35, 52,53,54,55,56,57,58,59]. Aji et al. reported ultrahigh stability in a multicomponent metallic alloy of composition Zr55Cu30Ni5Al10 (at %) [50]. They vapor-deposited the material using magnetron sputtering with a single sputtering target at a substrate temperature of 0.8 Tg (573 K) and a growth rate of 0.2 nm/s. The calorimetric curves of the vapor-deposited film showed an increase of the onset temperature of devitrification by 51 K with respect to the liquid-quenched glass of the same composition measured on heating at 10 K/min, ∆Ton = 7.1%, as shown in Fig. 6A. The crystallization temperature (Tx) also increased by 207 K. In addition, the hardness and elastic modulus were also improved by ~ 30% with respect to the bulk metallic glass.

DSC scans at heating rate of 20 K/min of Zr55Cu30Ni5Al10 glass samples: (a) bulk glass produced by copper-mold-casting (black); ultrastable glass produced by RF sputtering deposited at 573 K (green); bulk glass annealed at 683 K for 60 (red) and 360 min (blue). (b) Enthalpy of Zr55Cu30Ni5Al10 glass samples derived by integrating the curves shown in (a). Reprinted with permission from Aji et al. [50]

The thermodynamic stability in metallic glasses is difficult to quantify from calorimetric data since crystallization frequently occurs not far from the glass transition temperature, although these authors reported an apparent decrease of the fictive temperature in the stable glass (Fig. 6b). In parallel with the previous work, Yu et al. [51] reported ultrastability in the ternary Zr65Cu27.5Al7.5 glass vapor-deposited at 0.8 Tg (Tg = 676 K) using a higher growth rate of 1.4 nm/s. The as-grown glass had an 11 K increase in Ton (∆Ton = 1.6%), but an enthalpy higher than the liquid-cooled or annealed glasses. Another option to quantify stability is using the relaxation time. Ruta et al. [52] used X-ray photon correlation spectroscopy on Cu50Zr50 thin film MGs prepared by magnetron sputtering at different conditions to find that glasses prepared at 0.89Tg have higher structural relaxation times than fast quenched MGs, a factor 2–3 slower. Moreover, when taken to temperatures close to Tg, this vapor deposited MGs relax into a less stable configuration, with a higher relaxation time, in a similar way to hyperaged geological amber when taken to temperatures above its Tf [51].

In general, as it occurs in organic glasses, the deposition temperature and the growth rate are very influential parameters to obtain stable metallic glasses. However, some reports also point out that the specific technique used for deposition can also have a significant impact on the growth conditions to achieve high stability [55]. In fact, while most thin film ultrastable MGs are grown by magnetron sputtering in the temperature window between 0.7 and 0.85 Tg, some other approaches have shown the feasibility to obtain stable glasses at even lower temperatures. Ion beam assisted deposition (IBAD) has been used by Bai and coworkers [56] to obtain stable glassy materials of CuZr (Cu50Zr50) using very low deposition rates (down to 0.06 nm/s) at room temperature. Although these materials do not show a well-defined devitrification process in calorimetry scans, the increase of the crystallization temperature and the enhancement of the mechanical properties suggest that they are in a more stable state compared to liquid-quenched MGs. Very recently, the work of Luo et al. [35] has challenged the view that ultrastable vapor-deposited glasses need to be grown at temperatures in the vicinity of 0.8–0.85 Tg. By using ion beam assisted deposition (IBAD) and reducing the growth rate to 0.017 nm/s these authors demonstrate ultrastability in a Zr-based (Zr46Cu46Al8 (at.%)) MG at deposition temperatures as low as 0.43 Tg, (Fig. 7). As a cautionary note, in the technique used by this group the ions were used to sputter the atoms from the target to the surface of the substrate. This is in contrast to what is commonly referred to as IBAD, in which ions are used to bombard the substrate surface during deposition with the aim to increase the density of the thin films or to enhance adhesion [60]. The onset of devitrification of the vapor-deposited ultrastable glass increases by ∼60 K (∆Ton = 8.5%) and displays a better glass forming ability that the liquid-quenched glass. They also report and enhancement of Tx, so higher annealing temperatures are necessary to initiate crystallization. Remarkably, the crystalline phases obtained by annealing this Zr-based vapor-deposited ultrastable glass are different from the ones obtained by annealing a conventional MG. That may be due to different local atomic arrangements in both materials. Analogous conclusions are reached in the work of Ferry and coworkers [55] who observed an increase in the onset temperature of devitrification by ∼ 70–75 K (∆Ton = 10.5%) compared to bulk MGs by reducing the deposition rate a factor of 50 from ∼ 4 nm/s to ∼ 0.08 nm/s at 0.43 Tg for glasses of Zr50Cu44.5Al5.5 and Zr50Cu41.5Al5.5Mo3. Interestingly, using magnetron sputtering they achieved similar degree of kinetic stability than the work of Luo et al. [35] but with 10 times faster growth rates (∼ 0.17 nm/s versus ∼ 0.017 nm/s), which illustrates that the impact of the growth rate on glass stability may depend on the specificities of the technique used for deposition, among them on the energetics of the atomic species when they reach the substrate surface. These works [35, 54] clearly exemplify the influence of the deposition rate in attaining very high stability at a given deposition temperature. There is a minimum growth rate (whose value depends on Tsub for each deposition technique) beyond which no further enhancement of stability is achieved. Figure 7 illustrates the impact of reducing the growth rate on enhancing Tx. The role of oxygen or other impurities at this very low growth rates (or at higher temperatures) should be properly addressed, as their presence may substantially impact the physic-chemical and mechanical properties of the glass. It is remarkable that the influence of the growth rate on the degree of stability is much stronger in metallic glasses than in the case of organic molecules. As an example, Luo et al. achieved a variation of onset temperature with respect to Tg (ΔTon/Tg) of 7.1% over one order of magnitude change of growth rate between 1 and 10 nm/min, while in the case of the organic semiconductor TPD, Kearns et al. reached a lower ΔTon/Tg of 3% over more than two orders of magnitude variation in growth rate, from 0.3 to 70 nm/s [61]. This difference could be related to the fragility of the glass-forming systems [62]. A recent work by Muley et al. [62] investigated the stability, mechanical properties and structure of vapor-deposited glasses of Zr65Cu27.5Al7.5 with the same composition as those reported previously by Yu et al. [51]. While the general features of both studies are similar, the most stable glasses of Muley’s work were achieved at different conditions and with a different degree of stability compared to Yu’s work. And, in fact, growing above 0.707 Ton and at any deposition rate, the samples in Muley’s work were crystalline while in that by Yu et al. were amorphous. This points to the influence of uncontrolled processing parameters that may play a significant role in the properties of the material. Interestingly, the icosahedral order in these CuZrAl MG seems to improve for the kinetically more stable glasses grown at the slowest deposition rates. This in agreement with the earlier report by Aji et al. [50] in which atomic ordering analysis revealed that the stable MG had a higher medium range order (MRO) compared to liquid-cooled or annealed glasses. The changes in MRO may originate from enhanced surface mobility during vapor deposition at temperatures close to Tg that enable atoms to find more energetically favorable positions.

