Abstract

Cooperative adaptive cruise control systems have the potential to improve fuel efficiency and safety. However, due to the large amount of uncertainties, which are encountered in platooning applications, typical controller calibrations are often not reliable. Therefore, in order to ensure a satisfying performance in the presence of various information topologies and relevant uncertainties such as errors in data transmission or extreme manoeuvres of the lead vehicle, a risk-averse stochastic optimisation approach for controller calibration is suggested and demonstrated for a pre-existing control scheme. Realistic vehicle dynamics simulation experiments with a prescribed set of uncertainties, such as transmission delays and different vehicle parameters, are performed. The results show that the collision probability and energy consumption are reduced by the risk-averse calibration of the controller and its spacing policy compared with classical calibration which assumes perfect communication.

Similar content being viewed by others

1 Introduction

One important goal of recent traffic policies and legal regulations is the reduction of energy consumption in the broadest sense. Nonetheless, the transportation sector and the traffic volume expand and push the capacity of road infrastructure to its limits. One immediate possibility to mitigate both issues is to reduce the distance between successive vehicles. This way, road throughput is increased and energy consumption is reduced because of the efficient use of the slipstream of the vehicle in front (see e.g. [1, 2]). This is especially relevant for many vehicles travelling together in so-called platoons (see [3]). For heavy-duty vehicles, aerodynamic drag reduction is particularly relevant (see [4]).

However, due to the irreducible reaction time of human drivers, a minimum safety distance must be maintained, which limits the potential in terms of energy savings and traffic throughput. This restriction can, though, be alleviated by (partial) automation technologies, which have the potential of increasing road safety, as argued in [5]. For a survey of advanced driver assistance systems (ADAS) used in traffic automation, refer to [6, 7]. One such system is adaptive cruise control (ACC), which automatically establishes a desired distance by constantly monitoring and reacting to the movement of the preceding vehicle. When the control system can also utilise information (typically acceleration) transmitted by the lead vehicle, the system is generally referred to as cooperative adaptive cruise control (CACC, see [8]). By eliminating human reaction time through the use of such technologies, the inter-vehicle distances can be greatly reduced.

However, controlling a platoon of vehicles is not a trivial task. Relevant difficulties are the individual vehicle dynamics, various information flow topologies and string stability (see [3, 9,10,11]). A review of related challenges like vehicle communication, driver characteristics and control aspects is given in [12]. In terms of control, various techniques have been applied to CACC. For example, in [13] a \({\mathscr{H}}_{\infty }\) controller was developed, which explicitly satisfied string stability. Variants of PD-controllers were used in [8, 14]. Another popular method, that has received a lot of attention in recent years, is model predictive control (MPC). One advantage of MPC is the possibility to include knowledge about future disturbances like the upcoming road in the control architecture, as in [15]. In order to reduce the computational complexity stemming from the underlying optimisation, distributed MPC, where the platoon optimisation is split into local sub-problems, has been examined for example in [16, 17].

A key aspect of reliable and practical CACC systems is the consideration and handling of various types of uncertainties that may arise during the operation of a vehicle platoon. Operating uncertainties can stem from different sources: road topography, other road users, communication delays or errors within the platoon, position measurement errors and control lags may all jeopardise the proper functioning of the controllers. Disturbed measurement signals are typically also used to estimate velocities and accelerations leading to further inaccuracies. Therefore, a controller, that depends on those signals, will typically exhibit a certain over- or undershoot of the desired distance in practice. When information is passed between vehicles, the controller must also be able to handle transmission errors, delays or sudden connection interruptions. Finally, the leading vehicle might show unexpected behaviour like emergency braking. It is not obvious, though, how to tune a controller and its spacing policy for efficiency and safety in the presence of said disturbances and uncertainties.

Using MPC, compensation of known sensor and actuator delays by directly incorporating them in the optimisation problem was demonstrated in [18]. In [19] a min-max approach is presented, where the worst case regarding unknown delay and model uncertainties is optimised in every step. For other control methods the question arises how to choose controller parameters in order to make them robust against these uncertainties. The PD-controller parameters in [20, 21] were primarily tuned empirically. In [22], stability criteria are utilised in order to select controller parameters depending on the spacing policy. However, all these tuning approaches are not necessarily optimal with respect to energy consumption and safety.

Furthermore, another rarely discussed issue is the choice of the inter-vehicle distance. Typically, a simple constant time-gap policy is applied as in [14, 20, 22, 23], but the time-gap itself is an exogenous, user-defined parameter, even though the spacing policy evidently exerts great influence on energy consumption and safety. An alternative MPC-based approach is given in [24], where the spacing between the platoon members is not explicitly defined, but emerges from the optimisation of the cost function itself. Nonetheless, for most existing controllers, it is an open question how to choose the constant time headway in a sensible way that enables high energy savings while also guaranteeing safe operation.

