Abstract

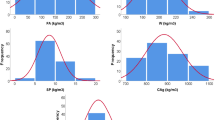

This study developed a prediction model of the carbonation depth of concrete containing mineral admixtures based on an intelligent algorithm. A carbonation test database of mineral admixture concrete was established considering the influence of 17 parameters. The intelligent algorithm and three existing carbonation depth prediction models were analysed based on the database. The evaluation results indicated that the prediction accuracy of the back-propagation neural network is higher than that of the support vector machine, and the prediction accuracies of the two intelligent algorithms are higher than those of the existing numerical prediction models for carbonation depth. A variable importance analysis indicated that the content of fly ash in mineral admixture has a relatively large influence on the carbonation depth, and the carbonation time is the most critical factor affecting the carbonation depth of concrete containing mineral admixture.

Similar content being viewed by others

Abbreviations

- W :

-

Water

- W/C :

-

Water-binder ratio

- \({K}_{{\mathrm{CO}}_{2}}\) :

-

Factor of CO2 concentration

- C 0 :

-

CO2 concentration by volume, %

- \({{\varvec{K}}}_{{\varvec{k}}1}\) :

-

Location factor

- \({{\varvec{K}}}_{{\varvec{k}}{\varvec{t}}}\) :

-

Curing and casting factor

- \({{\varvec{K}}}_{{\varvec{k}}{\varvec{s}}}\) :

-

Stress factor

- K F :

-

Fly ash replacement factor

- F :

-

Fly ash replacement ratio, %

- \({{\varvec{f}}}_{\mathbf{c}\mathbf{u}.{\varvec{k}}}\) :

-

Standard value of cube compressive strength, MPa

- w :

-

Water content, kg/m3

- c :

-

Cement content, kg/m3

- \({{\varvec{\gamma}}}_{\mathbf{c}}\) :

-

Coefficient for cement type

- \({\gamma }_{\mathrm{HD}}\) :

-

Coefficient of the degree of hydration

- \({n}_{0}\) :

-

CO2 concentration by volume, %

- \({r}_{1}\) :

-

Influence coefficient of cement variety

- \({r}_{2}\) :

-

Influence coefficient of fly ash

- \({r}_{3}\) :

-

Influence coefficient of climatic conditions

- \(d\left(t\right)\) :

-

Carbonation depth at service time t

- t :

-

Carbonization time, d

- \({K}_{\mathrm{c}}\) :

-

Cement variety

- Ma:

-

Types of mineral admixtures

- \({f}_{\mathrm{cu}}\) :

-

Cube compressive strength, MPa

- Cco2 :

-

Carbon dioxide concentration

- T :

-

Temperature

- R 2 :

-

Coefficient of determination

- R :

-

Correlation coefficient

- BP:

-

Back-propagation

- SVM:

-

Support vector machine

- C:

-

Cement

- FA:

-

Fly ash

- GGBS:

-

Ground granulated blast furnace slag

- SP:

-

Steel slag powder

- SF:

-

Silica fume

- MK:

-

Metakaolin

- Fine:

-

Fine aggregate

- Coarse:

-

Coarse aggregate

- CR:

-

Cement replacement rate

- CA:

-

Concrete admixture

- MSE:

-

Mean square error

- MAPE:

-

Mean absolute percentage error

- IAE:

-

Integral absolute error

- SD:

-

Standard deviation

- RMSD:

-

Root mean square deviation

- SRC:

-

Standardised regression coefficient

- ET:

-

Exposure time

- CD:

-

Carbonation depth

- CT:

-

Concrete curing time

- RH:

-

Relative humidity

References

Dong, B.; Qiu, Q.; Xiang, J., et al.: Electrochemical impedance measurement and modeling analysis of the carbonation behavior for cementititous materials. Constr. Build. Mater. 54, 558–565 (2014)

Roziere, E.; Loukili, A.; Cussigh, F.: A performance based approach for durability of concrete exposed to carbonation. Constr. Build. Mater. 23(1), 190–199 (2009)

Steffens, A.; Dinkler, D.; Ahrens, H.: Modeling carbonation for corrosion risk prediction of concrete structures. Cem. Concr. Res. 32(6), 935–941 (2002)

Taffese, W.Z.; Sistonen, E.; Puttonen, J.: CaPrM: Carbonation prediction model for reinforced concrete using machine learning methods. Constr. Build. Mater. 100, 70–82 (2015)

Boden, T.; Andres, B.; Marland, G.: Global co2 emissions from fossil-fuel burning. Cem. Manuf. Gas Flaring 1751, 37831–46335 (2006)

