Abstract

Large plastic deformation commonly occurs during the practical forming process in industries. Compared with uniaxial tension/compression, torsion is a more effective approach to investigate mechanical behavior under large deformation. The response of the large strain torsion of magnesium alloy is sensitive to the initial texture and twinning. Therefore, an extruded AZ31 alloy was pre-stressed in tension and compression to introduce dislocations and twins in the current work. Subsequently, torsion tests were conducted to clarify the effects of twinning and dislocation on subsequent deformation responses. The corresponding microstructure and deformation mechanisms were explored on the basis of viscoplastic self-consistent (VPSC) modeling. The experimental observations on stress-strain responses and pole figures were captured by simulation work. It was found that twins make less contribution to plastic deformation, which results in small change in texture direction under pure torsion and torsion after pretension. The activity of the slip/twin system and the mechanical properties are affected by different initial textures and active conditions of the system. Moreover, the stress state during combined tension-torsion loading benefits the reduction of texture intensity.

Similar content being viewed by others

References

Y. Yang, X.M. Xiong, J. Chen, X.D. Peng, D.L. Chen, and F.S. Pan, Research advances in magnesium and magnesium alloys worldwide in 2020, J. Magnes. Alloys, 9(2021), No. 3, p. 705.

B. Shi, C. Yang, Y. Peng, F. Zhang and F. Pan, Anisotropy of wrought magnesium alloys: A focused overview, J. Magnes. Alloys, (2022), DOI: https://doi.org/10.1016/j.jma.2022.03.006

M. Rakshith and P. Seenuvasaperuma, Review on the effect of different processing techniques on the microstructure and mechanical behaviour of AZ31 Magnesium alloy, J. Magnes. Alloys, 9(2021), No. 5, p. 1692.

Z.R. Zeng, M.Z. Bian, S.W. Xu, W.N. Tang, C. Davies, N. Birbilis, and J.F. Nie, Optimisation of alloy composition for highly-formable magnesium shee, Int. J. Miner. Metall. Mater., 29(2022), No. 7, p. 1388.

B.D. Shi and J. Mosler, On the macroscopic description of yield surface evolution by means of distortional hardening models: Application to magnesium, Int. J. Plast., 44(2013), p. 1.

B.D. Shi, A. Bartels, and J. Mosler, On the thermodynamically consistent modeling of distortional hardening: A novel generalized framework, Int. J. Plast., 63(2014), p. 170.

B.D. Shi, Y. Peng, and F.S. Pan, A generalized thermodynamically consistent distortional hardening model for Mg alloys, Int. J. Plast., 74(2015), p. 158.

G.G. Zhu, C. Yang, G. Shen, Y. Peng, and B.D. Shi, The asymmetric pre-yielding behaviour during tension and compression for a rolled AZ31 Mg alloy, Int. J. Mater. Form., 15(2022), No. 3, art. No. 26.

T. Hama, A. Kobuki, and H. Takuda, Crystal-plasticity finite-element analysis of anisotropic deformation behavior in a commercially pure titanium Grade 1 sheet, Int. J. Plast., 91(2017), p. 77.

J.L. Su, J. Teng, Z.L. Xu, and Y. Li, Biodegradable magnesium-matrix composites: A review, Int. J. Miner. Metall. Mater., 27(2020), No. 6, p. 724.

J.F. Song, J. Chen, X.M. Xiong, X.D. Peng, D.L. Chen and F.S. Pan, Research advances of magnesium and magnesium alloys worldwide in 2021, J. Magnes. Alloys, (2022), DOI: https://doi.org/10.1016/j.jma.2022.04.001

X.P. Zhang, H.X. Wang, L.P. Bian, S.X. Zhang, Y.P. Zhuang, W.L. Cheng, and W. Liang, Microstructure evolution and mechanical properties of Mg−9Al−1Si−1SiC composites processed by multi-pass equal-channel angular pressing at various temperatures, Int. J. Miner. Metall. Mater., 28(2021), No. 12, p. 1966.

G.Z. Kang and H. Li, Review on cyclic plasticity of magnesium alloys: Experiments and constitutive models, Int. J. Miner. Metall. Mater., 28(2021), No. 4, p. 567.

Z. Zhang, J.H. Zhang, J. Wang, Z.H. Li, J.S. Xie, S.J. Liu, K. Guan, and R.Z. Wu, Toward the development of Mg alloys with simultaneously improved strength and ductility by refining grain size via the deformation process, Int. J. Miner. Metall. Mater., 28(2021), No. 1, p. 30.

S. Biswas, B. Beausir, L.S. Toth, and S. Suwas, Evolution of texture and microstructure during hot torsion of a magnesium alloy, Acta Mater., 61(2013), No. 14, p. 5263.

B. Benoît, L.S. Tóth, Q. Fathallah, and K.W. Neale, Texture and mechanical behavior of magnesium during free-end torsion, J. Eng. Mater. Technol., 131(2009), No. 1, art. No. 011108.

M.R. Barnett, Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31, J. Light Met., 1(2001), No. 3, p. 167.

