Abstract

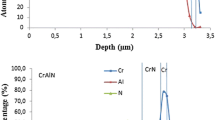

The Cr–Si–N coatings were prepared by combining system of high-power impulse magnetron sputtering and pulsed DC magnetron sputtering. The Si content in the coating was adjusted by changing the sputtering power of the Si target. By virtue of electron-probe microanalysis, X-ray diffraction analysis and scanning electron microscopy, the influence of the Si content on the coating composition, phase constituents, deposition rate, surface morphology and microstructure was investigated systematically. In addition, the change rules of micro-hardness, internal stress, adhesion, friction coefficient and wear rate with increasing Si content were also obtained. In this work, the precipitation of silicon in the coating was found. With increasing Si content, the coating microstructure gradually evolved from continuous columnar to discontinuous columnar and quasi-equiaxed crystals; accordingly, the coating inner stress first declined sharply and then kept almost constant. Both the coating hardness and the friction coefficient have the same change tendency with the increase of the Si content, namely increasing at first and then decreasing. The Cr–Si–N coating presented the highest hardness and average friction coefficient for an Si content of about 9.7 at.%, but the wear resistance decreased slightly due to the high brittleness. The above phenomenon was attributed to a microstructural evolution of the Cr–Si–N coatings induced by the silicon addition.

Similar content being viewed by others

References

X.Y. Guan, Y.X. Wang, G.A. Zhang, X. Jiang, L.P. Wang, Q.J. Xue, Tribol. Int. 106, 78 (2017)

Q.X. Fan, T.G. Wang, Y.M. Liu, Z.H. Wu, T. Zhang, T. Li, Z.B. Yang, Acta Metall. Sin. (Engl. Lett.) 29, 1119 (2016)

X.S. Wan, S.S. Zhao, Y. Yang, J. Gong, C. Sun, Surf. Coat. Technol. 204, 1800 (2010)

Y.X. Ou, J. Lin, H.L. Che, J.J. Moore, W.D. Sproul, M.K. Lei, Thin Solid Film 594, 147 (2015)

L. Shan, Y.X. Wang, J.L. Li, X. Jiang, J.M. Chen, Tribol. Int. 82, 78 (2015)

A. Gilewicz, P. Chmielewska, D. Murzynski, E. Dobruchowska, B. Warcholinski, Surf. Coat. Technol. 299, 7 (2016)

Z.T. Wu, Z.B. Qi, D.F. Zhang, B.B. Wei, Z.C. Wang, Surf. Coat. Technol. 289, 45 (2016)

J.J. Roa, E. Jiménez-Piqué, R. Martínez, G. Ramírez, J.M. Tarragó, R. Rodríguez, L. Llanes, Thin Solid Film 571, 308 (2014)

Q.M. Wang, K.H. Kim, Acta Mater. 57, 4974 (2009)

J.L. Lin, B. Wang, Y.X. Ou, W.D. Sproul, I. Dahan, J.J. Moore, Surf. Coat. Technol. 216, 251 (2013)

Q.Z. Wang, F. Zhou, M. Callisti, T. Polcar, J.Z. Kong, J.W. Yan, J. Alloy. Compd. 708, 1103 (2017)

S. Veprek, M.G.J. Veprek-Heijman, P. Karvankova, J. Prochazka, Thin Solid Films 476, 1 (2005)

P. Souček, J. Daniel, J. Hnilica, K. Bernátová, L. Zábranský, V. Buršíková, M. Stupavská, P. Vašina, Surf. Coat. Technol. 311, 257 (2017)

Q.S. Ma, L.H. Li, Y. Xu, J.B. Gu, L. Wang, Y. Xu, Appl. Surf. Sci. 392, 826 (2017)

T. Konishi, K. Yukimura, K. Takaki, Surf. Coat. Technol. 286, 239 (2016)

A. Anders, Surf. Coat. Technol. 257, 308 (2014)

I.L. Velicu, V. Tiron, G. Popa, Surf. Coat. Technol. 250, 57 (2014)

