Abstract

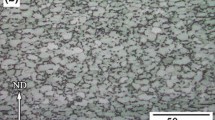

The development of microstructure in the course of warm deformation of niobium-10 hafnium-1 titanium (wt%) alloy (C103) was studied by plane strain compression (PSC) testing in the range of 500–650 °C and two strain rates (ἑ) 0.01 and 1 s−1 which are commercially being practiced for rolling of the alloys. A total of 75% reduction in thickness was imparted to the samples during the warm deformation. The purpose of the study was to establish the warm rolling process parameters (ἑ and T) useful in the optimization of thermomechanical processing schedules to realize thin sheets of this difficult to process refractory material. Weak softening was noticed at temperatures of 600 °C (~ 0.35Tm) and above in the stress–strain plots. Partial dynamic recrystallisation was observed at the regions where maximum strain was observed in the sample during deformation at high temperatures as evidenced by electron backscatter diffraction (EBSD). Samples deformed in the temperature range of 500 °C to 600 °C and at ἑ of 1 s−1 showed dynamic recovery. High angle grain boundary fraction is higher for the sample deformed at a temperature of 650 °C and ἑ of 0.01 s−1 compared to the sample deformed at a ἑ of 1 s−1. Based on detailed microstructural observations, it was concluded that C103 alloy can be warm rolled at a temperature of 650 °C and ἑ of 0.01 s−1 to obtain localized dynamically recrystallized grain structure in the material and it is expected that a dynamic recrytallization will further advance with increase in reduction during deformation.

Similar content being viewed by others

References

Moricca MD, Varma S. The high-temperature oxidation characteristics of alloys from the Nb-W-Cr system with C additions. JOM. 2008;60:66-9.

Wei W, Wang H, Zou C, Zhu Z, Wei Z. Microstructure and oxidation behavior of Nb-based multi-phase alloys. Materials & Design. 2013;46:1-7.

Vazquez A, Varma S. High-temperature oxidation behavior of Nb–Si–Cr alloys with Hf additions. Journal of Alloys and Compounds. 2011;509:7027-33.

Su L, Jia L, Weng J, Hong Z, Zhou C, Zhang H. Improvement in the oxidation resistance of Nb–Ti–Si–Cr–Al–Hf alloys containing alloyed Ge and B. Corrosion science. 2014;88:460-5.

Gerardi S. Niobium. ASM International, Metals Handbook, Tenth Edition. 1990;2:565-71.

Wadsworth J, Dougherty S, Nieh T, Kramer P. Evidence for dislocation glide controlled creep in niobium-base alloys. Scripta metallurgica et materialia. 1992;27:71-6.

Sarkar A, Kapoor R, Verma A, Chakravartty J, Suri A. Hot deformation behavior of Nb–1Zr–0.1 C alloy in the temperature range 700–1700° C. Journal of nuclear materials. 2012;422:1-7.

Leonard KJ, Busby JT, Zinkle SJ. Aging effects on microstructural and mechanical properties of select refractory metal alloys for space-reactor applications. Journal of nuclear materials. 2007;366:336-52.

Brady M, Verink E, Smith J. Oxidation behavior of two-phase γ+ σ Nb-Ti-Al alloys. Oxidation of metals. 1999;51:539-56.

Inouye H (1984) Niobium in high temperature applications. Niobium-Proceedings of the international symposium.

Taniguchi S, Shibata T. Cyclic oxidation behavior of Ni 3 Al-0.1 B base alloys containing a Ti, Zr, or Hf Addition. Oxidation of metals. 1986;25:201-16.

Swartzentruber B (2016) Nanoscale Electronics and Mechanics. Sandia National Lab.(SNL-NM), Albuquerque, NM (United States).

Sarkar A, Kapoor R, Verma A, Chakravartty J, Suri A. Hot deformation behavior of Nb–1Zr–0.1 C alloy in the temperature range 700–1700 C. Journal of nuclear materials. 2012;422:1-7.

Gill LL, Argent B. Hot working of niobium alloys. Journal of the Less Common Metals. 1961;3:305-11.

Delgrosso E, Carlson C, Kaminsky J. Development of niobium-zirconium-carbon alloys. Journal of the Less Common Metals. 1967;12:173-201.

Corn D, Douglass D, Smith C. The internal oxidation of Nb-Hf alloys. Oxidation of Metals. 1991;35:139-73.