Generally, in order to achieve smaller inter-vehicle distances one cannot simply reduce the target distance without respecting controller dynamics since for instance small over-or undershoots could already cause amplifications of errors downstream. This results in oscillations and possibly collisions at the end of the platoon. It is therefore an important question in practice how existing control schemes and spacing policies can be calibrated together in order to achieve robustness against the main sources of uncertainty.

For arbitrarily complex types of uncertainties typical robust control is challenging. Therefore, in this article a stochastic optimisation similar to the robust engine calibration approach presented in [25] is suggested. Suitable controller parameters and the spacing policy are determined by stochastic, risk-averse optimisation which adequately considers the possible disturbances like various transmission time delays while minimizing energy consumption and collision risk. For that purpose, either naturalistic driving data or simulation data is deployed and provides the basis for the stochastic optimisation, depending on data availability. The proposed stochastic calibration method will be demonstrated for a pre-existing CACC-scheme taken from [8]. The controller parameters and the associated spacing policy will be calibrated based on stochastic optimisation considering various uncertainties. Note that no new controllers are developed in this work. The presented calibration approach, though, is not at all limited to the utilised controller. Instead, the suggested method can be readily applied to various problem settings and control architectures.

The present paper is an extended version of the conference paper [26]. In particular, the optimisation is expanded to consider the entire energy consumption for various platoon sizes. Additionally, more detailed simulation studies are conducted using two different vehicle models.

The main contributions of this work are as follows:

-

A stochastic optimisation method for the risk-sensitive calibration of controllers and their spacing policies based on scenario simulation including multiple different uncertainties. The simulated cost distribution is evaluated and optimised using risk-measures. Note that the proposed optimisation approach is suitable for arbitrary control structures and spacing policies.

-

The impact of the platoon size on the optimal controller parametrisation and spacing policy is demonstrated.

-

Detailed, realistic co-simulation studies using high fidelity models are conducted. The results highlight the importance of high fidelity modelling in safety-critical applications, since a controller that appears stable in the simplified linear model could be revealed to destabilise the platoon in the high quality vehicle dynamics model provided by the commercial simulator IPG Truckmaker®;.

The article is structured as follows: In Section 2 the control system and the utilised controller are described and the stochastic optimisation problem is set up. In Section 3 the optimisation is conducted. Furthermore, simulation results with various controller configurations are presented and discussed using two different simulation approaches. A short summary is given in Section 4.

2 Cruise Control and Optimisation for Energy-Efficiency

2.1 Control Algorithm

For the remainder of the article we consider a platoon of N identical vehicles V0, \(\mathrm {V}_{1}, \dots , \mathrm {V}_{N-1}\), where V0 is the lead vehicle of the platoon. It is assumed that the lead vehicle follows a certain trajectory. Cut-ins of other vehicles are not considered. Furthermore, it is assumed that no information about traffic, the future trajectory of the lead vehicle or the street is available. A suitable CACC-scheme for the described situation can be found in [8]. Let si,vi,ai,Li denote the position, velocity, acceleration and length of vehicle \(V_{i}, i=0,\dots , N-1\). A simple vehicle model for controller design is given by

where ui is the control input and represents the desired acceleration, and τ is an engine time constant. The desired inter-vehicle distance dref(t) is assumed by the following linear spacing policy, where h is the time headway which is chosen considerably larger than τ:

The spacing error ei(t) between vehicle Vi and its front vehicle Vi− 1 is defined as

The controller with parameters \(K = \left (k_{p}, k_{d}, k_{dd}\right )\) is defined using a fictional input qi:

The actual input ui is determined by the relation

Note that ui depends on the controller input ui− 1 of the respective front vehicle. For more details and a full derivation refer to [8].

2.2 Power Consumption

Energy efficiency is expressed in terms of savings in consumed mechanical power. The considered forces are aerodynamic drag, rolling resistance and kinetic energy. Potential energy is not included, because it is assumed that there is no geographical information available. Power is therefore given by

where ρ is air density, A is the cross-sectional area of the vehicle, μR is the rolling resistance coefficient, and m is the vehicle’s mass. Note that road gradients and therefore potential energy are not considered in this work. However, if elevation information is available, above formulas can be adapted accordingly. C(d) is the inter-vehicle distance-dependent air drag coefficient determined by (see [23])

with constants Cj,j ∈{a,b,c}. Ca is the drag coefficient of the vehicle in the absence of any slipstream (i.e. Ca is the drag coefficient of the lead vehicle). If desired, more elaborate models for the air drag coefficient could be used as well (see [27]).

