Abstract

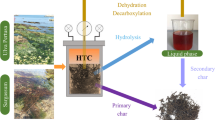

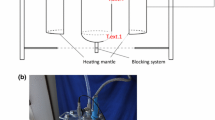

Fish waste disposal is a major cause for concern for the seafood processing industries. Fish processing generates enormous quantities of waste as almost 45% of the live weight of fish is regarded as waste. Current ways of managing fish waste involves dumping in oceans, landfills, or treating them with already established strategies. Dumping these wastes without any form of treatment is far from being environmental friendly. Current utilization strategies suffer from disadvantages such as incomplete utilization of solid and liquid wastes or generation of new waste effluents that needs further processing. Therefore, there is a need to find an alternate/supplemental method of seafood utilization. Previously, we have reported the use of microwave hydrothermal carbonization (MHTC) to carbonize fish waste to hydrochar. Here, a conventional heating method such as a custom autoclave reactor is reported that could also be used to carbonize fish waste to hydrochar. Upon response surface design optimization, it was found that a maximal yield of hydrochar (~ 35%) can be achieved at a holding temperature of 180 °C and at a holding time of 120 min. We have also characterized the elemental, proximate, energy, and surface properties of hydrochar produced by conventional hydrothermal carbonization (CHTC). It was found that the quality of the hydrochar produced by MHTC is largely comparable to CHTC. This further proves that HTC could be employed to generate energy from non-lignocellulosic wastes such as fish waste while getting rid of the waste in an eco-friendly manner.

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- C:

-

Carbon

- CCD:

-

Central composite design

- CHTC:

-

Conventional hydrothermal carbonization

- DoE:

-

Design of experiment

- EEF:

-

Energy enrichment factor

- HTC:

-

Hydrothermal carbonization

- H:

-

Hydrogen

- MHTC:

-

Microwave hydrothermal carbonization

- N:

-

Nitrogen

- O:

-

Oxygen

- RFW:

-

Raw fish waste

- SEM:

-

Scanning electron microscope

- S:

-

Sulfur

References

Rai AK, Bhaskar N, Baskaran V (2015) Effect of feeding lipids recovered from fish processing waste by lactic acid fermentation and enzymatic hydrolysis on antioxidant and membrane bound enzymes in rats. J Food Sci Technol 52(6):3701–3710. https://doi.org/10.1007/s13197-014-1442-3

Shahidul Islam M, Tanaka M (2004) Impacts of pollution on coastal and marine ecosystems including coastal and marine fisheries and approach for management: a review and synthesis. Mar Pollut Bull 48(7–8):624–649. https://doi.org/10.1016/j.marpolbul.2003.12.004

Hardy RW, Tacon AG (2002) Fish meal: historical uses, production trends and future outlook for sustainable supplies. Responsible Marine Aquaculture, p 311–325. https://doi.org/10.1079/9780851996042.0311

Arvanitoyannis IS, Kassaveti A (2008) Fish industry waste: treatments, environmental impacts, current and potential uses. Int J Food Sci Technol 43(4):726–745. https://doi.org/10.1111/j.1365-2621.2006.01513.x

Lopes C, Antelo LT, Franco-Uría A, Alonso AA, Pérez-Martín R (2015) Valorisation of fish by-products against waste management treatments—comparison of environmental impacts. Waste Manag 46:103–112. https://doi.org/10.1016/j.wasman.2015.08.017

Jamieson BL, Gagnon GA, Gonçalves AA (2017) Physicochemical characterization of Atlantic Canadian seafood processing plant effluent. Mar Pollut Bull 116(1):137–142

Grant MT, Corkum J, Morry C (2003) Management of wastes from Atlantic seafood processing operations. AMEC Earth & Environmental Limited TE23016, Dartmouth, p 135

Cashion T, Le Manach F, Zeller D, Pauly D (2017) Most fish destined for fishmeal production are food-grade fish. Fish Fish 18:837–844

Esteban M, Garcia A, Ramos P, Marquez M (2007) Evaluation of fruit–vegetable and fish wastes as alternative feedstuffs in pig diets. Waste Manag 27(2):193–200

Mandeville S, Yaylayan V, Simpson B (1992) Proximate analysis, isolation and identification of amino acids and sugars from raw and cooked commercial shrimp waste. Food Biotechnol 6(1):51–64

Ya T, Simpson B, Ramaswamy H, Yaylayan V, Smith J, Hudon C (1991) Carotenoproteins from lobster waste as a potential feed supplement for cultured salmonids. Food Biotechnol 5(2):87–93

Garcıa A, Esteban M, Marquez M, Ramos P (2005) Biodegradable municipal solid waste: characterization and potential use as animal feedstuffs. Waste Manag 25(8):780–787

Libra JA, Ro KS, Kammann C, Funke A, Berge ND, Neubauer Y, Titirici M-M, Fühner C, Bens O, Kern J (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2(1):71–106

