Abstract

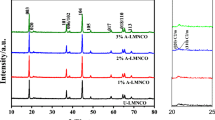

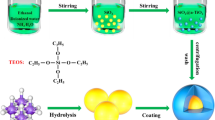

Modification of Si anode with various coating matrixes is a promising strategy to resolve the unstable solid electrolyte interphase issues. However, the complex preparation process and inherently weak interaction between Si and other matrixes impede its practical application. Inspired by the metallurgical process of aluminum, an aluminosilicate matrix was prepared as coating layer on the surface of Si nanoparticles after heat treatment. Si nanoparticles with a uniform native oxide layer were used as seed crystals for the adsorption of aluminum hydroxide. The strong symbiosis and bond between alumina and silica, such as mullite (3Al2O3·2SiO2) or kaolin (Al2O3·SiO2·2H2O), provide homogeneous and durable contact coating layer. The as-produced Si/SiO2·Al2O3 composite delivers a charge capacity of 1440 mAh·g−1 at 100 mA·g−1 and remains 879 mAh·g−1 at 3 A·g−1. After 200 cycles, the capacity retention remains high at 76%. The enhanced properties were ascribed to SiO2·Al2O3 synergistic composite coating layer, which could hinder the interfacial side chemical reaction and buffer volume change of Si.

Graphical abstract

摘要

选择合适的材料对硅进行表面改性可有效解决固体电解质界面不稳定问题。然而, 硅与其他材料之间界面相容性差以及改性方法复杂等问题阻碍了其实际应用。 将具有均匀原生氧化层的纳米硅为晶种诱导铝酸钠溶液中的氢氧化铝沉淀, 从而合成铝硅酸盐包覆的纳米硅负极材料。氧化铝和二氧化硅之间的强共生性和粘结性保证了包覆层的均匀和持久。 所制备的Si/SiO2·Al2O3复合材料在100 mA·g-1下的充电容量为1440 mAh·g-1, 在3 A·g-1下的充电容量为879 mAh·g-1。循环200圈后的容量保持率高达76%。 结果表明, 铝硅酸盐可有效抑制纳米硅的界面副反应和体积膨胀问题。

Similar content being viewed by others

References

Hwang SM, Lim YG, Kim JG, Heo YU, Lim JH, Yamauchi Y, Park MS, Kim YJ, Dou SX, Kim JH. A case study on fibrous porous SnO2 anode for robust, high-capacity lithium-ion batteries. Nano Energy. 2014;10:53.

Yang H, Wu HH, Ge M, Li L, Yuan Y, Yao Q, Chen J, Xia L, Zheng J, Chen Z, Duan J, Kisslinger K, Zeng XC, Lee WK, Zhang Q, Lu J. Simultaneously dual modification of ni-rich layered oxide cathode for high-energy lithium-ion batteries. Adv Funct Mater. 2019;29(13):1808825.

He SR, Zou JP, Chen LB, Chen YJ. A nanostructured Ni/T-Nb2O5@carbon nanofibers as a long-life anode material for lithium-ion batteries. Rare Met. 2021;40(2):374.

Hwang SM, Kim SY, Kim JG, Kim KJ, Lee JW, Park MS, Kim YJ, Shahabuddin M, Yamauchi Y, Kim JH. Electrospun manganese–cobalt oxide hollow nanofibres synthesized via combustion reactions and their lithium storage performance. Nanoscale. 2015;7(18):8351.

He Y, Jiang L, Chen T, Xu Y, Jia H, Yi R, Xue D, Song M, Genc A, Bouchet Marquis C, Pullan L, Tessner T, Yoo J, Li X, Zhang JG, Zhang S, Wang C. Progressive growth of the solid-electrolyte interphase towards the Si anode interior causes capacity fading. Nat Nanotechnol. 2021;16(10):1113.

Li M, Su A, Qin Q, Qin Y, Dou A, Zhou Y, Su M. Liu Y High-rate capability of columbite CuNb2O6 anode materials for lithium-ion batteries. Mater Lett. 2021;284(1):128915.

Wang YY, Zhao ZW, Liu Y, Hou LR, Yuan CZ. Precipitant-free solvothermal construction of spindle-like CoCO3/reduced graphene oxide hybrid anode toward high-performance lithium-ion batteries. Rare Met. 2020;39(9):1082.

Xue H, Zhao J, Tang J, Gong H, He P, Zhou H, Yamauchi Y, He J. High-loading nano-SnO2 encapsulated in situ in three-dimensional rigid porous carbon for superior lithium-ion batteries. Chemistry. 2016;22(14):4915.

