Abstract

Purpose

A pilot composting project was initiated as part of a 200 tons/day solid waste recycling plant with active involvement of several local stakeholders. The project aimed at introducing compost production and use in the village of Al Jalameh, Palestine. This paper describes the successes and lessons from the pilot project.

Methods

Based on the data collected on the population, waste production and economic activities, the best production methodology and composting units were designed and piloted. The compost was produced from animal manure, farm waste and organic fraction of domestic solid waste. Approaches to increase profit and sustain the initiative was implemented.

Results

The facility managed by Al Jalameh Agricultural Cooperative Society, recycles 60% organic fraction of domestic waste reducing the quantity of waste to the landfill. An estimated 1425 m3/year of compost are required for local agriculture while 800 tons/year is produced. With most of their compost coming from Israeli sources, the composting facility is at a competitive advantage. To increase the profit, around 28,125 kg of waste plastic sheets from greenhouses are collected for recycling each year generating a stable income of 5625.00 JOD/year.

Conclusions

The compost produced in the village is purchased by the local farmers increasing access to compost at competitive price. Farmers are economically encouraged by compost production that could solve the organic waste management issue and at the same time guarantee a sort of “self-production” of fertiliser useful for local agriculture. This initiative could be extended to other villages in Jenin and other developing countries where agriculture is their major occupation.

Similar content being viewed by others

Introduction

The Middle East is marked by increasing environmental problems. The Occupied Palestinian Territories is no exception. In Occupied Palestinian Territories, the increasing environmental degradation is worsened by years of conflicts. The area is characterized by dense and rapidly increasing population coupled with scarce water resources, climate change and land degradation. Their environmental situation is regarded as alarming (Zurbrugg and Drescher 2002) and strictly intertwined with political background (ARIJ 1997). The decades of conflict have affected Palestinian authorities’ efforts to safely and sustainably manage their environment and natural resources.

Open dumping and burning of solid wastes, which is considered a primitive form of landfilling (Rushbrook and WHO 2001) is practiced in most areas of Palestine (ARIJ 2005). This practice poses several threats both to humans and the environment. For instance, open dumpsites are susceptible to open burning and exposed to scavengers and disease vectors (Karthikeyan et al. 2007; Kurian and Visvanathan 2007; Mannapperuma and Basnayake 2004). Population living in the proximity of dumpsites are reported to suffer from various diseases (cholera, diarrhoea and malaria, where present), resulting from direct and indirect exposure to open dumping (Sankoh et al. 2013). Leachate generated from decomposing organic matter in waste can contaminate surface and groundwater. Additional public health risks associated with open burning of wastes are air pollution and explosions. Methane and carbon dioxide which are major greenhouse gases are associated with anaerobic decomposition of waste (Hegde et al. 2003). The scattering of wastes by wind and scavenging by animals create aesthetic nuisance (Abah and Ohimain 2010). Not the least is the odour emanating from the degradation of the waste which could become a disturbing issue for the surroundings. Moreover, scavengers working on the dumpsites are constantly exposed to gaseous emission from wastes and obnoxious odour, overheating and disease-carrying animals (like rats, reptiles and insects) (Thirarattanasunthon et al. 2012).

To develop a proper waste management system, the Palestinian Development and Investment Limited (PADICO) incorporated the Palestinian Solid Waste Recycling Company (TADWEER) in 2009 to implement waste recycling in the country. JSC (the local Joint Service Council for Solid Waste Management in the Governorate of Ramallah and Al Bireh) and Municipality signed a contract making the JSC responsible for providing the main infrastructure required for the collection and transportation of the separated waste to the recycling plant whiles the municipality makes available at least 1 dunum (1000 m2) of land for the establishment of the agricultural waste recycling and composting station. The goal set for the project was to ensure 50% recycling of the municipal solid waste. The recycling plant was designed for a capacity of 200 tons/day of solid waste and composed of screening and mechanical and manual sorting lines. The waste is separated for cartoons, plastic bottles, glass, and metals and the residual mixed waste is sent to the landfill. The recyclable materials are bagged for easy shipping to Israel and Jordan due to the absence of companies in Palestine to reuse the materials. All the non-recyclable materials are shredded to reduce the size before landfilling with the residual mixed waste after separation.