a Representative DSC curves at a heating rate of 20 K min−1 for Zr46Cu46Al8 MGs grown by IBAD technique. Ordinary glass produced by melt-spinning technique; vapor-deposited glass films produced at different growth rates as denoted below each curve. Tg and Tx are defined from the onset of the transformation as indicated by the intersection of the black lines. b Tg vs. deposition rate. For comparison, the Tg and Tx with their variation ranges for the ordinary glass are presented by the shaded magenta areas. Reprinted with permission from Luo et al., Nat Comm. 9, 1389 (2018) [35]

We also note on the existence of conflicting results in which increased deposition temperature produced metallic glasses with enhanced density and mechanical properties but with lower thermal stability, i.e. lower temperatures of crystallization. This was the case for MG of composition ≈ Zr60Cu8Ni25Al4Hf1Ti2[63]. Chu et al. observed no modification of the thermal stability (Tg = 400 °C and Tx = 500 °C) in sputter-deposited Zr51.4Cu29.5Ni12.3Al6.8 thin film metallic glasses prepared at different temperatures ranging from RT to 400 °C [59]. On the contrary, hardness and elastic modulus increased by 30% and 20%, respectively, in films grown at 400 °C with respect to those grown at room temperature.

The enhancement in mechanical properties is a common feature of most vapor-deposited metallic glasses and some authors consider them ultrastable because of this improvement [53]. Gianola and coworkers [64] investigated the mechanical properties of Pd77.5Cu6Si16.5 MG by nanoindentation. Maximum values of hardness were achieved in samples grown at 0.73Tg with values 33% higher (hardness = 9.7 GPa) than for the glass grown at room temperature (0.52Tg, hardness = 7.3 GPa). At this temperature shear banding was also enhanced in the more stable MGs. Dziuba et al. [53] related the enhanced mechanical properties of a Cu50Zr50 ultrastable glass to a low position in the potential energy landscape. Following this trend, Muley et al. [62] used a relation already established [65] to relate deformation energy and fictive temperature to quantify the improvement in thermodynamic stability of their vapor deposited glasses. Nevertheless, some vapor deposited metallic glasses show the opposite behavior, an improvement of the mechanical properties together with an apparent decrease of thermodynamic stability [51]. This uncorrelation could be a signature that in metallic glasses other parameters, such as local structure, should be considered to get the full picture when considering the characteristics of vapor deposited glasses.

