Abstract

Mining activities have always raised environmental and social concerns due to their impact on natural resources and people. During the last decade, the stakeholder base expected to respond to these sustainability concerns has broadened from directly involved parties to a range of indirect stakeholders along the downstream mineral value chain. These stakeholders variably engage in reporting, supplier risk assessments, exercising supply chain due diligence, third party assurance, and corporate social responsibility measures. This trend reflects a combination of societal, investor, and regulatory pressure as well as industry self-regulation along the supply chain. The present article examines this development from the complementary perspectives of international regulations and voluntary industry and multi-stakeholder initiatives affecting the industrial and the artisanal mining sector as well as the associated mineral supply chains. To this end, we provide an introductory analysis on the global uptake, implementation challenges, and lessons learnt with regard to both regulatory developments and voluntary initiatives. Key challenges identified include a misalignment between local reforms and international efforts, heterogeneous downstream market requirements, and evasive strategies as well as gaps to report on and achieve positive local sustainability impacts, partly brought about by emphasising corporate risk management over local community priorities. Meaningful stakeholder dialogue and increased local ownership are key factors to overcome some of these challenges.

Similar content being viewed by others

Introduction

Minerals and metals have always been a basis for the development of societies. Growing metal demand reflects population growth as well as economic development and technological progress but will put further pressure on the use of land, water resources, and ecosystems (Wellmer and Becker-Platen 2002). From a climate perspective, the extraction and processing of metals account for a significant share of global greenhouse gas emissions (approximately 10% in 2018; UNEP 2019). Adverse social impacts of poorly managed mining activities are broadly documented in the scientific literature and civil society reports (e.g., Joyce and Thomson 2000; Kemp et al. 2016; Joyce et al. 2018; Mancini and Sala 2018; Mines and Communities 2021; Human Rights Watch 2021). While representing a major livelihood base for more than 40 million people worldwide, artisanal and small-scale mining (ASM) activities may be associated with particularly high risks with regard to human rights violations, including child and forced labour or conflict financing. Concerns by local communities living next to industrial mines often reflect closely linked social, socio-economic, and environmental factors; the latter may be a driver of mining-community conflicts, for instance in cases of risks or adverse impacts on water quality and quantity (Kemp et al. 2010; Franks et al. 2014; Mancini and Sala 2018). Moreover, after agriculture, urbanisation, and infrastructure development, mining activities are the fourth largest driver for global deforestation (Hosonuma et al. 2012).

The obligation of organisations to act responsibly in their operations and within their sphere of influence has been internationally acknowledged in a number of guidelines and conventions. The ISO 26000 Guidance on Social Responsibility (ISO 2010) provides a normative framework for this obligation by defining responsibilities related to seven core categories of sustainability issues (Table 1). These categories include major social and environmental issues as well as fair operating practices along value chains. Social and environmental risks as defined therein relate to adverse impacts in the three social core issues “human rights,” “ labour practices” and “community involvement and development,” as well as to the core issue “environment.” In line with the OECD due diligence guidance for responsible business conduct (OECD 2018a), risk in this context refers “to the likelihood of adverse impacts on people, the environment and society that enterprises cause, contribute to, or to which they are directly linked” Thus, it is not defined by risks for the company itself (such as operational, financial or reputational risk), but rather a more “outward-facing approach to risk” (OECD 2018a).

Over the past decade, the mineral and metal producing industry as well as downstream manufacturing companies has faced growing customer, investor, and business partner expectations in terms of ensuring responsible practice along the supply chain, in line with the above social and environmental risk concept. Public pressure is especially high for the extractive sector because it features the highest risk score among all economic sectors, with environmental risks and social risks having nearly equal shares (S&P Global 2019). This high-risk profile of the mining sector correlates with high media attention on disastrous events and severe human rights as well as environmental impacts. Examples include the Brumadinho tailings dam failure in Brazil, the Diesel spill, and contamination at the Norilsk mining complex in Russia, as well as the occurrence of child labour in some artisanal cobalt mines in the Democratic Republic of the Congo (DRC).

A growing number of industry or multi-stakeholder initiatives and regulatory approaches have been put forward in the mining sector and along mineral supply chains over the past decade. Voluntary initiatives have broadened in scope towards a sector-wide and global perspective, including value chains from mineral extraction to material stewardship in the life cycle of products (Potts et al. 2018; van den Brink et al. 2019). The development of these initiatives reflects and anticipates further public and regulatory pressure on the backdrop of the sustainability challenges that the mining sector is facing. At the same time, they reflect industry self-regulation based on the measures that an increasing number of companies have taken to tackle social and environmental risks associated with their operations and along their supply chains (Ivic et al. 2021). Sustainability issues in mining are therefore increasingly incorporated into integrated sustainable supply chain management where a responsible sourcing approach links up- and downstream supply chains (e.g., Young 2015).

The increasing number of mining sector and supply chain initiatives goes hand in hand with growing sector-specific and cross-sectoral regulation in certain jurisdictions, as well as with the development of soft laws by international organisations such as the UN and the OECD. The concept of supply chain due diligence to safeguard against human rights violations has received special merit over the past decade (e.g., United Nations 2011; OECD 2016, 2018a), and is currently serving as an anchor point to expand risk assessments further, towards social and environmental factors. Associated measures of risk management in the supply chain apply to both large-scale industrial operations as well as the ASM sector.

This article presents an analysis of the development, implementation trends, challenges, and lessons learnt with regard to international regulatory approaches as well as voluntary sustainability initiatives targeting responsible mining and mineral supply chains. The analysis is based on a combined screening of scientific literature as well as public information related to initiatives and regulations. The inclusion of initiatives in the study is based on a data-driven approach using the S&P data base to identify major mining companies and their participation in voluntary initiatives. It is complemented by an expert knowledge-based approach related to relevant regulation, initiatives, and respective impacts based on the authors’ participation in international multi-stakeholder consultation processes that have been conducted in an OECD-hosted working group on due diligence in mineral supply chains since 2009. The selection furthermore draws on the authors’ professional experience in terms of providing advisory services for relevant government departments as well as frequent exchanges with industry and civil society representatives. Finally, the authors draw on experience associated with the long-term German-Congolese technical cooperation activities, in particular as far as local impacts of the respective regulations are concerned. We therefore consider the study’s selection of initiatives and regulations as representative of currently debated international supply chain governance developments, without implying that the inclusion or exclusion of certain regulations or initiatives speaks to their individual market relevance.

The analysis presented in this study focuses on the following key research questions:

-

(1)

What are the most relevant recent developments related to the uptake of environmental and social risks in regulations as well as in voluntary initiatives in mining and along mineral supply chains?

-

(2)

What impacts can be observed related to these efforts and what are the challenges and limitations of these governance approaches?

-

(3)

What lessons learnt may be identified and what do these imply for the future design or review of regulations, initiatives, and associated policy efforts?

To this end, “Responsible sourcing and supply chain due diligence regulationsS8” provides an overview on international regulatory approaches governing mining and mineral supply chains. Building on the due diligence concept initially developed for so-called “conflict minerals”Footnote 1, “Responsible sourcing and supply chain due diligence regulations” then explores some of the impacts of some of these regulations, focussing on the ASM sector in the DRC in Central Africa. This region was selected as a case study for illustration because it has been the geographic target area of one of the first of such regulations, section 1502 of the Dodd-Frank act, enacted in the USA in 2010 (US Congress 2010). For the time being, it is thus the only region that permits discussing the longer-term impacts of these regulations, with implications for the on-going rollout of similar mineral supply chain regulations with a global scope (e.g., European Parliament and Council 2017). Subsequently, “Voluntary sustainability initiatives in mining and mineral supply chains” evaluates the development of voluntary mining and supply chain initiatives and industry self-regulation as a base for identifying current challenges in terms of addressing environmental and social risks as well as overarching sustainability impacts. This evaluation focuses on the large-scale industrial mining sector and thus complements the ASM focus of the previous chapter. Finally, “Lessons learntS2” presents an overview on the lessons learnt associated with the implementation of international regulations and sustainability initiatives so far.