Environment, U.N.; Scrivener, K.L.; John, V.M., et al.: Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 114, 2–26 (2018)

Skibsted, J.; Snellings, R.: Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 124, 105799 (2019)

Zhang, X.; Zhou, X.; Zhou, H., et al.: Studies on forecasting of carbonation depth of slag high performance concrete considering gas permeability. Appl. Clay Sci. 79, 36–40 (2013)

Andrade, H.D.; de Carvalho, J.M.F.; Costa, L.C.B., et al.: Mechanical performance and resistance to carbonation of steel slag reinforced concrete. Constr. Build. Mater. 298, 123910 (2021)

Witkowski, H.; Koniorczyk, M.: The influence of pozzolanic additives on the carbonation rate and Life Cycle Inventory of concrete. Constr. Build. Mater. 254, 119301 (2020)

Hussain, S.; Bhunia, D.; Singh, S.B.: Comparative study of accelerated carbonation of plain cement and fly-ash concrete. J. Build. Eng. 10, 26–31 (2017)

Chang, H.; Wang, Y.; Wang, X., et al.: Effects of carbonation on phase composition of Metakaolin-blended cement pastes. Constr. Build. Mater. 324, 126639 (2022)

Younsi, A.; Turcry, P.; Aït-Mokhtar, A.: Quantification of CO2 uptake of concretes with mineral additions after 10-year natural carbonation. J. Clean. Prod. 349, 131362 (2022)

Sharma, R.; Khan, R.A.: Influence of copper slag and metakaolin on the durability of self compacting concrete. J. Clean. Prod. 171, 1171–1186 (2018)

Cheng, S.; Shui, Z.; Sun, T., et al.: Effects of fly ash, blast furnace slag and metakaolin on mechanical properties and durability of coral sand concrete. Appl. Clay Sci. 141, 111–117 (2017)

Rathnarajan, S.; Dhanya, B.S.; Pillai, R.G., et al.: Carbonation model for concretes with fly ash, slag, and limestone calcined clay-using accelerated and five-year natural exposure data. Cement Concr. Compos. 126, 104329 (2022)

Qin, L.; Gao, X.; Chen, T.: Influence of mineral admixtures on carbonation curing of cement paste. Constr. Build. Mater. 212, 653–662 (2019)

Shah, V.; Bishnoi, S.: Carbonation resistance of cements containing supplementary cementitious materials and its relation to various parameters of concrete. Constr. Build. Mater. 178, 219–232 (2018)

Tuuti, K.: Corrosion of Steel in Concrete, Report. Swedish Cement and Concrete Research Institute, Stockholm (1982)

Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N.: Fundamental modeling and experimental investigation of concrete carbonation. Mater. J. 88(4), 363–373 (1991)

Liu, K.; Alam, M.S.; Zhu, J., et al.: Prediction of carbonation depth for recycled aggregate concrete using ANN hybridized with swarm intelligence algorithms. Constr. Build. Mater. 301, 124382 (2021)

Gehlot, T.; Dave, M.; Solanki, D.: Neural network model to predict compressive strength of steel fiber reinforced concrete elements incorporating supplementary cementitious materials. Mater. Today Proc. (2022). https://doi.org/10.1016/j.matpr.2022.04.327

Moradi, M.J.; Khaleghi, M.; Salimi, J., et al.: Predicting the compressive strength of concrete containing metakaolin with different properties using ANN. Measurement 183, 109790 (2021)

Penido, R.E.K.; da Paixão, R.C.F.; Costa, L.C.B., et al.: Predicting the compressive strength of steelmaking slag concrete with machine learning—considerations on developing a mix design tool. Constr. Build. Mater. 341, 127896 (2022)

Atici, U.: Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst. Appl. 38(8), 9609–9618 (2011)

Chithra, S.; Kumar, S.R.R.S.; Chinnaraju, K., et al.: A comparative study on the compressive strength prediction models for High Performance Concrete containing nano silica and copper slag using regression analysis and Artificial Neural Networks. Constr. Build. Mater. 114, 528–535 (2016)

Felix, E.F.; Carrazedo, R.; Possan, E.: Carbonation model for fly ash concrete based on artificial neural network: Development and parametric analysis. Constr. Build. Mater. 266, 121050 (2021)

Cardoso, C.A.V.; Cruz, G.L.: Forecasting natural gas consumption using ARIMA models and artificial neural networks. IEEE Lat. Am. Trans. 14(5), 2233–2238 (2016)

