Abstract

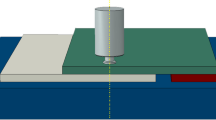

This paper reports on a new method based on the friction stir spot welding process to join Al/Cu in lap joint configuration. The feasibility of the friction diffusion bonding (FDB) of Al/Cu was investigated by varying the welding time between 20 and 50 s with all other parameters constant. A circular Cu plate was placed on the surface of an Al plate in the FDB process. The experimental results revealed that the intermetallic compounds, CuAl2 and Cu9Al4, were formed in the copper plates failed from the mechanical tests and the copper and aluminum diffused about 4μm and 2μm away from the interface into the Al and the Cu sides, respectively. Bonding was accompanied by interfacial diffusion with no significant mechanical mixing. The maximum tensile shear strength of Al/Cu joint was achieved at the welding time of 40 s and rotating speed of 1400 rpm.

Similar content being viewed by others

Data availability

All data that support the findings of this study are included within this article.

References

Thomas WM, Nicholas ED, Needham JC, Murch MG, Templesmith P, Dawes CJ (1991) Improvements relating to friction welding. International Patent Application, PCT/GB92/02203 (Patent)

Thomas WM, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1991) Improvements relating to friction stir welding. Eur Patent Spec 0615480:B1

Balasundaram R, Patel VK, Bhole SD, Chen DL (2014) Effect of zinc interlayer on ultrasonic spot welded aluminium-to-copper joints. Mater Sci Eng A 607:277–286

Saeid T, Abdollah-zadeh A, Sazgari B (2010) Weldability and mechanical properties of dissimilar aluminium-copper lap joints made by friction stir welding. J Alloy Compd 490:652–655

Zhou X, Zhang G, Shi Y, Zhu M, Yang F (2017) Microstructures and mechanical behavior of aluminium-copper lap joints. Mater Sci Eng A 705:105–113

Fei X, Ye Y, Jin L, Wang H, Lv S (2018) Special welding parameters study on Cu/Al joint in laser-heated friction stir welding. J Mater Process Technol 256:160–171

Ouyang J, Yarrapareddy E, Kovacevic R (2006) Microstructural evolution in the friction stir welded 6061 aluminum alloy (T6-temper condition) to copper. J Mater Process Technol 172:110–122

Xue P, Ni DR, Wang D, Xiao BL, Ma ZY (2011) Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al-Cu joints. Mater Sci Eng A 528:4683–4689

Galvão I, Oliveira JC, Loureiro A, Rodrigues DM (2012) Formation and distribution of brittle structures in friction stir welding of aluminium and copper: influence of process parameters. Intermetallics 22:122–128

Girard M et al (2010) Friction stir diffusion bonding of dissimilar metals. Sci Technol Weld Joining 15(8):661–667

Mofid MA, Loryaei E (2019) Investigating microstructural evolution at the interface of friction stir weld and diffusion bond of Al and Mg alloys. J Mater Res Technol 8(5):3872–3877

Kodama T, et al. Material flow in lap joint of dissimilar metallic foils by friction stir diffusion bonding with micro indentation. Mater Sci Forum 941:1450–1456. ISSN: 1662–9752

Ibrahim AB et al (2018) Effect of process parameters on microstructural and mechanical properties of friction stir diffusion cladded ASTM A516–70 steel using 5052 Al alloy. J Manuf Process 34:451–462

Mubiayi MP (2014) Member, IAENG and Esther T. Akinlabi, Member, IAENG, Friction stir spot welding of dissimilar materials: An Overview. WCECS 1–6

Bozzia S, Helbert-Ettera AL, Baudinb T, Criquic B, Kerbiguet JG (2010) Intermetallic compounds in Al 6016/IF-steel friction stir spot welds. Mater Sci Eng A 527:4505–4509

Su P, Gerlich A, North TH, Bendzsak GJ (2007) Intermixing in dissimilar friction stir spot welds. Metall Mater Trans A 38A:584–596

Chen C-L, Richter A, Kögler R, Wu L-T (2012) Dual-beam irradiation of friction stir spot welding of nanostructured ferritic oxide dispersion strengthened alloy. J Alloy Compd 536:S194–S199

Garg A, Bhattacharya A (2017) Strength and failure analysis of similar and dissimilar friction stir spot welds: influence of different tools and pin geometries. Mater Des 127:272–286

Abdollah-zadeh A, Saeid T, Sazgari B (2008) Microstructural and mechanical properties of friction stir welded aluminium/copper lap joints. J Alloy Compd 460:535–538

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R: Reports 50:1–78

Özdemir Ugur, Sayer Sami, Yeni Çinar, Bornova-Izmir, (2012) Effect of pin penetration depth on the mechanical properties of friction stir spot welded aluminum and copper. Mater Test Join Technol 54(4):233–239

Guo Y, Liu G, Jin H, Shi Z, Qiao G (2011) Intermetallic phase formation in diffusion-bonded Cu/Al laminates. J Mater Sci 46:2467–2473

Xue P, Xiao B, Ni DR, Ma ZY (2010) Enhanced mechanical properties of friction stir welded dissimilar Al-Cu joint by intermetallic compounds. Mater Sci Eng, A 527:5723–5727

Xue P, Ni DR, Wang D, Xiao BL, Ma ZY (2011) Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al-Cu joints. Mater Sci Eng A 528:4683–4689

Galvao I, Oliveira J, Loureiro A, Rodrigues D (2011) Formation and distribution of brittle structures in friction stir welding of aluminium and copper: influence of process parameters. Sci Technol Weld Joining 16(8):681–689

Wang XG, Yan FJ, Li XG, Wang CG (2017) Induction diffusion brazing of copper to aluminium. Sci Technol Weld Joining 22:170–175

Sauvage X, Enikeev N, Valiev R, Nasedkina Y, Murashkin M (2014) Atomic-scale analysis of the segregation and precipitation mechanisms in a severely deformed Al-Mg alloy. Acta Mater 72:125–136

Wei YN, Xiong JT, Li JL, Zhang FS, Liang SH (2017) Microstructure and enhanced atomic diffusion of friction stir welding aluminium/steel joints. Mater. Sci. Tech 1–7

Bakker H, Bonzel HP, Bruff CM, et al (1990) Numerical data and functional relationships in science and technology, Vol.26, (Diffusion in solid metals and alloys). Springer-Verlag: Berlin, pp. 141–153.

Baither D, Kim TH, Schmitz G (2008) Diffusion-induced recrystallization in silver-palladium layers. Scr Mater 58:99–102

Acknowledgements

The authors would like to express their gratitude to the editors, the authors of the references, and the reviewers for their helpful suggestions for improvement and publication of this paper.

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was supported by Kim Chaek University of Technology, Pyongyang, Democratic People’s Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Kim, TH., Ju, JM. & Son, WC. Investigation of friction diffusion bonding of Al/Cu lap joint. Weld World 66, 1155–1164 (2022). https://doi.org/10.1007/s40194-022-01290-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01290-9