Kannan S, Gariepy Y, Raghavan GV (2017) Optimization and characterization of hydrochar produced from microwave hydrothermal carbonization of fish waste. Waste Manag 65:159–168

Kannan S, Gariepy Y, Raghavan GV (2017) Optimization and characterization of hydrochar derived from shrimp waste. Energy Fuels 31(4):4068–4077

Reza MT (2011) Hydrothermal carbonization of lignocellulosic biomass. University of Nevada, Reno

Ramke H-G, Blöhse D, Lehmann H-J, Fettig J (2009) Hydrothermal carbonization of organic waste. In: Proc., Twelfth International Waste Management and Landfill Symposium, Sardinia, Italy

Lynam JG, Reza MT, Yan W, Vásquez VR, Coronella CJ (2015) Hydrothermal carbonization of various lignocellulosic biomass. Biomass Conversion and Biorefinery 5(2):173–181. https://doi.org/10.1007/s13399-014-0137-3

Lu X, Pellechia PJ, Flora JRV, Berge ND (2013) Influence of reaction time and temperature on product formation and characteristics associated with the hydrothermal carbonization of cellulose. Bioresour Technol 138:180–190. https://doi.org/10.1016/j.biortech.2013.03.163

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod Biorefin 4(2):160–177

Kannan S, Gariepy Y, Raghavan V (2015) Optimization of enzyme hydrolysis of seafood waste for microwave hydrothermal carbonization. Energy Fuel 29(12):8006–8016

Doshi P, Srivastava G, Pathak G, Dikshit M (2014) Physicochemical and thermal characterization of nonedible oilseed residual waste as sustainable solid biofuel. Waste Manag 34(10):1836–1846

Pala M, Kantarli IC, Buyukisik HB, Yanik J (2014) Hydrothermal carbonization and torrefaction of grape pomace: a comparative evaluation. Bioresour Technol 161:255–262

Cao X, Ro KS, Libra JA, Kammann CI, Lima I, Berge N, Li L, Li Y, Chen N, Yang J (2013) Effects of biomass types and carbonization conditions on the chemical characteristics of hydrochars. J Agric Food Chem 61(39):9401–9411

Delaquis E, Samson R, Seguin P, Mustafa A, Martel H (2014) Impacts of improved switchgrass and big bluestem selections on yield, morphological characteristics, and biomass quality. Advances in Agriculture 2014:14. https://doi.org/10.1155/2014/192824

Mustafa AF, Thacker PA, McKinnon JJ, Christensen DA, Racz VJ (2000) Nutritional value of feed grade chickpeas for ruminants and pigs. J Sci Food Agric 80(11):1581–1588

Mäkelä M, Benavente V, Fullana A (2015) Hydrothermal carbonization of lignocellulosic biomass: effect of process conditions on hydrochar properties. Appl Energy 155:576–584

Román S, Nabais J, Laginhas C, Ledesma B, González J (2012) Hydrothermal carbonization as an effective way of densifying the energy content of biomass. Fuel Process Technol 103:78–83

Elaigwu SE, Greenway GM (2016) Microwave-assisted and conventional hydrothermal carbonization of lignocellulosic waste material: comparison of the chemical and structural properties of the hydrochars. J Anal Appl Pyrolysis 118:1–8. https://doi.org/10.1016/j.jaap.2015.12.013

Afolabi OOD, Sohail M (2017) Comparative evaluation of conventional and microwave hydrothermal carbonization of human biowaste for value recovery. Water Sci Technol 75:2852–2863

Teri G, Luo L, Savage PE (2014) Hydrothermal treatment of protein, polysaccharide, and lipids alone and in mixtures. Energy Fuel 28(12):7501–7509

Elaigwu SE, Greenway GM (2016) Chemical, structural and energy properties of hydrochars from microwave-assisted hydrothermal carbonization of glucose. International Journal of Industrial Chemistry 7:1–8. https://doi.org/10.1007/s40090-016-0081-0

Álvarez-Murillo A, Sabio E, Ledesma B, Román S, González-García CM (2016) Generation of biofuel from hydrothermal carbonization of cellulose. Kinetics modelling. Energy 94:600–608. https://doi.org/10.1016/j.energy.2015.11.024

Donar YO, Çağlar E, Sınağ A (2016) Preparation and characterization of agricultural waste biomass based hydrochars. Fuel 183:366–372. https://doi.org/10.1016/j.fuel.2016.06.108

Cordero T, Marquez F, Rodriguez-Mirasol J, Rodriguez JJ (2001) Predicting heating values of lignocellulosics and carbonaceous materials from proximate analysis. Fuel 80(11):1567–1571. https://doi.org/10.1016/S0016-2361(01)00034-5

Yin C-Y (2011) Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 90(3):1128–1132. https://doi.org/10.1016/j.fuel.2010.11.031