The focus of our analysis is on the international perspective of governance approaches addressing social and environmental risks in mining and mineral supply chains from a responsible mining or responsible sourcing perspective. This concerns (self-) regulations and initiatives imposed on local mining and mineral trading activities by international stakeholders, mainly comprising downstream industry and downstream governments, investors, and multi-national major mining companies and their industry organisations. Highly specialised and commodity-specific initiatives such as the International Cyanide Management Code were excluded. In addition, while national-level mining sector regulation and governance in each mineral-producing country plays a vital part in setting standards and addressing the above risks as well as broader sustainable development issues, the latter developments are considered beyond the scope of the present contribution. Regarding the role of governments and national regulations as well as national governance developments, the reader is referred to Campbell (2012), Andrews et al. (2018), and UNEP (2021). Furthermore, it is important to note that adequate local consultation is critical for the practicality, local ownership and long-term sustainability of proposed international “solutions.” International supply chain approaches, for instance in the DRC’s cobalt sector, have partly been characterised by methodological shortcomings in this regard (e.g., Mancini et al. 2021).

Responsible sourcing and supply chain due diligence regulations

Background and current developments

Over the past decade, upstream (from mine to smelter/refiner) and downstream (manufacturing to sale of end product) supply chain actors, from artisanal miners and mining companies to OEM manufacturers, have been exposed to growing public expectations in terms of ensuring responsible supply and publicly reporting on their efforts. These rising expectations are reflected in a combination of soft and hard laws that either apply at cross-sectoral level or centre on specific sectors, such as certain commodity supply chains, with a focus of due diligence and human rights violations. Additional impetus is provided by the increasing global demand for implementing measures to cut carbon emissions, mitigate climate change effects, and address broader sustainability issues. Managing supply chains by integrating the right suppliers has been identified as the most prominent risk factor for sustainable supply chain management (Song et al. 2017).

The global governance framework guiding supply chain responsibility at the cross-sector level is largely focused on worker rights and human rights due diligence (e.g., Landau and Hardy 2021; Bright 2021). These regulations and guidelines may directly apply to some of the larger mining companies in certain jurisdictions but in many cases represent indirect requirements passed along the supply chain of downstream companies. General reference principles, defining responsibilities for both companies and governments, are provided through the ILO’s Tripartite Declaration of Principles concerning Multinational Enterprises and Social Policy (ILO 2017) and the UN Guiding Principles on Business and Human Rights (United Nations 2011). The OECD, in additional guidance documents, provides recommendations to promote responsible business conduct (OECD 2011; OECD 2018a). These documents complement and operationalise the former reference principles while also broadening the scope towards other adverse impacts, such as those related to corruption and environmental risks.

Several laws have been introduced requiring companies in some jurisdictions to implement certain measures that are broadly in line with or form subtopics of the above guidance documents. Among others, these comprise the EU Non-financial Reporting Directive (European Parliament and Council 2014), reporting under the UK Modern Slavery Act (Parliament of the United Kingdom 2015), and the French law requiring larger companies to apply due diligence or “vigilance” in their area of influence, extending to subsidiaries, suppliers and subcontractors (Assemblée Nationale 2017). While these laws are seen as important initial steps, several shortcomings have been identified, such as an insufficient level of detail in company reporting (Landau and Hardy 2021) or the lack of dialogue with external stakeholders (Bright 2021). The EU is currently developing a regulatory proposal on corporate due diligence and accountability dealing with a wide range of adverse supply chain impacts (European Parliament 2021), underlining a growing trend to reinforce soft with hard laws, especially in Europe.

The mining sector is variably affected by these cross-sectoral guidance documents and laws, in particular in cases where downstream supply chain stakeholders formulate expectations in their supplier policies and pass these upwards along the supply chain. While there are generally multiple supply chain tiers placed between downstream OEM manufacturers and upstream actors in the mining sector, some manufacturers have begun to “jump the chain” by directly engaging at the smelter level (Young et al. 2019) or by implementing local support projects in mineral-producing countries (e.g., GIZ 2018). These downstream initiatives further increase the mining sector’s exposure to both cross-sectoral and commodity-specific regulations.

Most frequently, downstream requirements circle around adverse impacts related to child and forced labour in upstream supply chains. This reflects mounting public concerns on these topics, translating into reputational liabilities for established company brands. Furthermore, reducing child and forced labour risks is one of the few areas where positive progress has been noted in global downstream supply chains, albeit audit results often being based on uncertain information (Kuruvilla et al. 2021). This represents a stark contrast to the prevalence of child labour risks encountered in certain commodity supply chains such as cobalt, where ASM activities contribute, on the long-term average, 10% to global mine production (Schütte 2021). The ILO estimates that 168 million children worldwide are engaged in child labour, including about one million children in the mining and quarrying sector (OECD 2017). Child labour is a complex problem, influenced by poverty and economic necessity on the one hand, and socio-cultural norms on the other (PACT 2016). Companies may employ different steps to monitor their supply chains and mitigate risks of child labour. Excluding artisanal mines employing children via supply chain disengagement, as practiced by some companies, may protect downstream brand reputation but commonly generates little positive impact on the ground. Rather, complete disengagement may push such mining activities towards an even more clandestine environment where responsible supply chain stakeholders may no longer exert any control or influence. In such cases, the “de-risking” of a company’s supply chain should take into account potential adverse social and economic impacts (OECD 2018a). Addressing the problem of child labour in a sustainable way, therefore, goes beyond supply chain regulation and single company actions, requiring integrated local development cooperation approaches that are effective over the longer term (PACT 2016).

Debates on responsible supply chains have further triggered commodity-specific developments, most notably with regard to the so-called conflict minerals, i.e., ores and concentrates of tin, tantalum, and tungsten; their metals; and gold. These are extracted, among others, via ASM operations in Central Africa where their extraction and trade are associated with a number of supply chain risks defined in the OECD Due Diligence Guidance for Responsible Supply Chains from Conflict-affected and High-risk Areas (OECD 2016)Footnote 2. Risks related to the illegal financing of armed groups have initially played the most prominent role, but additional risks such as child and forced labour are included as well, reinforcing the above cross-sectoral trends. While the OECD due diligence guidance itself is voluntary in nature, similar to the cross-sectoral guidance documents above, its implementation is required by law in several jurisdictions, either directly through an EU regulation (European Parliament and Council 2017) or indirectly through the US Dodd-Frank act (US Congress 2010) (Fig. 1). As these regulations influence global mineral supply chains from mining to manufacturing, the OECD Guidance has become a de facto industry standard for conflict minerals. Over the past 12 years, the OECD due diligence concept has been broadly adopted at a global scale, especially at the smelter level (Young 2015) and in the ASM sector of Central Africa (Schütte 2019). Based on this significant implementation period and geographic scope, it represents a noteworthy benchmark for other mandatory regulations, both in terms of practical functionality and in terms of impact generation, as further explored in “Implementation challenges and impacts.” Applying lessons learnt in this regard will, therefore, be critical when designing future regulations and expanding mandatory due diligence concepts to other raw materials or topics.