L.D. Giudice, S. Adjam, D.L. Grange, O. Banakh, A. Karimi, R. Sanjinés, Surf. Coat. Technol. 295, 99 (2016)

H. Zhou, J. Zheng, B.H. Gui, D.S. Geng, Q.M. Wang, Vacuum 129, 191 (2017)

T.G. Wang, S.S. Zhao, W.G. Hua, J.B. Li, J. Gong, C. Sun, Mater. Sci. Eng., A 527, 454 (2010)

J.F. Archard, J. Appl. Phys. 24, 981 (1953)

L.L. Huang, C.W. Zou, W. Xie, F. Peng, L.X. Shao, Ceram. Int. 42, 5062 (2016)

T.G. Wang, Y.M. Liu, T.F. Zhang, D.I. Kim, K.H. Kim, J. Mater. Sci. Technol. 28, 981 (2012)

M. Balzer, M. Fenker, Surf. Coat. Technol. 250, 37 (2014)

S. Veprek, M.G.J. Veprek-Heijman, Surf. Coat. Technol. 201, 6064 (2007)

S. Veprek, J. Vac. Sci. Technol. 31, 050822 (2013)

C.C. Chang, H.W. Chen, J.W. Lee, J.G. Duh, Surf. Coat. Technol. 284, 273 (2015)

S. Veprek, S. Reiprich, L. Shizhi, Appl. Phys. Lett. 66, 2640 (1995)

A. Lasalmonie, J.L. Strudel, J. Mater. Sci. 21, 1837 (1986)

S. Liu, R. Raghavan, X.T. Zeng, J. Michler, Appl. Phys. Lett. 104, 081919 (2014)

C.C. Chang, H.S. Chen, J.W. Lee, J.G. Duh, Thin Solid Films 584, 46 (2015)

P. Bansal, P.H. Shipway, S.B. Leen, Acta Mater. 55, 5089 (2007)

R. Gadow, M.J. Riegert-Escribano, M. Buchmann, J. Therm. Spray Technol. 14, 100 (2005)

V.V. Le, T.T. Nguyen, S.K. Kim, K.H. Pham, Surf. Coat. Technol. 218, 87 (2013)

T.G. Wang, D. Jeong, Y.M. Liu, Q.M. Wang, S. Iyengar, S. Melin, K.H. Kim, Surf. Coat. Technol. 206, 2638 (2012)

R. Bajwa, Z. Khan, H. Nazir, V. Chacko, A. Saeed, Acta Metall. Sin. (Engl. Lett.) 29, 902 (2016)

T. Polcar, A. Cavaleiro, Surf. Coat. Technol. 206, 1244 (2011)

Y.S. Hong, S.H. Kwon, T.G. Wang, D.I. Kim, J. Choi, K.H. Kim, Trans. Nonferrous Met. Soc. China 21, s62 (2011)

Acknowledgements

This work was supported by the Global Frontier Program through the Global Frontier Hybrid Interface Materials (GFHIM) of the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (No. 2013M3A6B1078874). In addition, it was also funded by the National Nature Science Foundation of China (No. 51301181), the Tianjin Key Research Program of Application Foundation and Advanced Technology (No. 15JCZDJC39700), the Tianjin Science and Technology correspondent project (No. 16JCTPJC49500), and the Innovation Team Training Plan of Tianjin Universities and colleges (No. TD12-5043).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Wang, TG., Dong, Y., Gebrekidan, B.A. et al. Microstructure and Properties of the Cr–Si–N Coatings Deposited by Combining High-Power Impulse Magnetron Sputtering (HiPIMS) and Pulsed DC Magnetron Sputtering. Acta Metall. Sin. (Engl. Lett.) 30, 688–696 (2017). https://doi.org/10.1007/s40195-017-0609-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0609-0