Zhou X, Liu Y, Ren Y, Mu T, Yin X, Du C, Huo H, Cheng X, Zuo P, Yin G. Engineering molecular polymerization for template-free SiOx/C hollow spheres as ultrastable anodes in lithium-ion batteries. Adv Funct Mater. 2021;31(21):2101145.

Cao C, Abate II, Sivonxay E, Shyam B, Jia C, Moritz B, Devereaux TP, Persson KA, Steinrück HG, Toney MF. Solid electrolyte interphase on native oxide-terminated silicon anodes for Li-ion batteries. Joule. 2019;3(3):762.

An W, Gao B, Mei S, Xiang B, Fu J, Wang L, Zhang Q, Chu PK, Huo K. Scalable synthesis of ant-nest-like bulk porous silicon for high-performance lithium-ion battery anodes. Nat Commun. 2019;10(1):1447.

Zhou Y, Feng S, Zhu P, Guo H, Yan G, Li X, Su M, Liu Y, Wang Z, Wang J. Self-sacrificial-reaction guided formation of hierarchical electronic/ionic conductive shell enabling high-performance nano-silicon anode. Chem Eng J. 2021;415(3):128998.

Qu X, Yu Z, Ruan D, Dou A, Su M, Zhou Y, Liu Y, Chu D. Enhanced electrochemical performance of Ni-rich cathode materials with Li1.3Al0.3Ti1.7(PO4)3 coating. ACS Sustain Chem Eng. 2020;8(15):5819.

Feng K, Li M, Liu W, Kashkooli AG, Xiao X, Cai M, Chen Z. Silicon-based anodes for lithium-ion batteries: from fundamentals to practical applications. Small. 2018;14(8):1702737.

Li L, Xia L, Yang H, Zhan X, Chen J, Chen Z, Duan J. Solid-state synthesis of lanthanum-based oxides Co-coated LiNi0.5Co0.2Mn0.3O2 for advanced lithium ion batteries. J Alloys Compd. 2020;832(15):154959.

Zhang X, Wang D, Qiu X, Ma Y, Kong D, Mullen K, Li X, Zhi L. Stable high-capacity and high-rate silicon-based lithium battery anodes upon two-dimensional covalent encapsulation. Nat Commun. 2020;11(1):3826.

Jo C, Groombridge AS, De La Verpilliere J, Lee JT, Son Y, Liang HL, Boies AM, De Volder M. Continuous-flow synthesis of carbon-coated silicon/iron silicide secondary particles for Li-ion batteries. ACS Nano. 2019;14(1):698.

Wu SJ, Wu ZH, Fang S, Qi XP, Yu B, Yang JY. A comparison of core–shell Si/C and embedded structure Si/C composites as negative materials for lithium-ion batteries. Rare Met. 2021;40(9):2440.

Ai Q, Fang Q, Liang J, Xu X, Zhai T, Gao G, Guo H, Han G, Ci L, Lou J. Lithium-conducting covalent-organic-frameworks as artificial solid-electrolyte-interphase on silicon anode for high performance lithium ion batteries. Nano Energy. 2020;72:104657.

Zhou Y, Su M, Dou A, Liu Y. Facile synthesis of Si/NiSi2/C composite derived from metal-organic frameworks for high-performance lithium-ion battery anode. J Electroanal Chem. 2020;873(15):114398.

Ren WF, Li JT, Zhang SJ, Lin AL, Chen YH, Gao ZG, Zhou Y, Deng L, Huang L, Sun SG. Fabrication of multi-shell coated silicon nanoparticles via in-situ electroless deposition as high performance anodes for lithium ion batteries. J Electroanal Chem. 2020;48:160.

Jin Y, Li S, Kushima A, Zheng X, Sun Y, Xie J, Sun J, Xue W, Zhou G, Wu J, Shi F, Zhang R, Zhu Z, So K, Cui Y, Li J. Self-healing SEI enables full-cell cycling of a silicon-majority anode with a coulombic efficiency exceeding 99.9%. Energy Environ Sci. 2017;10(2):580.

Stetson C, Yin Y, Norman A, Harvey SP, Schnabel M, Ban C, Jiang CS, DeCaluwe SC, Al-Jassim M. Evolution of solid electrolyte interphase and active material in the silicon wafer model system. J Power Sources. 2021;482(15):228946.

Jiang C, Xiang L, Miao S, Shi L, Xie D, Yan J, Zheng Z, Zhang X, Tang Y. Flexible interface design for stress regulation of a silicon anode toward highly stable dual-ion batteries. Adv Mater. 2020;32(17):1908470.

Fu L, Xu A, Song Y, Ju JH, Sun H, Yan YR, Wu SP. Pinecone-like silicon@carbon microspheres covered by Al2O3 nano-petals for lithium-ion battery anode under high temperature. Electrochim Acta. 2021;387(10):138461.

