Abstract

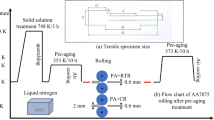

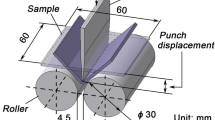

AA2219 sheets used in space applications need a combination of properties as strength and ductility for its enhanced usage. For this purpose, the heat treatment parameters were optimized to bring out the better strength in these alloys. AA2219 sheets were rolled at a cryogenic liquid nitrogen temperature at − 196 °C and room temperature for 50% and 75% reduction. DSC analysis was done to relate the effect of the precipitation kinetics to the strength of the material. The rolled samples were subjected to annealing at different temperatures for shorter periods. The annealing parameter was optimized by using mean results from the full factorial design based on the microhardness values obtained. Using the optimized annealing parameter, artificial ageing was performed at temperatures ranging from 75 to 125 °C for 30 h. The uni-directional rolled samples showed maximum strength after ageing at 125 °C for 24 h and cross-rolled sample at 100 °C for 18 h. A predictive model using regression and ANFIS were designed to determine the responses for the various input parameter settings for both the annealing and ageing and was validated. Analysis of variance was used to determine the significance of the ageing process parameters proving reduction percentage and ageing time having more effect on the heat treatment process.

Similar content being viewed by others

References

Shanmugasundaram T, Murty B S and Subramanya Sarma V, Scr Mater 54 (2006) 2013.

Gopala Krishna K, Sivaprasad K, Venkateswarlu K and Hari Kumar K C, Mater Sci Eng A 535 (2012) 129.

Panigrahi S K, Jayaganthan R, Pancholi V and Gupta M A, Mater Chem Phys 122 (2010) 188.

Feyissa F, Urnendu Das P, Ravi Kumar D and Ravi Sankar B, Des Res Conf 20 (2014) 1.

Panigrahi S K and Jayaganthan R, J Alloys Compd 509 (2011) 9609.

Panigrahi S K, Devanand D and Jayaganthan R, Trans Indian Inst Met 61 (2008) 159.

Kumar V and Kumar, Mater Sci Eng A 691 (2017) 211.

Panigrahi S K and Jayaganthan R, Metall Mater Trans A 41 (2010) 2675.

Dhal A, Panigrahi S K and Shunmugam M S, J Alloys Compd 649 (2015) 229.

Krymskiy S, Sitdikov O, Avtokratova E, Murashkin M and Markushev M, Rev Adv Mater Sci 31 (2012) 145.

Krishna K, Singh N, Karodi V and Kumar H, J Mater Eng Perform 20 (2011) 1569.

Kumar K, Grover S and Aggarwal, J Ind Eng Comput 2 (2011) 479.

Bagherian Azhiri R, Teimouri R, Ghasemi Baboly M and Leseman Z, Int J Adv Manuf Technol 71 (2014) 279.

Bozkurt Y, Mater Des 35 (2012) 440.

Bilici M K, Yükler A İ and Kurtulmuş M, Mater Des 32 (2011) 4074.

Sahoo P, Mater Des 30 (2009) 1341.

Sahoo P and Pal S K, Tribol Lett 28 (2007) 191.

Zhao D, Wang Y, Liang D and Zhang P, Mater Des 110 (2016) 676.

Prakash O, Talat M, Hasan S H and Pandey R K, Bioresour Technol 99 (2008) 7565.

Kadaganchi R, Gankidi M R and Gokhale H, Def Technol 11 (2015) 209.

Ravikumar K, Pakshirajan K, Swaminathan T and Balu K, Chem Eng J 105 (2005) 131.

Pan C M, Fan Y T, Xing Y, Hou H W and Zhang M L, Bioresour Technol 99 (2008) 3146.

Dewan M W, Huggett D J, Warren Liao T, Wahab M A and Okeil A M, Mater Des 92 (2016) 288.

Pérez J A, González M and Dopico D, Neural Comput Appl 19 (2010) 85.

Panigrahi S K and Jayaganthan R, Mater Des 32 (2011) 3150.

Sarkar A, Saravanan K, Nayan N, Murty S V S N, Narayanan P R, Venkitakrishnan P V and Mukhopadhyay J, Metall Mater Trans A 48 (2017) 321.

Taylor A S, Weiss M, Hilditch T, Hodgson P D and Stanford N, Mater Sci Forum 765 (2013) 434.

Palanisamy D and Senthil P, Mater Manuf Process 32 (2017) 654.

Gill S S, Singh R, Singh J and Singh H, Expert Syst Appl 39 (2012) 4171.

Aminah Z S, Noraini S A S M, Zuhailawati H and Anasyida A S, IOP Conf Ser Mater Sci Eng 114 (2016) 012127.

Kapoor G, Huang Y, Sarma V S, Langdon T G and Gubicza J, Mater Sci Eng A 688 (2017) 92.

Satish D R, Feyissa F and Kumar D R, Mater Manuf Process 32 (2017) 1345.

Dommeti S, Feyissa F and Ravi Kumar D 6 (2018)123.

Rajasekaran N R and Sampath V, J Miner Mater Charact Eng 10 (2011) 527.

Elgallad E M, Zhang Z and Chen X G, Mater Sci Eng A 625 (2015) 213.

Wangkasem P, Effect of Cryo-Rolling and Aging Processes on the Hardness, Electrical Conductivity and Microstructure of Aluminium Alloy ICEAS 127.

Panigrahi S K, Jayaganthan R and Chawla V, Mater Lett 62 (2008) 2626.

Immanuel R J and Panigrahi S K, Mater Sci Eng A 712 (2018) 747.

Babu S, Elangovan K, Balasubramanian V and Balasubramanian M, Met Mater Int 15 (2009) 21.

Pai T Y, Wan T J, Hsu S T, Chang T C, Tsai Y P, Lin C Y, Su H C and Yu L F, Comput Chem Eng 33 (2009) 1272.

Srinivasarao B and Lefebvre W, Effect of cryorolling on the microstructure and mechanical properties of AA2198 alloy, Proceedings of the 12th International Conference on Aluminium Alloys (2010), p 1961.

Xu Z, Liu M, Jia Z and Roven H J, J Alloys Compd 695 (2017) 827.

Sejzu M, Govindaraj R, and Prabhakaran R, Int J Sci Eng Res 7 (2016) 225.

Acknowledgements

This work was supported by the ISRO-RESPOND project. The authors wish to thank ISRO-RESPOND for their financial support and their approval for publishing this research (ISRO Sanction No: ISRO/RES/3/721/16-17).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Blessto, B., Sivaprasad, K., Muthupandi, V. et al. Analysis of Heat Treatment Response for Cryorolled AA2219 Alloy. Trans Indian Inst Met 72, 1881–1900 (2019). https://doi.org/10.1007/s12666-019-01665-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01665-5