Abstract

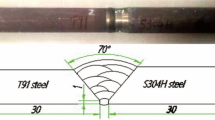

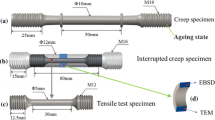

In the present study, creep activation energy for rupture was obtained as 221–348 kJ/mol for 22Cr15Ni3.5CuNbN due to the precipitation-hardening mechanism. The extrapolation strength of creep rupture time of 105 h at 923 K for 22Cr15Ni3.5CuNbN is more valid (83.71 MPa) predicted by the Manson–Haferd method, which is superior to other commercial heat-resistant steels. The tensile creep tests ranging from 180 to 240 MPa at 923 K were conducted to investigate creep deformation behavior of welded joint between a novel heat-resistant austenite steel 22Cr15Ni3.5CuNbN and ERNiCrCoMo-1 weld metal. Apparent stress exponent value of 6.54 was obtained, which indicated that the rate-controlled creep occurred in weldment during creep. A damage tolerance factor of 6.4 in the weldment illustrates that the microstructural degradation is the dominant creep damaging mechanism in the alloy. Meanwhile, the welded joints perform two types of deformation behavior with the variation in applied stress, which resulted from the different parts that govern the creep processing. Also, the morphology evolution of the fracture surfaces confirms the effects of stress level and stress state.

Similar content being viewed by others

References

B. Xiao, L. Xu, L. Zhao, H. Jing, Y. Han, Y. Zhang, Mater. Sci. Eng. A 711, 434 (2018)

Y. Zhang, H. Jing, L. Xu, L. Zhao, Y. Han, Y. Zhao, Mater. Sci. Eng. A 686, 102 (2017)

Y. Zhang, H. Jing, L. Xu, L. Zhao, Y. Han, J. Liang, Mater. Charact. 130, 156 (2017)

H. Yin, Y. Gao, Y. Gu, Mater. Des. 105, 66 (2016)

C. Wang, Y. Guo, J. Guo, L. Zhou, Mater. Des. 88, 790 (2015)

P. Yan, Z. Liu, H. Bao, Y. Weng, W. Liu, Mater. Des. 54, 874 (2014)

Y. Zhang, H. Jing, L. Xu, Y. Han, L. Zhao, B. Xiao, Mater. Charact. 139, 279 (2018)

X. Xie, C. Chi, H. Yu, J. Dong, M. Zhang, Y. Hu, H. Yang, C. Zhu, H. Yang, C. Zhu, Z. Cui, F. Lin, Research and development of a new austenitic heat- resisting steel SP2215 for 600–620 °C USC boiler superheater/reheater application, in Proceedings from the Eighth International Conference: Advances in Materials Technology for Fossil Power Plants, Electric Power Research Institute, Inc., Albufeira, October 11–14 (2016)

J. Dean, J. Campbell, G. Aldrich-Smith, T.W. Clyne, Acta Mater. 80, 56 (2014)

B. Wilshire, P.J. Scharning, Int. Mater. Rev. 53, 91 (2008)

S. Goyal, K. Laha, Mater. Sci. Eng. A 615, 348 (2014)

T. Shrestha, M. Basirat, I. Charit, G.P. Potirniche, K.K. Rink, Mater. Sci. Eng. A 565, 382 (2013)

T. Sakthivel, S.P. Selvi, K. Laha, Mater. Sci. Eng. A 640, 61 (2015)

J.A. Siefert, S.A. David, Sci. Technol. Weld. Join. 19, 271 (2014)

J.A. Siefert, J.P. Shingledecker, J.N. DuPont, S.A. David, Sci. Technol. Weld. Join. 21, 397 (2016)

W.M. Payten, D.W. Dean, K.U. Snowden, Mater. Sci. Eng. A 527, 1920 (2010)

Y. Zhang, H. Jing, L. Xu, Y. Han, L. Zhao, D. Wang, B. Xiao, Mater. Sci. Eng. A 721, 103 (2018)

J.G. Kaufman, Parametric Analyses of High-Temperature Data for Aluminum Alloys (ASM International, Portland, 2008)

