Abstract

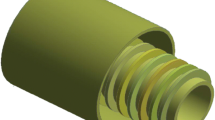

In this paper flow features and heat transfer characteristics of finned and finless double-tube counter flow heat exchanger at wide range of Reynolds numbers were numerically analyzed. Various fins configurations combined with use of water-based TiO2 nanofluid at different nanoparticles volume concentrations were employed in this study to show their effects on nanofluid Nusselt number, friction factor and thermal performance index. Furthermore, the thermal perfection and the overall assessment of heat exchanger were also taken into account in the light of thermodynamics second law efficiency which is defined as a ratio of recovered to expended exergy. The results showed that thermo-hydrodynamical performance of heat exchanger was intensively dependent to the thickness of embedded fins. Employed sensitivity analysis revealed that fins with large thicknesses equal or larger than 10 mm provide better thermal performance than fins with small thicknesses (i.e. t = 1 mm). Furthermore, the use of circular fin with thickness as large as 10 mm at the highest Reynolds number up to about 87,500 led to pronounce both Nusselt number and flow resistance up to 15% and 4.64 folds, respectively. On the other hand, using smooth heat exchanger operating at the lowest Reynolds number (i.e. Re = 3400) filled with 1% TiO2 water-based nanofluid led to obtain the highest recovered exergy and thermodynamic second law efficiency up to 0.46 W and 10.33%, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer surface area (m2)

- C 2 :

-

Model constant

- C p :

-

Specific heat at constant pressure \((\frac{\mathrm{J}}{\mathrm{kg K}})\)

- \({C}_{\mu }\) :

-

Model parameter

- D :

-

Tube diameter (m)

- D h :

-

Hydraulic diameter (m)

- f :

-

Friction factor

- h :

-

Heat transfer coefficient (W/m2 K), fin height (m)

- k :

-

Turbulent kinetic energy (m2/s2), thermal conductivity (W/mK)

- k b :

-

Boltzmann number

- L :

-

Length of tube (m)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- Nu :

-

Nusselt number (hDh/K)

- p :

-

Pressure (Pa)

- Pr :

-

Prandtl number \(\left({C}_{p}\mu /\mathrm{K}\right)\)

- q :

-

Heat flux (W/m2)

- Q :

-

Heat transfer rate (W)

- Re :

-

Reynolds number \((\rho u{D}_{h}/\mu )\)

- S :

-

Fin spacing (m)

- s :

-

Specific entropy \((\frac{\mathrm{J}}{\mathrm{K}})\)

- t :

-

Fin thickness (m)

- T :

-

Temperature (K)

- u :

-

Velocity component in flow direction (m/s)

- W :

-

Work (J)

- Y + :

-

Dimensionless distance from wall

- \(\Delta\) :

-

Difference operator

- \({\delta }_{ij}\) :

-

Delta Kronecker

- \(\varepsilon\) :

-

Turbulent dissipation rate, m2/s3

- \(\mu\) :

-

Dynamic viscosity, kg/m s

- \(\rho\) :

-

Density, kg/m3

- \(\alpha\) :

-

Thermal diffusivity (m2/s)

- \(\nu\) :

-

Kinematic viscosity (m2/s), specific volume (1/m3)

- \({\sigma }_{\tau }\) :

-

Turbulent Prandtl number in energy equation

- \({\sigma }_{k}\) :

-

Diffusion Prandtl number for \(k\)

- \({\sigma }_{\varepsilon }\) :

-

Diffusion Prandtl number for \(\varepsilon\)

- \(\mathrm{\varnothing }\) :

-

Nanoparticles volume concentration

- \(\psi\) :

-

Specific flow exergy

- \(\dot{X}\) :

-

Exergy rate

- \({\eta }_{\mathrm{\rm I}\mathrm{\rm I}}\) :

-

Second law efficiency

- \({\eta }_{\mathrm{t}-\mathrm{h}}\) :

-

Thermo-hydrodynamical performance index

- ave:

-

Average

- hw:

-

Hot water

- b:

-

Bulk quantity

- bf:

-

Base fluid

- fr:

-

Freezing

- in:

-

Inlet

- IT:

-

Inner tube

- \(i,j,k\) :

-

Spatial indices

- m:

-

Mean value

- nf:

-

Nanofluid

- out:

-

Outlet

- p:

-

Nanoparticle

- s:

-

Smooth, surface area

- t:

-

Turbulent quantity

- t-h:

-

Thermo-hydrodynamic

- w:

-

Wall

- CFD:

-

Computational fluid dynamics

- UDF:

-

User-defined function

- DTCHEX:

-

Double-tube counter flow heat exchanger

References

Mahian, O.; Kianifar, A.; Kalogirou, S.A.; Pop, I.; Wongwises, S.: A review of the applications of nanofluids in solar energy. Int. J. Heat Mass Transf. 57(2), 582–594 (2013)