A different approach towards ultrastability was adopted by Bai et al. [66] using high pressure in a PdNiCuP (Pd40.16Ni9.64Cu30.12P20.08) MG. Interestingly, they found that those glasses, after being held at approximately 15 GPa for 1 h, exhibit similar properties to vapor-deposited metallic glasses (at least to those reported previously by Luo et al. [35] and somehow to those reported by Aji et al. [50]), namely higher Tg by 8–11 K, higher density by up to 1%, higher hardness by up to 8%, higher glass forming ability (GFA: ΔT = Tx − Tg) up to 10 K at 18 GPa. Similar to Samwer’s glasses [51] these pressurized glasses do not have low enthalpy. They are located up in the potential energy landscape (PEL), but with high barriers (higher Tg) indicating that a lot of energy is needed to take them out from the energy minima where they are located. In the same manuscript they also reported that pressure induces changes in the local atomic order with respect to ‘normal’ liquid-quenched glasses. The effect of pressure-induced structural changes has also been explored in organic glass formers. Rams-Baron et al. showed that a liquid-cooled glass of etoricoxib formed at high pressure exhibited, when measured at ambient pressure, an increased devitrification temperature and higher density [67]. On the other hand, Rodriguez-Tinoco et al. investigated the effect of pressure on IMC glasses, both vapor-deposited and rejuvenated. Both exhibited an increase on the onset of devitrification with increasing pressure, though at a different pace. However, the rejuvenated glass submitted to high pressure and subsequently depressurized exhibited the same devitrification temperature that a glass formed at ambient temperature [68].

1.3 Polymer glasses

While there are many examples of reported ultrastable organic glasses made out from small molecules, the production of ultrastable polymers from the vapor is far more problematic. Because of the strong intermolecular forces between polymer chains, the polymer can thermally degrade rather than vaporize, manifested in some cases as a reduction of molecular weight or decomposition of some components [69]. Despite this difficulty, there are a few works reporting on the production of ultrastable polymer glasses from the vapor-phase, though most of them cannot be considered exactly equivalent to the physical vapor deposition, PVD, of molecular glasses.

Yoon et al. [70] described the preparation of vapor-deposited ultrastable polymer glasses of Teflon AF 1600, known to have weak molecular interactions and a low dielectric constant, by vacuum pyrolysis technique, i.e., pyrolysis of the target material and subsequent repolymerization on the substrate. Because of the pyrolysis process, they observe some chain scission, but they argue that the resulting thin film is still polymeric with an equivalent chemical state as the precursor. By tuning the substrate temperature during the deposition, they obtained glasses exhibiting large enthalpy overshoots and higher devitrification temperatures upon heating in a Flash DSC®. Glasses deposited at around 0.85Tg exhibit the largest devitrification temperatures but an increase in fictive temperature of 14% with respect to the rejuvenated glass, obtained by slowly cooling from the supercooled liquid.

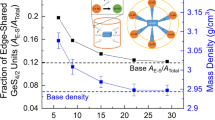

With the aim of fully avoiding changes in the polymer nature, Guo et al. used matrix assisted pulsed laser deposition (MAPLE) to prepare thin films of PMMA glasses [71]. As opposed to other evaporation routes, MAPLE provides a gentle and non-destructive means for the deposition of polymer films. By controlling the substrate temperature during deposition and setting a growth rate of 0.25 nm/s, they were able to form glassy polymer films with higher devitrification temperature, up to 40 K, and lower specific heat (a reduction of up to 20%), with respect to ordinary glasses prepared from the melt. Furthermore, the kinetic stability in the glassy state (transformation time at Tg) could be enhanced by two orders of magnitude. However, contrary to stable organic molecular glasses, which show an increase in density and a lower enthalpy, the stable polymer glasses exhibited a reduction in density of 40% (glass grown at 0.86Tg) and a higher enthalpy (up to 60 J/g higher for Tsub = 0.84Tg). The calculated Tf for these glasses was up to 24% higher. According to the authors, the origin of this unique combination of properties was related to the growth mechanism, different to the surface facilitation mechanism responsible for the formation of stable vapor deposited glasses of small molecules. In MAPLE, film formation proceeds by the assembly of nearly spherical polymer nano-globules. According to the authors, solvent evaporation of the globules in their path from the target to the substrate induce their collapse into stable globules. In parallel, limiting coalescence of each of these globules would result in a poorly packed structure. The combination of the two phenomena would give rise to a glass with higher devitrification temperature (due to the stability of the globules) but with lower overall density (due to limited coalescence).

A simpler approach, but reliable in the sense that the structure of the material is preserved, and similar to those of small-molecular glasses, was followed by Forrest and co-workers [72]. To obtain appreciable deposition rates at temperatures below those at which thermal degradation occurs, they used near-oligomeric (N ≃ 6–12) polystyrene and polymethyl methacrylate. By characterizing the properties of the resulting thin layer by ellipsometry, they found an increase in devitrification temperature of 6%, as well as an increase in density of about 1.6% and 25 K decrease in limiting fictive temperature, for layers deposited at 0.89 Tg. It should be noted that the Tg of the material is affected by the deposition conditions, since the molecular weight of the material changes due to temperature changes or time after the deposition has started (the smaller oligomers are evaporated first and then the largest ones). These glasses exhibit an (extrapolated) transformation time of up to 3 million years.

