Abstract

In this study combined NaOH/H2SO4 pretreatment of lignocellulosic biomasses (palm fronds, eucalyptus chips, almond shells and Aleppo pine cones) were used to separate hemicellulose and lignin and improve enzymatic digestibility of cellulose. The recovered celluloses were hydrolyzed using Cellic C-Tec2 or Cellic H-Tech2. The optimal saccharification yields 95.8, 94, 73.3 and 80.5% were obtained from the recovered celluloses of palm fronds, eucalyptus chips, almond shells and Aleppo pine cones respectively using Cellic H-Tec2. The highest ethanol yield [42.6 (±0.8 g) ethanol per 100 g glucose] was obtained from pretreated palm fronds which were hydrolyzed with Cellic H-Tech2. Hemicellulosic fractions obtained after ethanol precipitation were hydrolyzed using diluted acid (10%). These fractions were essentially composed of 38% xylose. Lignins, isolated from lignocellulosic biomasses were analyzed by FT-IR, the major bands characterize the aliphatic and phenolic hydroxyl groups as well as the ketones and aliphatic esters groups. This aromatic character makes it possible to use these lignins as precursor for vanillin production. The highest vanillin production of 162 µg mL−1 was obtained after 96 h of Aleppo pine cone lignin biotransformation by isolated white rot fungi.

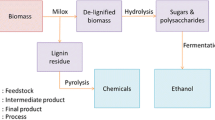

Graphical Abstract

Similar content being viewed by others

References

Asgher, M., Ahmad, Z., Iqbal, H.M.N.: Alkali and enzymatic delignification of sugarcane bagasse to expose cellulose polymers for saccharification and bioethanol production. Ind. Crops Prod. 44, 488–495 (2013)

Iqbal, H.M.N., Kyazze, G., Keshavarz, T.: Advances in valorization of lignocellulosic materials by bio-technology: an overview. BioResources. 8, 3157–3176 (2013)

Irshad, M., Anwar, Z., But, H.I., Afroz, A., Ikram, N., Rashid, U.: The industrial applicability of purified cellulose complex indigenously produced by Trichoderma viride through solid-state bio-processing of agro-industrial and municipal paper wastes. BioResources. 8, 145–157 (2013)

Isroi, M. R., Syamsiah, S., Niklasson, C., Cahyanto, M. N., Lundquist, K., Taherzadeh, M. J.: Biological pretreatment of lignocelluloses with white-rot fungi and its applications: a review. BioResources. 6, 5224–5259 (2011)

Ramos, L.P.: The chemistry involved in the steam treatment of lignocellulosic materials. Química Nova. 26, 863–871 (2003)

Wyman, C.E.: Alternative Fuels from biomass and their impact on carbon dioxide accumulation. Appl. Biochem. Biotechnol. 45, 897–915 (1994)

Ding, S.Y., Himmel, M.E.: The maize primary cell wall microfibril: a new model derived from direct visualization. J. Agric. Food Chem. 54, 597–606 (2006)

Zhang, Y.H. P., Lynd, L. R.: Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol. Bioeng. 88, 797–824 (2004)

Harmsen, P., Huijgen, W., Bermudez, L., Bakker, R.: Literature review of physical and chemical pretreatment processes for lignocellulosic biomass, Report/Wageningen UR, Food & Biobased Research;1184. Wageningen UR. Wageningen, Food & Biobased Research (2010)

Bilal, M., Asgher, M., Iqbal, H. M. N., Ramzan, M.: Enhanced bio-ethanol production from old newspapers waste through alkali and enzymatic delignification. Waste Biomass Valoriz. 1–11 (2017). doi:10.1007/s12649-017-9871-7

Tao, L., Aden, A., Elander, R., Pallapolu, V., Lee, Y., Garlock, R., Balan, V., Dale, B., Kim, Y., Mosier, N., Ladisch, M., Falls, M., Holtzapple, M., Sierra, R., Shi, J., Ebrik, M., Red-mond, T., Yang, B., Wyman, C., Hames, B., Thomas, S., Warner, R.: Process and techno-economic analysis of leading pretreatment technologies for lignocellulosic ethanol production using switchgrass. Bioresour. Technol. 102, 11105–11114 (2011)