The recycling plant is unable to recycle all the daily amount of waste generated because of the presence of a robust mixture of dry and wet fractions with the wet fraction accounting for 60–70% by weight of the total waste stream (ARIJ 2005). The JSC promoted the pilot project of recycling waste in the village of Al Jalameh with the aim of expanding the recovery and recycling ratio to all the villages in Jenin area by improving differentiated collection system and organic waste composting and reducing landfilled fraction. In this way, Al Jalameh could send to the landfill only 40% of the total urban waste as the remaining 60% organic waste would be composted. In this regard, containers for the wet waste fractions were strategically located in the surroundings of the houses in the village and organic waste is collected daily by the JSC.

An Al Jalameh Agricultural Cooperative Society (ACJ) showed interest in the project, above all in the production of compost with municipal organic waste. For this reason, the ACJ, the municipality of Marij Ibn Amer and Palestinian Agricultural Relief Committee, an agricultural development association, signed an agreement to create a station for recycling and composting to be managed by Al Jalameh Agricultural Cooperative. In the composting station, wet waste from farms, mainly greenhouse residues and manure, is collected to produce compost that could be sold to farmers on the local market thereby helping to improve agricultural practices towards a more sustainable agriculture. The beneficiaries of the project are the about 2700 villagers who, thanks to a better organization of the waste collection system focused on recycling, can improve their living conditions both from the hygiene and environmental point of view.

In this context, a pilot project was established to optimize organic waste collection and composting for local agriculture. This pilot project was implemented through agreement between the Department of Civil, Chemical, Environmental and Materials Engineering (DICAM) of the University of Bologna, Italy and the Arab American University of Jenin, contributing to a common research and design activities, with the contribution of the consortium Nexus Emilia Romagna and “Meets Jenin” association in partnership with PARC NGO and JSC.

Materials and methods

Description of the project area

Al Jalameh is a village in the West Bank, located 6 km north of the city of Jenin in Jenin governorate, Palestine. The estimated terrain elevation is 120 m above sea level and the annual rainfall is 300–400 mm. According to the Palestinian Central Bureau of Statistics, the town had a population of 2560 inhabitants in 2016 (PCBS 2017). The main economic activity of the people of Al Jalameh is rainfed and irrigated agriculture and animal rearing. Farming activities are carried out both in greenhouses and on open fields. Wheat and olive are cultivated on open fields whiles vegetables are cultivated in both greenhouses and open fields. Animals reared include poultry, small ruminants, and cattle. The village is considered to be agriculturally advanced due to its proximity to the green line as plastic houses and irrigated vegetation spread throughout its relatively small basin (LRC 2004). Figure 1 is a map showing Al Jalameh in Jenin.

Map showing Al Jalameh (LRC 2004)

Project approach

To achieve the goals of the pilot project, two main steps were firstly identified and carried out:

- 1.

Waste separation at the source, involving households, schools, businesses and farms.

- 2.

Creation of a collection system for organic waste and composting station, in cooperation with the Municipality and operated by the Agricultural Cooperative.

The first step of the project was developed on data collection, in terms of inhabitants and waste production in the East Jenin area including: Al Jalameh, Arraneh, Arrabuneh, Deir Ghazaleh, Jaloun, Faqoua’ah, Beat Qad, Deir Abu Di’ef, Um Al Tut, Jalqamous, Al Mugayer, Raba, and Arab American University (AAUJ). The best production methodology and the composting units were designed, considering the quantity and percentage of each kind of organic matter.

Composting materials and process

The compost was produced from municipal organic waste, agricultural waste and ash. Agricultural waste is generated from greenhouses (such as vegetables, damaged fruits and vegetables), animal manure and dry plants (straw and stalks of maize).

An open composting system (windrow or pile) was adopted for the case study due to the relatively short production time and less construction and operation cost. “Open” systems are the typical composting units realized in developing countries (Zurbrugg and Drescher 2002; Zurbrugg 2003). The open system of composting follows an orderly way of organizing the layers. The minimum required area for a composting unit is 1.25 m × 1.25 m (Edwards and Araya 2011), to prevent the heap from drying out quickly affecting the quality of the final compost produced. The area dedicated to the compost station in the present case study was around 3 m × 2.5 m. In the beginning, a shallow trench of depth, 20 cm and same surface area of 3 m × 2.5 m was dug. The bottom and sides of the trench were watered to prevent moisture rich in nutrients from leaking out of the base of the compost heap as proposed by Edwards and Araya (2011).

