Abstract

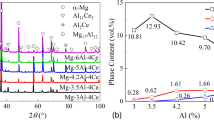

Microstructure, mechanical properties and corrosion resistance of as-cast and as-extruded Mg–4 wt% Zn–1 wt% La magnesium alloys were investigated. The alloys were produced by low-pressure die casting method and extruded at 350 °C after homogenization at 400 °C for 24 h. The results show that the as-cast alloy mainly consists of primary α-Mg matrix and Mg–Zn–La ternary second phases (also called T-Phase) along grain boundaries and isolated spherical particles inside the grains. After extrusion at 350 °C, the average grain size decreases by 81% due to dynamic recrystallization mechanism and T-phase particles are distributed along the extrusion direction. The elongation, yield strength and tensile strength of the as-cast Mg–4Zn–1La alloy increase by 179%, 90% and 40%, respectively, as a result of the extrusion process. The as-extruded Mg–4Zn–1La alloy shows better corrosion resistance than the as-cast alloy due to increased grain boundaries and decreased content of T-phase.

Similar content being viewed by others

References

Friedrich HE, Mordike BL. Magnesium Technology: Metallurgy, Design Data, Applications. Berlin: Springer; 2006. 63.

Mordike BL, Ebert T. Magnesium: properties—applications—potential. Mater Sci Eng A. 2001;302(1):37.

Gao X, Nie JF. Characterization of strengthening precipitate phases in a Mg–Zn alloy. Scripta Mater. 2007;56(8):645.

Cai S, Lei T, Li N, Feng F. Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg–Zn alloys. Mater Sci Eng C. 2012;32(8):2570.

Okamoto H, Schlesinger ME, Mueller EM, editors. ASM Handbook: Volume 3: Alloy Phase Diagrams. Materials Park: ASM International; 2016. 285.

Zhang Z, Liu X, Hu W, Li J, Le Q, Bao L, Zhu Z, Cui J. Microstructures, mechanical properties and corrosion behaviors of Mg–Y–Zn–Zr alloys with specific Y/Zn mole ratios. J Alloy Compd. 2015;624:116.

Luo AA, Mishra RK, Sachdev AK. High-ductility magnesium–zinc–cerium extrusion alloys. Scripta Mater. 2011;64(5):410.

Jeong HY, Kim B, Kim S, Kim HJ, Park SS. Effect of Ce addition on the microstructure and tensile properties of extruded Mg–Zn–Zr alloys. Mater Sci Eng A. 2014;612:217.

Du Y, Zheng M, Qiao X, Wang D, Peng W, Wu K, Jiang B. Improving microstructure and mechanical properties in Mg–6 mass% Zn alloys by combined addition of Ca and Ce. Mater Sci Eng A. 2016;656:67.

He SM, Peng LM, Zeng XQ, Ding WJ, Zhu YP. Comparison of the microstructure and mechanical properties of a ZK60 alloy with and without 1.3 wt% gadolinium addition. Mater Sci Eng A. 2006;433(1–2):175.

Feng H, Liu H, Cao H, Yang Y, Xu Y, Guan J. Effect of precipitates on mechanical and damping properties of Mg–Zn–Y–Nd alloys. Mater Sci Eng A. 2015;639:1.

Du YZ, Qiao XG, Zheng MY, Wu K, Xu SW. Development of high-strength, low-cost wrought Mg–2.5 mass% Zn alloy through micro-alloying with Ca and La. Mater Des. 2015;85:549.

Liang M, Liao H, Ding W, Peng L, Fu P. Microstructure characterization on Mg–2Nd–4Zn–1Zr alloy during heat treatment. Trans Nonferrous Met Soc China. 2012;22(10):2327.

Nakatsugawa I, Kamado S, Kojima Y, Ninomiya R, Kubota K. Corrosion of magnesium alloys containing rare earth elements. Corros Rev. 1998;16(1–2):139.

Du Y, Zheng M, Qiao X, Peng W, Jiang B. Effect of La addition on the microstructure and mechanical properties of Mg–6 wt% Zn alloys. Mater Sci Eng A. 2016;673:47.

Tamura Y, Kawamoto S, Soda H, McLean A. Effects of lanthanum and zirconium on cast structure and room temperature mechanical properties of Mg–La–Zr alloys. Mater Trans. 2011;52(9):1777.

Tong LB, Zhang QX, Jiang ZH, Zhang JB, Meng J, Cheng LR, Zhang HJ. Microstructures, mechanical properties and corrosion resistances of extruded Mg–Zn–Ca–xCe/La alloys. J Mech Behav Biomed Mater. 2016;62:57.