For two identical vehicles moving at the same constant velocity v, the savings in power consumption are given by

where Pleader is the power of the freely moving lead vehicle and Pfollower is the power of the follower. Figure 1 and Eq. 10 show that the power savings increase with higher velocity v and smaller time headway h. Consequently, for constant velocity a minimal distance policy should be pursued in order to minimise energy consumption of the platoon. However, for non-constant travelling speeds minimal distances might be counter-productive because a lot of energy can be wasted when the acceleration is changing frequently.

2.3 Performance Criterion

As a foundation for measuring the controller’s performance a criterion has to be formulated, which can be used for optimisation. In the case at hand the goal is to reduce energy consumption while also considering driving comfort and safety.

Firstly, the combined mechanical work JW of all the following vehicles in the platoon should be minimised with

where Wi is the work associated with the respective vehicle. The variables Wi depend on the inter-vehicle distances di(t) which affect the aerodynamic drag of each vehicle except the leading vehicle.

Secondly, for driving comfort, the accumulated changes in acceleration of all followers over the time interval [0,T] are penalised:

Alternatively, acceleration could also be penalised directly.

Thirdly, in order to ensure that the vehicles follow each other at all, a velocity deviation cost term is added, where \(\bar {v}\) denotes the average velocity in the time interval [0,T]:

It suffices to consider the velocities of first and last vehicle of the platoon.

Lastly, in terms of safety, a penalty is added to the performance criterion, penalising too small distances between successive vehicles:

where dcrit(v) is defined as the danger zone, that determines whether a penalty is active or not. If the distance is larger than dcrit(v), no penalty is applied, but if the distance becomes lower, the integral in Eq. 14 becomes positive and hence a penalty is applied to the performance criterion. In terms of the design of the danger zone it is important that it is smaller than the reference distance dref, defined in Eq. 2, which the controller tries to achieve. Otherwise the optimisation might lead to a controller that does not follow the reference properly. Therefore, for small velocities, the danger zone should be smaller than r. For higher velocities, it should be larger, because otherwise there is not enough time for the penalty (14) to accumulate in order for the optimisation to find a controller setting that prevents collisions. Taking these aspect into account, the danger zone dcrit(v) is here simply defined as

The design of the danger zone (15) can, of course, also take other forms.

To sum up, for a given, single trajectory of the lead vehicle the performance criterion can be written as a weighted sum. It is emphasised that a smaller value of J here implies better performance.

Note that this configuration of the performance criterion is but one example and the suggested optimisation approach is not limited to this formulation.

The weights in Eq. 16 naturally influence the optimisation results and the possible savings. For example, increasing the weight wW leads to higher energy savings due to shorter time-gaps. Safety and comfort deteriorate in return. A higher weight on comfort, on the other side, implies higher distances and therefore less savings but a lower safety penalty. These relations can be used as a baseline for empirically tuning the weights in order to achieve a desired trade-off between savings, comfort and safety.

2.4 Consideration of Uncertainties in Stochastic Optimisation

Several uncertainties arise when CACC systems are operated in practice. The most important one is the unpredictable behaviour of the lead vehicle. It is critical that the controller functions in a wide range of possible scenarios. Since the performance criterion (16) is always related to a trajectory of the lead vehicle, the optimisation based on one single trajectory will generally lead to highly specialised results that cannot be applied to a broad range of traffic scenarios. Therefore, the optimisation is rather based on a sample of trajectories which covers many different velocity profiles including extreme events such as emergency braking. Some exemplary, randomly generated trajectories are depicted in Fig. 2. They were created using the algorithm presented in [28], which makes use of modelling conditional probabilities of further accelerating and decelerating given past information, which allows the generation of highly realistic drive cycles. In addition, trajectories with constant cruising speed followed by an emergency braking manoeuvre were added to the sample as well in order to also consider this unlikely, but safety-relevant case. Alternatively, in [29] the authors present a framework that automatically generates platooning scenarios. Such a system or similar could of course also be implemented here. Furthermore, if available, naturalistic driving data can be used instead of generated drive cycles.

Since power consumption and hence the optimal controller calibration depend on vehicle specific parameters like the vehicle mass m, this uncertainty should be considered as well. The mass m can vary greatly from trip to trip depending on the cargo. The dependence of power consumption on mass is given by Eqs. 7–8. Higher mass increases rolling resistance and especially inertia resistance. Therefore, with a higher mass it is presumably less energy efficient to closely follow the lead vehicle and react to every movement immediately. Instead, a higher distance and smoother velocity trajectory seem preferable.