In windrow composting, the materials are piled up in elongated heaps (Rothenberger et al. 2006). The amount of heat produced is determined by the size of the pile whiles aeration is guaranteed through addition of bulky materials, passive or active ventilation or regular turning (Rothenberger et al. 2006; Strauss et al. 2003). Heat generated through thermophilic phase is used to disinfect the compost. The first layer is typically constituted by dry plant material, in this case using strong grass straw and long stalks of maize as used by Mhindu et al. (2013). The straw and stalks of maize were broken into fragments of short length and sprinkled in the shallow trench. Dry materials serve as foundation to the compost-making process by providing air-circulation spaces to ensure air supply to microorganisms for metabolism and heat production. This foundation layer also serves as drainage path for excess water from the upper layers of the heap. This layer was about 10 cm thick.

The second layer, which was 15 cm thick, consisted of animal manure obtained from herders. Animal dung has been found to contain high amount of nitrogen, phosphorous, potassium (Abbas et al. 2015; Brown 2008), and micro-nutrients (Dach and Starmans 2005) which promote microbial activity. The third layer was constituted of green plant materials, either fresh or wilted, mainly waste from operating greenhouses, such as damaged fruits and vegetables. Green materials also provide moisture and nutrients to the microorganisms for the decomposition of organic materials and humus (Edwards and Araya 2011). This layer was 25 cm thick. Some literature seems to exclude the need to sprinkle water on this layer (Dall’Ara et al. 2010, 2012), but in this case study, water was sprinkled on the layer because of the warm local climate. The importance of ash as admixture in composting has been well documented. Ash has been found to contain both macro and micro-nutrients (Kuba et al. 2008), increase microbial composition and activity (Jokinen et al. 2006), improve oxygenation and reduce odour emissions (Koivula et al. 2004), improves nutrient content and produce aesthetically appealing compost (Campbell et al. 1997). As additional step, ash was sprinkled on the pile bearing in mind that too much ash affects the quality of the compost produced as has been reported by some researchers (Campbell et al. 1997; Kurola et al. 2011). The ash was obtained from a local baker that bakes bread in the tabon (a clay oven shaped like a truncated cone). In the end, a soil cover was added, that contributed to biodegradation of the organic materials into mature compost with a complete ecosystem of bacteria, fungi, insects and small animals. The height of the heap ranged from 1.0 to 1.5 m tall. The heap was shaped such that the middle layers are thicker than at the sides forming a dome shape (Edwards and Araya 2011), which prevent excessive rainwater from entering the pile. In warm climates, as in this case study, the compost was turned after 1 month.

Results and discussions

Context description

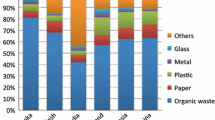

The population of the communities involved in the project, on the basis of preliminary data collection, was around 27,272 (PCBS 2008), and the average solid waste generation was about 20 tons/day. For these villages, JSC collects waste three times per week using the same work plan, driver and workers. The composition of municipal solid waste in Al Jalameh is presented in Table 1.

The daily household solid waste generated in the West Bank was 1728.2 tons (PCBS 2006) and the average waste generation per capita in rural areas such as Al Jalameh (which is considered a small village based on agricultural activities), is in the range of 0.4–0.6 kg/capita/day (ARIJ 2005). The case study proved to be important to support Palestinian Authority in developing measures on sustainable use of resources, considering wider economic, social and environmental consequences. On this issue, a very important achievement was the involvement of several stakeholders for sharing and diffusion of the urban waste separation, collection and organic waste composting project. In particular, an interesting result has been the involvement of women that are the first drivers of improved waste management from children education and house behaviour points of view.

Important added value is experimenting new models of waste management for a developing country as Palestine, for environmental and human health protection and to promote valorisation of urban waste as secondary raw materials, according to the principle of circular economy.

Integrated composting

Unit description

The 800 tons/year capacity composting plant realized comprised an operation area and a stock area. The operation area is divided into different compartments with space for compost maturation, shredding, bagging (in the second phase) and storage. The actual composting processes are performed on an area designated for that purpose, outside the operation area (not shown on the layout in Fig. 2). The stock area includes all the waste unloading and sorting, as well as storage space for recyclable plastics from greenhouses. The compartments have been arranged to ensure efficient workflow of the composting process. Figure 2 shows the layout of the compost station.

