Abstract

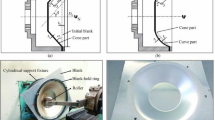

Metal sheet spinning is an advanced near-net forming technology for the manufacture of thin-walled ellipsoidal heads. The exact control of dimensional accuracy, however, is a considerable problem for spinning thin-walled parts with large diameter-to-thickness ratios. In this work, a marginal-restraint mandrel-free spinning process with two passes is proposed for the fabrication of thin-walled ellipsoidal heads without wrinkling. A finite element model is established and verified to study the influences of spinning parameters on the dimensional precision of thin-walled ellipsoidal heads. It is found that the spinning parameters considerably influence the deviations of wall thickness and contour characteristics. A small forming angle or small roller fillet radius during the first pass spinning, as well as the small angle between passes or high feed ratio during the second pass spinning, can improve the wall thickness precision. Meanwhile, as the forming angle or feed ratio is increased during the first pass spinning, the contour precision initially increases and then decreases. During the second pass spinning, the contour precision can be improved at a small angle between passes, whereas it deteriorates at a larger roller installation angle. The optimized spinning parameters are obtained and verified by experiments.

Similar content being viewed by others

References

Xia QX, Xiao GF, Long H et al (2014) A review of process advancement of novel metal spinning. Int J Mach Tools Manuf 85:100–121

Wong CC, Dean TA, Lin J (2003) A review of spinning, shear forming and flow forming processes. Int J Mach Tool Manuf 43(14):1419–1435

Zhang Q, Zhang C, Zhang MJ et al (2015) Research of net-shape power spinning technology for poly-V grooved aluminum pulley. Int J Adv Manuf Technol 81(9/12):1601–1618

Lin YC, Wu Q, He DG et al (2020) Effects of solution time and cooling rate on microstructures and mechanical properties of 2219 Al alloy for a larger spun thin-wall ellipsoidal head. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2020.01.095

Lin YC, Qian SS, Chen XM et al (2019) Staggered spinning of thin-walled Hastelloy C-276 cylindrical parts: numerical simulation and experimental investigation. Thin Wall Struct 140:466–476

Xia Q, Long JC, Zhu NY et al (2019) Research on the microstructure evolution of Ni-based superalloy cylindrical parts during hot power spinning. Adv Manuf 7(1):52–63

Lin YC, Qian SS, Chen XM et al (2020) Influences of feed rate and wall thickness reduction on the microstructures of thin-walled Hastelloy C-276 cylindrical parts during staggered spinning. Int J Adv Manuf Technol 106(9/10):3809–3821

Zhang HR, Zhan M, Guo J et al (2019) Forming the transverse inner rib of a curved generatrix part through power spinning. Adv Manuf 7(1):105–115

Huang CQ, Liu JX (2020) Effects of hot spinning and heat treatment on the microstructure, texture, and mechanical properties of A356 wheel hubs. Metall Mater Trans A 51:289–298

Saied EK, El-Abden SZ, Abd-Eltwab AA et al (2019) Combining conventional spinning with wall thickness reduction in one pass. Int J Mech Prod Eng Res Dev 9(3):1429–1436

Liu CH (2007) Dynamic finite element modeling for the conventional spinning process. J Chin Inst Eng 30(5):911–916

Wang L, Long H (2011) Investigation of material deformation in multi-pass conventional metal spinning. Mater Des 32(5):2891–2899

Zhan M, Yang H, Zhang JH et al (2007) 3D FEM analysis of influence of roller feed ratio on forming force and quality of cone spinning. J Mater Process Technol 187/188:486–491

El-Khabeery MM, Fattouh M, El-sheikh MN et al (1991) On the conventional simple spinning of cylindrical aluminium cups. Int J Mach Tools Manuf 31(2):203–219

Xiao Y, Han Z, Fan ZJ et al (2018) A study of asymmetric multi-pass spinning for angled-flange cylinder. J Mater Process Technol 256:202–215

Liu JH, Yang H, Li YQ (2002) A study of the stress and strain distribution of first-pass conventional spinning under different roller-traces. J Mater Process Technol 129(1):326–329

Hayama M, Kudo H, Shinokura T (1970) Study of the pass schedule in conventional simple spinning. Bull Jpn Soc Mech Eng 13(65):1358–1365