S.R. Agnew and Ö. Duygulu, Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B, Int. J. Plast., 21(2005), No. 6, p. 1161.

M.R. Barnett, M.D. Nave, and A. Ghaderi, Yield point elongation due to twinning in a magnesium alloy, Acta Mater., 60(2012), No. 4, p. 1433.

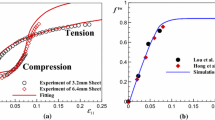

X.Y. Lou, M. Li, R.K. Boger, S.R. Agnew, and R.H. Wagoner, Hardening evolution of AZ31B Mg sheet, Int. J. Plast., 23(2007), No. 1, p. 44.

G. Proust, C.N. Tomé, and G.C. Kaschner, Modeling texture, twinning and hardening evolution during deformation of hexagonal materials, Acta Mater., 55(2007), No. 6, p. 2137.

P.D. Wu, X.Q. Guo, H. Qiao, S.R. Agnew, D.J. Lloyd, and J.D. Embury, On the rapid hardening and exhaustion of twinning in magnesium alloy, Acta Mater., 122(2017), p. 369.

B.B. Yang, C.Y. Shi, X.J. Ye, J.W. Teng, R.L. Lai, Y.J. Cui, D.K. Guan, H.W. Cui, Y.P. Li, and A. Chiba, Underlying slip/twinning activities of Mg−xGd alloys investigated by modified lattice rotation analysis, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.1016/j.jma.2021.06.008

P.P. Indurkar, S. Baweja, R. Perez, and S.P. Joshi, Predicting textural variability effects in the anisotropic plasticity and stability of hexagonal metals: Application to magnesium and its alloys, Int. J. Plast., 132(2020), art. No. 102762.

D. Sarker and D.L. Chen, Texture transformation in an extruded magnesium alloy under pressure, Mater. Sci. Eng. A, 582(2013), p. 63.

F.A. Mirza, D.L. Chen, D.J. Li, and X.Q. Zeng, Effect of strain ratio on cyclic deformation behavior of a rare-earth containing extruded magnesium alloy, Mater. Sci. Eng. A, 588(2013), p. 250.

B. Clausen, C.N. Tomé, D.W. Brown, and S.R. Agnew, Reorientation and stress relaxation due to twinning: Modeling and experimental characterization for Mg, Acta Mater., 56(2008), No. 11, p. 2456.

S.G. Hong, S.H. Park, and C.S. Lee, Role of \(\{10\bar{1}0\}\) twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy, Acta Mater., 58(2010), No. 18, p. 5873.

P.D. Wu, H. Wang, and K.W. Neale, On the large strain torsion of hcp polycrystals, Int. J. Appl. Mech., 4(2012), No. 3, p. 1250024.

L. Wu, A. Jain, D.W. Brown, G.M. Stoica, S.R. Agnew, B. Clausen, D.E. Fielden, and P.K. Liaw, Twinning-detwinning behavior during the strain-controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A, Acta Mater., 56(2008), No. 4, p. 688.

C. Yang, B.D. Shi, Y. Peng, and F.S. Pan, Transition from convex to concave of equal plastic work contours for wrought magnesium alloy under multi-axial loading, Int. J. Solids Struct., 150(2018), p. 117.

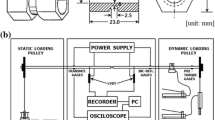

C. Yang, G.G. Zhu, H. Zhao, Y. Peng, and B.D. Shi, The roles of stress state and pre-straining on Swift effect for an extruded AZ31 Mg alloy, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.1016/j.jma.2021.08.003

X.D. Zhang, S.M. Li, X.Q. Guo, H.M. Wang, Q. Yu, and P.D. Wu, Effects of texture and twinning on the torsional behavior of magnesium alloy solid rod: A crystal plasticity approach in comparison with uniaxial tension/compression, Int. J. Mech. Sci., 191(2021), art. No. 106062.

C.M.A. Iftikhar and A.S. Khan, The evolution of yield loci with finite plastic deformation along proportional and non-proportional loading paths in an annealed extruded AZ31 magnesium alloy, Int. J. Plast., 143(2021), art. No. 103007.

B.D. Shi, Y. Peng, C. Yang, F.S. Pan, R.J. Cheng, and Q.M. Peng, Loading path dependent distortional hardening of Mg alloys: Experimental investigation and constitutive modeling, Int. J. Plast., 90(2017), p. 76.

B.C. Suh, J.H. Kim, J.H. Bae, J.H. Hwang, M.S. Shim, and N.J. Kim, Effect of Sn addition on the microstructure and deformation behavior of Mg−3Al alloy, Acta Mater., 124(2017), p. 268.

A. Tripathi, S.V.S.N. Murty, and P.R. Narayanan, Microstructure and texture evolution in AZ31 magnesium alloy during caliber rolling at different temperatures, J. Magnes. Alloys, 5(2017), No. 3, p. 340.