Description of the production processes and products

The ACJ tractor is used to purchase animal manure from herders and to collect the farm waste (hay) mainly on a seasonal manner; mostly at the beginning of summer and during autumn season. The farm waste quantities are stored in the collection area inside the compost station. As the organic waste separation starts from the household level in Al Jalameh, the domestic waste is brought to the compost station by the JSC workers in bulk to avoid leakage and start of the heap decomposition process. When all the components are on site, they are selected, prepared and the heaping process for the new pile starts. In the layout of the compost station, stockpiles are kept in a container near the shredding machine to reduce turn-around time. On the average 2000 tons/year of agricultural waste and 400 tons/year of municipal organic waste are used for composting. About 800 tons of compost is produced a year with a process efficiency of 30%. The ratio of organic waste to agricultural waste for the composting process was 1:20. The process flow diagram for the composting is shown in Fig. 3.

Business plan

According to Rouse et al. (2008) “marketing is about identifying and targeting customers and succeeding to sell products that satisfy customers at a price and in sufficient quantity to ensure the success of a business”. Similar to other products, in marketing compost, it is important to identify the target markets and potential competitors. Composting is not of common use in Al Jalameh. However, the Cooperative argued that selling the compost was not a problem as all the members of the Cooperative were encouraged to buy and to try the compost, forming the marketing approach for the first period of establishment of the composting plant. Table 2 presents information on agricultural status and compost needs in Al Jalameh area.

It is clear from Table 2 that there will be a total demand/need for compost of 1425 m3 annually (based on 675 m3 for green houses and 750 m3 for open fields) to serve the planted areas available in Al Jalameh. However, from the perspective of the ACJ members, it was recommended to perform analysis based on compost use inside the green houses rather than for the open field agriculture. This restricted the annual demand for the compost to around 675 m3 in Al Jalameh area.

Farmers in Al Jalameh use different types of fertilisers; chemical, organic, and compost fertilisers from Israel, Jordanian and individual local suppliers. Recent use of different types, sources, quantities and cost of fertilisers in Al Jalameh is presented in Table 3.

From Table 3, the cost of fertilisers for 1000 m2 of farmland ranges from NIS 720–900 for compost up to NIS 1500 for chemical fertiliser. The farmers using the compost were supplied mainly from Israeli sources. This implies that it is economically feasible to obtain a market share for the compost produced locally. In terms of composting, there are limited initiatives in the region that might be classified as actual competitors for the compost production in Al Jalameh. An analysis of local competitors for the compost revealed selling price as NIS 12.00–15.00 per 25 L of product (equivalent to NIS 480.00–600.00 per m3), with a production of 1333 m3 per year or 53.3 m3 per season. Similar to the findings from India (Drescher and Zurbrügg 2004) financial profits from compost sales proved to be very small, far from obtaining ‘gold from waste’. However, the objective of the composting project was not to make profit but for farmers to use the compost produced at the plant which is cheaper (about 40–52%) than chemical fertiliser. In addition, the long-term benefits from composting is likely to be higher with local government interests in composting coupled with increased and sustained public awareness on the benefits of compost relative to chemical fertilisers.

Compost application in agriculture

Compost is unable to compete favourably with inorganic fertilisers because the latter shows results very quickly (Harper 2004; Rouse et al. 2008). This affects the uptake of compost by farmers and other potential users particularly in low-income areas such as Al Jalameh. But given adequate time, compost has been reported to sustainably improve soil fertility (Diacono and Montemurro 2011; Golabi et al. 2004; Ouédraogo et al. 2001). Farmers in developing countries often cannot afford to wait for long-term results. As shown in Table 3, farmers in this region use large quantities of inorganic fertilisers. Restoring the soil structure due to years of dependence on inorganic fertilisers require relatively large quantities of and high investments in compost which serve as disincentive for local farmers. More often, farmers are not well informed on compost application and performance. This knowledge gap creates unrealistic expectations which leads to disappointment (Rouse et al. 2008) and, consequently, to a switch from compost back to inorganic fertilisers. For this reason, an effort has been made to enhance the awareness of farmers of Al Jalameh and to educate them on the effectiveness of compost as soil conditioner, which may lead to reduction in the need for chemical fertilisers. In addition, the marketing approach of encouraging members of the cooperative to use the compost would lead to a real breakthrough.