Countries with regulation and guidelines relevant for due diligence in mineral supply chains (EU CAHRA list as updated in June 2021 (European Union 2021)

Currently, the due diligence concept is taken up by the EU in further legislative processes that seek to achieve broader social and environmental performance improvements, reflecting that public pressure for mandatory requirements is increasing (Zorilla and Sydow 2020; European Parliament 2020). On this backdrop, the EU is establishing a regulation concerning batteries and waste batteries (European Commission 2020a), updating a former directive, and, among others, including requirements to (1) establish carbon footprints for electric vehicle batteries, (2) increase recycled metal content in battery manufacturing, and (3) establish supply chain due diligence procedures. It may be anticipated that this regulation will reinforce the adoption of broader sustainability frameworks. Importantly, in contrast to the EU’s regulation on the so-called conflict minerals, the EU battery regulation provisions shall explicitly include a wider risk assessment based on a range of social and environmental categories. Other general frameworks requiring supply chain due diligence on environmental issues were set up in recent years and include the OECD Responsible Business Conduct (OECD 2018a). Unlike for other sectors, such as the garment and footwear or the agricultural sectors (OECD/FAO 2016; OECD 2018b), a specific guidance on environmental supply chain due diligence (e.g., on hazardous chemicals, water and greenhouse gas emissions) is not yet available for the mining sector and related mineral supply chains. To address this gap, an international working group is currently developing a practical handbook on environmental due diligence in mineral supply chains under the OECD’s responsible business conduct framework.

Whereas downstream actors in the mineral supply chain frequently tend to put more emphasis on social aspects compared to environmental aspects (Sauer 2021), this is different for the issue of climate change. The carbon footprint of mining operations has become a prominent topic for investors and downstream industries as well as in regulatory guidelines, thus translating an environmental risk into a business risk as well. In fact, greenhouse gas emission reporting and reduction targets have recently emerged as one of the most prevalent issues in the mining and metals sector (EY 2020). The year 2015 marks two landmark events for the global sustainability framework: the Paris Agreement on Climate Change as well as the UN’s Resolution on the 2030 Agenda defining the SDGs. The Paris Agreement, its integration with SDG no. 13, the subsequent recommendations issued by the Task Force on Climate-related Financial Disclosures (TCFD 2017), the EU’s actions to take up the topic through its “Green Deal” concept (including a classification system for sustainable economic activities, the so-called EU taxonomy), and the development of national strategies emphasizing carbon emission reduction targets (e.g., in China’s 14th Five-Year Plan) demonstrate unprecedented momentum for policy changes. Importantly, global policy changes related to climate change do not only follow a green, but also an economic agenda. This reflects the expected impact of climate change on economic growth and income inequality (e.g., Dasgupta et al. 2020).

In general, the EU’s recent regulatory initiatives on conflict minerals and battery metals indicate that mandatory international responsible sourcing requirements tend to follow certain lead themes propagating through supply chains, rather than representing bottom-up approaches directly applicable to the upstream mineral supply chain. The latter is still mainly regulated at the national level. International efforts directly targeting the mining sector rather follow a soft-law approach, e.g., via the principles for sustainable raw materials recently developed by the EU (European Commission 2021), and otherwise rely on multi-stakeholder initiatives and industry self-regulation as discussed in “Voluntary sustainability initiatives in mining and mineral supply chains.” Furthermore, international regulations may be reinforced at the national level via grievance mechanisms related to multinational company practice, such as the OECD network of national contact points that has been active over the last 20 years.

Implementation challenges and impacts

An increasing momentum for new regulations affecting responsible mineral sourcing has been observed in recent years. As key upcoming regulations at the EU level are still in the legislative process, and others, notably the EU’s conflict mineral regulation, have only recently entered their first year of implementation following multi-year transitional periods, the on-the-ground impacts of these regulations can only be anticipated at this stage. Drawing on the longer-term implementation experience and impacts associated with due diligence measures established since 2010, therefore, constitutes an important benchmark for recent and upcoming regulations. These longer-term regulations include the “conflict mineral” provisions in section 1502 of the US Dodd-Frank act and the OECD due diligence guidance for responsible mineral supply chains. Implementation is further influenced by the industry initiatives that are aligned with, were often catalysed by, and contribute to operationalising these regulatory frameworks (Young 2015; OECD 2018a). The implementation analysis of these frameworks as presented below focuses on the ASM sector and the mining conditions in Central Africa, in particular in the DRC. This reflects the “conflict mineral” mine production patterns and market developments in recent years, as well as the design of the regulations. It is important to note, though, that the regulations apply to the large-scale industrial mining sector as well, and may in particular affect the interactions of large-scale mining companies with artisanal miners in their sphere of influence.

The US Dodd-Frank act and the EU regulation on supply chain due diligence for conflict minerals differ in a number of key points but share the ultimate objective of reducing conflict financing via the illegal taxation of tin, tantalum, tungsten, and gold mining and trade (e.g., IPIS 2019). Accordingly, conflict developments in the eastern DRC represent a key indicator to evaluate the impact of these regulations. A range of studies point out that due diligence implementation in the wake of the Dodd-Frank act has not sufficiently disrupted armed groups’ access to illegal financing from the mineral sector. In triggering a large-scale shift from henceforth tighter-controlled artisanal mining of tin and tantalum towards uncontrolled artisanal gold mining, it may indirectly even have led to a deteriorating security situation and increasing vulnerabilities for the local Congolese population in some areas (Parker and Vadheim 2017; Stoop et al. 2018). Indeed, a recent analysis of conflict intensity in the DRC between 2003 and 2020 found that the number of conflict events and civilian fatalities has never been higher than in the most recent years (Hanai 2021).

At the same time, there is broad agreement that conflict financing related to the illegal taxation of artisanal mining and trading activities is a symptom, rather than a root cause of the DRC conflict. Due diligence implementation is first and foremost a responsibility for companies to implement proper risk management in conflict-affected and high-risk areas such as the DRC, whereas it is not designed to directly solve the underlying conflicts (Salter and Mthembu-Salter 2016). In order to address the latter, due diligence regulations and initiatives need to be embedded into a larger approach of governance, mining, and security sector reform in the DRC, combined with creating local economic development perspectives (e.g., Seay 2012; Matthysen and Zaragoza Montejano 2013; Cuvelier et al. 2014). Anticipating these dynamics, the Dodd-Frank act includes provisions seeking to stimulate reform efforts and local development, and the EU conflict mineral policy design shows a similar approach. However, while private sector-led due diligence implementation has advanced at a global scale, broader sector reforms, and supportive policy interventions in the DRC and other affected countries are lagging behind or have failed.

It would be misleading, however, to conclude from the above observations that due diligence implementation along mineral supply chains did not create any impact on the local security situation. IPIS/ULULA (2019), in the broadest and most recent impact evaluation to date, underline the prevalence of problems pertaining to the DRC’s artisanal gold sector. At the same time, they highlight that illegal taxation as well as other due diligence risks are significantly lower in areas where due diligence initiatives have been implemented, mainly in tin and tantalum mining areas. A key challenge thus remains incomplete due diligence implementation in remote areas, combined with a lack of feasible due diligence approaches in the artisanal gold sector of the DRC (IPIS/ULULA 2019; Hanai 2021). The latter is exacerbated by the lack of effective controls of due diligence requirements in the United Arab Emirates, the most important midstream market for artisanal gold from Africa (e.g., Interpol 2021).

Beyond conflict issues, a broad body of literature discusses so-called unintended consequences of the Dodd-Frank act on the DRC’s population in general and on artisanal miner livelihoods in particular (e.g., Matthysen and Zaragoza Montejano 2013; Cuvelier et al. 2014; Radley and Vogel 2015; Diemel and Hilhorst 2018; Stoop et al. 2018). In this narrative, artisanal tin and tantalum mining communities have suffered from reduced market access and an international “de facto embargo,” lower commodity prices, interrupted mining activities and, hence, saw their income and livelihoods threatened (Matthysen and Zaragoza Montejano 2013; Radley and Vogel 2015). While some authors see these developments as direct consequences of the Dodd-Frank act, others argue that the regulation at least reinforced already detrimental DRC mining sector dynamics, such as the lack of sector reform and a biased formalisation approach to artisanal mining (Cuvelier et al. 2014). The lack of tangible progress in security improvements, unintended negative consequences, and a critical view of mineral smuggling risks in upstream industry initiatives such as the “iTSCi” scheme have led some authors to conclude that the industry has only established cosmetic compliance along the supply chain. In this scenario, exercising due diligence without due regard for the latter’s actual effectiveness in terms of reducing conflict impacts on the DRC’s population is thought to have become common practice (Radley and Vogel 2015; Vogel and Raeymaekers 2016; Diemel and Hilhorst 2018).