Alvira, P., Tomás-Pejó, E., Ballesteros, M., Negro, M.J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour. Technol. 101, 4851–4861 (2010)

Pan, X., Arato, C., Gilkes, N., Gregg, D., Mabee, W., Pye, K., Xiao, Z., Zhang, X., Saddler, J.: Biorefining of softwoods using ethanol organosolv pulping: preliminary evaluation of process streams for manufacture of fuel-grade ethanol and coproducts. Biotechnol. Bioeng. 90, 473–481 (2005)

Smichi, N., Messaoudi, Y., Gargouri, M.: Lignocellulosic biomass fractionation: production of ethanol, lignin and carbon source for fungal culture. Waste Biomass Valoriz. 1–10 (2017). doi:10.1007/s12649-017-9859-3

Carels, N.: The challenge of Bioenergies—an overview. In: dos Santos Bernardes, M.A. (ed.) Biofuel’s Engineering Process Technology, pp. 23–64. InTech, Rijeka (2011)

Stöcker, M.: Biofuels and biomass-to-liquid fuels in the biorefinery: catalytic conversion of lignocellulosic biomass using porous materials. Angew. Chem. Int. Ed. 47, 9200–9211 (2008)

Vorlop, K.D., Wilke, Th., Prüße, U.: Biocatalytic and catalytic routes for the production of bulk and fine chemicals from renewable resources. In: Kamm, B., Gruber, P.R., Kamm, M. (eds.) Biorefineries-Industrial Process and Products, vol. 1, pp. 385–405. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, (2006)

Arevalo-Gallegos, A., Ahmad, Z., Asgher, M., Parra-Saldivar, R., Iqbal, H. M. N.: Lignocellulose: a sustainable material to produce value-added products with a zero waste approach—a review. Int. J. Biol. Macromolec. 99, 308–318 (2017)

Zeikus, J.G., Jain, M.K., Elankovan, P.: Biotechnology of succinic acid production and markets for derived industrial products. Appl. Microbiol. Biotechnol. 51, 545–552 (1999)

Bozell, J.J., Holladay, J.E., Johnson, D., White, F.: Top value added chemicals from biomass Volume II-Results of screening for potential candidates from biorefinery lignin. PNNL. 16983 (2007)

Kamm, B., Kamm, M., Gruber, P.R., Kromu, S.: Biorefinery systems—an overview. In: Kamm, B., Gruber, P.R., Kamm, M. (eds.) Biorefineries-Industrial process and products. vol. 1, pp. 3–40. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim (2006)

Pilanee, V., Waraporn, A.: Feasibility study on vanillin production from jatropha curcas stem using steam explosion as a pretreatment. World Acad. Sci. Eng. Technol. 3, 05–20 (2009)

Alireza, S., Sepideh, M.R., Ali, G.: Oxidative production of vanillin from industrial lignin using oxygen and nitrobenzene: a comparative study. Int. J. Farm. Allied Sci. 24, 1165–1171 (2013)

Borges da Silval, E.A., Zabkoval, M., ArOlijol, J.D., Cateto, C.A., Barreiro’, F., Belgacem, M.N., Rodriguesl, A.E.: Valorisation of Kraft Lignin by producing vanillin and ligninbased polyurethanes: use of the biorefinery concept. NWBC, Helsinki (2009)

Asgher, M., Shahid, M., Kamal, S., Iqbal, H.M.N.: Recent trends and valorization of immobilization strategies and ligninolytic enzymes by industrial biotechnology. J. Mol. Catal. B 101, 56–66 (2014)

Asgher, M., Bashir, F., Iqbal, H.M.N.: A comprehensive ligninolytic pre-treatment approach from lignocellulose green biotechnology to produce bio-ethanol. Chem. Eng. Res. Des. 92(8), 1571–1578 (2014)

Bilal, M., Asgher, M., Iqbal, H. M. N., Hu, H., Zhang, X.: Biotransformation of lignocellulosic materials into value-added products—a review. Int. J. Biol. Macromolec. 98, 447–458 (2017)

Iqbal, H. M. N., Kamal, S.: Economical bioconversion of lignocellulosic materials to value-added products. J. Biotechnol. Biomater. 2, e112 (2012)