Xia QX, Wang YP, Yuan N et al (2011) Study on spinning of pentagonal cross-section hollow-part based on orthogonal experiment design. Adv Mater Res 314/316:783–788

Xia QX, Lai ZY, Long H et al (2013) A study of the spinning force of hollow parts with triangular cross sections. Int J Mach Tools Manuf 68(9/12):2461–2470

Kong Q, Yu Z, Zhao Y et al (2017) Theoretical prediction of flange wrinkling in first-pass conventional spinning of hemispherical part. J Mater Process Technol 246:56–68

Zhang YQ, Shan DB, Xu WC et al (2010) Study on spinning process of a thin-walled aluminum alloy vessel head with small ratio of thickness to diameter. J Manuf Sci Eng 132(1):014504

Xia QX, Shima S, Kotera H et al (2005) Study of the one-path deep drawing spinning of cups. J Mater Process Technol 159(3):397–400

Zoghi H, Arezoodar AF, Sayeaftabi M (2012) Effect of feed and roller contact start point on strain and residual stress distribution in dome forming of steel tube by spinning at an elevated temperature. Proc IMechE Part B J Eng Manuf 226:1880–1890

Shima S, Kotera H, Murakami H et al (1997) Development of flexible spin-forming method. J Jpn Soc Technol Plastic 38:40–44

Rao GJ, Li XH, Zhou L et al (2018) A multi-constraint spinning process of ellipsoidal heads. Int J Adv Manuf Technol 94(1/4):1505–1512

Kawai K, Yang LN, Kudo H (2007) A flexible shear spinning of axi-symmetrical shells with a general-purpose mandrel. J Mater Process Technol 192:13–17

Kawai K, Yang LN, Kudo H (2001) A flexible shear spinning of truncated conical shells with a general-purpose mandrel. J Mater Process Technol 113(1/3):28–33

Kang DC, Gao XC, Meng XF et al (1999) Study on the deformation mode of conventional spinning of plates. J Mater Process Technol 91(1/3):226–230

Han ZR, Fan ZJ, Xiao Y et al (2017) A research on thickness distribution of oblique cone in mandrel-free shear spinning. Int J Adv Manuf Technol 90:2901–2912

Li Y, Wang J, Lu GD et al (2014) A numerical study of the effects of roller paths on dimensional precision in mandrel-free spinning of sheet metal. J Zhejiang Univ-Sci A 15(6):432–446

Sekiguchi A, Arai H (2012) Control of wall thickness distribution by oblique shear spinning methods. J Mater Process Technol 212(4):786–793

Polyblank JA, Allwood JM (2015) Parametric toolpath design in metal spinning. CIRP Ann 64(1):301–304

Jia Z, Han ZR, Liu BM (2017) Numerical simulation and experimental study on the non-axisymmetric mandrel-free shear spinning. Int J Adv Manuf Technol 92(1/4):497–504

Liu CH (2007) The simulation of the multi-pass and die-less spinning process. J Mater Process Technol 192/193:518–524

Sugita Y, Arai H (2015) Formability in synchronous multipass spinning using simple pass set. J Mater Process Technol 217:336–344

Imamura Y, Ikawa K, Sakane Y et al (2017) Investigation of forming accuracy in mandrel-free hot-spinning. Procedia Eng 207:1701–1706

Guo H, Wang J, Lu G et al (2017) A study of multi-pass scheduling methods for die-less spinning. J ZheJiang Univ-Sci A 18(6):413–429

User’s Manual (2012) ABAQUS analysis user’s manual. ABAQUS Inc version 6:12–3

Han D, Zhan M, Yang H (2013) Deformation mechanism of TA15 shells in hot shear spinning under various load conditions. Rare Metal Mat Eng 42(2):243–248

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51775564), the 973 program (Grant No. 2014CB046600), and the Fundamental Research Funds for the Central Universities of Central South University (Grant No. 2019zzts946).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, YC., Chen, JY., He, DG. et al. Marginal-restraint mandrel-free spinning process for thin-walled ellipsoidal heads. Adv. Manuf. 8, 189–203 (2020). https://doi.org/10.1007/s40436-020-00296-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-020-00296-0