Abstract

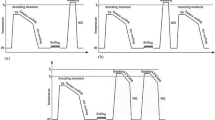

To study the effects of the deformation degree and cooling rate on the microstructure and phase transformation temperature for the B1500HS steel, the samples were heated at 900 °C for 5 min, compressed by 10, 20, 30 and 40% at the strain rate of 0.1 s−1, and then cooled down at the rates of 50, 40, 25, 20 and 15 °C/s by the thermo-mechanical simulator, respectively. The start and finish temperatures of the phase transformation were determined by the tangent method, and the volume fraction of the phase transformation was ascertained by the level principle according to the dilatometric curves. The volume fraction of the retained austenite was determined by X-ray diffraction. The results show that the volume fraction of the bainite rises with an increase in the deformation degree as the cooling rate is lower than the critical rate. At the same cooling rate, the phase transformation temperature rises with an increase in the deformation degree, and the sizes of both the martensite and bainite phases reduce due to the austenite grain refinement induced by the deformation. The volume fraction of the retained austenite reduces as the deformation degree increases. The critical cooling rate of the un-deformed samples is approximately 25 °C/s and the critical cooling rate rises as the deformation degree increases.

Similar content being viewed by others

References

L. Komgrit, H. Hamasaki, R. Hino, F. Yoshida, Elimination of springback of high-strength steel sheet by using additional bending with counter punch. J. Mater. Process. Technol. 229, 199–206 (2016). doi:10.1016/j.jmatprotec.2015.08.029

H. Karbasian, A.E. Tekkaya, A review on hot stamping. J. Mater. Process. Technol. 210, 2103–2118 (2010). doi:10.1016/j.jmatprotec.2010.07.019

J. Min, J. Lin, J. Li, W. Bao, Investigation on hot forming limits of high strength steel 22MnB5. Comput. Mater. Sci. 49, 326–332 (2010). doi:10.1016/j.commatsci.2010.05.018

H. Li, L. He, G. Zhao, L. Zhang, Constitutive relationships of hot stamping boron steel B1500HS based on the modified Arrhenius and Johnson–Cook model. Mater. Sci. Eng., A 580, 330–348 (2013). doi:10.1063/1.4806961

H. Li, C. Wang, L. He, C. Zhang, Effect of heating and mold temperature on the mechanical properties and microstructure of B1500HS boron steel. Mater. Perform. Charact. 6(1), 17–32 (2017). doi:10.1520/MPC20160108

M. Merklein, J. Lechler, T. Stoehr, Investigations on the thermal behavior of ultra high strength boron manganese steels within hot stamping. Int. J. Mater. Form. 2, 259–262 (2009). doi:10.1007/s12289-009-0505-x

J. Cui, G. Sun, J. Xu, X. Huang, G. Li, A method to evaluate the formability of high-strength steel in hot stamping. Mater. Des. 77, 95–109 (2015). doi:10.1016/j.matdes.2015.04.009

P. Hein, J. Wilsius, Status and innovation trends in hot stamping of USIBOR 1500P. Steel Res. Int. 79, 85–91 (2008). doi:10.1002/srin.200806321

M. Maikranz-Valentin, U. Weidig, U. Schoof, H.H. Becker, K. Steinhoff, Components with optimised properties due to advanced thermomechanical process strategies in hot sheet metal forming. Steel Res. Int. 79, 92–97 (2008). doi:10.1002/srin.200806322

H. Li, L. He, C. Zhang, H. Cui, Research on the effect of boundary pressure on the boundary heat transfer coefficients between hot stamping die and boron steel. Int. J. Heat Mass Trans. 91, 401–415 (2015). doi:10.1016/j.ijheatmasstransfer.2015.07.102

S. Denis, E. Gautier, A. Simon, G. Beck, Stress-phase-transformation interactions-basic principles, modelling and calculation of internal stresses. Mater. Sci. Technol. 1, 805–814 (1985). doi:10.1179/mst.1985.1.10.805

A. Barcellona, D. Palmeri, Effect of plastic hot deformation on the hardness and continuous cooling transformations of 22MnB5 microalloyed boron steel. Metall. Mater. Trans. A 40, 1160–1174 (2009). doi:10.1007/s11661-009-9790-8

M. Naderi, W. Bleck, An investigation into martensitic transformation in hot stamping process. WIT Trans. Eng. Sci. 57, 95–104 (2007). doi:10.2495/MC070101

M. Nikravesh, M. Naderi, G.H. Akbari, Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater. Sci. Eng., A 540, 24–29 (2012). doi:10.1016/j.msea.2012.01.018

A.J. Craven, K. He, L.A.J. Garvie, T.N. Baker, Complex heterogeneous precipitation in titanium–niobium microalloyed Al-killed HSLA steels—I. (Ti, Nb)(C, N) particles. Acta Mater. 48, 3857–3868 (2000). doi:10.1016/S1359-6454(00)00194-4

J.D. Verhoeven (ed.), Steel Metallurgy for the Non-metallurgist (ASM International, Novelty, 2007)