Dong M, Wang Z, Li H, Guo H, Li X, Shih K, Wang J. Metallurgy inspired formation of homogeneous Al2O3 coating layer to improve the electrochemical properties of LiNi0.8Co0.1Mn0.1O2 cathode material. ACS Sustain Chem Eng. 2017;5(11):10199.

Cheng Y, Wei K, Yu Z, Fan D, Yan DL, Pan Z, Tian B. Ternary Si-SiO-Al composite films as high-performance anodes for lithium-ion batteries. ACS Appl Mater Interfaces. 2021;13(29):34447.

Shin J, Cho E. Agglomeration mechanism and a protective role of Al2O3 for prolonged cycle life of Si anode in lithium-ion batteries. Chem Mater. 2018;30(10):3233.

Xu K, Zhang Z, Su W, Wei Z, Zhong G, Wang C, Huang X. Alumina coated nano silicon synthesized by aluminothermic reduction as anodes for lithium ion batteries. Funct Mater Lett. 2017;10(2):1650073.

Zhu H, Shiraz M, Liu L, Hu Y, Liu J. A facile and low-cost Al2O3 coating as an artificial solid electrolyte interphase layer on graphite/silicon composites for lithium-ion batteries. Nanotechnology. 2021;32(14):144001.

Zhang Y, Xia G, Zhang J, Wang D, Dong P, Duan J. Boosting high-voltage cyclic stability of nickel-rich layered cathodes in full-cell by metallurgy-inspired coating strategy. Appl Surf Sci. 2020;509(15):145380.

Liu G, Wu G, Chen W, Li X, Peng Z, Zhou Q, Qi T. Increasing precipitation rate from sodium aluminate solution by adding active seed and ammonia. Hydrometallurgy. 2018;176:253.

Zhang H, Liu K, Liu Y, Lang Z, He W, Ma L, Man J, Jia G, Cui J, Sun J. Observably improving initial coulombic efficiency of C/SiOx anode using -C-O-PO3Li2 groups in lithium ion batteries. J Power Sources. 2020;447(31):227400.

Li J, Yang JY, Wang JT, Lu SG. A scalable synthesis of silicon nanoparticles as high-performance anode material for lithium-ion batteries. Chin J Rare Met. 2019;43(2):199.

Ke CZ, Liu F, Zheng ZM, Zhang HH, Cai MT, Li M, Yan QZ, Chen HX, Zhang QB. Boosting lithium storage performance of Si nanoparticles via thin carbon and nitrogen/phosphorus co-doped two-dimensional carbon sheet dual encapsulation. Rare Met. 2021;40(6):1347.

Lee J, Moon J, Han SA, Kim J, Malgras V, Heo YU, Kim H, Lee SM, Liu HK, Dou SX, Yamauchi Y, Park MS, Kim JH. Everlasting living and breathing Gyroid 3D network in Si@SiOx/C nanoarchitecture for lithium ion battery. ACS Nano. 2019;13(8):9607.

Xiao Z, Lei C, Yu C, Chen X, Zhu Z, Jiang H, Wei F. Si@Si3N4@C composite with egg-like structure as high-performance anode material for lithium ion batteries. Energy Storage Mater. 2020;24:565.

Zhang FZ, Ma YY, Jiang MM, Luo W, Yang JP. Boron heteroatom-doped silicon-carbon peanut-like composites enables long life lithium-ion batteries. Rare Met. 2021. https://doi.org/10.1007/s12598-021-01741-0.

Liu Z, Li L, Chen J, Yang H, Xia L, Chen J, Duan J, Chen Z. Effects of chelating agents on electrochemical properties of Na0.9Ni0.45Mn0.55O2 cathode materials. J Alloys Compd. 2021;855(2):157485.

Qu X, Huang H, Wan T, Hu L, Yu Z, Liu Y, Dou A, Zhou Y, Su M, Peng X, Wu H, Wu T, Chu D. An integrated surface coating strategy to enhance the electrochemical performance of nickel-rich layered cathodes. Nano Energy. 2022;91(1):106665.

Li P, Hwang JY, Sun YK. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery. ACS Nano. 2019;13(2):2624.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 52004103, 51974137 and 51774150), China Postdoctoral Science Foundation (No. 2020M671361), and Jiangsu Postdoctoral Science Foundation (No. 2020Z090).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, Y., Niu, PH., Li, ZH. et al. Metallurgy of aluminum-inspired formation of aluminosilicate-coated nanosilicon for lithium-ion battery anode. Rare Met. 41, 1880–1888 (2022). https://doi.org/10.1007/s12598-022-01961-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-01961-y