Apart from that, for the operation of the controller, the actual inter-vehicle distance di(t) has to be measured and is subjected to measurement noise. Consequently, the resulting spacing error ei(t), which the controller relies on, as well as the estimated derivatives of ei(t) are disturbed and not precisely known.

Additionally, the controller (3)–(4) needs knowledge of the desired acceleration ui− 1 of the vehicle in front of it. This information might be corrupted though, due to unknown transmission delays or a total loss of communication, leading to suboptimal performance of the controller. A control calibration that relies heavily on the inter-vehicle communication is prone to errors if the communication fails.

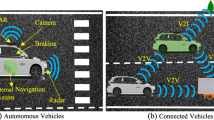

A graphic representation of the platoon is given in Fig. 3. Each of the N vehicles communicates with the vehicle behind itself and transmits its own control input ui. Due to transmission errors or delays a disturbed version \(\tilde {u}_{i}\) is received by the following vehicle. Additionally, each vehicle measures the distance between its predecessor and itself.

Since most related uncertainties are not analytically tractable, a simulation-based optimisation is suggested. By simulating the N vehicles \(\mathrm {V}_{0}, \dots , \mathrm {V}_{N-1}\) with numerous different lead vehicle trajectories, vehicles masses, and measurement noise, a sample of performance values J is obtained. Consequently, being a random variable, J cannot be minimised directly. Instead, the distribution of J has to be considered. Statistics that describe key aspects of the estimated probability distribution, can then be optimised since they are again deterministic values. Suitable statistics, commonly referred to as risk measures, are for example the expected value, the Value-at-Risk and the Conditional Value-at-Risk:

Definition 1 (Risk measures)

Let X be a continuous random variable on the probability space \(\left ({\Omega }, \mathfrak {S}, \mathbb {P}\right )\) (see e.g. [30]). Let α ∈ (0,1).

-

i)

The Value-at-Risk (VaR) at the confidence level α is defined as

$$ \text{VaR}_{\alpha}\left( X\right) := \inf\{x\in\mathbb{R}: \mathbb{P}\left[X \leq x\right] \geq \alpha\}. $$ -

ii)

The Conditional Value-at-Risk (CVaR) at the confidence level α is defined as

$$ \text{CVaR}_{\alpha}\left( X\right) := \mathbb{E}\left[ X | X \geq \text{VaR}_{\alpha}\left( X\right)\right]. $$

The precise definitions generally vary a bit from author to author (see [31, 32]). Different risk measures quantify different levels of risk-aversion. For example, minimizing the expected value leads to good average values, but extreme values of J are still possible and not necessarily unlikely. In contrast, minimizing the Conditional Value-at-Risk is a more risk-averse approach, as the focus here lies exclusively on the highest outcomes of J. For example, minimizing CVaR at a confidence level of 90% means minimizing the average of the worst 10%. Therefore, the resulting calibration can lead to higher average values but also reduces the probability of entering the penalised danger zone and thus also lowers the risk of crashing into the lead vehicle.

Since Eq. 16 consists of a performance and a safety part, applying different risk measures to the two components appears reasonable. For Jperformance, an optimal expected value is demanded, since occasional high values are only inconvenient but not dangerous. For Jsafety, on the other side, it is more reasonable to account for the worst cases by applying the CVaR, since in terms of safety the extreme events matter most. Therefore, for a selected confidence level α the final optimisation formulation is

Any suitable solver can be used in order to solve (17). For each evaluation of the objective function in Eq. 17, each trajectory has to be simulated using an average heavy duty vehicle and the performance criterion (16) needs to be calculated. Vehicle mass is altered from trajectory to trajectory randomly following a uniform distribution in the interval [13,000;40,000], where mass is measured in kilograms. From the resulting sample of performance values, the objective can be determined using numeric approximations of the expected value and the conditional value-at-risk. Note that this optimisation is carried out off-line and not during the operation of an actual platoon. Therefore, the computational complexity is not of importance for the real world applicability of the proposed optimisation formulation.

3 Optimisation and Platoon Simulation

3.1 Optimisation Results

In this section the results of the stochastic optimisation are presented and discussed. The considered decision variables are the controller parameters kp,kd and the time headway h. The third controller parameter kdd is set to zero in order to exclude feedback of the vehicle’s jerk (see [8]). Furthermore, the desired distance at standstill is set to r = 0.6 m. Three different information flow topologies regarding the transmission of the front vehicle’s control input u are examined:

-

(a)

perfect communication

-

(b)

communication with an unknown bounded time delay

-

(c)

no communication

In case (b) a new time delay for each vehicle is drawn from a uniform distribution for each simulation run. The upper limit of the random time delay is set to 1 s, which is well above the time delays typically considered in the literature [33,34,35] and therefore covers all relevant scenarios. Case (c) is a hypothetical situation in which the controller should not be operated in general and it could not be called CACC any more, because there is no cooperation between the platoon members. However, it is still interesting to analyse the optimal controller configuration for the case that communication is lost. For specialised platooning solutions based on model predictive or sliding mode control that are robust against communication loss or that do not use communication at all, the reader is referred to [24, 36].