A range of authors argue that the above narrative on unintended consequences and negative impacts may misread the supply chain due diligence engagement concept and overemphasises the role of the Dodd-Frank act versus other influencing factors. A focus on short-term impacts without acknowledging longer-term changes through time might then rather serve certain corporate interests to discredit established reporting requirements (e.g., Salter and Mthembu-Salter 2016; Koch and Kinsbergen 2018; Schütte 2019). For example, it has been well established that several large international tin and tantalum buyers disengaged from the DRC in the 2009-2012 period, creating concerns for the local hardships resulting from this limited de facto embargo (Geenen 2012; Seay 2012). In the years following this initial period of uncertainty, however, the DRC and the Great Lakes region as a whole showed conflict mineral export volumes eventually rising to above pre-Dodd-Frank levels, in conjunction with increasing diversification among the (re-)engaging international buyers (Schütte 2019). This development reflects general commodity market demand trends in combination with the newly introduced supply chain due diligence engagement concept, deemed acceptable by both regulators and the industry itself. However, complying with international risk management expectations is easier for those local ASM operations that show well-established organisational structures and legal production means, while weakly organised illegal ASM producers are marginalised further (Diemel and Hilhorst 2018).

Voluntary sustainability initiatives in mining and mineral supply chains

Background and current developments

Speaking to the needs of a broad range of stakeholders, voluntary mining and sustainability initiatives provide a bridge between international regulations and national laws. Representing either multi-stakeholder initiatives or, essentially, a means of industry self-regulation, these initiatives take up existing or anticipated future market and regulatory requirements with regard to mining and mineral supply chain standards. While international regulations related to responsible mineral supply chains established over the past decade tend to focus on human rights violations and due diligence procedures, frequently connected to social problems in the ASM sector, voluntary initiatives usually target a broader range of sustainability topics. These pertain to both the ASM sector and large-scale industrial mining, but global implementation is significantly more advanced in the latter sector. For this reason, this chapter largely focuses on initiatives in industrial mining, but supply chain initiatives partly connected to ASM suppliers are considered as well. Voluntary sustainability initiatives and their assurance schemes (respective standards established by initiatives that set sustainability practices and/or reporting and largely require certification or verification) may either focus on the level of mine sites or seek to provide assurance and information exchange among a larger number of up- and downstream supply chain stakeholders (Fig. 2). The following overview initially presents a selection of initiatives that pertain to the mine site level before moving on to initiatives that encompass the whole mineral supply chain.

Timeline of selected sustainability initiatives with sustainability requirements to be applied for a mining, b upstream supply chain (mine to smelter/refiner), and c the whole supply chain (from mine to manufacturing /end producers) and development from 2000 to 2021. Grey bars indicate implementation or applicability periods; light grey bars indicate consultation and development phases; updates of standard versions are marked in dark grey; hatched grey bars indicate continuous standard updates, at least every 2 years. Time periods were compiled based on web information published by the respective organisations and industry initiatives. ASM Artisanal and Small-Scale Mining, CAP Cobalt Action Partnership of the Global Battery Alliance, ICMM International Council on Mining and Metals, IFC International Finance Corporation, IRMA Initiative for Responsible Mining Assurance, LBMA London Bullion Market Association, MAC Mining Association of Canada, WGC World Gold Council.*The Fairmined and Fairtrade Gold initially co-developed a joint standard but split up and published separate standards from 2013 onwards

Similar to international regulations, the mining sector is influenced by both cross-sectoral as well as sector-specific voluntary initiatives. Initially established in the late 1990s, internationally acknowledged cross-sectoral standards such as the Global Reporting Initiative (GRI 2020) or the Environmental and Social Performance Standards of the International Finance Cooperation (IFC 2012) are widely used for sustainability reporting and social and environmental risk management, respectively. Investors and lenders represent a key target audience for these standards, but other stakeholders and the general public may rely on them as well. With semi-regular updates, these standards incorporate a broad range of sustainability issues, including recent developments such as disclosure on carbon emissions. They are applied by a broad range of major mining companies worldwide, irrespective of commodity type.

High public concerns on the sustainability impacts associated with mining and, more recently, expectations towards mining companies to move beyond reporting and risk management have given rise to additional sector-specific sustainability initiatives. These are meant to enable a higher degree of transparency on operational performance, provide more specific information, and variably include an independent assurance process (Jenkins and Yakovleva 2006; de Villier et al. 2014). The momentum for voluntary sustainability initiatives and the associated development of guidelines specifically designed for the mining sector may be traced back to public discussions following a number of environmental incidents in the 1990s that spurred societal anti-mining movements (Franks 2015). One follow-up of these discussions was the founding of the International Council of Mining and Metals (ICMM) in 2001, leading to the first international industry framework to address negative social and environmental impacts in mining. Until today, the ICMM’s sustainable development framework with its ten principles, renamed to the ICMM’s Mining Principles, is the sustainability scheme which most major multinational mining companies have subscribed to.

Three years after the founding of ICMM, the Mining Association of Canada initiated the Towards Sustainable Mining (TSM) initiative, releasing a first TSM standard in 2004. To date, the TSM framework has been adopted by nine countries representing 26% of global mineral and metal production valueFootnote 3 in 2017. Unlike ICMM, the TSM approach, through its national platforms, involves not only large players in the mining sector but all mining companies operating in the country. This approach is based on the logic that the occurrence of major environmental or social incidents at a given mining operation does not only jeopardise this operator’s social license to operate locally, but threatens public acceptance of the mining industry as a whole. Promoting country-wide performance improvement in the mining industry has been a major driver for the uptake of the TSM model by all national mining associations that adopted the scheme to date. Additional reasons applying in some countries include enhancing societal acceptance, increasing assurance and transparency, and facilitating investment and economic growth (Table 2). These partial differences in expectations reflect the countries’ differing economic situation as well as variable exposure to investor and customer expectations. Interestingly, even for countries with an advanced and comprehensive national regulatory framework for mining, such as Australia, the adoption of TSM was motivated by stakeholder expectations to increase transparency and accountability in the mining industry.

Improving relationships with communities is a major driver for engaging in sustainability schemes (Mori Junior and Ali 2016). However, the aim to increase trust and societal acceptance of the mining industry is difficult to achieve. For example, a gap in “localising” transparency and benefits for local communities was identified for the Extractive Industries Transparency Initiative (EITI), a voluntary international standard for disclosing company payments and government revenues (Wilson and Van Alstine 2014). An analysis of the TSM approach implemented in Spain and in Finland shows that, so far, the process has not led to increased societal acceptance of mining (Lesser 2021). This may reflect an insufficient time period to achieve sufficient implementation progress, but may also be related to the need for a joint effort including society and governments as well as a continuous dialogue to build credibility and trust. This challenge might be reflected in critical views on the TSM approach where mining companies may choose on their own on what to report and addressing only corporate policies and management systems while excluding actual operational performance (Kuyek 2019). Recent developments within the TSM framework have taken up this criticism, for instance by introducing an external verification mechanism in 2021.

Moving beyond the mine site level, the earliest engagement of downstream supply chain stakeholders, from manufacturers to end producers, took place in the jewellery sector, referring to diamonds and gold in particular. Initiatives in this and later on other sectors emerged on the backdrop of early international debates on conflict financing and severe human rights violations associated with mining and mineral trade. In 2003, the Kimberley Process Certification Scheme, designed to exclude so-called “conflict diamonds” from the market, was the first scheme to encompass the whole mineral supply chain. However, beyond documentation of origin and demonstration of conflict-free status as far as non-state actors are concerned, it did not impose any additional sustainability requirements. Soon thereafter, in 2005, the Responsible Jewellery Council was formed, with an objective to provide assurance for a broad scale of social and environmental requirements in the jewellery supply chain (in particular gold and precious stones) from industrial mining to manufacturing. In parallel, an initial Fairmined Standard for Gold was presented in 2004, targeting the certification of ASM operations against environmental and social standards, with a view to marketing certified artisanal gold in jewellery supply chains.

