Abstract

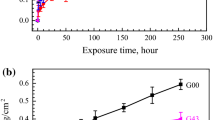

Oxide pegging is a widely accepted mechanistic model explaining the reactive element effect on the improved adherence of scale. However, previous models for the oxide peg formation process have not considered the effects of more than one active element added into the alloy during the peg formation. This study proposes a new model of oxide peg formation and growth for the doping of two reactive elements in an alloy (the precipitated Y and solid solute Ti). Different amounts of Ti and Y were added to a CoNiCrAl alloy, and the characteristics of the resulting oxide pegs, such as their linear density, size, and forming process, are obtained by examining alloy samples subjected to an isothermal oxidation operation at a temperature of 1150 °C. It is found that the amount of Y determines the density of the oxide pegs, and Ti does not form a Ti-rich oxide core if a Y-rich oxide exists in the sample. In samples with the same Y content, the oxide pegs primarily grow in length, and with increased Ti content, they grow along the β-phase boundary and into the alloy. Based on these results, a three-step model for oxide peg formation and growth is conceived.

Similar content being viewed by others

References

Salam S, Hou PY, Zhang YD, Wang HF, Zhang C, Yang ZG. Compositional effects on the high-temperature oxidation lifetime of MCrAlY type coating alloys. Corros Sci. 2015;95:143.

Chen LC, Zhang C, Yang ZG. Effect of pre-oxidation on the hot corrosion of CoNiCrAlYRe alloy. Corros Sci. 2011;53(1):374.

Lan H, Yang ZG, Xia ZX, Zhang YD, Zhang C. Effect of dysprosium addition on the cyclic oxidation behaviour of CoNiCrAlY alloy. Corros Sci. 2011;53(4):1476.

Wang HF. Effects of reactive elements on the high temperature oxidation performance of CoNiCrAl alloy. Beijing: Tsinghua University; 2015. 80.

Barrett CA. Effect of 0.1 at.% zirconium on the cyclic oxidation resistance of β-NiAl. Oxid Met. 1988;30(5–6):361.

Hamadi S, Bacos MP, Poulain M, Seyeux A, Maurice V, Marcus P. Oxidation resistance of a Zr-doped NiAl coating thermochemically deposited on a nickel-based superalloy. Surf Coat Technol. 2009;204(6–7):756.

Hamadi S, Bacos MP, Poulain M, Zanna S, Seyeux A, Maurice V, Marcus P. Oxidation of a Zr-doped NiAl bondcoat thermochemically deposited on a nickel-based superalloy. Mater High Temp. 2009;26(2):195.

Pint BA. The role of chemical composition on the oxidation performance of aluminide coatings. Surf Coat Technol. 2004;188–189:71.

Haynes JA, Pint BA, More KL, Zhang Y, Wright IG. Influence of sulfur, platinum, and hafnium on the oxidation behavior of CVD NiAl bond coatings. Oxid Met. 2002;58(5–6):513.

Yan K, Guo HB, Peng H, Gong SK. Oxidation behaviour of electron beam physical vapour deposition β-NiAlHf coatings at 1100°C in dry and humid atmospheres. Rare Met. 2016;35(7):513.

Jedliński J, Mrowec S. The influence of implanted yttrium on the oxidation behaviour of β-NiAl. Mater Sci Eng. 1987;87(1–2):281.

Schumann E. The effect of Y-ion implantation on the oxidation of β-NiAl. Oxid Met. 1995;43(1–2):157.

Schumann E, Yang JC, Rühle M, Graham MJ. High-resolution SIMS and analytical TEM evaluation of alumina scales on β-NiAl containing Zr or Y. Oxid Met. 1996;46(1–2):37.

Pfeil LB. Improvements in heat resistant alloys. UK patent 459848; 1937.

Whittle DP, Stringer J. Improvements in high temperature oxidation resistance by additions of reactive elements or oxide dispersions. Philos Trans R Soc Lond A. 1980;295(1413):309.

Allam IM, Whittle DP, Stringer J. Improvements in oxidation resistance by dispersed oxide addition: Al2O3-forming alloys. Oxid Met. 1979;13(4):381.

Giggins CS, Kear BH, Pettit FS, Tien JK. Factors affecting adhesion of oxide scales on alloys. Metall Trans. 1974;5(7):1685.

Tien JK, Pettit FS. Mechanism of oxide adherence on Fe–25Cr–4Al (Y or Sc) alloys. Metall Trans. 1972;3(6):1587.

Mennicke C, He MY, Clarke DR, Smith JS. The role of secondary oxide inclusions (“pegs”) on the spalling resistance of oxide films. Acta Mater. 2000;48(11):2941.

Guo HB, Li DQ, Zheng L, Gong SK, Xu HB. Effect of co-doping of two reactive elements on alumina scale growth of β-NiAl at 1200°C. Corros Sci. 2014;88:197.

He J, Peng H, Gong SK, Guo HB. Synergistic effect of reactive element co-doping in two-phase (γ′ + β) Ni-Al alloys. Corros Sci. 2017;120:130.

Unocic KA, Leonard DN, Pint BA. Effect of boron on the oxidation behavior of NiCrAlYHfTi in H2O and CO2 environments. Surf Coat Technol. 2014;260(15):17.

Pint BA. Optimization of reactive-element additions to improve oxidation performance of alumina-forming alloys. J Am Ceram Soc. 2004;86(4):686.

Unocic KA, Pint BA. Oxidation behavior of co-doped NiCrAl alloys in dry and wet air. Surf Coat Technol. 2013;237(25):8.

Yang L, Choi R, Zheng Y, Bidabadi MHS, Rehman A, Zhang C, Chen H, Yang ZG. Spalling resistance of thermally grown oxide based on NiCoCrAlY(Ti) with different oxide peg sizes. Rare Met. 2020. https://doi.org/10.1007/s12598-019-01339-7.

Salam S, Hou PY, Zhang YD, Lan H, Wang HF, Zhang C, Yang ZG. Element accumulation beneath the scale/alloy interface of a CoNiCrAlReY alloy. Corros Sci. 2014;89:318.

Lan H, Zhang WG, Yang ZG. Investigation of Pt–Dy co-doping effects on isothermal oxidation behavior of (Co, Ni)-based alloy. J Rare Earths. 2012;30(9):928.

He J, Zhang Z, Peng H, Gong SK, Guo HB. The role of Dy and Hf doping on oxidation behavior of two-phase (γ′ + β) Ni–Al alloys. Corros Sci. 2015;98:699.

He J. Study on the mechanisms of reactive elements in the two phase (γ′ + β) Ni–Al alloys. Beijing: Beihang University; 2016. 89.

Lan H. Effects of heat treatment and alloying elements on the high temperature oxidation behaviors of MCrAlY(Re) bond coat materials. Beijing: Tsinghua University; 2011. 98.

Acknowledgements

This study was financially supported by Tsinghua University Initiative Scientific Research Program and the National Magnetic Confinement Fusion Energy Research Project of China (No. 2015GB118001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Zheng, Y., Wan, CL. et al. Characteristics of oxide pegs in Ti- and Y-doped CoNiCrAl alloys at 1150 °C. Rare Met. 40, 2059–2064 (2021). https://doi.org/10.1007/s12598-020-01577-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01577-0