Abstract

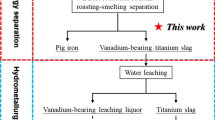

The carbothermic reduction of vanadium titanomagnetite concentrate (VTC) with the assistance of Na2CO3 was conducted in an argon atmosphere between 1073 and 1473 K. X-ray diffraction and scanning electron microscopy were used to investigate the phase transformations during the reaction. By investigating the reaction between VTC and Na2CO3, it was concluded that molten Na2CO3 broke the structure of titanomagnetite by combining with the acidic oxides (Fe2O3, TiO2, Al2O3, and SiO2) to form a Na-rich melt and release FeO and MgO. Therefore, Na2CO3 accelerated the reduction rate. In addition, adding Na2CO3 also benefited the agglomeration of iron particles and the slag—metal separation by decreasing the viscosity of the slag. Thus, Na2CO3 assisted carbothermic reduction is a promising method for treating VTC at low temperatures.

Similar content being viewed by others

References

F. Zheng, F. Chen, Y. Guo, T. Jiang, A. Y. Travyanov, and G. Qiu, Kinetics of hydrochloric acid leaching of titanium from titanium-bearing electric furnace slag, JOM, 68(2016), No. 5, p. 1476.

X.W. Lv, Z.Q. Lun, J.Q. Yin, and C.Q. Bai, Carbothermic reduction of vanadium titanomagnetite by microwave irradiation and smelting behavior, ISIJ Int., 53(2013), No. 7, p. 1115.

S. Wang, Y.F. Guo, T. Jiang, L. Yang, F. Chen, F.Q. Zheng, X.L. Xie, and M.J. Tang, Reduction behaviors of iron, vanadium and titanium oxides in smelting of vanadium titanomagnetite metallized pellets, JOM, 69(2017), No. 9, p. 1646.

S. Samanta, S. Mukherjee, and R. Dey, Upgrading metals via direct reduction from poly-metallic titaniferous magnetite ore, JOM, 67(2015), No. 2, p. 467.

M.Y. Wang, S.F. Zhou, X.W. Wang, B.F. Chen, H.X. Yang, S.K. Wang, and P.F. Luo, Recovery of iron from chromium vanadium-bearing titanomagnetite concentrate by direct reduction, JOM, 68(2016), No. 10, p. 2698.

Y.Q. Zhao, T.C. Sun, H.Y. Zhao, C. Chen, and X.P. Wang, Effect of reductant type on the embedding direct reduction of beach titanomagnetite concentrate, Int. J. Miner. Metall. Mater., 26(2019), No. 2, p. 152.

X.H. Li, J. Kou, T.C. Sun, S.C. Wu, and Y.Q. Zhao, Effects of calcium compounds on the carbothermic reduction of vanadium titanomagnetite concentrate, Int. J. Miner. Metall. Mater., 27(2020), No. 3, p. 301.

Y.L. Zhen, G.H. Zhang, and K.C. Chou, Viscosity of CaO-MgO-Al2O3-SiO2-TiO2 melts containing TiC particles, Metall. Mater. Trans. B, 46(2015), p. 155.

W.Q. Fu, Y.C. Wen, and H.E. Xie, Development of intensified technologies of vanadium-bearing titanomagnetite smelting, J. Iron. Steel. Res. Int., 18(2011), No. 4, p. 7.

L. Zhang, L.N. Zhang, M.Y. Wang, G.Q. Li, and Z.T. Sui, Precipitation selectivity of perovskite phase from Ti-bearing blast furnace slag under dynamic oxidation conditions, J. Non-Cryst. Solids, 353(2007), No. 22–23, p. 2214.

L.Y. Shi, Y.L. Zhen, D.S. Chen, Q. Tao, and L.N. Wang, Carbothermic reduction of vanadium-titanium magnetite in molten NaOH, ISIJ Int., 58(2018), No. 4, p. 627.

Y.M. Zhang, L.Y. Yi, L.N. Wang, D.S. Chen, W.J. Wang, Y.H. Liu, H.X. Zhao, and T. Oi, A novel process for the recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite: Sodium modification—direct reduction coupled process, Int. J. Miner. Metal. Mater., 24(2017), No. 5, p. 504.

Y.M. Zhang, L.N. Wang, D.S. Chen, W.J. Wang, Y.H. Liu, H.X. Zhao, and T. Oi, A method for recovery of iron, titanium, and vanadium from vanadium-bearing titanomagnetite, Int. J. Miner. Metal. Mater., 25(2018), No. 2, p. 131.

F.C. Meng, Y.H. Liu, T.Y. Xue, Q. Su, W.J. Wang, and T. Qi, Structures, formation mechanisms, and ion exchange properties of alpha-, beta-, and gamma-Na2TiO3, RSC Adv., 6(2016), No. 113, p. 112625.