D. Šeruga, M. Nagode, Mater. Sci. Eng. A 528, 2804 (2011)

G. Dimmler, P. Weinert, H. Cerjak, Int. J. Pres. Ves. Pip. 85, 55 (2008)

H. Ghassemi Armaki, K. Maruyama, M. Yoshizawa, M. Igarashi, Mater. Sci. Eng. A 490, 66 (2008)

S. Manson, A. Haferd, Technical Report Archive & Image Library (1953)

W. Bendick, L. Cipolla, J. Gabrel, J. Hald, Int. J. Pres. Ves. Pip. 87, 304 (2010)

R. Orr, O. Sherby, J. Dorn, Trans. Am. Soc. Met. 7, 113 (1953)

K. Maruyama, H.G. Armaki, K. Yoshimi, Int. J. Pres. Ves. Pip. 84, 171 (2007)

J.S. Lee, H.G. Armaki, K. Maruyama, T. Muraki, H. Asahi, Mater. Sci. Eng. A 428, 270 (2006)

B. Wilshire, A.J. Battenbough, Mater. Sci. Eng. A 443, 156 (2007)

M.T. Whittaker, B. Wilshire, Mater. Sci. Eng. A 527, 4932 (2010)

R.M. Goldhoff (ed.), Development of a Standard Methodology for the Correlation and Extrapolation of Elevated Temperature Creep and Rupture Data, Volume 2: A State-of-the-Art Review, Final Report (Metal Properties Council Inc., New York, 1979)

M.K. Booker (ed.), Development of a Standard Methodology for the Correlation and Extrapolation of Elevated Temperature: A Summary of a State-of-the-Art Review and a Workshop. Final Report (Metal Properties Council, Inc., New York, 1974)

A. Iseda, H. Okada, H. Semba, M. Igarashi, Energy Mater. 2, 199 (2013)

M.S. Pham, S.R. Holdsworth, K.G.F. Janssens, E. Mazza, Int. J. Plast. 47, 143 (2013)

B. Xiao, L. Xu, L. Zhao, H. Jing, Y. Han, Mater. Sci. Eng. A 690, 104 (2017)

B. Xiao, L. Xu, L. Zhao, H. Jing, Y. Han, Z. Tang, Mater. Sci. Eng. A 707, 466 (2017)

M.F. Ashby, B.F. Dyson, Creep damage mechanics and micromechanisms, in Proceedings of the 6th International Conference on Fracture (ICF6), National Aeronautical Laboratory, New Delhi, 4–10 December (1984)

S. Tu, R. Wu, R. Sandström, Int. J. Pres. Ves. Pip. 58, 345 (1994)

S. Tu, R. Sandström, Int. J. Pres. Ves. Pip. 57, 335 (1994)

A.A. Benzerga, J. Leblond, A. Needleman, V. Tvergaard, Int. J. Fract. 201, 29 (2016)

L. Zhao, N. Alang, K. Nikbin, Fatigue Fract. Eng. Mater. 41, 456 (2018)

M.F. Ashby, C. Gandhi, D.M.R. Taplin, in Perspectives in Creep Fracture, ed. by M.F. Ashby, L.M. Brown (Pergamon, Oxford, 1983), p. 699

J. Wen, S. Tu, F. Xuan, X. Zhang, X. Gao, J. Mater. Sci. Technol. 32, 695 (2016)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51475326) and the Demonstration Project of National Marine Economic Innovation (No. BHSF2017-22). The authors also wish to acknowledge the supplier of the steel and welded joint: China Jiangsu Wujin Stainless Steel Pipe Group Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zhang, Y., Jing, HY., Xu, LY. et al. Creep Behavior and Life Assessment of a Novel Heat-Resistant Austenite Steel and Its Weldment. Acta Metall. Sin. (Engl. Lett.) 32, 638–650 (2019). https://doi.org/10.1007/s40195-018-0822-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0822-5