A very different kind of highly stable polymer glass, not prepared from the vapor phase but by chemical vitrification, is that of geological glasses such as amber. Amber is a fossilized tree resin which has undergone a maturation and stabilization process for tens or even hundreds of millions of years. This is another route to go very deep in the PEL (Fig. 3), which will be described more in detail in Sect. 4 in the framework of low-temperature properties of ultrastable glasses. Another potential route to stabilization has been demonstrated by aging below Tg ultrathin polymer films and spherical nanoparticles [73, 74].

1.4 Chalcogenide glasses

Amorphous chalcogenides are useful for applications ranging from phase change memory materials for random access memory applications to photovoltaics. Zhang et al. have prepared thin film glasses of Sb2Se3 by vapor deposition in the temperature window where glass stability could be present [75]. Although they could not clearly identify the glass transition signature by DSC, they report an enhanced crystallization temperature, lower surface roughness and high refractive index for glasses grown at 373 K as an indication of enhanced thermal (kinetic) stability of the material. In particular, the crystallization temperature increased by 17 K with respect to a glass grown at room temperature. Interestingly, this work reports a distinct (and surprisingly smaller) coordination number for the stable glass with respect to the ordinary amorphous material, but close, at the same time, to the one of the crystal. Stable glasses are also less dense, implying that there is not always a direct correlation between stability and density. In the case of chalcogenides, this could be due to the large number of intramolecular interactions, which can result in strong repulsive forces in a dense molecular packing.

Amorphous selenium has also been grown as a thin film from the vapor in the range of temperatures and growth rates that could lead to high stability [41]. In addition, since a-Se is very sensitive to above-band gap visible light, white illumination was used during growth to investigate the effect of this parameter. Glasses grown in the dark and under white-light illumination showed signs of high stability, both in terms of kinetic and thermodynamic stability, an indirect indication that the surface mobility is enhanced compared to the bulk dynamics. However, films prepared under white light exhibited lower density, but higher kinetic stability (higher onset of devitrification) when directly compared to films grown in the dark, providing access to a different local minimum on the potential energy landscape, not accessible by any other means. Apparently, light would induce the formation of a chain structure that lowers density but increases kinetic stability due to the difficulty of breaking these extra bonds. Since the formation of these networks is induced by light, it is exclusively a surface effect and therefore, the propagation of these networks throughout the film is only achievable because of the illumination of the sample during the PVD deposition. As happened with the stable chalcogenide glass and some metallic glasses, amorphous selenium shows that density (or thermodynamic stability) does not necessarily correlate always with kinetic stability.

2 Mechanism of formation of low enthalpy glasses by vapor deposition

A priori, one would think that molecules landing onto the substrate during vapor deposition would be submitted to extremely fast cooling rates, from the high temperatures at which they are ejected from the source (typically around the Tm of the material) to the low temperatures of the substrate (around or below Tg). Consequently, without invoking any equilibration mechanism, glasses produced by PVD should vitrify at higher temperatures due to the arrest of the structural relaxation and, therefore, would be less stable (lower density) than those prepared by controlled cooling from the melt. This intuitive description does not match with reality, it is just the opposite, since highly stable glasses are nowadays routinely produced in this way [1]. Therefore, a particular molecular mechanism that allows equilibration of the molecules during the deposition process must exist and, in fact, decreasing the growth rate at a fixed substrate temperature leads to more equilibrated glasses [25, 35, 61]. In the following we describe several alternative views that may explain the enhanced stability of vapor-deposited organic glasses, though this subject is still under intense investigation. Although this section mainly deals with molecular glasses where most of the research has been done, several very recent works on metallic glasses are also included.

2.1 Is surface diffusion responsible for ultrastable glass formation?

Surface diffusion seems to be a relevant quantity and only recently sensitive approaches have been devised to infer its value over extended temperature intervals. Enhanced molecular diffusion at the surface is responsible for fast surface crystal growth in many organic glasses as crystal growth rate is nearly proportional to the surface diffusion coefficient, Ds [130]. One way to measure surface diffusion is by the embossing of surface gratings onto glassy surfaces and subsequent measurement by diffraction of the decay of the grating pattern [89, 131]. Surface diffusion can also be accessed by measuring the evolution of the response when a probe is placed on the surface, inducing the formation of a meniscus due to surface-mediated flow. Fakhraai and coworkers, for instance, used the tobacco mosaic virus to investigate surface diffusion in molecular glasses of TPD [100, 122]. In general, measured Ds values on organic glasses range from 10–11 to 10–16 m2/s at Tg, 4 to 8 orders of magnitude larger than the bulk counterpart, as shown in Fig. 8 [89, 100].