Initiatives addressing human rights in conflict-affected and high-risk areas in mineral supply chains for other commodities than precious stones or precious metals only emerged around 2010, related to the intensifying debates on conflict financing and human rights violation in the DRC and the increasing pressure from emerging regulations and guidelines at that time (see “Responsible sourcing and supply chain due diligence regulations”). One of the earliest industry schemes, the Conflict-Free Smelter Program, later on rebranded as the Responsible Minerals Assurance Process (RMAP) and aligned with the OECD due diligence guidance (OECD 2016), was initiated by the electronics industry around 2009. The scheme is a flagship program of the Responsible Minerals Initiative (RMI), managed by an industry body, the Responsible Business Alliance. Itassesses RMAP standard compliance through third party audits at the smelter or refinery level, as this location naturally represents the choke point of metal supply chains. The RMI has identified around 330 smelters and refiners of so-called conflict minerals worldwide, out of which about 250 were participating in the RMAP program at the time of research (RMI 2021). In 2018, following reports on child labour in artisanal cobalt supply chains from the DRC, RMAP adopted an additional standard for cobalt refiners. When the London Metal Exchange (LME) announced the introduction of responsible sourcing requirements in 2019, this increased the momentum for the development of additional initiatives covering LME-listed brands, and the uptake of the related due diligence requirements for relevant commodities such as aluminium and copper (ASI 2020; The Copper Mark 2021).

Whereas the upcoming LME requirements for listed brands mainly relate to compliance with the OECD due diligence guidance as well as ISO 14001 (environmental management) and OHSAS 18001/ISO 45001 (operational safety and health) certification, ongoing discussions on supply chain regulations and ESG requirements are driving a trend towards including a broader range of social and environmental issues. One of the latest developments, in 2021, is RMAP’s formulation of voluntary ESG standard criteria for smelters and refiners that wish to demonstrate compliance beyond minimum human rights due diligence requirements. This may help them preparing for anticipated regulatory requirements as well as meeting the current social and environmental requirements expected for LME brands from 2022 onwards (LME 2021).

So far, commodity-specific schemes that encompass the whole supply chain including recycling are rare and currently limited to the Responsible Jewellery Council’s Code of Practice and the Aluminium Stewardship Initiative. However, apart from responsible supply chains, resource efficiency and circularity are major pillars of raw material sourcing and diversification strategies, especially with regard to critical raw materials (e.g., European Commission 2020b; The White House 2021). Therefore, it may be expected that the life cycle approach will gain more relevance in the development of current and new sustainability initiatives. This particularly applies to those initiatives that are relevant for strategic and critical raw materials, such as the rare earth elements or battery metals. For example, on-going European legislative developments that address the life cycle of batteries might drive initiatives to include life cycle approaches in the future.

The major drivers of sustainable supply chain management, including in mineral supply chains, comprise (1) legal demands and regulations (as discussed in “Responsible sourcing and supply chain due diligence regulations”), (2) customer demand, and (3) response to stakeholder demands (Seuring and Müller 2008; Young et al. 2013; Potts et al. 2018). However, based on general guidance documents such as those provided by the OECD, most initiatives tend to focus on a risk-based approach in supply chain management, in particular as far as human rights violations and, to a lesser extent, health and safety are concerned. Other sustainability issues such as local value generation and local development are less addressed by these initiatives (Franken et al. 2020), and indeed, local stakeholders are frequently underrepresented in international standard development and governance. This lack of local ownership is reflected in the findings of the yearly reports of the Responsible Mining Foundation, where companies overall score lowest on the issue of community wellbeing, in contrast to environmental or safety issues (RMF 2020).

Implementation challenges and impacts

Most major international mining companies are members of voluntary sustainability initiatives (Table 3) and have subscribed to their respective reporting and assurance requirements. A result of these activities is enhanced transparency on selected sustainability parameters, initially at the corporate level and increasingly at the project level and along the supply chain as well (e.g., UNEP 2020). A range of initiatives have started disclosing performance results at the level of individual certified or assessed operational sites (e.g., IRMA, TSM, and ASI). Furthermore, reporting based on monitoring frameworks increasingly includes the site level as well, as exemplified by the Responsible Mining Index or the Global Tailings Review, an international monitoring initiative founded by ICMM, the United Nations Environment Programme and the Principles for Responsible Investment in 2019. As far as the supply chain is concerned, a lack of transparency has been identified as a major obstacle for downstream actors to assess responsible sourcing practice among their suppliers (e.g., Amnesty International 2017; van den Brink et al. 2019). Significant progress in this regard may be observed in the conflict mineral sector. The implementation of due diligence initiatives in the sector has improved transparency, enabling downstream companies to identify smelters and refiners in their supply chain (Young 2015) while international trade data have become increasingly consistent (Schütte 2019).

Notwithstanding selective progress in terms of sustainability disclosures, challenges remain. On the one hand, this concerns the degree of granularity and dissemination of reported results. Better access to data and to the detailed results of assurance processes could help to increase transparency further (Mori Junior and Ali 2016). On the other hand, the level of disclosure in reporting frameworks (e.g., GRI) and in sustainability initiatives (e.g., ICMM) does not always reflect the level of generated impact. While there is some progress, site-specific reporting is not yet the norm and most disclosures still take place at the corporate level. Since environmental and social impacts mostly occur at the site level, this may lead to a mismatch of information (Mancini and Sala 2018). Also, most initiatives formulate management rather than performance requirements which make it difficult to assess impacts and sustainability contributions (Mori Junior et al. 2016). Consequently, the broad uptake and more standardised sustainability reporting and disclosure in the mining industry do not necessarily serve as a sufficient indicator for company performance and actual sustainability impacts (de Villier et al. 2014). Some initiatives, such as TSM, envisage to eventually increase performance across the whole mining sector. For these initiatives, there may be a certain incentive to increase their membership base and thus not to be too hard on low performers at the entry stage, allowing for more time to achieve certain compliance levels at a later stage (Mori Junior and Ali 2016). This approach is mirrored by some certification schemes such as the Initiative for Responsible Mining Assurance (IRMA 2018) that introduced later on progressive performance levels to facilitate participation of mining companies.

Most sustainability initiatives have been developed and applied by mining companies headquartered in OECD countries. Chinese companies, on the other hand, operating as major mining producers in China or abroad, are currently not often participating in these schemes, with few exceptions (e.g., in the gold sector). This also applies to some other non-OECD jurisdictions. As a result, information on environmental and social standards applied in the large Chinese mining sector is, for the most part, difficult to obtain for international supply chain stakeholders. In contrast, Chinese companies involved in mineral processing and further downstream seem to engage more frequently in supply chain schemes such as the RMAP and cobalt sourcing initiatives.

The role of industry-led sustainability or responsible sourcing initiatives for supporting companies to conduct due diligence in their mineral supply chains is acknowledged and referenced in the OECD due diligence guidance and the EU regulation on conflict minerals (OECD 2011; European Commission 2020a;). It is important to note, though, that the OECD due diligence guidance defines company participation in such initiatives as a supporting measure which does not exempt a given company from conducting its own due diligence process. The company itself always bears the ultimate responsibility for its operations and supply chains and their compliance with national and international regulations. This mirrors a common concern raised by civil society, emphasising that the mere participation in sustainability initiatives is not sufficient for a company to address its social and environmental risks (Sydow and Reichwein 2018). This is exemplified by the Brumadinho tailings dam breach in 2019, the most disastrous accident in the Brazilian mining sector to date (Silva Rotta et al. 2020). Although the operator, Vale, had subscribed to a relevant sustainability scheme (in this case, ICMM’s Mining Principles) that included third-party auditing, corporate risk assessment and management of environmental and social risks were apparently not prioritised as needed in order to optimise short-term financial performance (Macchione Saes and Muradian 2021). This did not only lead to dam failure and its tragic consequences but also resulted in a massive destruction of shareholder value in the end, the operating result being 8.543 billion US$ lower in 2019 compared to 2018 (Macchione Saes and Muradian 2021). An analysis of 50 mining and hydrocarbon projects supports the finding that actual or anticipated negative social and/or environmental impacts can induce local conflict and lead to substantive business costs, which are often not factored in adequately into business risks (Franks et al. 2014).