For all three information flow topologies the same optimisation including all other uncertainties as discussed in Section 2.4 is conducted in Matlab®;/Simulink. The optimisation uses a pattern-search algorithm based on repeated simulations of the platoon.

The resulting calibrations \(u_{a}^{*}\), \(u_{b}^{*}\) and \(u_{c}^{*}\), depending on the platoon size N, are presented in Fig. 4. Additionally, the actual controller values for a platoon consisting of N = 5 vehicles are listed in Table 1. As expected, the time headway h increases with worse communication. Simultaneously, the controller gains kp and kd increase. This reflects the fact that the controller needs to react more aggressively to the measured distance errors and their derivatives when no or only delayed feed-forward information about the front vehicle’s control input is available. In the case of perfect information, kp is almost zero, indicating that the position measurement is basically not used. The impact of the platoon size on the optimal calibration is much smaller than the influence of the information flow topology. With perfect information, the size of the platoon is practically irrelevant for the calibration, as can be seen in Fig. 4. For non-perfect information, larger platoon sizes imply slightly increased optimal time headways h. The controller parameters kp and kd also increase. The differences in the optimal calibration are most significant for information topology (c), where there is no information and the controller has to rely on measurements exclusively. The controller becomes slightly more aggressive for larger platoons.

3.2 Simulation Results

The optimal calibrations \(u_{a}^{*}\), \(u_{b}^{*}\) and \(u_{c}^{*}\) were tested on approximately 45 h of heavy duty vehicle drive cycles measured on real roads. This was done using all possible combinations of calibration and information flow topology. The vehicles are simulated using the linear model (1), which was also used in the optimisation. The validation results are presented in Table 2.

For each combination, the probability of entering the danger zone (15) per kilometre, the probability of a collision within the platoon per kilometre and the average savings in work due to aerodynamic drag are given. Additionally, \(J^{*} = \mathbb {E}\left [ J_{\text {performance}} \right ] + \text {CVaR}_{\alpha }\left (J_{\text {safety}} \right )\) is stated. For all three controller configurations there is no collision for the first information topology (a). In case (b) with time delays the calibration \(u_{a}^{*}\) which relies primarily on the feed-forward information of its front vehicle already introduces a substantial risk of collision. In case (c), however, when there is no communication at all, the risk of collisions increases dramatically in the two calibrations that assume and rely on perfect or delayed communication. In that case, only \(u_{c}^{*}\) provides acceptable safety. Interestingly, however, in scenario (b) the probability of entering the danger zone and of collision is increased by \(u_{c}^{*}\) (compared to \(u_{b}^{*}\)) even though the time headway is considerably larger. It is also remarkable, that controller \(u_{c}^{*}\) has a higher probability of entering the danger zone in topology (b) than in (c). This means that more information is not beneficial for the controller \(u_{c}^{*}\) in that respect. For each information flow topology J∗ is minimal for the calibration that was designed for this topology, which is indicated in bold. The aggregated energy savings of the whole platoon are greatest in the case of perfect information flow but generally do not vary strongly. Furthermore, the higher objective values and the higher controller gains hint at the fact that driving comfort deteriorates with worse information flow.

In Fig. 5, one of the cycles used in the validation presented in Table 2 is analysed in more detail. The platoon consisting of five vehicles was simulated using model (1), which was also used for the design and optimisation of the controllers given in Table 1. The lead vehicle follows the defined velocity trajectory and the other platoon members follow. The simulation was executed with an information transfer delay of 0.5 s. The controller input variance over the entire drive cycle is almost equal for all vehicles of the platoon and also for the three different controllers. This implies that there are no increasing oscillations in the platoon. The main difference can be seen in the average distance, where controller \(u_{a}^{*}\) implies significantly smaller distances than \(u_{c}^{*}\), which is a consequence of the different desired time headways (see Table 1). Average velocity and acceleration are also fairly similar among all vehicles and controllers. Furthermore, during the simulations no collision occurred in any of the three cases. These results indicate that all three controllers work reasonably well in the simulated setting.

