Abstract

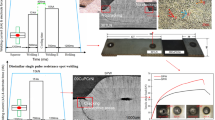

This paper presents the influence of welding current, electrode-workpiece distance, electrode composition, electrode diameter, electrode tip angle, shielding gas composition, and pulsed current frequency over the arc stagnation pressure of gas tungsten arc welding (GTAW). In this study, arc application tests were carried out over a 1-mm diameter hole on a non-melting water-cooled copper plate. The hole was connected to a differential pressure sensor through an extension tube. As a result, the welding arc pressure was observed to be directly proportional to the square of the welding current and to the tungsten electrode diameter. Moreover, the pressure increases as the electrode-workpiece distance is reduced, and it is inversely proportional to the electrode tip angle, for angles greater than 45°. Also, the electrode composition, the pulsed current frequency, and the gas composition influence the welding arc stagnation pressure.

Similar content being viewed by others

References

Lin ML, Eagar TW (1986) Pressures produced by gas tungsten arcs. Metall Trans B 17(3):601–607

Lee SY, Na S-J (1996) A numerical analysis of a stationary gas tungsten welding arc considering various electrode angles. Weld J Incl Weld Res Supplement 75(9):269s

Lancaster JF (1984) The physics of welding. Phys Technol 15(2):73

Fan D, Ushio M, Matsuda F (1986) Numerical computation of arc pressure distribution (welding physics, process & instrument). Trans JWRI 15(1):1–5

Fan HG, Shi YW (1996) Numerical simulation of the arc pressure in gas tungsten arc welding. J Mater Process Technol 61(3):302–308

Rokhlin SI, Guu AC (1993) A study of arc force, pool depression, and weld penetration during gas tungsten arc welding. Weld J (USA) 72(8):381

Converti J (1981) Plasma-jets in arc welding. Tese de Doutorado. Massachusetts Institute of Technology

Guu AC, Rokhlin SI (1992) Technique for simultaneous real-time measurements of weld pool surface geometry and arc force. Weld J N Y 71:473-s

Oh D-S, Kim Y-S, Cho S-M (2005) Derivation of current density distribution by arc pressure measurement in GTA welding. Sci Technol Weld Join 10(4):442–446

Saedi HR, Unkel W (1988) Arc and weld pool behavior for pulsed current GTAW. Weld J 67(11):247

Lin ML, Eagar TW (1985) Influence of arc pressure on weld pool geometry. Weld J 64(6):163s–169s

Burleigh TD, Eagar TW (1983) Measurement of the force exerted by a welding arc. Metall Mater Trans A 14(6):1223–1224

Adonyi Y, Richardson RW (1992) BAESLACK, WAIII. Investigation of arc force effects in subsurface GTA welding. Weld J (USA) 71(9):321

Adonyi-Bucuroiu I (1989) A study of arc force effects during submerged gas tungsten-arc welding. Tese de Doutorado. The Ohio State University

Savage WF, Nippes EF, Agusa K (1979) Effect of arc force on defect formation in GTA welding. Weld J 58(7):212

Goodarzi M, Choo R, Toguri JM (1997) The effect of the cathode tip angle on the GTAW arc and weld pool: I. Mathematical model of the arc. J Phys D Appl Phys 30(19):2744

da Cunha TV, Bohórquez CEN (2014) Dispositivo para medição da pressão do arco e sua aplicação no estudo do processo TIG. Soldagem Inspeção 19(2):152–158

Matsuda F, Ushio M, KUMAGAI T (1989) Fundamental arc characteristics of La-, Y-and Ce-oxide tungsten electrodes. Weld Int 3(6):497–502

Yamauchi N, Taka T (1979) TIG arc welding with a hollow tungsten electrode. International Institute of Welding, Document, n. 212–452, p. 79

Murphy AB et al (2009) A computational investigation of the effectiveness of different shielding gas mixtures for arc welding. J Phys D Appl Phys 42(11):115–205

Zähr J et al (2012) Numerical and experimental studies of the influence of process gases in TIG welding. Weld World 56(3–4):85–92

da Cunha TV (2013) Desenvolvimento e avaliação de tecnologia para soldagem TIG com pulsação ultrassônica. 266 f. Tese (Doutorado) - Curso de Pós-graduação em Engenharia Mecânica, Universidade Federal de Santa Catarina, Florianópolis, 2013

Cook GE, Eassa HE-DEH (1985) The effect of high-frequency pulsing of a welding arc. IEEE Trans Ind Appl (5):1294–1299

Yamaota T, Shimada W, Gotoh T (1979) Characteristics of high frequency pulsed DC TIG welding process. Weld Res Abroad 25(10)

NXP Semiconductors, Datasheet MPXV7002DP. March 2017. [Online]. Available: https://www.nxp.com/docs/en/data-sheet/MPXV7002.pdf

Lancaster JF (1986) Metal transfer and mass flow in the weld pool. In: Lancaster JF (ed) The physics of welding, 2nd edn. [s.l.]. Cap. 7, Pergamon, pp 228–305

Acknowledgments

The authors are grateful to the Welding Technology Laboratory (LTS) of the Federal University of Santa Catarina (UFSC, Technological Center of Joinville), the Brazilian National Council for Scientific and Technological Development (CNPq), and the company IMC Soldagem for supporting of this work.

Funding

The Brazilian National Council for Scientific and Technological Development (CNPq) supported the present work by funding research grants.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest/competing interests

Not applicable.

Availability of data and material

Not applicable.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for Publication by Commission II - Arc Welding and Filler Materials

Rights and permissions

About this article

Cite this article

de Simas Asquel, G., Bittencourt, A.P.S. & da Cunha, T.V. Effect of welding variables on GTAW arc stagnation pressure. Weld World 64, 1149–1160 (2020). https://doi.org/10.1007/s40194-020-00919-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00919-x