Being effective, transparent and accountable may be regarded as a prerequisite for initiatives to be successful, but they also need to demonstrate positive social, environmental and economic outcomes (Mori Junior et al. 2016). When it comes to moving beyond risk management and inducing local development the possible limitations of sustainability initiatives become evident (Stark and Levin 2011; Hilson et al. 2016). Similarly, although the Sustainable Development Goals are today widely taken up in company reporting, policies and government frameworks, there may still be a need to turn the risk mitigation agenda into a more development-oriented agenda (Ivic et al. 2021). In line with this notion, there is frequently a gap between comprehensive sustainability reporting and local implementation efforts (RMF 2020). As early as two decades ago, Hilson and Murck (2000) stated that companies need to put sustainability strategies more into practice. Until today, sustainability efforts in the mining sector, be it by corporate action or through international initiatives, are perceived as creating insufficient benefits for local communities (Frederiksen 2018).

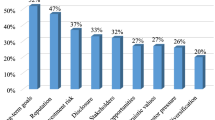

This finding is supported by the high relevance of the “Social License to Operate.” The latter is considered as the most pressing social issue from a mining industry perspective, as reflected in annual ratings by advisory service providers (EY 2020). Indeed, pursuing a Social License to Operate has been at the heart of mining industry strategies during the last two decades (Humphreys 2000; Joyce and Thomson 2000; Thomson and Boutilier 2011). And yet, it seems that social challenges are often far from being resolved and the concepts employed so far might not have been sufficiently successful in reducing negative social impacts. Although there has been some progress with regard to corporate social responsibility, that is, contributing to sustainable development beyond regulatory requirements at a local level, the global dimension of managing and demonstrating sustainable practise is only progressing slowly (Rodrigues and Mendes 2018).

However, national and local governments play a major role in this process, as they set the legal and fiscal frameworks as well as national and local development strategies. Confidence in national government institutions and their regulatory capacities plays an important role in moderating impact factors influencing the acceptance of mining (Zhang and Moffat 2015). Transparency and accountability, enforcement of governance frameworks as well as combatting corruption are key elements to generate sustainable development in the extractive sector (Pedro et al. 2017). The IGF’s mining policy framework assessment indicates that half of the 14 investigated countries had low preparedness for the issue of generating socio-economic benefits through their national framework while the other half was only rated at medium level (IGF 2021). This finding points to the mutual influences of implementation challenges between national and international sustainability efforts in the mining sector.

Lessons learnt

The current implementation of international regulations and voluntary mining sector initiatives is characterised by a range of challenges in terms of implementation effectiveness and impact generation. The review of these challenges as presented in “Responsible sourcing and supply chain due diligence regulations” and “Voluntary sustainability initiatives in mining and mineral supply chains” provides an opportunity to extract a number of lessons learnt. These may be considered for the design or review of further regulations, initiatives, and associated policy efforts.

At first glance, due diligence regulations may be regarded as a successful blueprint for addressing social and environmental challenges in mineral supply chains. Indeed, it has been demonstrated that their implementation is feasible and has led to positive outcomes, such as improved supply chain transparency. At the same time, however, the implicit objectives of such regulations have not been fully met as far as conflict financing in Central Africa is concerned. The link between the illegal exploitation of natural resources and armed group financing has not been broken, and civilian conflict casualties are higher than ever (e.g., Hanai 2021). Moreover, the regulations have created hardships for certain parts of the local population.

These challenges were encountered for a number of reasons. Implementation of the regulations in the Central African upstream mineral supply chain, largely referring to the ASM sector, did not encounter a level playing field at the local level. Remote local production regions and weakly organised ASM producers encountered challenges, financing models to absorb implementation costs lacked robustness, and local solution ownership was low. International conflict mineral initiatives were imposed upon the affected local stakeholders in Central Africa with only minor consultation. The parallel lack of a level playing field with regard to international mineral buyer requirements allowed armed groups in the DRC to employ evasive strategies, namely to move away from illegal taxation in the tin and tantalum sector to focus on the local gold sector. This move was mainly made possible due to the lack of robust downstream due diligence requirements and controls on artisanal gold purchases in the United Arab Emirates. The EU’s upcoming battery regulation deals with battery metal commodities largely extracted via industrial mining (with the notable exception of cobalt) and of a less-fungible nature than gold. Implicit risks such as smuggling may therefore be lower than in the conflict mineral space. Nonetheless, care must be taken to avoid triggering two-class markets for commodities such as nickel or cobalt, or for certain product subgroups (e.g., battery vs. non-battery applications). Leveraging and seeking alignment with already established standards such as the Chinese guidelines for social responsibility in outbound mining investments (CCCMC 2017) may provide opportunities to develop a concerted approach among Western and Chinese stakeholders and, hence, obtain higher market penetration of due diligence control procedures.

The significance as well as the challenges of implementing supporting measures and embedding new regulations into a larger framework of local reform policies should not be underestimated. In the DRC, the local population’s vulnerabilities and socio-economic hardships reflect multiple factors beyond the scope of due diligence regulations and mining sector initiatives. These refer, for example, to lacking incentives for policy reforms, differing policy priorities, as well as uncertain macro-impacts such as commodity price developments or local currency depreciation (e.g., Geenen 2012; Cuvellier et al. 2014; IPIS/ULULA 2019). Comparable factors may apply not only to artisanal but also to industrial mining elsewhere, considering the broad range of sustainability impacts generated by mining activities. While stimulating local reforms and development may be indirectly included in international regulations through “accompanying measures” (as foreseen by the EU conflict mineral regulation) achieving actual success with these measures in the longer term might well prove harder than regulatory implementation itself.

Industry-led or multi-stakeholder sustainability initiatives play a supporting role in addressing environmental and social risks in mineral supply chains, but they also show limitations. Among others, the initiatives are useful in formulating and harmonising sustainability expectations, increasingly in line with downstream supply chain requirements, allowing mining companies to adopt these in their corporate policy framework. Following this exercise, however, there still seems to be a gap in terms of implementation and performance. As the Brumadinho tailings dam failure shows, a focus on optimising short-term financial results may reduce effective corporate sustainability risk assessments and management, a deficit that might lead to problematic or even catastrophic social and environmental incidents in the longer term. In general, there seems to be a need for more comprehensive social and environmental risk assessments (Franks et al. 2014). More transparency on the audit results and the assessment of performance and site-related social and environmental impacts in the framework of international initiatives may help addressing this gap. This could also support generating trust in company management as well as government agencies, a prerequisite for a meaningful dialogue on environmental and social impacts (Mori Junior et al. 2016; Pedro et al. 2017).

Company engagement in sustainability initiatives should support generating positive environmental, social and economic outcomes. However, a gap still frequently exists in terms of demonstrating positive implementation impacts on the ground and creating benefits for local communities. Risk-based approaches are appropriate to address expectations by regulators and investors as well as downstream companies in general, but may be insufficient to meet local expectations. Therefore, mining companies should strive to go beyond risk management (Stark and Levin 2011; Frederiksen 2018; Ivic et al. 2021). Also, to contribute to positive long-term development a life-cycle perspective of the mine, including post-closure development, appears necessary (Stark and Levin 2011; Mori Junior et al. 2016). Local stakeholder consultation and participation is key for generating local benefits. Whereas industry-led sustainability initiatives have developed guidance standards for corporate approaches to the Social License to Operate as well as corporate social responsibility measures, there is still a need to improve stakeholder engagement towards building trust and meaningful dialogue (Frederiksen 2018; Ruokonen 2020; Lesser 2021).

