Abstract

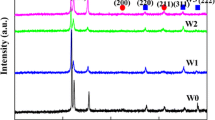

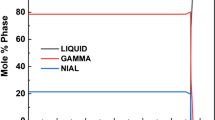

In the present study, a series of AlCoCrxFeNi2.1 (x = 0, 0.25, 0.5, 0.75, 1.0) eutectic high entropy alloys (EHEAs) have been designed and prepared. And the effect of Cr content on the microstructures and mechanical properties of the AlCoCrxFeNi2.1 alloys was systematically investigated. The results indicate that the AlCoCrxFeNi2.1 (x > 0) alloys exhibit almost complete lamellar eutectic microstructures with a mixture structure of FCC and B2 phases. And the AlCoFeNi2.1 alloy without Cr element exhibited a hypoeutectic microstructure with a primary B2 phase. In addition, the eutectic microstructures for AlCoCrxFeNi2.1 eutectic alloys do not change significantly. The room temperature compressive tests results show that with an increase in Cr content (from x = 0 to x = 1.0), the yield strength will first decrease, and thereafter increase. The trend is the opposite with the fracture strength and plastic strain. They show an increase trend at first, and then decrease. The AlCoCr0.5FeNi2.1 (Cr0.5) alloy shows the best comprehensive mechanical properties. The tensile yield strength, fracture strength, and elongation are 536.5 MPa, 1062 MPa, and 13.8%, respectively. Furthermore, the Cr0.5 alloy also displays a high strength with a yield strength of 362 MPa at 700 ºC. In summary, by changing the Cr content, AlCoCrxFeNi2.1 eutectic high entropy alloys with excellent comprehensive mechanical properties were obtained and prepared.

Similar content being viewed by others

Data availability

The data are the original data about microstructure and mechanical properties of the composites.

References

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, T.J. Li, Sci. Rep. 4, 6200 (2014)

Y. Dong, L. Jiang, H. Jiang, Y. Lu, T. Wang, T. Li, Mater. Des. 82, 91 (2015)

F. He, Z. Wang, X. Shang, C. Leng, J. Li, J. Wang, Mater. Des. 104, 259 (2016)

Ł Rogal, J. Morgiel, Z. Świątek, F. Czerwiński, Mater. Sci. Eng. A 651, 590 (2016)

Y.P. Lu, X.Z. Gao, L. Jiang, Z.N. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao, T.J. Li, Acta Mater. 124, 143 (2017)

X. Jin, Y. Zhou, L. Zhang, X.Y. Du, B.S. Li, Mater. Lett. 216, 144 (2018)

H. Jiang, D.X. Qiao, Y.P. Lu, Z. Ren, Z.Q. Cao, T.M. Wang, T.J. Li, Scr. Mater. 165, 145 (2019)

Q.F. Wu, Z.J. Wang, T. Zheng, C. Da, Z.S. Yang, J.J. Li, J.J. Kai, J.C. Wang, Mater. Lett. 253, 268 (2019)

L. Wang, X. Wu, C. Yao, J. Shen, Y. Zhang, Y. Ge, G. Zhang, Metall. Mater. Trans. A 51, 5781 (2020)

H. Jiang, D. Qiao, W. Jiao, K. Han, L. Yiping, P.K. Liaw, J. Mater. Sci. Technol. 61, 119 (2021)

I.S. Wani, T. Bhattacharjee, S. Sheikh, Y.P. Lu, S. Chatterjee, P.P. Bhattacharjee, S. Guo, N. Tsuji, Mater. Res. Lett. 4, 174 (2016)

I.S. Wani, T. Bhattacharjee, S. Sheikh, I.T. Clark, M.H. Park, T. Okawa, S. Guo, P.P. Bhattacharjee, N. Tsuji, Intermetallics 84, 42 (2017)

T. Wang, M. Komarasamy, S. Shukla, R.S. Mishra, J. Alloys Compd. 766, 312 (2018)

P. Li, H. Sun, S. Wang, X. Hao, H. Dong, J. Alloys Compd. 814, 152322 (2020)

R. John, A. Karati, J. Joseph, D. Fabijanic, B.S. Murty, J. Alloys Compd. 835, 155424 (2020)

M.H. Asoushe, A.Z. Hanzaki, H.R. Abedi, B. Mirshekari, T. Wegener, S.V. Sajadifar, T. Niendorf, Mater. Sci. Eng. A 799, 140012 (2021)

S.R. Reddy, S. Yoshida, U. Sunkari, A. Lozinko, J. Joseph, R. Saha, D. Fabijanic, S. Guo, P.P. Bhattacharjee, N. Tsuji, Mater. Sci. Eng. A 764, 138226 (2019)

M.J. Kim, G.C. Kang, S.H. Hong, H.J. Park, S.C. Mun, G. Song, K.B. Kim, J. Mater. Sci. Technol. 57, 131 (2020)

Y. Dong, Z. Yao, X. Huang, F. Du, C. Li, A. Chen, F. Wu, Y. Cheng, Z. Zhang, J. Alloys Compd. 823, 153886 (2020)

F. Meng, S.F. Bauer, Y. Liao, I. Baker, Intermet. 56, 28 (2015)

L.Y. Sheng, J.T. Guo, H.Q. Ye, Mater. Des. 30, 964 (2009)

F. Meng, J. Qiu, I. Baker, Mater. Sci. Eng. A 586, 45 (2013)

C.G. Mckamey, C.T. Liu, J. Mater. Res. 24, 1156 (1989)

C.G. Mckamey, Scr. Metall. Mater. 24, 2119 (1990)

Y.Y. Liao, I. Baker, Mater. Sci. Eng. A 528, 3998 (2011)

M. Zamanzade, H. Vehoff, A. Barnoush, Acta Mater. 69, 210 (2014)

E. Hamzah, M. Kanniah, M. Harun, J. Mater. Sci. 42, 9063 (2007)

I. Baker, Mater. Sci. Eng. A 192, 1 (1995)

Y. Liao, I. Baker, J. Mater. Sci. 46, 2009 (2011)

X.Z. Gao, Y.P. Lu, B. Zhang, N.N. Liang, G.Z. Wu, G. Sha, J.Z. Liu, Y.H. Zhao, Acta Mater. 141, 59 (2017)

A. Akhtar, E. Teghtsoonian, Philos. Mag. 25, 897 (1972)

N.D.O.P. Modi, D.P. Mondal, A.K. Jha, A.H. Yegneswaran, H.K. Khaira, Mater. Charact. 46, 347 (2004)

I.M.B.M. Dollar, A.W. Thompson, Acta Metall. 36, 311 (1988)

N.P.L.L.I. Gladshtein, B.F. Belyaev, Metallurgist 56, 579 (2012)

Acknowledgements

This work financially was supported by the National Natural Science Foundation of China (No. 51901116), the Natural Science Foundation of Shandong Province (No. ZR2020QE019), the China Postdoctoral Science Fund (No. 2021M692724).

Author information

Authors and Affiliations

Contributions

Hui Jiang Methodology, Investigation, Writing—original draft, preparation, Project administration. Kaiming Han Investigation, Writing—original draft, Quanwei Wang and Rui Wang: Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose in this paper.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Jiang, H., Li, L., Wang, R. et al. Effects of Chromium on the Microstructures and Mechanical Properties of AlCoCrxFeNi2.1 Eutectic High Entropy Alloys. Acta Metall. Sin. (Engl. Lett.) 34, 1565–1573 (2021). https://doi.org/10.1007/s40195-021-01303-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01303-4