Abstract

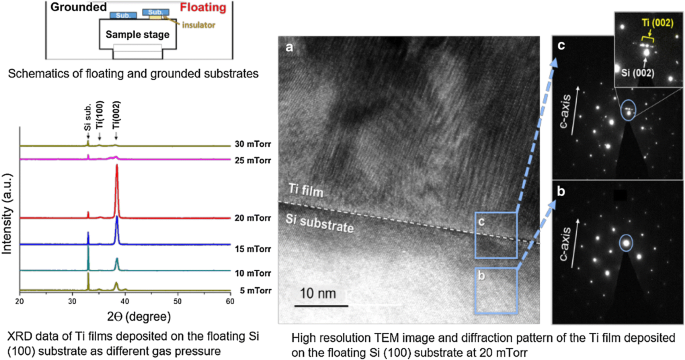

The possibility of preparing highly (002) oriented Ti films on the Si (100) substrate was studied using RF sputtering. The deposition behavior was compared between floating and grounded substrates at room temperature. Highly (002) oriented Ti films could be successfully prepared on the floating Si (100) substrate, which was revealed by X-ray diffraction and high resolution transmission electron microscope. To understand the different deposition behavior between floating and grounded substrates, the incident energy of ions during RF sputtering was estimated from the substrate temperature measured by the K-type thermocouple. The incident energy on the floating substrate was lower by 20% than that on the grounded substrate. It was suggested that the lower incident energy on the floating substrate would be responsible for the deposition of highly (002) oriented Ti films at room temperature.

Graphic Abstract

Similar content being viewed by others

References

Jackson, N., O’Keeffe, R., Waldron, F., O’Neill, M., Mathewson, A.: Influence of aluminum nitride crystal orientation on MEMS energy harvesting device performance. J. Micromech. Microeng. 23(7), 1–9 (2013). https://doi.org/10.1088/0960-1317/23/7/075014

Tran, A.T., Wunnicke, O., Pandraud, G., Nguyen, M.D., Schellevis, H., Sarro, P.M.: Slender piezoelectric cantilevers of high quality AlN layers sputtered on Ti thin film for MEMS actuators. Sens. Actuators A Phys. 202, 118–123 (2013). https://doi.org/10.1016/j.sna.2013.01.047

Ting, C., Wittmer, M.: The use of titanium-based contact barrier layers in silicon technology. Thin Solid Films 96, 327–345 (1982)

Huang, L., Liu, B., Zhu, Q., Chen, S., Gao, M., Qin, F., Wang, D.: Low resistance Ti Ohmic contacts to 4H-SiC by reducing barrier heights without high temperature annealing. Appl. Phys. Lett. 100(26), 1–4 (2012). https://doi.org/10.1063/1.4730435

Suzuki, M., Kawakami, T., Arai, T., Kobayashi, S., Koide, Y., Uemura, T., Shibata, N., Murakami, M.: Low-resistance Ta/Ti Ohmic contacts for p-type GaN. Appl. Phys. Lett. 74(2), 275–277 (1999). https://doi.org/10.1063/1.123279

Kaur, M., Singh, K.: Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C Mater. Biol. Appl. 102, 844–862 (2019). https://doi.org/10.1016/j.msec.2019.04.064

Boyer, R.R.: An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. a213, 103–114 (1996)

Iriarte, G.F., Bjurstrom, J., Westlinder, J., Engelmark, F., Katardjiev, I.V.: Synthesis of C-axis-oriented AlN thin films on high-conducting layers_Al, Mo, Ti, TiN, and Ni. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 52(7), 1170–1174 (2005)

Xiong, J., Gu, H.S., Hu, K., Hu, M.Z.: Influence of substrate metals on the crystal growth of AlN films. Int. J. Miner. Metall. Mater. 17(1), 98–103 (2010). https://doi.org/10.1007/s12613-010-0117-y

Chawla, V., Jayaganthan, R., Chawla, A.K., Chandra, R.: Morphological study of magnetron sputtered Ti thin films on silicon substrate. Mater. Chem. Phys. 111(2–3), 414–418 (2008). https://doi.org/10.1016/j.matchemphys.2008.04.048

Chawla, V., Jayaganthan, R., Chawla, A.K., Chandra, R.: Microstructural characterizations of magnetron sputtered Ti films on glass substrate. J. Mater. Process. Technol. 209(7), 3444–3451 (2009). https://doi.org/10.1016/j.jmatprotec.2008.08.004

Chen, A.Y., Bu, Y., Tang, Y.T., Wang, Y., Liu, F., Xie, X.F., Gu, J.F.: Deposition-rate dependence of orientation growth and crystallization of Ti thin films prepared by magnetron sputtering. Thin Solid Films 574, 71–77 (2015). https://doi.org/10.1016/j.tsf.2014.10.053

Jeyachandran, Y.L., Karunagaran, B., Narayandass, S.K., Mangalaraj, D.: The effect of thickness on the properties of titanium films deposited by dc magnetron sputtering. Mater. Sci. Eng., A 458(1–2), 361–365 (2007). https://doi.org/10.1016/j.msea.2006.12.088

Tetsu Miyoshi, Y.H., Nittono, O.: Microstructure and preferred orientation in pure titanium films deposited by two-facing-target-type dc sputtering. Thin Solid Films 281–282, 128–131 (1996). https://doi.org/10.1016/0040-6090(96)08592-6

Muslim, N., Soon, Y.W., Lim, C.M., Voo, N.Y.: Influence of sputtering power on properties of titanium thin films deposited by rf magnetron sputtering. ARPN J. Eng. Appl. Sci. 10(16), 7148–7189 (2015)

Maissel, L.I., Schaible, P.M.: Thin films deposited by bias sputtering. J. Appl. Phys. 36(1), 237–242 (1965). https://doi.org/10.1063/1.1713883

Smidt, F.A.: Use of ion beam assisted deposition to modify the microstructure and properties of thin films. Int. Mater. Rev. 35, 61–128 (1990)

Zhang, L., Shi, L.Q., He, Z.J., Zhang, B., Lu, Y.F., Liu, A., Wang, B.Y.: Deposition of dense and smooth Ti films using ECR plasma-assisted magnetron sputtering. Surf. Coat. Technol. 203(22), 3356–3360 (2009). https://doi.org/10.1016/j.surfcoat.2009.04.022

Burton, A.W., Ong, K., Rea, T., Chan, I.Y.: On the estimation of average crystallite size of zeolites from the Scherrer equation: a critical evaluation of its application to zeolites with one-dimensional pore systems. Microporous Mesoporous Mater. 117(1–2), 75–90 (2009). https://doi.org/10.1016/j.micromeso.2008.06.010

Hoshi, Y., Suzuki, E., Shimizu, H.: Control of crystal orientation of Ti thin films by sputtering. Electrochim. Acta 44, 3945–3952 (1999)

Kersten, H., Rohde, D., Berndt, J., Deutsch, H., Hippler, R.: Investigations on the energy influx at plasma processes by means of a simple thermal probe. Thin Solid Films 377–378, 585–591 (2000)

Acknowledgements

This work was supported by Global Frontier Program through the Global Frontier Hybrid Interface Materials (GFHIM) of the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (MSIT) (No. NRF-2013M3A6B1078874) and the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. NRF-2015R1A5A1037627).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kwon, J.H., Kim, D.Y., Kim, KS. et al. Preparation of Highly (002) Oriented Ti Films on a Floating Si (100) Substrate by RF Magnetron Sputtering. Electron. Mater. Lett. 16, 14–21 (2020). https://doi.org/10.1007/s13391-019-00182-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-019-00182-3