Azmi, W.H.; Sharif, M.Z.; Yusof, T.M.; Mamat, R.; Redhwan, A.A.M.: Potential of nanorefrigerant and nanolubricant on energy saving in refrigeration system–a review. Renew. Sustain. Energy Rev. 69, 415–428 (2017)

Sharma, S.: Fabricating an experimental setup to investigate the performance of an automobile car radiator by using aluminum/water nanofluid. J. Therm. Anal. Calorim. 133(3), 1387–1406 (2018)

Ghanbari, S.; Javaherdeh, K.: Investigation of applying nanoporous graphene non-Newtonian nanofluid on rheological properties and thermal performance in a turbulent annular flow with perforated baffles. J. Therm. Anal. Calorim. 139(1), 629–647 (2020)

Ahmad, S.; Pop, I.: Mixed convection boundary layer flow from a vertical flat plate embedded in a porous medium filled with nanofluids. Int. Commun. Heat Mass Transfer 37(8), 987–991 (2010)

Tuncer, A.D.; Sözen, A.; Khanlari, A.; Gürbüz, E.Y.; Variyenli, H.I.: Upgrading the performance of a new shell and helically coiled heat exchanger by using longitudinal fins. Appl. Therm. Eng. 191, 116876 (2021)

Roy, N.C.: Natural convection of nanofluids in a square enclosure with different shapes of inner geometry. Phys. Fluids 30(11), 113605 (2018)

Roy, N.C.: MHD natural convection of a hybrid nanofluid in an enclosure with multiple heat sources. Alex. Eng. J. 61(2), 1679–1694 (2022)

Roy, N.C.: Augmentation in heat transfer for a hybrid nanofluid flow over a roughened surface. Case Stud. Therm. Eng. 27, 101215 (2021)

Bahiraei, M.; Mazaheri, N.; Rizehvandi, A.: Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple-tube heat exchanger equipped with inserted ribs. Appl. Therm. Eng. 149, 588–601 (2019)

Pak, B.C.; Cho, Y.I.: Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. Int. J. 11(2), 151–170 (1998)

Duangthongsuk, W.; Wongwises, S.: Effect of thermophysical properties models on the predicting of the convective heat transfer coefficient for low concentration nanofluid. Int. Commun. Heat Mass Transf. 35(10), 1320–1326 (2008)

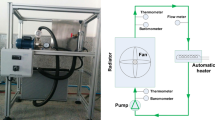

Duangthongsuk, W.; Wongwises, S.: An experimental study on the heat transfer performance and pressure drop of TiO2-water nanofluids flowing under a turbulent flow regime. Int. J. Heat Mass Transf. 53(1–3), 334–344 (2010)

Qi, C.; Luo, T.; Liu, M.; Fan, F.; Yan, Y.: Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers. Manag. 197, 111877 (2019)

Bahmani, M.H.; Sheikhzadeh, G.; Zarringhalam, M.; Akbari, O.A.; Alrashed, A.A.; Ahmadi Sheikh Shabani, G.; Goodarzi, M.: Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Ad. Powder Technol. 29(2), 273–282 (2018)

Rashidi, S.; Eskandarian, M.; Mahian, O.; Poncet, S.J.J.O.T.A.: Combination of nanofluid and inserts for heat transfer enhancement. J. Therm. Anal. Calorim. 135(1), 437–460 (2019)

Hamza, N.F.A.; Aljabair, S.: Evaluation of thermal performance factor by hybrid nanofluid and twisted tape inserts in heat exchanger. Heliyon. 2022, e11950 (2022)

Sivasankaran, S.; Bhuvaneswari, M.: Numerical study on influence of water based hybrid nanofluid and porous media on heat transfer and pressure loss. Case Stud. Therm. Eng. 34, 102022 (2022)

Rabby, M.I.I.; Sharif, M.A.R.; Hossain, F.: Numerical study of laminar convective heat transfer from a corrugated pipe into an Al2O3–AlN/H2O hybrid nanofluid. Case Stud. Therm. Eng. 39, 102454 (2022)

Elias, M.M.; Shahrul, I.M.; Mahbubul, I.M.; Saidur, R.; Rahim, N.A.: Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int. J. Heat Mass Transf. 70, 289–297 (2014)

Targui, N.; Kahalerras, H.: Analysis of a double pipe heat exchanger performance by use of porous baffles and pulsating flow. Energy Convers. Manag. 76, 43–54 (2013)

Bashi, M.; Rashidi, S.; Esfahani, J.A.: Exergy analysis for a plate-fin triangular duct enhanced by a porous material. Appl. Therm. Eng. 110, 1448–1461 (2017)