A. Chapuis and Q. Liu, Modeling strain rate sensitivity and high temperature deformation of Mg−3Al−1Zn alloy, J. Magnes. Alloys, 7(2019), No. 3, p. 433.

S.B. Yi, C.H.J. Davies, H.G. Brokmeier, R.E. Bolmaro, K.U. Kainer, and J. Homeyer, Deformation and texture evolution in AZ31 magnesium alloy during uniaxial loading, Acta Mater., 54(2006), No. 2, p. 549.

F. Kabirian, A.S. Khan, and T. Gnäupel-Herlod, Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions, Int. J. Plast., 68(2015), p. 1.

Y.L. Xu, Y.D. Huang, Y.Y. Wang, W.M. Gan, S.W. Wang, E. Maawad, N. Schell, and N. Hort, Investigations on the tensile deformation of pure Mg and Mg−15Gd alloy by in situ X-ray synchrotron radiation and visco-plastic self-consistent modeling, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.1016/j.jma.2021.06.011

L. Hu, H.Y. Lv, L.X. Shi, Y. Chen, Q. Chen, T. Zhou, M.G. Li, and M.B. Yang, Research on deformation mechanism of AZ31 magnesium alloy sheet with non-basal texture during uniaxial tension at room temperature: A visco-plastic self-consistent analysis, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.10116/j.jma.2020.12.008

J. Kuang, Y.Q. Zhang, X.P. Du, J.Y. Zhang, G. Liu, and J. Sun, On the strengthening and slip activity of Mg−3Al−1Zn alloy with pre-induced \(\{10\bar{1}2\}\) twins, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.1016/j.jma.2021.07.016

H. Qiao, X.Q. Guo, S.G. Hong, and P.D. Wu, Modeling of \(\{10\bar{1}2\}\)-\(\{10\bar{1}2\}\) secondary twinning in pre-compressed Mg alloy AZ31, J. Alloys Compd., 725(2017), p. 96.

A. Maldar, L.Y. Wang, G.M. Zhu, and X.Q. Zeng, Investigation of the alloying effect on deformation behavior in Mg by visco-plastic self-consistent modeling, J. Magnes. Alloys, 8(2020), No. 1, p. 210.

Y. Cheng, A. Chapuis, Y.C. Xin, Q. Liu, and P.D. Wu, Mg−3Al−1Zn alloy deformed along different strain paths: Role of latent hardening, J. Magnes. Alloys, (2021). DOI: https://doi.org/10.1016/j.jma.2021.07.025

R. Hielscher and H. Schaeben, A novel pole figure inversion method: specification of the MTEX algorithm, J. Appl. Crystallogr., 41(2008), 6, p. 1024.

D.W. Brown, J.D. Almer, B. Clausen, P.L. Mosbrucker, T.A. Sisneros, and S.C. Vogel, Twinning and de-twinning in beryllium during strain path changes, Mater. Sci. Eng. A, 559(2013), p. 29.

Y.J. Wang, Y. Zhang, and H.T. Jiang, Tension-compression asymmetry and corresponding deformation mechanism in ZA21 magnesium bars with bimodal structure, Int. J. Miner. Metall. Mater., (2021). DOI: https://doi.org/10.1007/s12613-021-2388-x

D. Sarker and D.L. Chen, Detwinning and strain hardening of an extruded magnesium alloy during compression, Scripta Mater., 67(2012), No. 2, p. 165.

J. Koike and R. Ohyama, Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature, Acta Mater., 53(2005), No. 7, p. 1963.

C.N. Tomé, R.A. Lebensohn, and U.F. Kocks, A model for texture development dominated by deformation twinning: Application to zirconium alloys, Acta Metall. Mater., 39(1991), No. 11, p. 2667.

X.Q. Guo, W. Wu, P.D. Wu, H. Qiao, K. An, and P.K. Liaw, On the Swift effect and twinning in a rolled magnesium alloy under free-end torsion, Scripta Mater., 69(2013), No. 4, p. 319.

C. Yang, Y.B. Mei, D. Meng, G.G. Zhu, S.W. Liu, Y. Peng, L. Wu, C.Y. Zha, and B.D. Shi, Mechanical anisotropy induced by strain path change for AZ31 Mg alloy sheet, Metals, 10(2020), No. 8, art. No. 1409.

Acknowledgements

This work was financially supported by the projects by the National Natural Science Foundation of China (No. 51771166), the Hebei Natural Science Foundation, China (Nos. E2019203452 and E2021203011), the central government guiding local science and technology development (No. 216Z1001G), the talent project of Human Resources and Social Security Department of Hebei Province, China (No. A202002002), the key project of the Department of Education of Hebei Province (No. ZD2021107), the Cultivation Project for Basic Research and Innovation of Yanshan University (No. 2021LGZD002), the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology, China (No. P2020-013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, Q., Meng, D., Fu, Z. et al. Effect of axial preloading on mechanical behavior during the free-end torsion of an extruded AZ31 magnesium alloy. Int J Miner Metall Mater 29, 1351–1360 (2022). https://doi.org/10.1007/s12613-022-2417-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2417-4