Plastic recycling for sustaining compost project

As it is unlikely to recover all the production costs from compost sales, a supplementary source of revenue was identified in reselling of plastics used in greenhouses. Part of the compost plant unit functions is to collect the damaged plastics from the green houses and sell these plastics to a factory in Jalbun area. Damaged plastic sheets and pipes are collected during the changing sheets period. Each farmer, informed of this possibility, contacts the Agricultural Cooperative (ACJ) involved in plastic collection and transport. The ACJ tractor is in charge of collecting the plastic sheets from the farms and storing it (Fig. 4), until the amount of plastics is around one tonne, i.e., the transport lot for the plastic recycling facility in Jalbun. The Jalbun factory is about 15 km from the Al Jalameh village and it is interested in buying plastics from greenhouses, the plastic sheets and the plastic pipes used for irrigation. At the Jalbun factory, the plastics are sorted (Fig. 5) and shredded, washed, dried and plasticised by outside heating or dissolved in a heating chamber and then forced by a plunger into cold moulds to set or extruded. In this case, it is extruded through a sieve, which results in a continuous pipe to be cut into lengths or coiled (extrusion moulding). In this way, the plastics from greenhouses and irrigation pipes are used to produce plastic pipes to be used as conduit for electrical cabling.

From analysis, each 1000 m2 of farmland may be able to return 250 kg of plastic sheets from greenhouses annually. In effect, 60 kg of plastic sheets are expected to be produced by each greenhouse, in this way.

In Al Jalameh village there are 450,000 m2 of area used for greenhouses (Table 1). The total production of plastic sheets from greenhouses will, therefore, be about 112,500 kg/year. Obviously not all the farmers are expected to change the plastic sheets in the greenhouse every year, but approximately every 4 years. Assuming a 4-year changing rate as average, around 28,125 kg of plastic sheets could be available for recycling each year.

Based on an agreement with Jalbun Company Board of Directors, the plastic sheets would be purchased from the Cooperative for 200.00 Jordanian Dinar (JOD) (equivalent to 280 USD) per tonne. In this way, the Cooperative could have a stable income of 5625.00 JOD (equivalent to 7900.00 USD) per year. In the layout of the composting station (Fig. 2), a dedicated area has been identified to stock the plastics coming from the farmers. The Cooperative goes to pick the plastics up from each farmer, thus solving the big issue of greenhouse waste disposal.

Conclusions

Given the large amount of biodegradable waste (about 60%) in the waste stream in Al Jalameh, composting for local agricultural use would provide considerable benefits for the solid waste management system. The organic waste composting is decentralised as the separation of organic fraction and composting is performed as near to the source of generation as possible. This reduces the cost and environmental and health risks associated with the collection and transportation of organic waste. In Al Jalameh village, the farmers are economically encouraged by compost production that could solve the organic waste management issue and at the same time guarantee a sort of “self-production” of fertilisers useful for local agriculture. An annual demand of about 1425 m3 is required by local farmers for planted areas whiles 800 tons/year of compost is produced at Al Jalameh. Using the market price of compost as basis, farmers would still enjoy cheaper prices from the purchase of the compost produced (about 40–52%) compared to chemical fertiliser. The compost production at Al Jalameh was adequate and meets the needs of local farmers, but the financial returns is very small. To address the low financial returns from the sale of compost, a stable annual income of 5625.00 JOD (equivalent to 7900.00 USD) was obtained from the sale of 28,125 kg of plastic sheets from greenhouses to a local recycling company at Jalbun. In addition, majority of the farmers are members of the Agricultural Cooperative Society and so the marketing approach of encouraging members of the cooperative to use the compost produced would ensure sustainability of the project. The strong local stakeholder involvement and the management of the composting plant by a local agricultural cooperative is one of the greatest strengths of the composting project in Al Jalameh. Based on the successes of the pilot composting project, the initiative could be extended to other villages in Jenin and generally to low-income communities in developing countries where agriculture is the major occupation.

Research on this topic is of great importance within this region because of the political and environmental sensitivity, particularly due to the restrictions on the water supply and system imposed by the prevailing political context and the ongoing Palestinian-Israeli conflict. This project highlights the major factors determining solid waste policy making in a socio-political system in transition.

The research investigated technical, economic, and socio-institutional factors that determine biological treatment of waste and it identifies the agencies involved in waste management, but the complexity of the internal and external forces and networks for the different actors and links for decision makers is left for future research.