Simulation of a specific real drive cycle using the linear vehicle model (1). For all three controllers the platoon shows no oscillations and no collision occurs

3.3 Advanced Vehicle Dynamics Simulation

The results presented in Sections 3.1 and 3.2 were all obtained using the simple linear vehicle model (1). Also the controller structure itself was derived from that model. Consequently, it is not surprising that the simulation used in Table 2 and Fig. 5 shows satisfying results. However, this unfortunately does not guarantee the same performance under real driving conditions with real vehicles, whose powertrain and internal dynamics differ from the simplistic model (1). Since expensive and time-consuming real world tests are often not feasible in early development stages, an alternative approach is to use more elaborate vehicle dynamics simulations instead. One possible solution is provided by the commercial software IPG Truckmaker®;. It provides very detailed simulation models for single heavy duty vehicles. The simulation of entire platoons can be realised by running multiple instances of Truckmaker®;, one for each platoon member, simultaneously, as in [24]. The utilised simulation framework is illustrated in Fig. 6. The coordination of the platoon is governed by a central Matlab®; session which communicates with the individual vehicles using the Truckmaker®; for Simulink interface. The respective control actions are calculated in the Coordinator-Matlab®; session and distributed to the respective parallel Truckmaker®; instances.

Using this co-simulation framework the same real world drive cycle as in Fig. 5 was analysed again using a transmission delay of 0.5 s. The results are depicted in Fig. 7. In contrast to the simulations with the simple linear vehicle model, the more elaborate simulation reveals that controller \(u_{c}^{*}\) is not effective in practice. This can be seen in the bar plots of the controller input variance, which increases a lot for the vehicles at the end of the platoon.

Simulation of a real drive cycle using the high fidelity co-simulation environment described in Fig. 6. The third controller induces oscillations

The oscillations of the control inputs increase with every vehicle in the platoon leading to strong oscillations in the last platoon member. The average distances are virtually the same as in Fig. 5, though. In the bottom panel of Fig. 7 one can see how the average acceleration per vehicle is more or less constant for the different vehicles for the first two controllers. However, for the third controller \(u_{c}^{*}\) the average acceleration varies among the vehicles. The reason for the bad performance of the third controller are the large gains in \(u_{c}^{*}\). The vehicle strongly reacts to distance measurements but the vehicle now behaves differently than assumed in the derivation of the controller because of the more detailed non-linear simulation model. In this situation the controller gains are too large and induce oscillations. The other two controllers show satisfying performance also in the high fidelity simulation. In fact, the results of both the simple and elaborate simulation look almost identical. None of the three controllers lead to a collision within the platoon in this test scenario.

Finally, in order to further compare the controllers, an emergency braking manoeuvre was simulated using the Truckmaker®; co-simulation. The results for all three controller configurations are depicted in Fig. 8 for the last platoon member. In this scenario, the platoon travels at roughly 80 km/h when the platoon leader suddenly brakes with a negative acceleration of − 7 m/s until it comes to a complete halt. Once again, a transmission time delay of 0.5 s was assumed. Controller \(u_{a}^{*}\), which was designed for perfect information flow, reacts slowest which can be seen in the top two panels of Fig. 8. This is due to the small controller gains and the delayed information coming from the front vehicle. Controllers \(u_{b}^{*}\) and \(u_{c}^{*}\) react faster but \(u_{c}^{*}\) again introduces oscillations. In the bottom panel the inter-vehicle distance between the last platoon member V4 and its predecessor V3 is depicted. The first controller leads to a collision which is indicated by the negative distance. The other two controllers can prevent a collision. Only controller \(u_{b}^{*}\), which was optimised for this information topology, exhibits a satisfactory performance in this test scenario. The trajectories are smooth and no collision occurs even though the desired distances are only marginally larger than with controller \(u_{a}^{*}\).

To sum up, the results clearly show how important the information topology and thorough testing through simulation are. The findings of the high fidelity validation with Truckmaker®; can be used in order to select more suitable optimisation weights in Eq. 16. For example, increased weight on driving comfort will lower a controller’s tendency to large and oscillating control inputs.

4 Conclusion

In this work an optimisation method for the calibration of tuning parameters and spacing policies for CACC-controllers was presented. Related uncertainties were considered by a sample-based, stochastic approach using risk-measures in the optimisation. The discussed approach offers a way to balance the conflicting effects of reducing inter-vehicle distances in CACC applications. On the one hand, shorter distances imply less energy consumption due to slipstream usage and increased traffic throughput. On the other hand, safety is negatively affected. By means of optimisation, an energy efficient and safety-aware controller parametrisation and spacing policy can be identified. The conducted optimisations showed, how different communication flow topologies and platoon sizes influence the optimal choice of these parameters. It was shown that communication delays or errors in particular require considerably different spacing and parameter values for energy and safety optimality. Simulation results proved that ignoring uncertainties like variable transmission time delays or a total loss of communication dramatically increases the probability of collisions. While there are some assumptions and limitations in the presented work, like the exclusion of vehicle cut-ins and road topography, the suggested stochastic optimization approach is flexible enough to also take these aspects into account in the future.

