Abstract

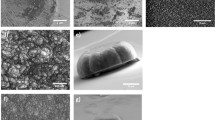

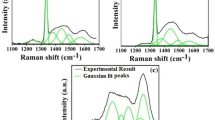

In this paper, chemical vapor deposition (CVD) method was used to grow long crystalline dendrites of copper with controlled grain morphology and lengths of up to 1 \({{\rm \mu}}\)m. The grown copper nanodendrites (CuND) were characterized by scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), atomic force microscopy (AFM), Raman, and X-ray photoelectron spectroscopy (XPS) analyses. The influence of the methane and hydrogen concentrations during growth was evaluated. SEM and AFM results revealed the high-quality grain morphology. XPS studies showed sharp peaks after 900 eV which was attributed to the presence of CuND. Raman spectra revealed the characteristics band at 150, ~200, and ~600 cm−1 for CuND. Analysis of the marginal means showed that growth temperature and flow are the two most significant control variables and that flow has a two-level effect on the length of CuND. Similarly, at the highest flow rate, i.e., 15 sccm, the CVD led to the growth of longer CuNDs. In particular, the length of CuNDs was found to increase when the flow rate was increased from 5 to 15 sccm by keeping fixed the temperature at 900 \({{^\circ}}\)C and growth time for 30 min. Surprisingly, when the temperature was increased to 1000 \({{^\circ}}\)C at a flow rate of 5 sccm and growth time of 30 min, the length of CuNDs was slightly increased, while at high flow rate there is no change in the length.

Similar content being viewed by others

References

Filipič, G.; Cvelbar, U.: Copper oxide nanowires: a review of growth. Nanotechnology. 23(19), 194001 (2012). http://stacks.iop.org/0957-4484/23/i=19/a=194001. Accessed 2 June 2015

Nam, D.; et al.: Effects of (NH4)2SO4 and BTA on the nanostructure of copper foam prepared by electrodeposition. Electrochim. Acta. 56(25), 9397–9405 (2011). http://dx.doi.org/10.1016/j.electacta.2011.08.025

Popov K., Nikolic N., Rakocevic Z.: The representative particle of copper powder and branch of copper dendrites. J. Serbian Chem. Soc. 67(12), 861–866 (2002)

Zhang C., Du F.L.: Growth of Carbon Fibers from copper dendrite nanostructures catalyzed decomposition of acetylene. Adv. Mater. Res. 465, 101–107 (2012)

Zhang, D.; et al.: Direct electrodeposion of reduced graphene oxide and dendritic copper nanoclusters on glassy carbon electrode for electrochemical detection of nitrite. Electrochim. Acta. 107, 656–663 (2013). http://www.sciencedirect.com/science/article/pii/S0013468613010906. Accessed 2 June 2015

Wang R.C., Li C.H.: Cu, Cu-Cu2O core-shell, and hollow Cu2O nanodendrites: structural evolution and reverse surface-enhanced Raman scattering. Acta Mater. 59(2), 822–829 (2011)

Sun, S.; et al.: Nanoparticle-aggregated paddy-like copper dendritic nanostructures. CrystEngComm 13(6), 1916–1921 (2011)

Yin, M.; et al.: Copper oxide nanocrystals. J. Am. Chem. Soc. 127(26), 9506–9511 (2005). https://www.researchgate.net/profile/Stephen_OBrien3/publication/7758815_Copper_oxide_nanocrystals/links/09e4150b38b929f6f5000000.pdf

Kumaran, C.K.S.; et al.: Preparation of Copper cactus like structure by chemical method. 1(1), 14–18 (2012). https://www.researchgate.net/profile/Dhayalan_Velauthapillai/publication/266503787_Preparation_of_Copper_cactus_like_structure_by_chemical_method/links/544427460cf2a76a3ccd6bfa.pdf

Hu C., Gao Z., Yang X.: A facile hydrothermal route to synthesis of nonporous and porous hierarchical copper dendrites. J. Cryst. Growth 306(2), 390–394 (2007)

Truong, Q.D.; Kakihana, M.: Hydrothermal growth of cross-linked hyperbranched copper dendrites using copper oxalate complex. J. Crystal Growth. 348(1), 60–64 (2012). http://dx.doi.org/10.1016/j.jcrysgro.2012.03.052

Zhang X. et al.: Copper dendrites: synthesis, mechanism discussion, and application in determination of L-tyrosine & dESIGN 2008. Crystal Growth Design 8(4), 1430–1434 (2008)

Liu L. et al.: A systematic study of atmospheric pressure chemical vapor deposition growth of large-area monolayer graphene. J. Mater. Chem. 22(4), 1498 (2012)

Abuhimd, H. et al.: Chemical vapor deposition grown vertically aligned single walled carbon nanotubes length assurance. Int. J. Adv. Manuf. Technol. 64(Special Issue), 545–553. (2012). http://link.springer.com/article/10.1007/s00170-012-4426-3

Nembhard, H.B.: Nanotechnology: a big little frontier for quality. Qual. Prog. 40(7), 23–29 (2007)

Yuangyai, C.; Nembhard, H.B.: Design of experiments: a key to innovation in nanotechnology. In: Emerging Nanotechnologies for Manufacturing. Elsevier Inc., pp. 207–234 (2009). doi:10.1016/B978-0-8155-1583-8.00008-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abuhimd, H. Low-Pressure Chemical Vapor Deposition Copper Nanodendrites Growth Design. Arab J Sci Eng 42, 1371–1379 (2017). https://doi.org/10.1007/s13369-016-2246-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-016-2246-8