Abstract

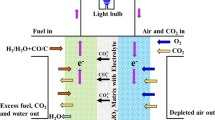

The high-temperature molten carbonate fuel cell is an ultra-clean and highly efficient power generator. It is operated at ~550–650 °C, which is considered optimal in facilitating fast fuel cell reaction kinetics, utilizing waste heat efficiently, and allowing use of commercial construction materials. Commercial MW-size (mega watt) power plants of FuelCell Energy products have already been deployed worldwide. Metallic hardware materials are extensively utilized and may experience high-temperature reducing and oxidizing atmospheres in the presence of molten alkali carbonate electrolyte. Material selections are founded on many decades of focused research and development and field experience. Results to date show that the baseline stack module materials meet 5-year life goal and BOP (balance of plant) construction materials meet 20-year life goal. Material durability is well understood, and solutions are available to further extend the durability. This paper will review hardware materials experience and development approaches that would further reduce cost and extend life.

Similar content being viewed by others

References

M. Farooque, H. Maru, J. Power Sources 160, 827 (2006)

C. Yuh, L. Chen, A. Franco, M. Farooque, in High Temperature Corrosion and Oxidation of Materials, Materials Science and Technology (MS&T 2013) (Montreal, Quebec, Canada, 27–31 Oct, 2013), p. 2531

S. Frangini, J. Power Sources 182, 462 (2008)

A. Schoeler, T.D. Kaun, I. Bloom, M. Lanagan, M. Krumpelt, J. Electrochem. Soc. 147, 916 (2000)

J. Hoffmann, C. Yuh, A. GodulaJepek, Electrolyte and material challenge, in Handbook of Fuel Cells—Fundamentals, Technology and Applications, vol. 4, ed. by W. Vielstich, A. Lamm, H. Gasteiger (Wiley, Hoboken, 2003), pp. 921–941

D. Shores, M. Pischke, The hot corrosion of current collector/separators and carbonate fuel cells, eds. D. Shores, H. Maru, I. Uchida, and J. R. Selman. 3rd International Symposium Carbonate Fuel cell Technology (The Electrochemical Society, Pennington, NJ, 1993) PV 93-3, pp. 214–229

C. Yuh, A. Hilmi, L. Chen, A. Franco, M. Farooque, ECS Trans. 41, 21 (2012)

C. Yuh, M. Farooque, Materials and life considerations, in Encyclopedia of Electrochemical Power Sources, ed. by J. Garche, et al. (Elsevier, Amsterdam, 2009), p. 497

Z. Yang, G. Xia, M. Walker, C. Wang, J. Stevenson, P. Singh, Int. J. Hydrogen Energy 32, 3770 (2007)

T. Sourmail, Mater. Sci. Technol. 17, 1 (2001)

C. Hsieh, W. Wu, Overview of intermetallic sigma phase precipitation in stainless steels. ISRN Metall. 2012, Article ID 732471

A.J. Sedricks, Corrosion of Stainless Steels (Wiley-Interscience, Hoboken, 1996)

P.J. Maziasz, B.A. Pint, J.P. Shingledecker, N.D. Evans, Y. Yamamoto, K.L. More, E. Lara-Curzio, Int. J. Hydrogen Energy 32, 3622 (2007)

R.A. Donado, L.G. Marianowski, H.C. Maru, J. Electrochem. Soc. 131, 2541 (1984)

C. Yuh, L. Chen, A. Franco, M. Farooque, review of high-temperature fuel cell hardware materials. Symposium. ASME 2010 Eighth International Fuel Cell Science, Engineering and Technology Conference (Brooklyn, New York, 14–16 June, 2010) FuelCell2010-33163

J. Li, C. Yuh, T. Lucas, M. Primerano, US Patent 6372374, 16 Apr 2002

Acknowledgements

The authors would like to acknowledge FCE’s technical staffs on the combined contribution to the progress reported in this paper. The authors also thank Adam Franco for performing metallographic analysis and Richard Johnsen for identifying commercial Al-coated ferritic stainless steels for high-temperature service.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Yuh, CY. Hardware Materials in Molten Carbonate Fuel Cell: A Review. Acta Metall. Sin. (Engl. Lett.) 30, 289–295 (2017). https://doi.org/10.1007/s40195-017-0547-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0547-x