Mozafarie, S.S.; Javaherdeh, K.; Ghanbari, O.: Numerical simulation of nanofluid turbulent flow in a double-pipe heat exchanger equipped with circular fins. J. Therm. Anal. Calorim. 143(6), 4299–4311 (2021)

Hatami, M.; Ganji, D.D.; Gorji-Bandpy, M.: Experimental and numerical analysis of the optimized finned-tube heat exchanger for OM314 diesel exhaust exergy recovery. Energy Convers. Manag. 97, 26–41 (2015)

Chen, H.; Ding, Y.; He, Y.; Tan, C.: Rheological behavior of ethylene glycol based titania nanofluids. Chem. Phys. Lett. 444(4–6), 333–337 (2007)

Yang, L.; Hu, Y.: Toward TiO2 nanofluids—part 1: preparation and properties. Nanoscale Res. Lett. 12(1), 1–21 (2017)

Mohammadi, M.; Abadeh, A.; Nemati-Farouji, R.; Passandideh-Fard, M.: An optimization of heat transfer of nanofluid flow in a helically coiled pipe using Taguchi method. J. Therm. Anal. Calorim. 138(2), 1779–1792 (2019)

Shih, T.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J.: A new k-ϵ eddy viscosity model for high Reynolds number turbulent flows. Comput. Fluids 24(3), 227–238 (1995)

Jayakumar, J.S.; Mahajani, S.M.; Mandal, J.C.; Iyer, K.N.; Vijayan, P.K.: CFD analysis of single-phase flows inside helically coiled tubes. Comput. Chem. Eng. 34(4), 430–446 (2010)

Aly, W.I.A.: Numerical study on turbulent heat transfer and pressure drop of nanofluid in coiled tube-in-tube heat exchangers. Energy Convers. Manag. 79, 304–316 (2014)

Sekrani, G.; Poncet, S.; Proulx, P.: Modeling of convective turbulent heat transfer of water-based Al2O3 nanofluids in an uniformly heated pipe. Chem. Eng. Sci. 176, 205–219 (2018)

Khanafer, K.; Vafai, K.: A critical synthesis of thermophysical characteristics of nanofluids. Int. J. Heat Mass Transf. 54(19–20), 4410–4428 (2011)

Corcione, M.: Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 52(1), 789–793 (2011)

Wang, X.; Xu, X.; Choi, S.U.S.: Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Transf. 13(4), 474–480 (1999)

Xuan, Y.; Roetzel, W.: Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 43(19), 3701–3707 (2000)

Hamilton, R.L.; Crosser, O.K.: Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1(3), 187–191 (1962)

Yu, W.; Choi, S.U.S.: The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J. Nanopart. Res. 5(1), 167–171 (2003)

Timofeeva, E.V.; Gavrilov, A.N.; McCloskey, J.M.; Tolmachev, Y.V.; Sprunt, S.; Lopatina, L.M.; Selinger, J.V.: Thermal conductivity and particle agglomeration in alumina nanofluids: experiment and theory. Phys. Rev. E 76(6), 061203 (2007)

Brinkman, H.C.: The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 20(4), 571–571 (1952)

Batchelor, G.K.: The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J. Fluid Mech. 83(1), 97–117 (1977)

Çengel, Y.A.; Cimbala, J.M.: Fluid Mechanics: Fundamentals and Applications. McGraw-Hill Higher Education, New York (2010)

Gnielinski, V.: New equations for heat and mass transfer in turbulent pipe and channel flow. Int. Chem. Eng. 16(2), 359–368 (1976)

Petukhov, B.S.; Irvine, T.F.; Hartnett, J.P.: Advances in heat transfer. Academic, New York. 6, 503–564 (1970)

Bergman, T.L.; Incropera, F.P.; DeWitt, D.P.; Lavine, A.S.: Fundamentals of Heat and Mass Transfer. Wiley, New York (2011)

Etghani, M.M.; Baboli, S.A.H.: Numerical investigation and optimization of heat transfer and exergy loss in shell and helical tube heat exchanger. Appl. Therm. Eng. 121, 294–301 (2017)

Alimoradi, A.: Investigation of exergy efficiency in shell and helically coiled tube heat exchangers. Cast Stud. Therm. Eng. 10, 1–8 (2017)

Cengel, Y.A.; Boles, M.A.: Thermodynamics: An Engineering Approach, 7th edn. McGraw-Hill Education, New York (2011)

Colebrook, C.F.: Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civ. Eng. 11, 133–156 (1939)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing financial interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammadi, M. Numerical Study of Turbulent Nanofluid Flow in Double-Tube Heat Exchanger: The Role of Second Law Analysis. Arab J Sci Eng 48, 12269–12290 (2023). https://doi.org/10.1007/s13369-023-07732-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07732-w