Copyright 2017 American Chemical Society. TPD data obtained from [100]

This eightfold enhancement of surface diffusion with respect to bulk diffusion [131] allows to circumvent the restrictions to molecular rearrangement imposed by the slow bulk dynamics. Indeed, at the surface layer, molecules exhibit diffusion levels that allow them to reach stable packing arrangements in timescales comparable to the residence time of these molecules on the surface. This time is determined by the growth rate. For a given deposition rate g, the mobile surface layer of depth ξ will be equilibrated on a time scale ξ/g. If the surface layer is considered to have 1 nm and the growth rate is 0.1 nm/s, then the residence time of each molecule is 10 s. If surface diffusion is high enough, the residence time may be enough for the molecules to efficiently sample the energy landscape and find close to equilibrium configurations before being buried by other incoming molecules. Surface diffusion typically follows an Arrhenius dependence with temperature with activation energies around 100 kJ/mol (Table I and Fig. 8). This behavior is in contrast to bulk diffusion, which follows a super-Arrhenius dependence with temperature, inducing a more abrupt kinetic arrest as temperature is decreased.

The relevance of surface diffusion as an indicator of the formation of stable glasses has been analyzed in detail in several reports involving organic molecules with different degrees of hydrogen bonding (HB) and/or variations of molecular size [131]. HB reduces surface diffusion due to their robustness at surface layers, which makes the barrier for diffusion approximately the same on the surface as in the bulk. As an example, the surface diffusion coefficient of o-terphenyl (OTP), a non HB-molecule, and sorbitol (HB molecule), two molecules with similar sizes, differ by 105 at Tg [132]. In the same reasoning line, it was shown that molecules forming extensive intermolecular HB, such as polyalcohols, produced glasses of lower kinetic stability compared to non-hydrogen-bonding molecules at the same deposition rate [88, 91, 93, 132].

Molecular size also plays a role in surface diffusion. In non-HB molecules, such as OTP, TNB or IMC, it has been shown a decrease in surface diffusion as the size of the molecules increases (five orders of magnitude increase of DS per decreasing 1 nm in size, as seen in Fig. 9a) [133, 134]. This behavior is attributed to a steep gradient of mobility beyond the free surface and the penetration of large molecules into areas with lower mobility. This anchoring effect leads to slower diffusion of the hole molecule (understanding the movement of the molecule as the movement of its center-of-mass) even though the top part of the molecule is in a more mobile environment [135].

Representation of a measured surface diffusion values and b transformation time (as a measurement of kinetic stability of the vapor deposited glass) with respect to the size of the molecule. Symbols with the text “ub” indicate the upper bound for the surface diffusion in these materials. The left figure shows a good correlation of the surface diffusion in non-HB systems within an extended range of molecular sizes, d. Reprinted with permission from Yinshan Chen et al., J. Chem. Phys. 150, 024,502 (2019), AIP publishing [131]

While the decrease of glass stability correlates well with the increase of hydrogen bonding and the reduction of surface diffusion, glass stability seems to be less affected by molecular size, at least for d < 1 nm, as seen in Fig. 9b. A possible explanation for this uncorrelation is that stable glass formation does not show a simple relationship with the translational molecular motion due to surface diffusion. Since glass stabilization relies on the improvement of local packing arrangement, other processes involving a reduced amount of translational movement may be responsible for the high stability attained during growth [131].

The influence of other mechanisms beyond surface diffusion on the stability of the glass is illustrated in the experimental work of Samanta et al. [122] They analyzed ultrastable glass formation of two molecular glass formers, TNB and 9-(3,5-di(naphthalen-1-yl)phenyl)anthracene (α,α-A), with very different values of surface diffusion. While TNB exhibits measurable enhanced surface diffusion compared to bulk, α,α-A does not, due to pairing or aggregation of anthracenyl substituents on the free surface. Remarkably, they observe that both systems can be prepared in similar stability states. Moreover, they infer enhanced dynamics by dewetting experiments. Their conclusion is clear: enhanced surface diffusion is not a requisite for enhanced dynamics and, hence, for the formation of highly stable glasses by PVD [122]. The decoupling between DS and τs (surface relaxation time) has also been observed in polymers, where surface diffusion is avoided by the large degree of entanglement between polymeric chains. Notwithstanding, enhanced surface relaxation time has been measured [136, 137]. All these observations point towards a complex scenario, where surface equilibration to reach ultrastability cannot be explained by surface diffusion alone.

2.2 Surface relaxation

As discussed above, the crucial factor that seems to allow the formation of ultrastable glasses is a surface equilibration mechanism that operates fast enough to enable the equilibration of molecules in timescales comparable to the residence time of the adsorbed molecules before they are buried by other molecules during growth. A process that may not be related to translational molecular movements, but to a local relaxation mechanism, thus decoupling surface diffusion and mobility. In the previously mentioned experiment, Samanta et al. investigated thin film dynamics (10 nm) of TNB and α,α-A by measuring the dewetting dynamics as a proxy to surface relaxation time [122]. As-deposited thin films showed evidence of dewetting on a silicon substrate, even at a Tsub which yielded stable glasses, an indication of a reduced relaxation time at the surface. This is not the only evidence of fast dynamics at the surface. Very recently, fast surface dynamics has been directly probed by Thoms et al. [138] through the recording of the dielectric relaxation spectra during film growth of a molecular glass former (2-methyltetrahydrofuran, MTHF) at Tsub = 0.82 Tg and at g = 0.2 nm/s onto interdigitated electrodes (IDE). This work provides direct evidence of the existence of a mobile surface layer, 2.5 nm thick, with an average relaxation time of 0.1 s, orders of magnitude faster than the bulk, that grows with a high kinetic stability. Higher deposition rates, to the point that the residence time of the molecules at the surface is below \({\tau }_{\mathrm{s}}\), may result in films with lower stability because equilibration is restricted.