Danso-Boateng E, Shama G, Wheatley AD, Martin SJ, Holdich RG (2015) Hydrothermal carbonisation of sewage sludge: effect of process conditions on product characteristics and methane production. Bioresour Technol 177:318–327. https://doi.org/10.1016/j.biortech.2014.11.096

Li L, Diederick R, Flora JRV, Berge ND (2013) Hydrothermal carbonization of food waste and associated packaging materials for energy source generation. Waste Manag 33(11):2478–2492. https://doi.org/10.1016/j.wasman.2013.05.025

Parshetti GK, Chowdhury S, Balasubramanian R (2014) Hydrothermal conversion of urban food waste to chars for removal of textile dyes from contaminated waters. Bioresour Technol 161:310–319. https://doi.org/10.1016/j.biortech.2014.03.087

Kaushik R, Parshetti GK, Liu Z, Balasubramanian R (2014) Enzyme-assisted hydrothermal treatment of food waste for co-production of hydrochar and bio-oil. Bioresour Technol 168:267–274. https://doi.org/10.1016/j.biortech.2014.03.022

Schimmelpfennig S, Glaser B (2012) One step forward toward characterization: some important material properties to distinguish biochars. J Environ Qual 41(4):1001–1013

Afolabi OOD, Sohail M, Thomas CPL (2015) Microwave hydrothermal carbonization of human biowastes. Waste and Biomass Valorization 6(2):147–157. https://doi.org/10.1007/s12649-014-9333-4

He C, Giannis A, Wang J-Y (2013) Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: hydrochar fuel characteristics and combustion behavior. Appl Energy 111:257–266. https://doi.org/10.1016/j.apenergy.2013.04.084

Reza MT, Lynam JG, Uddin MH, Coronella CJ (2013) Hydrothermal carbonization: fate of inorganics. Biomass Bioenergy 49:86–94. https://doi.org/10.1016/j.biombioe.2012.12.004

Chen W-H, Ye S-C, Sheen H-K (2012) Hydrothermal carbonization of sugarcane bagasse via wet torrefaction in association with microwave heating. Bioresour Technol 118:195–203. https://doi.org/10.1016/j.biortech.2012.04.101

Basso D, Patuzzi F, Castello D, Baratieri M, Rada EC, Weiss-Hortala E, Fiori L (2016) Agro-industrial waste to solid biofuel through hydrothermal carbonization. Waste Manag 47:114–121

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81(8):1051–1063. https://doi.org/10.1016/S0016-2361(01)00131-4

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, D-xylose, and wood meal. Ind Eng Chem Res 51(26):9023–9031

Peterson SC, Appell M, Jackson MA, Boateng AA (2013) Comparing corn stover and switchgrass biochar: characterization and sorption properties. J Agric Sci 5(1):1

Zhang F, Wu Q (2012) Functional materials development from kitchen waste. Procedia Environ Sci 16:70–74

Liu Z, Quek A, Hoekman SK, Srinivasan M, Balasubramanian R (2012) Thermogravimetric investigation of hydrochar-lignite co-combustion. Bioresour Technol 123:646–652

Hu B, Wang K, Wu L, Yu SH, Antonietti M, Titirici MM (2010) Engineering carbon materials from the hydrothermal carbonization process of biomass. Adv Mater 22(7):813–828

Kammann C, Ratering S, Eckhard C, Müller C (2012) Biochar and hydrochar effects on greenhouse gas (carbon dioxide, nitrous oxide, and methane) fluxes from soils. J Environ Qual 41(4):1052–1066

Gajić A, Koch H-J (2012) Sugar beet (Beta vulgaris L.) growth reduction caused by hydrochar is related to nitrogen supply. J Environ Qual 41(4):1067–1075

Kambo HS, Dutta A (2015) A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew Sust Energ Rev 45:359–378

Acknowledgements

The authors are grateful to Dr. Valerie Orsat for providing access to the FTIR equipment. The authors would like to acknowledge the “Elemental Analysis Service” at the University of Montreal and Dr. Arif Mustafa for the help with the bomb calorimetry experiments. The authors would like to acknowledge Dr. Darwin Lyew and Dr. Ramesh Murugesan for their help in consultations during the course of the research.

Funding

This work was supported by operating grants from the Natural Sciences and Engineering Research Council of Canada (NSERC) to GSVR and it was also supported by the Faculty for the Future grant by Schlumberger Foundation to SK.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors are affiliated to the McGill University and have filed for a patent for the method described in this study. The authors declare that they do not have any non-financial competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 295 kb)

Rights and permissions

About this article

Cite this article

Kannan, S., Gariepy, Y. & Vijaya Raghavan, G.S. Optimization of the conventional hydrothermal carbonization to produce hydrochar from fish waste. Biomass Conv. Bioref. 8, 563–576 (2018). https://doi.org/10.1007/s13399-018-0323-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-018-0323-9