K.F. Starodubov, Heat treatment of low carbon steel. Metal Sci. Heat Treat. 7, 453–454 (1966)

S. Morito, Y. Adachi, T. Ohba, Morphology and crystallography of sub-blocks in ultra-low carbon lath martensite steel. Mater. Trans. 50, 1919–1923 (2009). doi:10.2320/matertrans.mra2008409

S. Morito, X. Huang, T. Furuhara, T. Maki, N. Hansen, The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 54, 5323–5331 (2006). doi:10.1016/j.actamat.2006.07.009

P.M. Kelly, A. Jostsons, R.G. Blake, The orientation relationship between lath martensite and austenite in low carbon, low alloy steels. Acta Metall. Mater. 38, 1075–1081 (1990). doi:10.1016/0956-7151(90)90180-O

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, T. Maki, The morphology and crystallography of lath martensite in Fe–C alloys. Acta Mater. 51, 1789–1799 (2003). doi:10.1016/S1359-6454(02)00577-3

H. Kitahara, R. Ueji, M. Ueda, N. Tsuji, Y. Minaminoa, Crystallographic analysis of plate martensite in Fe-28.5 at.% Ni by FE-SEM/EBSD. Mater. Charact. 54, 378–386 (2005). doi:10.1016/j.matchar.2004.12.015

S. Morito, H. Yoshida, T. Maki, X. Huang, Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng., A 438, 237–240 (2006). doi:10.1016/j.msea.2005.12.048

Y.L. Zhao, J. Shi, W.Q. Cao, M.Q. Wang, G. Xie, Effect of direct quenching on microstructure and mechanical properties of medium-carbon Nb-bearing steel. J. Zhejiang Univ. Sci. A 11, 776–781 (2010). doi:10.1631/jzus.A1000147

K.S. Kim, L.X. Du, C.R. Gao, Influence of vanadium content on bainitic transformation of a low-carbon boron steel during continuous cooling. Acta Metall. Sin. 28, 692–698 (2015). doi:10.1007/s40195-015-0249-1

D.Q. Bai, S. Yue, T.M. Maccagno, J.J. Jomas, Effect of deformation and cooling rate on the microstructures of low carbon Nb-B steels. ISIJ Int. 38, 371–379 (1998). doi:10.2355/isijinternational.38.371

H. Li, K. Gai, L. He, C. Zhang, H. Cui, M. Li, Non-isothermal phase-transformation kinetics model for evaluating the austenization of 55CrMo steel based on Johnson–Mehl–Avrami equation. Mater. Des. 92(731–741), 2015 (2016). doi:10.1016/j.matdes.12.110

P. Maynier, J. Dollet, P. Bastien, Hardenability Concepts with Applications to Steels (AIME, New York, 1978), pp. 518–544

H. Li, G. Zhao, S. Niu, C. Huang, FEM simulation of quenching process and experimental verification of simulation results. Mater. Sci. Eng., A 452–453, 705–714 (2007). doi:10.1016/j.msea.2006.11.023

M. Abbasi, M. Naderi, A. Saeed-Akbari, Isothermal versus non-isothermal hot compression process: a comparative study on phase transformations and structure–property relationships. Mater. Des. 45, 1–5 (2013). doi:10.1016/j.matdes.2012.08.062

M. Abbasi, A. Saeed-Akbari, M. Naderi, The effect of strain rate and deformation temperature on the characteristics of isothermally hot compressed boron-alloyed steel. Mater. Sci. Eng., A 538, 356–363 (2012). doi:10.1016/j.msea.2012.01.060

J. Min, J. Lin, Y. Min, Effect of thermo-mechanical process on the microstructure and secondary-deformation behavior of 22MnB5 steels. J. Mater. Process. Technol. 213, 818–825 (2013). doi:10.1016/j.jmatprotec.2012.12.012

R.M. Wu, W. Li, C.L. Wang et al., Stability of retained austenite through a combined intercritical annealing and quenching and partitioning (IAQP) treatment. Acta Metall. Sin. 28, 386–393 (2015). doi:10.1007/s40195-015-0217-9

N.R.V. Bangaru, A.K. Sachdev, Influence of cooling rate on the microstructure and retained austenite in an intercritically annealed vanadium containing HSLA steel. Metall. Mater. Trans. A 13, 1899–1906 (1982). doi:10.1007/BF02645933

H.B. Ryu, J.G. Speer, J.P. Wise, Effect of thermomechanical processing on the retained austenite content in a Si–Mn transformation-induced-plasticity steel. Metall. Mater. Trans. A 33, 2811–2816 (2002). doi:10.1007/s11661-002-0266-3

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51175302, 51575324), and the Science and Technology Development Program of Shandong and Huangdao (Nos. 2014GGX103024, 20140132).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Li, HP., Jiang, R., He, LF. et al. Influence of Deformation Degree and Cooling Rate on Microstructure and Phase Transformation Temperature of B1500HS Steel. Acta Metall. Sin. (Engl. Lett.) 31, 33–47 (2018). https://doi.org/10.1007/s40195-017-0594-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0594-3