It is often argued that the structural relaxation of a free-standing thin-layer or a supported ultrathin layer speeds-up. However, there is a strong debate on that topic, extensively studied in polymers, mainly due to the sensitivity of the dynamics to many factors, especially the sample boundary conditions [136, 139]. In the limit of a monolayer, the structural relaxation time of this nanoconfined layer would correspond to the surface dynamics that controls the stability of a glass growing from the vapor. In this sense, Zhang et al. using dewetting as a proxy for relaxation time for TPD thin layers, observed that, as the thickness decreases, molecular motion speeds up [140]. Interestingly, in a subsequent work, Zhang [141] compared the evolution of these relaxation times with that of the surface diffusion. They observed that, by reducing the thickness, the later stays invariant while the former increases, supporting the uncorrelation between surface mobility and diffusion, discussed above.

The role of surfaces on the relaxation dynamics of a structure, and how the cooperative structural relaxation speeds up at the free interface, is explained in a simple way by the random first-order transition theory (RFOT). In this framework, the vitrification of glasses is due to the cage effect, i.e., the constraining of a particle because it is surrounded by its neighbors. In mean field theory this leads to a friction crisis at the mode coupling theory (MCT) critical temperature (TC), below which any large-scale motions require cooperativity and the definition of a cooperative length-scale. Since surface particles feel a weaker structural cage, they would undergo dynamic arrest at a lower temperature and remain more mobile below the bulk glass transition temperature [142]. Under this framework, hence, the acceleration of the surface relaxation is related to the effect of free surfaces on the bulk relaxation process, and this surface relaxation time can be expressed as \({\tau }_{\mathrm{s}}\propto \sqrt{{\tau }_{\mathrm{bulk}}}\).

Some molecular dynamics simulations have also pointed in a similar direction. Kuon et al. [143] investigated the emerging heterogeneous dynamics at the surface of a supported supercooled liquid film in comparison with the dynamics of a bulk-like region of the film. The dynamics at the surface turns out to be almost three orders of magnitude faster than the dynamics within the bulk. Note that the reported difference in surface and bulk dynamics is much lower than the experimentally determined difference in diffusion coefficients (up to 8 orders of magnitude). In another work, Berthier and co-workers were able to computationally reproduce a vapor deposited glass, equilibrated at low temperatures, by using a swap Monte Carlo algorithm [144]. This study provides a quantitative test of the role of surface mobility in the creation of vapor deposited glasses. From the decay of a self-intermediate scattering function, they extract the relaxation times of the different particles of the simulated system. At high temperature there is a population of fast particles across all the sample, but at low temperature fast particles are concentrated on the surface of the material. The surface relaxation time follows a super-Arrhenius dependence with temperature, like the one followed by bulk dynamics, but with lower values and lower divergence temperature (see Fig. 10). They argue that this faster surface relaxation process is at the origin of the ultrastability of vapor deposited glasses and conclude that the surface relaxation time and deposition rate determine the distance to equilibrium for vapor-deposited films in the exact same way that bulk relaxation time and cooling rate control the distance from equilibrium for liquid-cooled films.

copyright 2017 American Physical Society [144]

Examples of the variation of bulk and surface structural relaxation processes as a function of the inverse of the temperature. In a, the overall relaxation time in two different simulations (constant volume (NVT, canonical ensemble) and constant pressure (NPT, Isothermal–isobaric ensemble)) is represented together with the bulk and surface contributions. In b, the surface relaxation time is fitted in a short temperature range with an Arrhenius curve. The bulk relaxation time is fitted, in all cases, with a VFT curve. Reprinted with permission from (a) J. Chem. Phys. 149, 074501 (2018), AIP publishing [143] and (b) Phys. Rev. Lett. 119, 188002 (2017),