Conclusions

Over the past decade international regulations and voluntary industry or multi-stakeholder initiatives addressing social and environmental risks at the cross-sectoral level as well as in mining and mineral supply chains have gained increasing importance. The stakeholder base expected to respond to the sustainability and due diligence concerns has broadened from directly involved parties to a range of indirect stakeholders situated along the downstream mineral value chain. Human rights due diligence requirements have become an international minimum standard for many mineral supply chains, applicable to both large-scale industrial mining as well as ASM operations. Building on the initial due diligence concept, regulatory approaches and voluntary initiatives are currently expanding towards a broader range of mineral commodities as well as to additional topics, such as climate change impact or product recycling rates. This makes it highly pertinent to reflect on the implementation experience so far and identify lessons learnt to consider for the future design and implementation of such regulations, initiatives and associated policy measures.

While many companies have successfully adopted due diligence procedures and supply chains have become more transparent, conflict financing in Central Africa still persists in certain parts of the local ASM sector for a number of reasons. The implicit objectives of “conflict mineral” regulations have thus not yet been fully achieved. Anticipating similar challenges, care must therefore be taken to design future regulations with realistic objectives in mind, providing sufficient time frames for compliance including at the upstream end, and reinforcing implementation incentives for accompanying measures at the local level as well as global outreach efforts to ensure a level playing field.

Standard development, risk management, and reporting have been at the centre of many initiatives in the mining sector and along mineral supply chains. Although the industry has achieved notable implementation progress, current social and environmental risk assessments might not be comprehensive enough while public corporate reporting lacks site-specific data on sustainability performance and impacts. At the same time, a strong prioritisation of risk management might insufficiently consider local concerns and longer-term development priorities, and thus undermine the social acceptance of mining activities.

Considering these challenges, more emphasis should be put on closing the gap between downstream supply chain expectations, regulatory requirements, upstream governance capacities, and the social acceptance of mining activities. Among others, this will necessitate meaningful dialogue between all stakeholders and adapted reporting concepts that consider local impact generation as well. Moreover, the larger sustainable development framework often relies on structural development issues that typically fall under the primary responsibility of national governments. As such, international regulations and voluntary initiatives contribute to promoting responsibility in the mining sector and along mineral supply chains, but may not solely by themselves guarantee sustainability in mining.

Notes

A term used for tin, tantalum, tungsten, their ores and gold as defined in the US Dodd-Frank act related to conflict financing in the Democratic Republic of the Congo (US Congress 2010).

For the purpose of this article, we refer to this document as the OECD due diligence guidance in the following.

Excluding coal, uranium, and diamonds, calculated based on metal production value according to Drobe (2019).

References

Amnesty International (2017) Time to recharge corporate action and inaction to tackle abuses in the cobalt supply chain. https://www.amnesty.org/download/Documents/AFR6273952017ENGLISH.PDF. Accessed 08 August 2021

Andrews T, Gamu J, Le Billon P, Oh CH, Reyes D, Shin J (2018) The role of host governments in enabling or preventing conflict associated with mining. Canadian International Resources and Development Institute (CIRDI). https://www.undp.org/publications/role-host-governments-enabling-or-preventing-conflict-associated-mining. Accessed 21 July 2021

ASI (2020) ASI and London Metal Exchange (LME) announce collaboration, Aluminium Stewardship Initiative. https://aluminium-stewardship.org/asi-and-london-metal-exchange-lme-announce-collaboration/. Accessed 24 July 2021

Assemblée Nationale (2017) LOI n° 2017-399 du 27 mars 2017 relative au devoir de vigilance des sociétés mères et des entreprises donneuses d’ordre (1). Journal official de la République Francaise, 28 mars 2017. https://www.legifrance.gouv.fr/jorf/jo/2017/03/28/0074. Accessed 16 June 2021

Bright C (2021) Mapping human rights due diligence regulations and evaluating their contribution in upholding labour standards in global supply chains. In: Delautre G, Echeverría Manrique E, Fenwick C (eds) Decent work in a globalized economy – Lessons from public and private initiatives. International Labour Office, Geneva, pp 75–108

Campbell B (2012) Corporate social responsibility and development in Africa: redefining the roles and responsibilities of public and private actors in the mining sector. Resourc Policy 37:138–143. https://doi.org/10.1016/j.resourpol.2011.05.002

CCCMC (2017) Guidelines for social responsibility in outbound mining investments, second edition. China Chamber of Commerce of Metals, Minerals & Chemicals Importers & Exporters (CCCMC). http://www.cccmc.org.cn/docs/2017-08/20170804141709355235.pdf. Accessed 14 June 2021

Cuvelier J, van Bockstael S, Vlassenroot K, Iguma C (2014) Analyzing the impact of the Dodd-Frank act on Congolese livelihoods. Study for the Conflict Prevention and Peace Forum (SSRC). https://www.ssrc.org/publications/view/analyzing-the-impact-of-the-dodd-frank-act-on-congolese-livelihoods/. Accessed 17 October 2018

Dasgupta S, Emmerling J, Shayegh S (2020) Inequality and growth impacts from climate change – insights from South Africa. European Institute on Economics and the Environment. https://media.rff.org/documents/WP_20-10.pdf. Accessed 17 June 2021

De Villier C, Low M, Samkin G (2014) The institutionalisation of mining company sustainability disclosures. J Clean Prod 84:51–58. https://doi.org/10.1016/j.jclepro.2014.01.089

Diemel JA, Hilhorst DJM (2018) Unintended consequences or ambivalent policy objectives? Conflict minerals and mining reform in the DR Congo. Dev Policy Rev 37:453–469. https://doi.org/10.1111/dpr.12372

Drobe M (2019) Vorkommen und Produktion mineralischer Rohstoffe –ein Ländervergleich (2020), Bundesanstalt für Geowissenschaften und Rohstoffe, 31pp, https://www.bgr.bund.de/DE/Themen/Min_rohstoffe/Downloads/studie_Laendervergleich_2020.pdf. Accessed 26 June 2021

EGC (2021) EGC responsible sourcing standard. Entreprise Générale du Cobalt, March 2021. https://www.egcobalt-rdc.com/app/uploads/2021/03/20210326-EGC-Responsible-Sourcing-Standards-English.pdf. Accessed 14 June 2021

European Commission (2020a) Proposal for a regulation of the European Parliament and of the Council concerning batteries and waste batteries, repealing directive 2006/66/EC and amending regulation (EU) no 2019/1020. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020PC0798. Accessed 16 June 2021

European Commission (2020b) Critical raw materials resilience: charting a path towards greater security and sustainability. European Commission. https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0474&from=EN. Accessed 24 July 2021

European Commission (2021) EU principles for sustainable raw materials. Publications office of the European Union. https://op.europa.eu/en/publication-detail/-/publication/6d541f66-0f81-11ec-9151-01aa75ed71a1/language-en/format-PDF/source-230540125. Accessed 16 September 2021

European Parliament (2020) Briefing — Towards a mandatory EU system of due diligence for supply chains. https://www.europarl.europa.eu/RegData/etudes/BRIE/2020/659299/EPRS_BRI(2020)659299_EN.pdf Accessed 20 June 2021

European Parliament (2021) European Parliament resolution of 10 March 2021 with recommendations to the Commission on corporate due diligence and corporate accountability (2020/2129(INL)). https://www.europarl.europa.eu/doceo/document/TA-9-2021-0073_EN.pdf. Accessed 16 June 2021