References

Abah SO, Ohimain EI (2010) Assessment of dumpsite rehabilitation potential using the integrated risk based approach: a case study of Eneka, Nigeria. World Appl Sci J 8:436–442

Abbas M, Manzoor F, Atiq-ur-Rehman M, Kanwar A (2015) Comparison of nitrogen, phosphorus and potassium contents in cow dung and slurry generated in biogas plant. J Agric Res 53:179–186

ARIJ (1997) The Status of the environment in the West Bank. Applied Research Institute—Jerusalem, Bethlehem, Palestine

ARIJ (2005) Analysis of waste management policies in Palestine: domestic solid waste and wastewater. Applied Research Institute—Jerusalem, Bethlehem, Palestine

Brown C (2008) Available nutrients and value for manure from various livestock types. Factsheet No. 08-041. Ministry of Agriculture. Food and Rural Affairs Ontario, Canada

Campbell AG, Folk RL, Tripepi RR (1997) Wood ash as an amendment in municipal sludge and yard waste composting processes. Compost Sci Util 5:62–73. https://doi.org/10.1080/1065657X.1997.10701864

Dach J, Starmans D (2005) Heavy metals balance in Polish and Dutch agronomy: actual state and previsions for the future. Agri Ecosyst Environ 107:309–316. https://doi.org/10.1016/j.agee.2005.02.017

Dall’Ara A, Billi L, Bonoli A, Poglayen J, Massi P, Golfari G (2010) On-farm fertilizer production optimization. In: Ecomondo 2010. Conference WASTE. Industrial research related to management and enhancement, Rimini, Italy, 3–6 Nov 2010. Maggs, Milan, Italy, pp 32–38

Dall’Ara A, Bonoli A, Serranti S (2012) An innovative procedure to characterize properties from tailored composts. Environ Eng Manag J 11:1825–1832

Diacono M, Montemurro F (eds) (2011) Long-term effects of organic amendments on soil fertility. A review. Vol 2. Sustainable agriculture. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-0394-0_34

Drescher S, Zurbrügg C (2004) Decentralized composting in India. In: Ali M (ed) Sustainable composting: case studies and guidelines for developing countries. WEDC, UK

Edwards S, Araya H (2011) How to make compost. In: Lim LC, Edwards S, Scialabba NE-H (eds) Climate change and food systems resilience in Sub-Saharan Africa. Food and Agriculture Organization of the United Nations, Rome, Italy

Golabi MH, Denney M, Iyekar C (2004) Use of composted organic wastes as alternative to synthetic fertilizers for enhancing crop productivity and agricultural sustainability on the tropical island of Guam. In: 13th International Soil Conservation Organization Conference: conserving soil and water for society: sharing solutions from 4 to 8 July 2004, Brisbane, Australia, 2004. Australian Society of Soil Science Inc, pp 1–6

Harper M (2004) A composting business in India. In: Ali M (ed) Sustainable composting: case studies and guidelines for developing countries. WEDC, UK

Hegde U, Chang T-C, S-s Yang (2003) Methane and carbon dioxide emissions from Shan-Chu-Ku landfill site in northern Taiwan. Chemosphere 52:1275–1285. https://doi.org/10.1016/S0045-6535(03)00352-7

Jokinen HK, Kiikkilä O, Fritze H (2006) Exploring the mechanisms behind elevated microbial activity after wood ash application. Soil Biol Biochem 38:2285–2291. https://doi.org/10.1016/j.soilbio.2006.02.007

Karthikeyan OP, Swati M, Nagendran R, Joseph K (2007) Performance of bioreactor landfill with waste mined from a dumpsite. Environ Monit Assess 135:141–151. https://doi.org/10.1007/s10661-007-9709-z

Koivula N, Räikkönen T, Urpilainen S, Ranta J, Hänninen K (2004) Ash in composting of source-separated catering waste. Bioresour Technol 93:291–299. https://doi.org/10.1016/j.biortech.2003.10.025

Kuba T, Tschöll A, Partl C, Meyer K, Insam H (2008) Wood ash admixture to organic wastes improves compost and its performance. Agric Ecosyst Environ 127:43–49. https://doi.org/10.1016/j.agee.2008.02.012