When discussing about any property “at the surface”, it is fundamental to consider the length scale across which this property propagates into the bulk. By measuring the relaxation dynamics of thin glassy TNB and α,α-A films, Samanta et al. concluded that while the bulk of the glass is in a deeply quenched glassy state, the molecules within 10 nm from the surface can have a faster dynamics and are able to equilibrate before becoming part of the bulk [122]. Similar conclusions are obtained by More et al. [145]. They used molecular dynamics simulations to study empirical coarse-grained models of organic molecules containing model fluorocarbon tails of increasing length: zero, one, four, and eight fluorocarbons, with a structure composed of a phenyl “body” and a fluorocarbon “tail”, to simulate the formation of a vapor deposited glass. They observe that longer molecules tend to become trapped locally during deposition reaching less optimized packing. They also observe that films show a tail-enriched surface due to the migration of tails towards the surface. Very interestingly, this tail enrichment is progressively erased during deposition, i.e., during growth, the film reconfigures towards a more homogeneous structure. This means that the more mobile surface layer extends beyond the length of the molecule. They conclude that significant rearrangement could occur in layers below the immediate free surface, even for molecules that do not show significantly enhanced surface diffusion (molecules with long tails). Early evidence for enhanced mobility below the surface, based on the breadth of the interfaces determined by neutron scattering, was already presented by Swallen et al. in 2007 [1]. In the same direction, Wolynes stated that the enhanced mobility of the surface would penetrate the bulk at least on the cooperative length-scale, of few intermolecular spaces. This intense mobility gradient is relaxed, diffusing the excess mobility towards the bulk. At the end, the distance the excess mobility penetrates is calculated as 20 times the correlation length, i.e., 20 nm for Indomethacin, one of the most studied ultrastable glasses, an amount significantly larger than “just the surface” [142].

2.3 Ultrastability and fragility

There have been several attempts to correlate glass stability and fragility with distinct and uncertain success. Here we briefly outline some of the most relevant works. If the enhanced surface mobility is a consequence of a different molecular arrangement around the molecules at the surface with respect to the more crowded environment in the bulk, as proposed by most of the above-mentioned interpretations, it is reasonable to think that the fragility of the glass-former may play a role on ultrastable glass formation. As described in Sect. 1, the fragility is defined as the degree to which the relaxation time increases when approaching Tg and is often considered as a deviation of the Arrhenius dependence between relaxation time and temperature [12]. Several works have shown a moderate positive correlation between fragility and ultrastability. Yu and Samwer [51] reported a mild correlation between the onset temperature of the transformation of vapor-deposited organic and metallic glasses (Ton) and the kinetic fragility index m of the corresponding supercooled liquid. Tylinski et al. [93] thoroughly analyzed the potential role of fragility in the formation of ultrastable glasses by considering additional measures of fragility and increasing the number of explored systems. As an indicator of the stability achieved for each material, they use the transformation time needed to transform the glass into the supercooled liquid at a temperature above Tg. By analyzing data corresponding to 14 systems, they observe a slight positive correlation between fragility and the transformation time. The correlation is especially good when using log(τα) at 1.25Tg as proxy for fragility. It is noted that log(η) (an equivalent parameter to log(τ)) was previously successfully correlated with the surface diffusion [132], Fig. 11. There are several empirical arguments to support the positive correlation between stability and fragility. Chen and co-workers argue that the loss of neighbors at the surface can be compared to an “excitation”, similar to a temperature increase [132]. Since strong systems follow an Arrhenius behavior, energy barriers do not increase significantly upon cooling and one might think that strong systems are “easier” to equilibrate even by cooling from the liquid and, therefore, also by vapor deposition. The advantage of fast surface dynamics would not provide then any significant enhancement. In other words, fragile glass-forming liquids should lead to highly stable vapor-deposited glasses and stronger liquids may fail to reach high stability in the glassy state [93, 146]. This view was supported by early experiments on molecular [147] and metallic glasses [51], but contradicts more recent data on organic (methyl-m-toluate and ethylcyclohexane) and metallic glasses (ZrCuAl family) with strong character that have been grown as highly stable glasses [51, 94] (see Table 1 for values of m and associated indicators of stability). Therefore, there are also arguments and experimental data to justify the opposite conclusion. Larger fragilities, i.e., more abrupt slowing down of structural relaxation dynamics upon cooling, is related to larger cooperative rearranging regions: since more molecules should cooperatively relax to reach equilibrium, the process becomes slower. Therefore, one would assume that, if more fragile materials indeed have longer co-operative length scales, the size of cooperatively rearranging regions might grow sufficiently, so the ability to relax via the surface, crucial for ultrastable glasses, would be lost. Conversely, for strong glass formers, with small co-operative length scales, the ability of the surface to enable relaxation may be retained at much deeper supercooling. Royall and co-workers tested this hypothesis by plotting the parameter θ0 = (Teq − T0)/(Tg − T0), with respect to the inverse fragility D found after Vogel–Fulcher–Tammann fitting of the liquid by equation \({\tau }_{\alpha }={\tau }_{0}\times \mathrm{exp}\left(\frac{D{T}_{0}}{T-{T}_{0}}\right)\) [148]. T0 is the Vogel–Fulcher–Tammann divergence temperature and Teq is equivalent to Tf. They observe a negative correlation between both parameters, indicating that stronger glass formers should yield more stable glasses (Fig. 11).