Furthermore, the importance of high-fidelity simulation environments was demonstrated, as they can unveil shortcoming of the controllers that were masked by less elaborate models. The presented co-simulation framework can help identifying problems before costly real-world testing is conducted. Future research may deal with the consideration of additional uncertainties such as the already mentioned traffic situations and environmental conditions like rain. Also, the application of the stochastic optimisation to different control architectures is of interest.

References

Bonnet, C., Fritz, H.: Fuel consumption reduction in a platoon: experimental results with two electronically coupled trucks at close spacing. Technical report, SAE Technical Paper (2000)

Alam, A., Gattami, A., Johansson, K. H.: An experimental study on the fuel reduction potential of heavy duty vehicle platooning. In: 13th International IEEE Conference on Intelligent Transportation Systems, pp 306–311 (2010)

Li, S. E., Zheng, Y., Li, K., Wang, J.: An overview of vehicular platoon control under the four-component framework. In: 2015 IEEE Intelligent Vehicles Symposium (IV), pp 286–291 (2015)

Alam, A., Besselink, B., Turri, V., Martensson, J., Johansson, K. H.: Heavy-duty vehicle platooning for sustainable freight transportation: a cooperative method to enhance safety and efficiency. IEEE Control. Syst. Mag. 35(6), 34–56 (2015)

(2016) Prioritising the safety potential of automated driving in Europe. Technical report, European Transport Safety Council

Ziebinski, A., Cupek, R., Erdogan, H., Waechter, S.: A survey of ADAS technologies for the future perspective of sensor fusion. In: International Conference on Computational Collective Intelligence, pp 135–146. Springer (2016)

Okuda, R., Kajiwara, Y., Terashima, K.: A survey of technical trend of ADAS and autonomous driving. In: Technical Papers of 2014 International Symposium on VLSI Design, Automation and Test, pp 1–4. IEEE (2014)

Ploeg, J., Scheepers, B. T. M., Van Nunen, E., Van de Wouw, N., Nijmeijer, H.: Design and experimental evaluation of cooperative adaptive cruise control. In: 2011 14th International IEEE Conference on Intelligent Transportation Systems (ITSC), pp 260–265 (2011)

Dunbar, W. B., Caveney, D.S.: Distributed receding horizon control of vehicle platoons: stability and string stability. IEEE Trans. Autom. Control 57(3), 620–633 (2012)

Moser, D., del Re, L., Jones, S.: A risk constrained control approach for adaptive cruise control. In: 2017 IEEE Conference on Control Technology and Applications (CCTA), pp 578–583 (2017)

Feng, S., Zhang, Y., Li, S. E., Cao, Z., Liu, H.X., Li, L.: String stability for vehicular platoon control: definitions and analysis methods. Annu. Rev. Control (2019)

Dey, K. C., Yan, L., Wang, X., Wang, Y., Shen, H., Chowdhury, M., Yu, L., Qiu, C., Soundararaj, V.: A review of communication, driver characteristics, and controls aspects of cooperative adaptive cruise control (cacc). IEEE Trans. Intell. Transp. Syst. 17(2), 491–509 (2016)

Ploeg, J., Shukla, D. P., van de Wouw, N., Nijmeijer, H.: Controller synthesis for string stability of vehicle platoons. IEEE Trans. Intell. Transp. Syst. 15(2), 854–865 (2014)

Naus, G. J. L., Vugts, R. P. A., Ploeg, J., van De Molengraft, M. J. G., Steinbuch, M.: String-stable cacc design and experimental validation: a frequency-domain approach. IEEE Trans. Veh. Technol. 59 (9), 4268–4279 (2010)

Kaku, A., Kamal, M. A. S., Mukai, M., Kawabe, T.: Model predictive control for ecological vehicle synchronized driving considering varying aerodynamic drag and road shape information. SICE J. Control Meas. Syst. Integr. 6(5), 299–308 (2013)

Fardad, M., Lin, F., Jovanović, M. R.: On the dual decomposition of linear quadratic optimal control problems for vehicular formations. In: 49th IEEE Conference on Decision and Control (CDC), pp 6287–6292. IEEE (2010)

Zheng, Y., Li, S. E., Li, K., Borrelli, F., Hedrick, J. K.: Distributed model predictive control for heterogeneous vehicle platoons under unidirectional topologies. IEEE Trans. Control Syst. Technol. 25 (3), 899–910 (2017)