Neto, A.B.; Bonini, C.S.B.; Bisi, B.S., et al.: Artificial neural network for classification and analysis of degraded soils. IEEE Lat. Am. Trans. 15(3), 503–509 (2017)

Luo, D., Niu, D., Dong, Z.: Application of neural network for concrete carbonation depth prediction (2014)

Kellouche, Y.; Boukhatem, B.; Ghrici, M., et al.: Exploring the major factors affecting fly-ash concrete carbonation using artificial neural network. Neural Comput. Appl. 31(2), 969–988 (2019)

Zhang, Y.; Niu, D.G.; Li, S.B.: Experimental study on fly ash concrete carbonation. Sci. Technol. Eng. 17(27), 275–278 (2017)

He, X.Y.; Han, K.; Du, L., et al.: Study on effect of mineral admixture on carbonation resistance of C30 concret. Sci. Technol. Vis. 11, 98–99 (2018)

Li, J.Z.; Zhu, L.: Study on carbonation resistance of fly ash high performance concrete. China Concr. Cem. Prod. 10, 28–30 (2018)

Yao, Z.Y.; Meng, Z.L.; Zhang, F.S.; et al.: Effect of admixture content on carbonation property of concret. Exp. Res. 121, 64–68 (2019)

Chen, K.: Experimental study on the carbonization characteristics of concrete with fly ash content. Jiangxi Build. Mater. 1, 22–23 (2020)

Huang, C.Y.; Huang, L.P.; Huang, J.F.; et al.: Experimental study on compressive strength and carbonation profiles of recycled concrete with high mineral admixture content. Fujian Constr. Technol. 2, 31–34 (2020)

Fan, Y.H.; He, Z.; Cai, X.H., et al.: Study on mechanical properties and carbonization resistance of concrete with different fly ash content and curing conditions. Guangdong Build. Mater. 37(7), 4–6+3 (2021)

Wang, Y.L.; Wang, S.Y.; Liu, Q.L.: Influences of active admixtures on anti-carbonization performance of concrete. Bull. Chin. Ceram. Soc. 40(2), 439–446 (2021)

Khunthongkeaw, J.; Tangtermsirikul, S.; Leelawat, T.: A study on carbonation depth prediction for fly ash concrete. Constr. Build. Mater. 20(9), 744–753 (2006)

Khalil, E.A.B.; Anwar, M.: Carbonation of ternary cementitious concrete systems containing fly ash and silica fume. Water Sci. 29(1), 36–44 (2015)

Singh, N.; Singh, S.P.: Carbonation and electrical resistance of self compacting concrete made with recycled concrete aggregates and metakaolin. Constr. Build. Mater. 121, 400–409 (2016)

Zhou, W.L.; Fang, K.L.; Zhan, B.: Study on the carbonation resistance of concrete mixed with fly ash and mineral powder. Concr. Cem. Prod. 12, 14–19 (2012)

Wang, X.; Wang, Y.; Liushuan, Y., et al.: Research on the anti-carbonation performance of high-volume fly ash concrete. Concrete 2013(2), 5–7 (2013)

Liu, Y.H.; Li, C.: Study on the anti-carbonation performance of high-volume fly ash concrete. Henan Build. Mater. 6, 26–27 (2013)

Tian, L.M.; Zhang, J.H.; Li, B.: Experimental study on carbonization and steel corrosion of concrete with large volume of fly ash. J. Langfang Normal Univ. Nat. Sci. Ed. 14(4), 98–99 (2014)

Min, J.; Han, J.Y.; Song, X.Y.: Carbonization properties of slag and fly ash concrete. Compr. Util. Fly Ash 5, 19–21 (2014)

Yin, H.: Research on the Carbonization Performance of Concrete with Large Amount of Mineral admixture. Yanshan University (2016)

Zhang, Y.C.; Lu, L.C.; Yao, Y.G., et al.: Research on the carbonation effect of fly ash concrete. Constr. Technol. 45(S2), 526–529 (2016)

Chen, J.; Wen, X.D.; He, Y.L., et al.: Early carbonation characteristics and prediction of high-volume mineral admixture concrete. Highway 64(12), 230–235 (2019)

Dong, W.; Su, Y.; Lin, Y.J., et al.: Effect of fly ash on carbonation resistance of recycled concrete. J. Yangtze River Acad. Sci. 36(9), 142 (2019)

Atiş, C.D.: Accelerated carbonation and testing of concrete made with fly ash. Constr. Build. Mater. 17(3), 147–152 (2003)