Relationship between thermodynamic stability and fragility for different glass-formers, following two alternative approaches. (Left) The transformation time of the ultrastable glass measured above Tg is used as a signature of the thermodynamic stability (longer transformation times are related to higher stability), while the value of the structural relaxation time of the corresponding supercooled liquid at 1.25Tg is used as a measurement of fragility (lower values of log(τ) imply larger fragility values, note the inverted horizontal axis). (Right) The stability parameter ϑ0 is used as a measurement of thermodynamic stability (lower ϑ0 means larger stability) while the parameter D obtained from the VFT fitting of log(τ) vs 1000/T is used as an indicator of fragility (larger D means lower fragility). Colors and symbols match in both figures and the legend. Reprinted with permission from Tylinski M et al., J Chem Phys 145, 174506 (2016), AIP publishing, and Royall CP et al., J Phys Condens Matter 30, 363001 (2018), IOP Science [93, 148].

The lack of clear correlation between fragility and ultrastable glass formation may undermine a direct connection between structural relaxation (and its faster counterpart at the surface) and ultrastable glass formation. In this direction, Mangalara et al. proposed a new model [149] based on the well-known mismatch between variations in structural relaxation time (and, hence, Tg) and density near free surfaces: while the former is affected along a length scale of 10 nm, gradients in density exhibit much shorter length scales, of about 1 nm [150]. In their model, they introduce an intermediate layer in the growing glass with mixed properties: it exhibits bulk like liquid density (like in the inner layers of the glass) and nearly suppressed Tg (like in the very surface layer), i.e., with decoupled density and structural relaxation. Because of the lower Tg, vitrification of the intermediate layer occurs at lower temperature, allowing the formation of a lower enthalpy glass. A similar conclusion is reached by Sussman and co-workers in a molecular dynamics study of thin film glasses [151]. In that work, the authors invoked the concept of softness, related to local structure around a particle, to decouple changes in local structure to changes in dynamics at different points of a thin film. In bulk, there is a direct connection between the local structural environment of a particle and its easiness to rearrange [152, 153], however, near free surfaces, relaxation is dominated by mechanisms that are independent of the local structure. In other words, the faster equilibration process that brings to the formation of an ultrastable glass may not be uniquely linked to the change in local structure at the very surface. And they go further in their interpretation of the simulation results: the relaxation dynamics in glassy thin films is characterized by two independent processes, one that depends on local structure, active at the surface of the film, and another one that is purely Arrhenius and depends on the position in the film but not on local structure.

2.4 Alternative explanations for enhanced surface mobility

Different authors have explored the hypothesis that fast surface mobility is a consequence of the change in structure at the surface layer and have proposed alternative ideas to explain the formation of stable glasses by vapor deposition. We briefly summarize some of them: Ngai and coworkers, in the frame of the Ngai’s coupling model, relate surface diffusion to the secondary Johari-Goldstein (JG) relaxation found in many glass formers [154]. In this context, JG-beta relaxation has been linked to the surface mobility in analogy to the role of structural relaxation in bulk dynamics. They have compared the range of deposition temperatures at which a physical vapor deposited glass exhibits enhanced stability in relation to the liquid quenched counterpart, with the temperature range where the JG-beta relaxation is allowed to relax during the experimental timescale (i.e., lower than 100 s) (see Fig. 12). The two ranges matched fairly, suggesting that the activity of the secondary mode was connected to the enhancement of stability observed in vapor deposited glasses.

Relaxation dynamics of supercooled celecoxib (top) and stability of the vapor-deposited glass measured through their onset of devitrification in heating scans (bottom). In the indicated temperature range, beta relaxation time is lower than 100 s, and the vapor deposited glass shows enhanced kinetic stability with respect to the ordinary glass. Reprinted with permission from K. L. Ngai et al., J. Phys. Chem. Lett. 8, 2739–2744 (2017) [154].

A related explanation involving the beta relaxation is also provided by Schick and co-workers to interpret their experimental data [94]. They explored the role of the growth rate in the formation of stable glasses of ethylcyclohexane at different substrate temperatures, to determine the time required to equilibrate the glass at that temperature, maximizing its kinetic stability. The equilibration time of vapor deposited glasses across a wide temperature range, spanning near 100 K below Tg, followed a much weaker temperature dependence than the structural relaxation. Their measure of equilibration time is within two orders of magnitude of the beta relaxation, even though the authors remark that the temperature dependence is not the same (Fig. 13), and they argue that the β process is just a speed limit for surface relaxation.

Timescales of different dynamic processes in ethylcyclohexane. Red stars correspond to the frequency dependence of dynamic glass transition temperatures from AC calorimetry. The required surface equilibration times (τsurface = 10 τKWW) at each substrate temperature are shown as solid blue triangles. Solid black squares and circles correspond to the α- and β-relaxations of ethylcyclohexane. T0 and TK are shown as a reference. Reprinted with permission from Y. Z. Chua et al., J. Chem. Phys. 142, 054506 (2015), AIP publishing [94]