Abstract

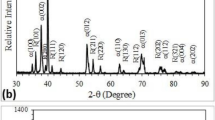

In this paper, we report the use of blowing nitrogen gas for the successful fabrication of a composite layer composed of Ti/TiN on a substrate of commercially pure titanium (cp-2) using the friction stir processing technique. The prepared composite layer was characterized by X-ray diffraction, scanning electron microscopy and energy-dispersive X-ray spectrometry. The maximum microhardness of the Ti/TiN composite reached 1024 HV, which is 6.4 times higher than that of the titanium substrate. The results of wear test indicated that the Ti/TiN composite layer possesses excellent abrasive and adhesive wear resistance because of the formation of the TiN and its high hardness.

Similar content being viewed by others

References

C. Leyens, M. Peters (eds.), Titanium and Titanium Alloys: Fundamentals and Applications (Wiley-VCH, Weinheim, 2003)

R. Boyer, G. Welsh, E.W. Collings, Materials Properties Handbook—Titanium Alloys (ASM International, Materials Park, 1994)

V. Gorynin, Mater. Sci. Eng. A 263, 112 (1999)

A. Zhecheva, W. Sha, S. Malinov, A. Long, Surf. Coat. Technol. 200, 2192 (2005)

A. Zhecheva, S. Malinov, W. Sha, Surf. Coat. Technol. 201, 2467 (2006)

E.C. Santos, M. Morita, M. Shiomi, K. Osakada, M. Takahashi, Surf. Coat. Technol. 201, 1635 (2006)

M.S.F. Lima, F. Folio, S. Mischler, Surf. Coat. Technol. 199, 83 (2005)

R.S. Mishra, Z.Y. Ma, Friction stir welding and processing. Mater. Sci. Eng. R 50, 1 (2005)

M. Barmouz, M.K. Besharati-Givi, J. Seyfi, Mater. Charact. 62, 108 (2011)

R. Sathiskumar, N. Murugan, I. Dinaharan, S.J. Vijay, Mater. Character. 84, 16 (2013)

A. Shamsipur, S.F. Kashani-Bozorg, A. Zarei-Hanzaki, Surf. Coat. Technol. 206, 1372 (2011)

C.J. Lee, J.C. Huang, P.J. Hsieh, Scr. Mater. 54, 1415 (2006)

A. Shafiei-Zarghani, S.F. Kashani-Bozorg, A. Zarei-Hanzaki, Mater. Sci. Eng. A 500, 84 (2009)

Y. Morisada, H. Fujii, T. Nagaoka, M. Fukusumia, Scr. Mater. 55, 1067 (2006)

Y. Morisada, H. Fujii, T. Nagaoka, M. Fukusumia, Mater. Sci. Eng. A 419, 344 (2006)

Y. Morisada, H. Fujii, T. Nagaoka, M. Fukusumia, Mater. Sci. Eng. A 433, 50 (2006)

A. Shamsipur, S.F. Kashani-Bozorg, A. Zarei-Hanzaki, Surf. Coat. Technol. 218, 62 (2013)

S. Mridha, J. Mater. Proc. Technol. 168, 471 (2005)

W. Sha, M.A. Haji, M. Don, A. Mohamed, X. Wu, B. Siliang, A. Zhecheva, Mater. Charact. 59, 229 (2008)

Z.D. Cuia, S.L. Zhua, H.C. Manb, X.J. Yanga, Surf. Coat. Technol. 190, 309 (2005)

M.P. Kapczinski, C. Gil, E.J. Kinast, C.A. Santos, Mater. Res. 6, 265 (2003)

T.B. Massalski, H. Okamoto, P.R. Subramanian, L. Kacprzak (eds.), Binary Alloy Phase Diagrams, 2nd edn. (ASM International, Materials Park, 1990)

M. Fazel-Najafabadi, S.F. Kashani-Bozorg, A. Zarei-Hanzaki, Mater. Des. 31, 4800 (2010)

P.Q. La, J.Q. Ma, Y.T. Zhu, J. Yang, W.M. Liu, Q.J. Xue, R.Z. Valiev, Acta Mater. 53, 5167 (2005)

S. Hogmark, S. Jacobson, O. Vingsbo, Metals Handbook, 10th edn. (ASM International, Metals Park, 1990)

S.V. Kailas, J. Mater. Eng. Perform. 12, 629 (2003)

S.K. Biswas, A.V. Kailas, Tribol. Int. 30, 369 (1997)

A.V. Kailas, S.K. Biswas, J. Tribol. 119, 31 (1997)

G. Purceka, O. Saraya, O. Kula, I. Karamanb, G.G. Yapici, M. Haouaouib, H.J. Maierc, Mater. Sci. Eng. A 517, 97 (2009)

N. Chelliah, A.V. Kailas, Wear 266, 704 (2009)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Shamsipur, A., Kashani-Bozorg, SF. & Zarei-Hanzaki, A. Surface Modification of Titanium by Producing Ti/TiN Surface Composite Layers via FSP. Acta Metall. Sin. (Engl. Lett.) 30, 550–557 (2017). https://doi.org/10.1007/s40195-017-0529-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0529-z