Mader W (1987) Characterization of Defects in Materials, Materials Research Society Symposium Proceedings. Materials Research Society Pittsburgh, Pennsylvania.

Korotayev A, Tyumentsev A, Pinzhin YP, Kolobov YR, Glazunov M, Markov K, et al (1980) Influence of the Structural State on the Mecha nlsm by Which a Non-Metallic Phase is Formed During Diffusion Saturation of Niobium Alloys with Oxygen. Phys Met Metallogr(Engl Transl). 50; 92–9

Ye T, Labun P, Christian J, Taylor G. Structure and orientation of zirconia in a niobium metal matrix. Acta Metallurgica. 1985;33:477-86.

Yao D, Cai R, Zhou C, Sha J, Jiang H. Experimental study and modeling of high temperature oxidation of Nb-base in situ composites. Corrosion science. 2009;51:364-70.

Villars P (2014) Material Phases Data System (MPDS). CH-6354 Vitznau, Switzerland (ed), La2CuIrO6 (CuLa2IrO6) Crystal Structure, sd. 1211389.

Casais M, Gutierrez-Puebla E, Monge M, Rasines I, Ruı́z-Valero C. VM9O25 (M= Nb, Ta), a combination of tetrahedral VO4 and octahedral MO6 units. Journal of Solid State Chemistry. 1993;102:261-6.

Zheng J, Hou X, Wang X, Meng Y, Zheng X, Zheng L. Isothermal oxidation mechanism of a newly developed Nb–Ti–V–Cr–Al–W–Mo–Hf alloy at 800–1200 C. International Journal of Refractory Metals and Hard Materials. 2016;54:322-9.

Medeirosa S, PRASADA Y, FRAZIERA W. Microstructural modeling of metadynamic recrystallization in hot working of IN 718 superalloy [J]. Materials Science and Engineering: A. 2000;293:198-207.

Srinivasan N, Prasad Y. Microstructural control in hot working of IN-718 superalloy using processing map. Metallurgical and Materials Transactions A. 1994;25:2275-84.

Watts A, Ford H. On the basic yield stress curve for a metal. Proceedings of the Institution of Mechanical Engineers. 1955;169:1141-56.

Sellars C, Sah J, Beynon J, Foster S (1976) Plane strain compression testing at elevated temperatures. Report on research work supported by Science Research Council grant B/RG/1481, University of Sheffield.

Murty SN, Torizuka S, Nagai K, Kitai T, Kogo Y. Dynamic recrystallization of ferrite during warm deformation of ultrafine grained ultra-low carbon steel. Scripta materialia. 2005;53:763-8.

Nayan N, Gurao NP, Murty SN, Jha AK, Pant B, Sharma S, et al (2015) Microstructure and micro-texture evolution during large strain deformation of an aluminium–copper–lithium alloy AA 2195. Materials & Design (1980–2015). 65; 862–8.

Nayan N, Gurao N, Murty SN, Jha AK, Pant B, George KM. Microstructure and micro-texture evolution during large strain deformation of Inconel alloy IN718. Materials Characterization. 2015;110:236-41.

Narayana Murty S, TORIZUKA S, NAGAI K. Microstructural and micro-textural evolution during single pass high Z-large strain deformation of a 0.15 C steel. ISIJ international. 2005;45:1651-7.

Narayana Murty S, Torizuka S, Nagai K, Koseki N, Kogo Y (2005) Classification of microstructural evolution during large strain high< i> Z</i> deformation of a 0.15 carbon steel. Scripta materialia. 52; 713–8.

Murty SN, Torizuka S, Nagai K, Koseki N, Kogo Y. Classification of microstructural evolution during large strain high Z deformation of a 0.15 carbon steel. Scripta Materialia. 2005;52:713-8.

Puchi E, Staia M. Mechanical behavior of aluminum deformed under hot-working conditions. Metallurgical and Materials Transactions A. 1995;26:2895-910.

Puchi E, Staia M. High-temperature deformation of commercial-purity aluminum. Metallurgical and Materials Transactions A. 1998;29:2345-59.

Schotten K, Bleck W, Dahl W. Modelling of flow curves for hot deformation. Steel research. 1998;69:193-7.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nayan, N., Gurao, N.P., Murty, S.V.S.N. et al. Plane Strain Compression of Nb-10Hf-1Ti alloy: Effect on Microstructure and Micro-Texture. Trans Indian Inst Met 74, 957–968 (2021). https://doi.org/10.1007/s12666-021-02205-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02205-w