Polmear IJ. Light Alloys: from Traditional Alloys to Nanocrystals. Oxford: Elsevier/Butterworth-Heinemann; 2006. 237.

Neil WC, Forsyth M, Howlett PC, Hutchinson CR, Hinton BRW. Corrosion of magnesium alloy ZE41—the role of microstructural features. Corros Sci. 2009;51(2):387.

Zhao MC, Liu M, Song GL, Atrens A. Influence of microstructure on corrosion of as-cast ZE41. Adv Eng Mater. 2008;10(1–2):104.

Wei LY, Dunlop GL, Westengen H. Precipitation hardening of Mg–Zn and Mg–Zn–RE alloys. Metall Mater Trans A. 1994;26(7):1705.

Huang ML, Li HX, Ding H, Zhao JW, Hao SM. Study of intermetallics and phase equilibria of Mg–Zn–La system in Mg-rich corner at 345 °C. J Alloy Compd. 2014;612(5):479.

Sun H, Li C, Fang W. Evolution of microstructure and mechanical properties of Mg–3.0Zn–0.2Ca–0.5Y alloy by extrusion at various temperatures. J Mater Process Technol. 2016;229:633.

Zhang BP, Geng L, Huang LJ, Zhang XX, Dong CC. Enhanced mechanical properties in fine-grained Mg–1.0Zn–0.5Ca alloys prepared by extrusion at different temperatures. Scripta Mater. 2010;63(10):1024.

Li C, Sun H, Li X, Zhang J, Fang W, Tan Z. Microstructure, texture and mechanical properties of Mg–3.0Zn–0.2Ca alloys fabricated by extrusion at various temperatures. J Alloy Compd. 2015;652:122.

Rokhlin LL. Magnesium Alloys Containing Rare Earth Metals: Structure and Properties. London: CRC Press; 2003. 20.

Petch NJ. The cleavage strength of polycrystals. J Iron Steel Inst. 1953;174:25.

Caceres CH, Mann GE, Griffiths JR. Grain size hardening in Mg and Mg–Zn solid solutions. Metall Mater Trans A. 2011;42(7):1950.

Chun JS, Byrne JG. Precipitate strengthening mechanisms in magnesium zinc alloy single crystals. J Mater Sci. 1969;4(10):861.

Yu H, Kim YM, You BS, Yu HS, Park SH. Effects of cerium addition on the microstructure, mechanical properties and hot workability of ZK60 alloy. Mater Sci Eng A. 2013;559:798.

Zhao MC, Liu M, Song GL, Atrens A. Influence of pH and chloride ion concentration on the corrosion of Mg alloy ZE41. Corros Sci. 2008;50(11):3168.

Inoue M, Iwai M, Matuzawa K, Kamado S, Kojima Y. Effect of impurities on corrosion behavior of pure magnesium in salt water environment. J Jpn Inst Light Met. 1998;48(6):257.

Song GL, Atrens A. Corrosion mechanisms of magnesium alloys. Adv Eng Mater. 1999;1(1):11.

Birbilis N, Ralston KD, Virtanen S, Fraser HL, Davies CHJ. Grain character influences on corrosion of ECAPed pure magnesium. Corros Eng Sci Technol. 2010;45(3):224.

Argade GR, Panigrahi SK, Mishra RS. Effects of grain size on the corrosion resistance of wrought magnesium alloys containing neodymium. Corros Sci. 2012;58:145.

Jiang J, Ma A, Saito N, Shen Z, Song D, Lu F, Nishida Y, Yang D, Lin P. Improving corrosion resistance of RE-containing magnesium alloy ZE41A through ECAP. J Rare Earths. 2009;27(5):848.

Yang HM, Zhang NY, Liu N, Xie WD, Peng XD. Microstructure, mechanical properties, and corrosion resistance of Mg–9Li–3Al–1.6Y alloy. Rare Met. 2016;35(5):374.

Acknowledgements

This study is financially supported by the Scientific Research Projects of Karabuk University (BAP) (No. KBU-BAP-16/1-DR-075).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zengin, H., Turen, Y., Ahlatci, H. et al. Microstructure, mechanical properties and corrosion resistance of as-cast and as-extruded Mg–4Zn–1La magnesium alloy. Rare Met. 39, 909–917 (2020). https://doi.org/10.1007/s12598-018-1045-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1045-7