European Parliament and Council (2014) Directive 2014/95/EU of the European Parliament and of the Council of 22 October 2014 amending Directive 2013/34/EU as regards disclosure of non-financial and diversity information by certain large undertakings and groups. Official Journal of the European Union L 330/1, 15 May 2014. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014L0095&from=FI. Accessed 16 June 2021

European Parliament and Council (2017) Regulation (EU) 2017/821 of the European Parliament and of the Council of 17 May 2017 laying down supply chain due diligence obligations for Union importers of tin, tantalum and tungsten, their ores, and gold originating from conflict-affected and high-risk areas. Official Journal of the European Union, L 130, 19 May 2017. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32017R0821. Accessed 16 June 2021

European Union (2021) Indicative, non-exhaustive list of conflict-affected and high-risk areas. European Union. https://www.cahraslist.net/. Accessed 15 September 2021

EY (2020) Global mining and metals top 10 business risks and opportunities — 2021. Ernst & Young. https://www.ey.com/en_gl/mining-metals/top-10-business-risks-and-opportunities-for-mining-and-metals-in-2021 Accessed 20 July 2021

Franken G, Turley L, Kickler K (2020) Voluntary sustainability initiatives: An approach to make mining more responsible? In: Bleicher A, Pehlken A (eds) The material basis of energy transitions. Academic Press, pp 169–186. https://doi.org/10.1016/B978-0-12-819534-5.00011-8

Franks DM (2015) Mountain movers – mining, sustainability and agents of change. Rothledge, London. https://doi.org/10.4324/9781315884400

Franks DM, Davis R, Bebbington AJ, Ali SH, Kemp D, Scurrah M (2014) Conflict translates environmental and social risk into business costs. PNAS 111(21):7576–7581. https://doi.org/10.1073/pnas.1405135111

Frederiksen T (2018) Corporate social responsibility, risk and development in the mining industry. Resour Policy 59:495–505. https://doi.org/10.1016/j.resourpol.2018.09.004

Gardner M (2020) SUSTAINABILITY: Norway adopts Canadian initiative for sustainable mining. Canadian Mining Journal. March 4, 2020. https://www.canadianminingjournal.com/news/sustainability-norway-adopts-canada-initiative-for-sustainable-mining/. Accessed 06 July 2021.

Geenen S (2012) A dangerous bet: The challenges of formalizing artisanal mining in the Democratic Republic of Congo. Resour Policy 37:322–330. https://doi.org/10.1016/j.resourpol.2012.02.004

GIZ (2018) BMW, BASF and Samsung launch a project for sustainable cobalt mining. Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH. https://www.giz.de/en/press/72347.html. Accessed 16 June 2021

Glencore (2020) Pathway to net zero – 2020 climate report. Glencore. https://www.glencore.com/dam/jcr:c1e7faf7-1928-4251-819e-aa8918be42ba/2020-climate-report.pdf. Accessed 15 September 2021

GRI (2020) GRI Standards. Global Reporting Initiative (GRI). https://www.globalreporting.org/standards/. Accessed 12 August 2021

Hanai K (2021) (2021), Conflict minerals regulation and mechanism changes in the DR Congo. Resources Policy 74:102394. https://doi.org/10.1016/j.resourpol.2021.102394

Hilson G, Murck B (2000) Sustainable development in the mining industry: clarifying the corporate perspective. Resourc Policy 26:227–238

Hilson G, Hilson A, McQuilkena J (2016) Ethical minerals: Fairer trade for whom? Resourc Policy 49:232–247. https://doi.org/10.1016/j.resourpol.2016.05.002

Hosonuma N, Herold M, De Sy V, De Fries RS, Brockhaus M, Verchot L, Angelsen A, Romijn E (2012) An assessment of deforestation and forest degradation drivers in developing countries. Environ Res Lett 7(4):044009. https://doi.org/10.1088/1748-9326/7/4/044009

Human Rights Watch (2021) Human rights watch. https://www.hrw.org. Accessed 14 September 2021

Humphreys D (2000) A business perspective on community relations in mining. Resourc Policy 26:127–131

IEA (2021) The role of critical minerals in clean energy transitions. International Energy Agency (IEA). https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions. Accessed 9 June 2021

IFC (2012) Performance standards on social and environmental sustainability. International Finance Corporation (IFC). https://www.ifc.org/wps/wcm/connect/24e6bfc3-5de3-444d-be9b-226188c95454/PS_English_2012_Full-Document.pdf?MOD=AJPERES&CVID=jkV-X6h. Accessed 12 August 2021

IGF (2021) Mining policy framework — assessment and reports. Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development. https://www.igfmining.org/report/. Accessed 07 July 2021

ILO (2017) Tripartite declaration of principles concerning multinational enterprises and social policy. International Labour Organization. https://www.ilo.org/wcmsp5/groups/public/%2D%2D-ed_emp/%2D%2D-emp_ent/%2D%2D-multi/documents/publication/wcms_094386.pdf. Accessed 16 June 2021

Interpol (2021) Illegal gold mining in central Africa. Analytical report for EU project “Enhancing Africa’s response to transnational organized crime” (ENACT). https://www.interpol.int/content/download/16493/file/2021%2007%2027%20ENGLISH%20PUBLIC%20VERSION_FINAL_Illegal%20gold%20mining%20in%20Central%20Africa.pdf. Accessed 9 February 2022

IPIS (2019) Regulating responsible sourcing of 3TG minerals. IPIS Insights on Due Diligence on Mineral Sourcing, International Peace Information Service (IPIS). https://ipisresearch.be/publication/ipis-insights-due-diligence-mineral-sourcing-regulating-responsible-sourcing-3tg-minerals/. Accessed 14 June 2021

IPIS/ULULA (2019) Assessing the impact of due diligence programmes in eastern DRC: a baseline study. International Peace Information Service (IPIS). https://ipisresearch.be/publication/assessing-impact-due-diligence-programmes-eastern-drc-baseline-study/. Accessed 14 June 2021

IRMA (2018) IRMA Standard for Responsible Mining - IRMA-STD-001. Initiative for Responsible Mining Assurance. https://responsiblemining.net/wp-content/uploads/2018/07/IRMA_STANDARD_v.1.0_FINAL_2018-1.pdf. Accessed 14 September 2021

ISO (2010) ISO 26000:2010 Guidance on social responsibility, International Organization for Standardization. https://www.iso.org/standard/42546.html. Accessed 14 June 2021

Ivic A, Saviolidis NM, Johannsdottir L (2021) Drivers of sustainability practices and contributions to sustainable development evident in sustainability reports of European mining companies. Discov Sustain 2:17. https://doi.org/10.1007/s43621-021-00025-y

Jenkins H, Yakovleva N (2006) Corporate social responsibility in the mining industry: Exploring trends in social and environmental disclosure. J Clean Prod 14:271–284. https://doi.org/10.1016/j.jclepro.2004.10.004

Joyce SA, Thomson I (2000) Earning a social licence to operate: social acceptability and resource development in Latin America. Can Min Metall Bull 93:1037

Joyce S, Sairinen R, Vanclay F (2018) Using social impact assessment to achieve better outcomes for communities and mining companies. In: Lodhia SK (ed) Mining and sustainable development, 1st edn. Routledge, London, pp 65–86

Kemp D, Bond CJ, Franks DM, Cote C (2010) Mining, water and human rights: making the connection. J Clean Prod 18:1553–1562. https://doi.org/10.1016/j.jclepro.2010.06.008

Kemp D, Worden S, Owen JR (2016) Differentiated social risk: rebound dynamics and sustainability. Resourc Policy 50:19–26. https://doi.org/10.1016/j.resourpol.2016.08.004

Koch D-J, Kinsbergen S (2018) Exaggerating unintended effects? Competing narratives on the impact of conflict minerals regulation. Resour Policy 57:255–263. https://doi.org/10.1016/j.resourpol.2018.03.011