Abstract

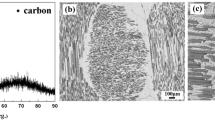

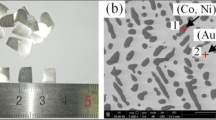

Cf/SiC composites were joined to itself with (and without) Mo interlayer at 1150 °C for 10 min by Cu–Pd–V filler metal. For two kinds of the joints, after the interfacial reactions, continuous V–C layers and dispersive V–C particles were formed at surface of the joined Cf/SiC composite. It was worth noting that much more dispersive particles were formed in case of Cf/SiC–Mo–Cf/SiC joint which was favorable to the Cf/SiC joint strength. Meanwhile, when adding a Mo interlayer in Cf/SiC joint, a continuously distributed (V, Mo)–Si compounds with high melting point was formed near the Mo interface, which can strengthen the joining interface and improve the high-temperature strength. As a consequence, the joint strength at room temperature was remarkably increased to 148.9 MPa from 99.3 MPa by inserting the Mo interlayer. When tested at 800 °C, the average three-point bend strength of the joints was improved to 120.1 MPa, nearly twice of that without Mo interlayer.

Similar content being viewed by others

References

Zhang Y, Xu Y D, Lou J J, Zhang L T, Cheng L F (2005) Braking behavior of C/SiC composites prepared by chemical vapor infiltration. J Appl Ceram Tec 2:114–121

Ishikawa T, Kajii S, Matasanaga K, Hogani T, Kohtoku Y, Nagasawa T (1998) A tough, thermally conductive silicon carbide composite with high strength up to 1600 °C in air. Science 282:1295–1297

Rebelo Kornmeier J, Hofmann M, Schmidt S (2007) Non-destructive testing of satellite nozzles made of carbon fibre ceramic matrix composite C/SiC. Mater Charact 58:922–927

Sanokawa Y, Ido Y, Sohda Y (1997) Application of continuous fiber reinforced silicon carbide matrix composites to a ceramic gas turbine model for automobiles. Ceram Eng Sci Proc 18:221–228

Asthana R, Singh M, Sobczak N (2010) Wetting behavior and interfacial microstructure of palladium- and silver-based braze alloys with C-C and SiC-SiC composites. J Mater Sci 45:4276–4290

Weil K S, Hardy J S, Rice J P, Kim J Y (2006) Brazing as a means of sealing ceramic membranes for use in advanced coal. Fuel 85:156–162

Tillmann W, Lugscheider E, Schlimbach K, Manter C, Indacochea J E (1998) Heat-resistant active brazing of silicon nitride. Part 2: Metallurgical characterization of the braze joint. Weld J 77:103–108

Asthana R, Singh M (2008) Joining of partially sintered alumina to alumina, titanium, Hastealloy and C-SiC composite using Ag-Cu brazes. J Eur Ceram Soc 28:617–631

Chen B, Xiong H P, Cheng Y Y, Mao W, Ye L, Li X H (2010) Microstructure and Strength of Cf/SiC joints with Ag-Cu-Ti brazing filler. J Mater Eng 10:27–31(in Chinese)

Xiong J H, Huang J H, Zhang H, Zhao X K (2010) Brazing of carbon fiber reinforced SiC composite and TC4 using Ag-Cu-Ti active brazing alloy. Mat Sci Eng A 527:1096–1101

McDermid J R, Drew RAL (1991) Thermodynamic brazing alloy design for joining silicon carbide. J Am Ceram Soc 74:1855–1860

McDermid J R, Pugh M D, Drew RAL (1989) The inter-action of reaction-bonded silicon carbide and Inconel 600 with a nickel-based brazing alloy. Metall Mater Trans A 20:1803–1810

Tong Q Y , Cheng L F, Zhang L T (2002) Micro structure and Properties of Joints of 2D C/SiC Composites. J Mater Eng 11:14–21 (in Chinese)

Li W W, Chen B, Xiong Y, Xiong H P, Cheng Y Y, Zou W J (2017) Joining of Cf/SiBCN composite with two Ni-based brazing fillers and interfacial reactions. J Mater Sci Technol 33:487–491

Tamai T (1996) Reaction phases in SiC/SiC or Si3N4/Si3N4 joint brazed with Cu-Ti alloys. J Mate Sci Lett 15:1025–1027

Xiong H P, Chen B, Pan Y, Mao W, Cheng Y Y (2014) Interfacial reactions and joining characteristics of a Cu-Pd-V system filler alloy with Cf/SiC composite. Ceram Int 40(6):7857–7863

Xiong H P, Chen B, Zhao H S, Cheng Y Y, Ye L (2016) V-containing-active high-temperature brazes for ceramic joining. Weld World 60:99–108

Xiong H P, Chen B, Pan Y, Zhao H S, Ye L (2014) Joining of Cf/SiC composite with a Cu-Au-Pd-V brazing filler and interfacial reactions. J Eur Ceram Soc 34(6):1481–1486

Qin Y, Feng J. Active brazing carbon/carbon composite to TC4 with Cu and Mo composite interlayer (2009). Mater Sci Eng A 525:181–185

Deng J L, Zheng B H, Fan S W, Wang X, Zhang L T, Cheng L F (2018)Influence of thermal shock and environment temperature on mechanical properties of C/SiC/GH783 joint brazed with Cu-Ti+Mo. Adv Compos Hybrid Mater 1:199–205

Li Z F, Liu H Y, Li A J, Zhang H L, Huang Y P, Shi Y (2014) Effect of microstructure of Mo-Cu alloy on the thermal expansion coefficient. Adv Mater Res 873:67–71

Li W W, Chen B, Xiong H P, Zou W J, Ren H S (2017) Reactive brazing Cf/SiC to itself and to Mo using the NiPdPtAu-Cr filler alloy. J Eur Ceram Soc 37:3849–3859

Liu G W, Valenza F, Muolo M L, Passerone A (2010) SiC/SiC and SiC/Kovar joining by Ni-Si and Mo interlayers. J Mater Sci 45(16):4299–4307

Li W, Chen B, Xiong H, Zou W, Ren H (2019) Joining of Cf/SiC composite to GH783 superalloy with NiPdPtAu-Cr filler alloy and a Mo interlayer. J Mater Sci Technol 35:2099–2106

Funding

This work is supported by the National Nature Science Foundation of China under grant nos. 59905022, 50475160, and 51275497. We also would like to thank the Aeronautical Science Foundation of China under grant 2008 ZE21005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Li, W., Feng, H., Chen, B. et al. Joining of Cf/SiC composite with Cu–Pd–V filler alloy and Mo interlayer. Weld World 65, 713–719 (2021). https://doi.org/10.1007/s40194-020-01033-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01033-8