D.S. Chen, L.S. Zhao, Y.H. Liu, T. Qi, J.C. Wang, and L.N. Wang, A novel process for recovery of iron, titanium, and vanadium from titanomagnetite concentrates: NaOH molten salt roasting and water leaching processes, J. Hazard. Mater., 244–245(2013), p. 588.

D.S. Chen, B. Song, L.N. Wang, T. Qi, Y. Wang, and W.J. Wang, Solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal, Miner. Eng., 24(2011), No. 8, p. 864.

L.H. Zhou and F.H. Zeng, Statistical analysis of the effect of Na2CO3 as additive on the reduction of vanadic-titanomag-netite-coal mixed pellets, Adv. Mater. Res., 97–101(2010), p. 465.

Z.H. Zhu, G.Q. Lu, and R.T. Yang, New insights into alkali-catalyzed gasification reactions of carbon: Comparison of Na2O reduction with carbon over Na and K catalysts, J. Catal., 192(2000), No. 1, p. 77.

E. Foley and K.P. Mackinnon, Alkaline roasting of ilmenite, J. Solid State Chem., 1(1970), No. 3–4, p. 566.

V. Tathavadkar, and A. Jha, The effect of molten sodium titanate and carbonate salt mixture on the alkali roasting of ilmenite and rutile minerals, [in] VII International Conference on Molten Slags Fluxes and Salts, Cape Town, p. 255.

A. Lahiri, and A. Jha, Kinetics and reaction mechanism of soda ash roasting of ilmenite ore for the extraction of titanium dioxide, Metall. Mater. Trans. B, 38(2007), No. 6, p. 939.

S. Parirenyatwa, L. Escudero-Castejon, Y. Hara, A. Jha, and S. Sanchez-Segado, Comparative study of alkali roasting and leaching of chromite ores and titaniferous minerals, Hydrometallurgy, 165(2016), p. 213.

C. Li, A.F. Reid, and S. Saunders, Nonstoichiometric alkali ferrites and aluminates in the systems NaFeO2-TiO2, KFeO2-TiO2, KAlO2-TiO2, and KAlO2-SiO2, J. Solid State Chem., 3(1971), No. 4, p. 614.

J.W. Kim and H.G. Lee, Thermal and carbothermic decomposition of Na2CO3 and Li2CO3, Metall. Mater. Trans. B, 32(2001), No. 1, p. 17.

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melançon, A.D. Pelton, and S. Petersen, FactSage thermochemical software and databases, Calphad, 26(2002), No. 2, p. 189.

P.C. Holloway, T.H. Etsell, and A. L. Murland, Roasting of La Oroya zinc ferrite with Na2CO3, Metall. Mater. Trans. B, 38(2007), No. 5, p. 781.

P.C. Holloway, T.H. Etsell, and A.L. Murland, Use of secondary additives to control the dissolution of iron during Na2CO3 roasting of la ooya zinc ferrite, Metall. Mater. Trans. B, 38(2007), No. 5, p. 793.

E.N. Selivanov, K.V. Pikulin, L.I. Galkova, R.I. Gulyaeva, and S.A. Petrova, Kinetics and mechanism of natural wolframite interactions with sodium carbonate, Int. J. Miner. Metal. Mater., 26(2019), No. 11, p. 1364.

R.Z. Xu, J.L. Zhang, W.X. Han, Z.Y. Chang, and K.X. Jiao, Effect of BaO and Na2O on the viscosity and structure of blast furnace slag, Ironmaking Steelmaking, 47(2020), No. 2, p. 168.

A. Tomita, Catalysis of carbon—gas reactions, Catal. Surv. Jpn., 5(2001), No. 1, p. 17.

W. Pan, Z.J. Ma, Z.X. Zhao, W. H. Kim, and D.J. Min, Effect of Na2O on the reduction of Fe2O3 compacts with CO/CO2, Metall. Mater. Trans. B, 43(2012), No. 6, p. 1326.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2018YFC1900500), the National Natural Science Foundation of China (Nos. 21908231, 51774260, 51804289, and 51904286), the Key Research Program of Frontier Sciences of the Chinese Academy of Sciences (No. QYZDJ-SSW-JSC021), the CAS Interdisciplinary Innovation Team, and the Special Project for Transformation of Major Technological Achievements in Hebei Province, China (No. 19044012Z).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interests

The authors declared that they do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted

Rights and permissions

About this article

Cite this article

Chen, L., Zhen, Y., Zhang, G. et al. Carbothermic reduction of vanadium titanomagnetite with the assistance of sodium carbonate. Int J Miner Metall Mater 29, 239–247 (2022). https://doi.org/10.1007/s12613-020-2160-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2160-7