Abstract

The present investigation discusses the effects of B4C addition on the morphologies of primary carbides and eutectic colonies in Fe–Cr–C weld-surfacing alloys. Results reveal that a series of Fe–Cr–C weld-surfacing alloys with different B4C contents are successfully fabricated onto AISI 316 stainless steel by plasma-transferred arc welding. The microstructure of the coatings is mainly γ-Fe,Ni eutectic matrix, and hexagonal M(=Cr, Fe)7(C,B)3 and M(=Cr, Fe)23(C,B)6 carbides are non-uniformly distributed in the eutectic matrix. The average microhardness of the cladding coating is 820HV, which is almost five times of that of the AISI 316 stainless steel substrate (180HV). The maximum microhardness value of the coating is about 1,280HV. Higher current levels have resulted in higher dilution levels and also in melting/burning of the substrate.

Similar content being viewed by others

References

Bourithis E, Tazedakis A, Papadimitriou G: A study on the surface treatment of “Calmax” tool steel by a plasma transferred arc (PTA) process. J. Mater. Process. Technol. 128, 169–177 (2002)

Hou Q.Y, Gao J.S, Zhou F: Microstructure and wear characteristics of cobalt-based alloy deposited by plasma transferred arc weld surfacing. Surf. Coat. Technol. 194, 238–243 (2005)

Buytoz, S.: Microstructural properties of M7C3 eutectic carbides in a Fe–Cr–C alloy. Mater. Lett. 60], 605–608 (2006)

Deuis R.L, Yellup J.M, Subramanian C: Metal-matrix composite coatings by PTA surfacing. Compos. Sci. Technol. 58, 299–309 (1998)

Katsich C, Badisch E, Manish R, Heath G.R, Franek F: Erosive wear of hardfaced Fe–Cr–C alloys at elevated temperature. Wear 267(11), 1856–1864 (2009)

Wang X, Han F, Liu X, Qu S, Zou Z: Microstructure and wear properties of the Fe–Ti–V–Mo–C hardfacing alloy. Wear 265, 583–589 (2008)

Liu X.-B, Gu Y.-J: Plasma jet clad γ/Cr7C3 composite coating on steel. Mater. Lett. 60, 577–580 (2006)

Buchanan V.E.: Solidification and microstructural characterisation of iron–chromium based hardfaced coatings deposited by SMAW and electric arc spraying. Surf. Coat. Technol. 203, 3638–3646 (2009)

Gür A.K, Yildiz T: The Effect at Wear Behavior of Coating Layer of Proportion Gases N2, e-J. New World Sci. Acad. 3(4), 627–635 (2008)

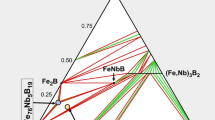

Raynor, G.V., Rivlin, V.G.: Phase equilibria in iron ternary alloys. The Institute of Metals, The Bath Press, UK (1988)

Xibao W.: The metallurgical behavior of B4C in the iron-based surfacing alloy during PTA powder surfacing. Appl. Surf. Sci. 252, 2021–2028 (2005)

Buytoz S, Yildirim M.M, Eren H: Microstructural and microhardness characteristics of gas tungsten are synthesized Fe–Cr–C coating on AISI 4340. Mater. Lett. 59, 607–614 (2005)

Cheng J, Xu B, Liang X, Wu Y, Liu Z: Effect of electromagnetic stirring on the microstructure and wear behavior of iron-based composite coatings. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 15, 451–456 (2008)

Buytoz, S.: Microstructural properties of M7C3 eutectic carbides in a Fe–Cr–C alloy. Mater. Lett. 60–5, 605–608 (2006)

Zhang L, Sun D, Yu H, Li H: Characteristics of Fe-based alloy coating produced by plasma cladding process. Mater. Sci. Eng. A 457(1–2), 319–324 (2007)

Ravi Bharath R, Ramanathan R, Sundararajan B, Bala Srinivasan P: Optimization of process parameters for deposition of Stellite on X45CrSi93 steel by plasma transferred arc technique. Mater. Des. 29(9), 1725–1731 (2008)

Zhang L, Liu B, Yu H, Sun D: Rapidly solidified non-equilibrium microstructure and phase transformation of plasma cladding Fe-based alloy coating. Surf. Coat. Technol. 201, 5931–5936 (2007)

Aizenshtein M, Mizrahi I, Froumin N, Hayun S, Dariel M.P, Frage N: Interface interaction in the B4C/(Fe–B–C) system. Mater. Sci. Eng. A 495, 70–74 (2008)

Kirchgaßner M, Badisch E, Franek F: Behaviour of iron-based hardfacing alloys under abrasion and impact. Wear 265, 772–779 (2008)

Fan C, Chen M.-C, Chang C.-M, Wu W: Microstructure change caused by (Cr,Fe)23C6 carbides in high chromium Fe–Cr–C hardfacing alloys. Surf. Coat. Technol. 201, 908–912 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buytoz, S., Orhan, A., Gur, A.K. et al. Microstructural Development of Fe–Cr–C and B4C Powder Alloy Coating on Stainless Steel by Plasma-Transferred Arc Weld Surfacing. Arab J Sci Eng 38, 2197–2204 (2013). https://doi.org/10.1007/s13369-013-0599-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-013-0599-9