Abstract

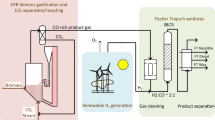

An increasing share of power production from sun and wind energy in Europe led to an increasing interest in novel energy storage technologies. The production of hydrogen from electricity via electrolysis enables the conversion of electrical energy into chemical energy, which can be stored with high energy density, if further process steps are applied. The Fischer-Tropsch process is well-known for the production of diesel fuel from different fuel types. Within the present work, results of an experimental campaign with a laboratory-scale Fischer-Tropsch plant are illustrated. The described experimental campaign was executed to determine the performance of a diesel fuel production from biomass. Furthermore, the investigation included the integration of hydrogen from wind power promoting a combined power-to-gas and biomass-to-liquid process. As a result, the investigated process is aiming at the storage of wind energy by the use of a chemical process enabling high energy density. Therefore, extensive measurement data was collected illustrating the influence of load changes on the operated laboratory-scale Fischer-Tropsch plant. The experimental campaign showed that an increased gas stream feed, enabled by the addition of hydrogen from wind power, leads to an increased output of Fischer-Tropsch products. Furthermore, the executed experimental campaign proved the suitability of different catalysts with respect to fluctuating load changes.

Similar content being viewed by others

Abbreviations

- BtL :

-

Biomass to liquid

- DVGW:

-

German Association for Gas and Water (Deutscher Verein des Gas- and Wasserfachs)

- FTsynthesis:

-

Fischer-Tropsch synthesis

- HP reactor:

-

Heat pipe reactor

- PtG:

-

Power-to-Gas

- PtL:

-

Power-to-Liquid

- RME:

-

Rapeseed methyl ester

- RWGS:

-

Reverse water-gas-shift reaction

- SNG:

-

Synthetic natural gas

- SSD:

-

Soft shut down

- UNFCCC:

-

United Nations Framework Convention on Climate Change

- α :

-

Anderson-Schulz-Flory product distribution [−]

- C5–C9 :

-

Gasoline/naphta fraction [kg/h]

- C10–C19 :

-

Diesel fraction [kg/h]

- C20–C60 :

-

Wax fraction [kg/h]

- H2/CO ratio:

-

Ratio between hydrogen and carbon monoxide [−]

- n :

-

Variable number for polymerization reaction [−]

- n.CO.out:

-

Carbon monoxide entering slurry reactor [mol/h]

- n.CO.in:

-

Carbon monoxide exiting slurry reactor [mol/h]

- m :

-

Chain length number [−]

- W m :

-

Fraction share with specific chain length [−]

- X CO :

-

Carbon monoxide conversion [%]

References

http://unfccc.int (read on October 17th 2016)

http://europa.eu/legislation_summaries/energy/european_energy_policy/ (read on Oct. 17th 2016)

Sterner M (2009) Bioenergy and renewable power methane in integrated 100% renewable energy systems: limiting global warming by transforming energy systems. Kassel Univ, Press

Aicher T, Gonzalez MI, Schaub G, Götz M (2014) Betrachtungen des Gesamtsystems im Hinblick auf Dynamik und Prozessintegration. in: Energiewasserpraxis 65, 51–55

Mayer J, Jakuttis M, Binder S, Hornung A (2014) Energetische und wirtschaftliche Betrachtung einer dezentralen Methanolsynthese in: Proceedings 13.Symposium Energieinnovation Graz

Götz M, Lefebvre J, Mörs F, McDaniel KA, Graf F, Bajohr S, Kolb T (2015) Renewable Power-to-Gas: a technological and economic review. Renew Energy 85:1371–1390. https://doi.org/10.1016/j.renene.2015.07.066

Graf F, Krajete A, Schmack U (2014) Techno-ökonomische Studie zur biologischen Methanisierung bei Power-to-Gas-Konzepten. DVGW Forschungsbericht

Götz M, Graf F, Koch A, Lefebvre J, Bajohr S, Kolb T (2015) Coupling of biomass based processes with PtG, methanation technologies, process concepts, and economics in: Proceedings World Gas Conference, Paris

Graf F, Henel M, Tichler R, Schaaf T (2014) Technoökonomische Studie von Power-to-Gas-Konzepten. DVGW Forschungsbericht

Kaim-Albers N, Holtrup F, Tornic S (2015) Energie für Deutschland 2015 - Fakten, Perspektiven und Positionen im globalen Kontext. World Energy Council - Weltenergierat Berlin

Sauciuc A, Abosteif Z, Weber G, Potetz A, Rauch R, Hofbauer H, Schaub G, Dumitrescu L (2011) Influence of pressure on the performance of biomass based Fischer-Tropsch synthesis, in: Hofbauer H. (Ed.): Proceedings of the International Conference on Polygeneration Strategies (ICPS11), Vienna

Rauch R, Kiennemann A, Sauciuc A (2013) Fischer-Tropsch synthesis to biofuels (BtL Process), in: the role of catalysis for the sustainable production of bio-fuels and bio-chemicals, Triantafyllidis K. (Ed.), Amsterdam

Maier L (2014) Production of synthetic iso-paraffinic kerosene from wood, Master thesis, FH Burgenland, Pinkafeld

Fürnsinn S (2007) Outwitting the dilemma of scale: cost and energy efficient scale-down of the Fischer-Tropsch fuel production from biomass, PhD thesis, TU Wien

Müller S (2013) Hydrogen from biomass for industry—industrial application of hydrogen production based on dual fluid gasification, PhD thesis, TU Wien

Faajii PC, Hamelinck CN, Van Hardeveld MRM (2002) Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. Biomass Bioenergy 23:129–152. https://doi.org/10.1016/S0961-9534(02)00037-5

Patzlaff J, Liu Y, Graffmann C, Gaube J (1999) Studies on product distributions of iron and cobalt catalyzed Fischer-Tropsch synthesis. Appl Catal A: Gen 186:109–119. https://doi.org/10.1016/S0926-860X(99)00167-2

Funding

The authors acknowledge financial support by the Austrian government through the “Klima- und Energiefonds” financed project Winddiesel_klienIF within the “e!Mission.at” funding scheme. The project Winddiesel_klienIF is executed in cooperation with Energie Burgenland AG, Bilfinger SE, Güssing Energy Technologies GmbH, REPOTEC GmbH & Co KG, Energy & Chemical Engineering GmbH, and the Institute of Chemical Engineering from TU WIEN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Müller, S., Groß, P., Rauch, R. et al. Production of diesel from biomass and wind power – Energy storage by the use of the Fischer-Tropsch process. Biomass Conv. Bioref. 8, 275–282 (2018). https://doi.org/10.1007/s13399-017-0287-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0287-1