Bhushan, K., Ulhas, P., Arpana, J.: Biotransformation of low cost lignocellulosic substrates into vanillin by white rot fungus, Phanerochaete chrysosporium NCIM1197. Indian J. Biotechnol. 12, 281–283 (2013)

Timothy, DHB., Mark, A., Elizabeth, M.H., Rahman, R.: Review: pathways for degradation of lignin in bacteria and fungi. Nat. Prod. Rep. 28, 1883–1896 (2011)

Van Soest, P.J.: Use of detergents in the analysis of fibrous feeds. Il. A rapid method for the determination of fiber and lignin. J. AOAC. 5, 829–835 (1963)

Messaoudi, Y., Smichi, N., Aallaf, T., Allaf, K., Gargouri, M.: Effect of instant controlled pressure drop pretreatment of lignocellulosic wastes on enzymatic saccharification and ethanol production. Ind. Crops Prod. 77, 910–919 (2015)

Pasha, C., Valli, N., Rao, L.V.: Lantana camara for fuel ethanol production using thermotolerant yeast. Lett. Appl. Microbiol. 44, 666–672 (2007)

Nutawan, Y., Phattayawadee, P., Pattranit, T., Mohammad, N.E.: Bioethanol production from rice straw. Energy Res. J. 1, 26–31 (2010)

Prabu, P.C., Udayasoorian, C.: Phenol Metabolism by white rot fungus Phanerochaete chrysosporium isolated from indian paper mill effluent enriched soil samples. Asian J. Plant Sci. 4, 56–59 (2005)

Betts, W.B., Dart, R.K., Ball, A.S., Pedlar, S.L.: Biosynthesis and structure of lignocellulose. In: Betts, W.B. (ed.) Biodegradation: Natural and Synthetic Materials, pp. 139–155. Springer, Berlin (1991)

Sun, Y., Cheng, J.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 83, 1–11 (2002)

Sjostrom, E.: Wood Chemistry. Fundamentals and Applications, 2nd edn., p. 292. Academic Press, San Diego (1993)

Seonghun, K., Chul, H.K.: Bioethanol production using the sequential acid/alkali pretreated empty palm fruit bunch fiber. Renew. Energy. 54, 150–155 (2013)

Novozymes, A/S.: Cellulosic ethanol: Novozymes Cellic® CTec2 and HTec2—Enzymes for hydrolysis of lignocellulosic. Luna No. 01668-03 (2010)

Harun, R., Jason, WSY., Cherrington, T., Danquah, M.K.: Exploring alkaline pretreatment of microalgal biomass for bioethanol production. Appl. Energy. 88, 3464–3467 (2011)

Carolina, C.M., Arturo, J.G., Mahmoud, E.H.: A comparison of pretreatment methods for bioethanol production from lignocellulosic materials. Process Saf. Environ. Prot. 90, 189–202 (2012)

Chang, V.S., Holtzapple, M.T.: Fundamental factors affecting biomass enzymatic reactivity. Appl. Biochem. Biotechnol. 84, 5–37 (2000)

Draude, K.M., Kurniawan, C.B., Duff, STB.: Effect of oxygen deliginification on the rate and extent of enzymatic hydrolysis of lignocellulosic material. Bioresour. Technol. 79, 113–120 (2001)

Yoshida, M., Liu, Y., Uchida, S., Kawarada, K., Ukagami, Y., Ichinose, H., Kaneko, S., Fukuda, K.: Effects of cellulose crystallinity, hemicellulose, and lignin on the enzymatic hydrolysis of Miscanthus sinensis to monosaccharides. Biosci. Biotechnol. Biochem. 72, 805–810 (2008)

Targonski, Z.: Alkali process for enhancing susceptibility of autohydrolysed beech sawdust to enzymatic hydrolysis. Enz Microb. Technol. 7, 126–128 (1985)

Kim, S., Holtzapple, M.T.: Lime pretreatment and enzymatic hydrolysis of corn stover. Bioresour. Technol. 96, 1994–2006 (2005)

Park, J.Y., Shiroma, R., Al-Haq, M.I., Zhang, Y., Ike, M., Arai-Sanoh, Y., Ida, A., Kondo, M., Tokuyasu, K.: A novel lime pretreatment for subsequent bioethanol production from rice straw—calcium capturing by carbonation (CaCCO) process. Bioresour. Technol. 101, 6805–6811 (2010)