Gao, Y.; Cheng, L.; Gao, Z., et al.: Effects of different mineral admixtures on carbonation resistance of lightweight aggregate concrete. Constr. Build. Mater. 43, 506–510 (2013)

Feng, Z.J.; Ye, X.L.: Research on the influence of mineral admixtures on carbonization of concrete. Sci. J. Intell. Syst. Res. 2020, 20–28 (2020)

Shi, H.; Xu, B.; Zhou, X.: Influence of mineral admixtures on compressive strength, gas permeability and carbonation of high performance concrete. Constr. Build. Mater. 23(5), 1980–1985 (2009)

Zhao, Q.; He, X.; Zhang, J., et al.: Long-age wet curing effect on performance of carbonation resistance of fly ash concrete. Constr. Build. Mater. 127, 577–587 (2016)

Sisomphon, K.; Franke, L.: Carbonation rates of concretes containing high volume of pozzolanic materials. Cem. Concr. Res. 37(12), 1647–1653 (2007)

Kurda, R.; de Brito, J.; Silvestre, J.D.: Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 29, 12–19 (2019)

Papadakis, V.G.: Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 30(2), 291–299 (2000)

Yang, Y.; Ning, C.P.: Experimental study and theoretical analysis of carbonation performance of activated admixture recycled concrete. Concrete 5, 94–98 (2017)

China Association for Engineering Construction Standardization (CECS): Standard for Durability Assessment of Concrete Structures (2007)

Zhang, Y.; Jiang, L.X.: A practical mathematical model of concrete carbonation depth based on the mechanism. Ind. Constr. 28(1), 16–19 (1998)

Xiao, J.; Gou, C.F.: A review of concrete carbonation research. Concrete 1, 40–44 (2010)

Adhikary, B.B.; Mutsuyoshi, H.: Prediction of shear strength of steel fiber RC beams using neural networks. Constr. Build. Mater. 20(9), 801–811 (2006)

Zhou, Z.: A review of the development status of BP neural network. Shanxi Electron. Technol. 2, 90–92 (2008)

Aljarah, I.; Faris, H.; Mirjalili, S.: Optimizing connection weights in neural networks using the whale optimization algorithm. Soft Comput. 22(1), 1–15 (2018)

Kwon, S.J.; Song, H.W.: Analysis of carbonation behavior in concrete using neural network algorithm and carbonation modeling. Cem. Concr. Res. 40(1), 119–127 (2010)

Vapnik, V.: The Nature of Statistical Learning Theory. Springer, Berlin (1999)

Simon, H.: The Principle of Neural Network. Ye Shiwei and Shi Zhongzhi (translated). Machinery Industry Press, Beijing (2004)

Zhang, H.R.; Han, Z.Z.; Li, C.G.: Support vector machines. Comput. Sci. 12, 135–137 (2002)

Taylor, K.E.: Summarizing multiple aspects of model performance in a single diagram. J. Geophys. Res. Atmos. 106(D7), 7183–7192 (2001)

Liu, R.X.; Kuang, J.; Gong, Q., et al.: Principal component regression analysis with SPSS. Comput. Methods Progr. Biomed. 71(2), 141–147 (2003)

Wei, P.; Lu, Z.; Song, J.: Variable importance analysis: a comprehensive review. Reliab. Eng. Syst. Saf. 142, 399–432 (2015)

Parrott, L.J.: A Review of Carbonation in Reinforced Concrete (1987)

Duval, R.: La durabilité des armatures et du béton d’enrobage, p. 173–225. Pressesde l’École Nationale des Ponts et Chaussées, Paris (1992)

Peng, Z.; Shi, C.; Shi, Z., et al.: Alkali-aggregate reaction in recycled aggregate concrete. J. Clean. Prod. 255, 120238 (2020)

Felix, E.F.; Carrazedo, R.; Possan, E.: Parametric analysis of carbonation process in reinforced concrete structures through Artificial Neural Networks. Revista ALCONPAT 7(3), 302–316 (2017)

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Project No. 52108132), the Natural Science Foundation of Hebei Province (Project No. E2021202067), the Colleges and Universities in Hebei Province Science and Technology Research (Project No. QN2021037).

Author information

Authors and Affiliations

Contributions

P.C. and S.C. designed the whole test scheme; Y.W., H.W., Y.L., Z.W. and W.Z. performed the experiments. P.C. made comments and amendments on the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, Y., Chen, P., Cao, S. et al. Prediction of Carbonation Depth for Concrete Containing Mineral Admixtures Based on Machine Learning. Arab J Sci Eng 48, 13211–13225 (2023). https://doi.org/10.1007/s13369-023-07645-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07645-8