Kurian J, Visvanathan C (2007) Dumpsite rehabilitation. In: Lehmann EC (ed) Landfill research focus. Nova Science Publishers Inc, New York, pp 337–360

Kurola JM, Arnold M, Kontro MH, Talves M, Romantschuk M (2011) Wood ash for application in municipal biowaste composting. Bioresour Technol 102:5214–5220. https://doi.org/10.1016/j.biortech.2011.01.092

LRC (2004) Al Jalama: A Border village totally isolated by the wall and the military checkpoints. Applied Research Institute in Jerusalem (ARIJ) and the Land Research Center (LRC). poica.org/2004/04/al-jalama-a-border-village-totally-isolated-by-the-wall-and-the-military-checkpoints/. Accessed 15 Oct 2018

Mannapperuma N, Basnayake B (2004) Tropical climate influence on municipal solid waste landfill dynamics-lysimeter studies. Trop Agric Res 16:316–326

Mhindu RL, Wuta M, Ngorima E (2013) Composting of selected organic wastes from peri-urban areas of Harare, Zimbabwe. Int J Recycl Org Waste Agric 2:14. https://doi.org/10.1186/2251-7715-2-14

Ouédraogo E, Mando A, Zombré N (2001) Use of compost to improve soil properties and crop productivity under low input agricultural system in West Africa. Agric Ecosyst Environ 84:259–266. https://doi.org/10.1016/S0167-8809(00)00246-2

PCBS (2006) The Palestinian environment on world environment day. Palestinian Central Bureau of Statistics, Palistine

PCBS (2008) Summary statistics, west bank (1997–2006). Palestinian Central Bureau of Statistics. http://www.pcbs.gov.ps/Portals/_pcbs/populati/demd3.aspx. Accessed 12 Oct 2018

PCBS (2017) Localities in Jenin governorate by type of locality and population estimates, 2007–2016. Palestinian Central Bureau of Statistics, Palistine

Rothenberger S, Zurbrugg C, Enayetullah I, Sinha M (2006) Decentralised composting for cities of low and middle income countries: a users manual. Waste Concern/EAWAG, Switzerland

Rouse J, Rothenberger S, Zurbrügg C (2008) Marketing compost: a guide for compost producers in low and middle-income countries. EAWAG, Switzerland

Rushbrook P, WHO (2001) Guidance on minimum approaches for improvements to existing municipal waste dumpsites. WHO Regional Office for Europe, Copenhagen

Sankoh FP, Yan X, Tran Q (2013) Environmental and health impact of solid waste disposal in developing cities: a case study of granville brook dumpsite, Freetown, Sierra Leone. J Environ Prot 4:665. https://doi.org/10.4236/jep.2013.47076

Strauss M, Drescher S, Zurbrügg C, Montangero A, Cofie O, Drechsel P (2003) Co-composting of faecal sludge and municipal organic waste: a literature and state-of-knowledge review. International Water Management Institute (IWMI) Accra, Ghana; Swiss Federal Institute of Environmental Science and Technology (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) CH-Duebendorf, Switzerland

Thirarattanasunthon P, Siriwong W, Robson M, Borjan M (2012) Health risk reduction behaviorsmodel for scavengers exposed to solid waste in municipal dump sites in Nakhon Ratchasima Province, Thailand. Risk Manag Healthc Policy 5:97–104. https://doi.org/10.2147/RMHP.S30707

Zurbrugg C, Drescher S (2002) Markets for Compost—a key factor for success of urban composting schemes in developing countries. City Matters Magazine, London

Zurbrugg C (2003) Solid waste management in developing countries. SANDEC/EAWAG, SWM introductory text pp 1–5

Acknowledgements

Authors are grateful to The Nexus Emilia Romagna and “Meets Jenin” Associations for the study opportunity; the Arab American University of Jenin (AAUJ), Palestinian Agricultural Relief Committees (PARC), Al Jalameh Agricultural Cooperative Society and JSC (Joint Service Council for Solid Waste Management in the Governorate of Ramallah and Al Bireh) for supporting in all research phases.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bonoli, A., Zanni, S. & Awere, E. Organic waste composting and sustainability in low-income communities in Palestine: lessons from a pilot project in the village of Al Jalameh, Jenin. Int J Recycl Org Waste Agricult 8, 253–262 (2019). https://doi.org/10.1007/s40093-019-0264-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40093-019-0264-8