Wang, M., Hoogendoorn, S. P., Daamen, W., van Arem, B., Shyrokau, B., Happee, R.: Delay-compensating strategy to enhance string stability of adaptive cruise controlled vehicles. Transp. B: Transport Dynamics 6(3), 211–229 (2018)

Chen, N., Wang, M., Alkim, T., van Arem, B.: A robust longitudinal control strategy of platoons under model uncertainties and time delays. J. Adv. Transp. (2018)

Milanés, V., Shladover, S. E., Spring, J., Nowakowski, C., Kawazoe, H., Nakamura, M.: Cooperative adaptive cruise control in real traffic situations. IEEE Trans. Intell. Transp. Syst. 15(1), 296–305 (2014)

Wang, C., Nijmeijer, H.: String stable heterogeneous vehicle platoon using cooperative adaptive cruise control. In: 2015 IEEE 18th International Conference on Intelligent Transportation Systems, pp 1977–1982 (2015)

Emirler, M. T., Güvenç, L., Güvenç, B. A.: Design and evaluation of robust cooperative adaptive cruise control systems in parameter space. Int. J. Automot. Technol. 19(2), 359–367 (2018)

Turri, V., Besselink, B., Johansson, K. H.: Cooperative look-ahead control for fuel-efficient and safe heavy-duty vehicle platooning. IEEE Trans. Control Syst. Technol. 25(1), 12–28 (2017)

Thormann, S., Schirrer, A., Jakubek, S.: Safe and efficient cooperative platooning. IEEE Trans. Intell. Transp. Syst. 1–13 (2020)

Wasserburger, A., Hametner, C., Didcock, N.: Risk-averse real driving emissions optimization considering stochastic influences. Eng. Optim. 52(1), 122–138 (2020)

Wasserburger, A., Schirrer, A., Hametner, C.: Stochastic optimization for energy-efficient cooperative platooning. In: 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, pp 1–6 (2019)

Hussein, A. A., Rakha, H. A.: Vehicle platooning impact on drag coefficients and energy/fuel saving implications. arXiv:2001.00560 (2020)

Wasserburger, A., Hametner, C.: Automated generation of real driving emissions compliant drive cycles using conditional probability modeling. In: 2020 IEEE Vehicle Power and Propulsion Conference (VPPC). Accepted for Publication (2020)

Hyun, S., Song, J., Shin, S., Bae, D. -H.: Statistical verification framework for platooning system of systems with uncertainty. In: 2019 26th Asia-Pacific Software Engineering Conference (APSEC), pp 212–219. IEEE (2019)

Ash, R. B., Robert, B., Doleans-Dade, C.A, Catherine, A.: Probability and Measure Theory. Academic Press, New York (2000)

Mitra, S., Ji, T.: Risk measures in quantitative finance. Int. J. Bus. Contin. Risk Manag, 1 (2), 125–135 (2010)

Acerbi, C., Tasche, D.: Expected shortfall: a natural coherent alternative to value at risk. Econ. Notes 31(2), 379–388 (2002)

Tian, B., Deng, X., Xu, Z., Zhang, Y., Zhao, X.: Modeling and numerical analysis on communication delay boundary for CACC string stability. IEEE Access 7, 168870–168884 (2019)

Tian, B., Wang, G., Xu, Z., Zhang, Y., Zhao, X.: Communication delay compensation for string stability of CACC system using LSTM prediction. Veh. Commun. 29, 100333 (2021)

Xing, H., Ploeg, J., Nijmeijer, H.: Compensation of communication delays in a cooperative ACC system. IEEE Trans. Veh. Technol. 69(2), 1177–1189 (2019)

Rupp, A., Steinberger, M., Horn, M.: Sliding Mode Based Platooning: Theory and Applications. Studies in Systems, Decision and Control, pp. 393–431. Springer International Publishing AG (2020)

Acknowledgements

The financial support by the Austrian Federal Ministry for Digital and Economic Affairs, the National Foundation for Research, Technology and Development, the Christian Doppler Research Association, and AVL List GmbH is gratefully acknowledged. This work has been created in cooperation with the Austrian flagship research project “Connecting Austria” (grant no. 865122).

Funding

Open access funding provided by TU Wien (TUW).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wasserburger, A., Schirrer, A. & Hametner, C. Stochastic Optimisation for the Design of Energy-Efficient Controllers for Cooperative Truck Platoons. Int. J. ITS Res. 20, 398–408 (2022). https://doi.org/10.1007/s13177-022-00294-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13177-022-00294-5