Abstract

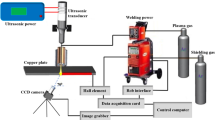

Enhancing the keyholing capability of the plasma arc is of great significance for the welding of medium-thick plate structures. A novel new process of pulsed power ultrasonic vibration assisted plasma arc welding was proposed to realize the effective use of ultrasonic energy and the effective improvement of the plasma arc keyholing ability. Three kinds of plasma arc welding (PAW) experiments without ultrasonic vibration (UV), with continuous power UV and with pulsed power UV were conducted on stainless steel plates to compare the difference of keyholing/penetrating capability of plasma arc. It was found that under the same welding conditions, PAW without UV could not form open keyhole, UV-assisted PAW (U-PAW) could not produce sustainable open keyhole, and pulsed power UV-assisted PAW (PU-PAW) could ensure establishment of open keyhole. And compared to PAW, PU-PAW was able to form an open keyhole even if the welding speed was increased by 10%. The pulsed power UV induced further constriction of plasma arc, and the plasma arc pressure was increased from 955 Pa in PAW to 1391 Pa in PU-PAW, so that the keyholing/penetrating ability of plasma arc was enhanced.

Similar content being viewed by others

References

Wu CS, Wang L, Ren WJ, Zhang XY (2014) Plasma arc welding: process, sensing, control and modeling. J Manuf Process 16:74–85. https://doi.org/10.1016/j.jmapro.2013.06.004

Fortain JM (2008) Plasma welding evolution & challenges. IIW Doc. XII-1948–08: 1–11.

Zhang YM, Zhang SB, Jiang M (2002) Keyhole double-sided arc welding process. Weld J 81(11):249s–255s

Wu CS, Jia CB (2016) Plasma arc welding technology. In: Encyclopedia of plasma technology, First Edition. DOI: https://doi.org/10.1081/E-EPLT-120053341, Taylor & Francis.

Vredeveldt HL (2014) Increased power density plasma arc welding: the effect of an added radial gas flow around the arc root. Dissertation, Delft University of Technology

Li TQ, Yang XM, Chen L, Zhang Y, Cheng LY, Chun YJ (2020) Arc behaviour and weld formation in gas focusing plasma arc welding. Sci Technol Weld Join 25:329–335. https://doi.org/10.1080/13621718.2019.1702284

Li TQ, Chen L, Zhang Y, Yang XM, Lei YC (2020) Metal flow of weld pool and keyhole evolution in gas focusing plasma arc welding. Int J Heat Mass Transf 150:119296. https://doi.org/10.1016/j.ijheatmasstransfer.2019.119296

Mahrle A, Schnick M, Rose S, Demuth C, Beyer E, Füssel U (2011) Process characteristics of fibre-laser-assisted plasma arc welding. J Phys D Appl Phys 44:345502. https://doi.org/10.1088/0022-3727/44/34/345502

Zhang YM, Liu YC (2007) Control of dynamic keyhole welding process. Automatica 43:876–884. https://doi.org/10.1016/j.automatica.2006.11.008

Wu CS, Jia CB, Chen MA (2010) A control system for keyhole plasma arc welding of stainless steel with medium thickness. Weld J 89(11):225s–231s

Liu ZM, Liu YK, Wu CS, Luo Z (2015) Control of keyhole exit position in plasma arc welding process. Weld J 94(6):196s–202s

Da Cunha TV, Bohórquez CEN (2015) Ultrasound in arc welding: a review. Ultrasonics 56:201–209. https://doi.org/10.1016/j.ultras.2014.10.007

Sun QJ, Lin SB, Yang CL, Zhao GQ (2009) Penetration increase of AISI 304 using ultrasonic assisted tungsten inert gas welding. Sci Technol Weld Join 14:765–767. https://doi.org/10.1179/136217109X12505932584772

Fan YY, Yang CL, Lin SB, Fan CL, Liu WG (2012) Ultrasonic wave assisted GMAW Weld J 91:91s–99s

Fan CL, Zhou L, Liu Z, Yang CL, Lin SB, Xie WF, Tong H (2018) Arc character and droplet transfer of pulsed ultrasonic wave-assisted GMAW. Int J Adv Manuf Technol 95:2219–2226. https://doi.org/10.1007/s00170-017-1414-7

Jose MJ, Kumar SS, Sharma A (2016) Vibration assisted welding processes and their influence on quality of welds. Sci Technol Weld Join 21:243–258. https://doi.org/10.1179/1362171815Y.0000000088

Wu CS, Zhao CY, Zhang C, Li YF (2017) Ultrasonic vibration-assisted keyholing plasma arc welding. Weld J 96:279s–286s

Zhang C, Wu CS, Tian SS (2020) Effect of ultrasonic vibration on current density and keyholing capability of plasma arc. Sci Technol Weld Join 25:422–430. https://doi.org/10.1080/13621718.2020.1735062

Tian SS, Wang L, Wu CS, Tanaka M (2021) Influence of ultrasonic vibration on keyholing/penetrating capability in plasma arc welding with controlled pulse waveform. Weld World 65(6):1107–1117. https://doi.org/10.1007/s40194-021-01115-1

Wang JF, Sun QJ, Liu JP, Wang B, Feng JC (2017) Effect of pulsed ultrasonic on arc acoustic binding in pulsed ultrasonic wave-assisted pulsed gas tungsten arc welding. Sci Technol Weld Join 22:465–471

Chen C, Fan CL, Cai XY, Lin SB, Yang CL, Zhuo YM (2020) Microstructure and mechanical properties of Q235 steel welded joint in pulsed and un-pulsed ultrasonic assisted gas tungsten arc welding. J Mater Process Tech 275:116335. https://doi.org/10.1016/j.jmatprotec.2019.116335

Li YF, Wu CS, Chen MA (2020) Effects of ultrasonic vibration on the transport coefficients in plasma arc welding. Metals 10:312

Jia C, Wu CS, Gao JQ (2010) Study on the thermal lag effect of keyhole in controlled pulse key-holing plasma arc welding. Acta Metall Sin 46:991–996. https://doi.org/10.3724/SP.J.1037.2010.00073

M Zare M JampourFarrokhi (2011) A heuristic method for gray images pseudo coloring with histogram and RGB layers. IEEE 3rd Int Conf on Communication Software and Networks, 27–29 May 2011 Xi’an China https://doi.org/10.1109/iccsn.2011.6014949

Funding

This study is funded by the National Natural Science Foundation of China (Grant No. 51775312).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Qiao, J., Fang, B. & Wu, C. Effect of pulsed power ultrasonic vibration on keyholing/penetrating capability in waveform-controlled plasma arc welding. Weld World 66, 529–539 (2022). https://doi.org/10.1007/s40194-021-01226-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01226-9