Chang, V., Nagwani, M., Holtzapple, M.: Lime pretreatment of crop residues bagasse and wheat straw. Appl. Biochem. Biotechnol. 74, 135–159 (1998)

Mumoz, G., Mendonca, R.T., Baeza, J., Berlin, A., Saddler, J.N., Freer, J.: Bioethanol production from bioorganosolv pulps of Pinus radiata and Acacia dealbata. J. Chem. Technol. Biotechnol. 82, 767–774 (2007)

Victor, A., Pulidindi, I.N., Gedanken, A.: Assessment of holocellulose for the production of bioethanol by conserving Pinus radiata cones as renewable feedstockJ. Environ. Manag. 162, 215–220 (2015)

Ballesteros, I., Negro, M.J., Olivia, J.M., Cabanas, A., Manzanares, P., Ballesteros, M.: Ethanol production from steam-explosion pretreated wheat straw. Appl. Biochem. Biotechnol. 6, 129–132 (2006)

da Silva, A.S.A, Inoue, H., Endo, T., Yano, S., Bon, EP.: Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour. Technol. 101, 7402–7409 (2010)

McIntosh, S., Vancov, T.: Enhanced enzyme saccharification of Sorghum bicolor straw using dilute alkali pretreatment. Bioresour. Technol. 101, 6718–6727 (2010)

Sills, D.L., Gossett, J.M.: Assessment of commercial hemicellulases for saccharification of alkaline pretreated perennial biomass. Bioresour. Technol. 102, 1389–1398 (2011)

Durie, R.A., Lynch, B.M., Strenhell, S.: Comparative studies of brown coal and lignin. Aust. J. Chem. 13, 156–168 (1960)

Pilipchuk, Y.S., Pen, R.Z., Finkel’shtein, A.V.: Identification in infrared spectra of lignin of absorption frequencies corresponding to C–H Bonds”. Zh. Fiz. Khim. 39, 1768–1770 (1965)

Bolker, H.I., Somerville, N.G.: Infrared spectroscopy of lignins. Pulp Pap. Mag. Can. 64, 187–194 (1963)

Alriols, M.G., Garcia, A., Llano-ponte, R., Labidi, J.: Combined organosolv and ultrafiltration lignocellulosic biorefinery process. Chem. Eng. J. 157, 113–120 (2010)

Garcia, A., Toledano, A., Andres, M.A., Labidi, J.: Study of the antioxidant capacity of Miscanthus sinesis lignins. Process Biochem. 45, 935–940 (2010)

Sun, H., Xu, Y.K., Xu, G.Z.: Isolation of hemicellulose from wood chips via extraction with kraft green liquor. Chem. Res. Chin. Univ. 26, 667–671 (2010)

Buchala, A.J., Fraser, C.G., Wilkie, KCB.: Extraction of hemicellulose from oat tissues during the process of delignification. Phytochem. 11, 1249–1254 (1972)

Blakeney, A.B., Harris, P.J., Henry, R.J., Stones, B.A.: A simple and rapid preparation of alditol acetates for monosaccharide analysis. Carbohydr. Res. 113, 291–299 (1983)

Lavarack, B.P., Griffin, G.J., Rodman, D.: The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenerg. 23, 367–380 (2002)

Taherzadeh, M.J., Karimi, K.: Acid based hydrolysis process for bioethanol production from lignocellulosic materials: a review. BioResources. 2, 472–499 (2007)

Canilha, L., Carvalho, W., Felipe, MGA., Silva, JBA.: Xylitol production from wheat straw hemicellulosic hydrolysate: hydrolysate detoxification and carbon source used for inoculum preparation. Braz. J Microbiol. 39, 333–336 (2008)

Chandel, A.K., Kapoor, R.K., Singh, A.K., Kuhad, R.C.: Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresour. Technol. 98, 1947–1950 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Messaoudi, Y., Smichi, N., Bouachir, F. et al. Fractionation and Biotransformation of Lignocelluloses-Based Wastes for Bioethanol, Xylose and Vanillin Production. Waste Biomass Valor 10, 357–367 (2019). https://doi.org/10.1007/s12649-017-0062-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0062-3