Abstract

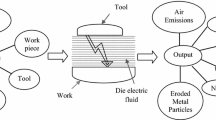

To achieve safer machining environment, and minimize emission of harmful and toxic substances during electrical discharge machining (EDM) process along with improvement in its performance, this paper emphasizes on identifying the best parametric combination of a green EDM process using superiority and inferiority ranking (SIR) method. Decision making trial and evaluation laboratory method is also employed to visualize the interrelationships between the responses of the said process while splitting them into cause and effect groups. In this process, peak current, pulse duration, dielectric level and flushing pressure are the input parameters, while process time, relative tool wear ratio, process energy, concentration of aerosol and dielectric consumption are considered as the responses. The optimal parametric combination as derived employing the SIR method is validated with the help of developed regression equations for each of the responses, which show that the adopted approach outperforms the other popular optimization techniques in obtaining the best mix of the green EDM process parameters for having improved machining performance and less hazardous effects on the environment.

Similar content being viewed by others

References

Abbas, N.M., Solomon, D.G., Bahari, M.F.: A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 47(7–8), 1214–1228 (2007)

Bhuyan, R., Routara, B.: Optimization the machining parameters by using VIKOR and entropy weight method during EDM process of Al-18% SiCp metal matrix composite. Decis. Sci. Lett. 5(2), 269–282 (2016)

Brans, J.P., Vincke, P., Mareschal, B.: How to select and how to rank projects: the PROMETHEE method. Eur. J. Oper. Res. 24(2), 228–238 (1986)

Chakraborty, S., Das, P.P.: A multivariate quality loss function approach for parametric optimization of non-traditional machining processes. Manag. Sci. Lett. 8(8), 873–884 (2018)

Chakraborty, S., Das, P.P., Kumar, V.: Application of grey-fuzzy logic technique for parametric optimization of non-traditional machining processes. Grey Syst.: Theory Appl. 8(1), 46–68 (2018)

Chen, Y.C., Lien, H.P., Tzeng, G.H.: Measures and evaluation for environment watershed plans using a novel hybrid MCDM model. Expert Syst. Appl. 37(2), 926–938 (2010)

Choi, A.C.K., Kaebernick, H., Lai, W.H.: Manufacturing processes modelling for environmental impact assessment. J. Mater. Process. Technol. 70(1–3), 231–238 (1997)

Das, P.P., Chakraborty, S.: Parametric optimization of non-traditional machining processes using Taguchi method and super ranking concept. Yugosl. J. Oper. Res. (2018). https://doi.org/10.2298/YJOR180821033D

Dewangan, S., Gangopadhyay, S., Biswas, C.K.: Multi-response optimization of surface integrity characteristics of EDM process using grey-fuzzy logic-based hybrid approach. Eng. Sci. Technol., Int. J. 18(3), 361–368 (2015)

El-Taweel, T.A.: Multi-response optimization of EDM with Al–Cu–Si–TiC P/M composite electrode. Int. J. Adv. Manuf. Technol. 44(1–2), 100–113 (2009)

Fontela, E., Gabus, A.: The DEMATEL Observer, DEMATEL 1976 Report. Battelle Geneva Research Center, Geneva (1976)

Gabus, A., Fontela, E.: Perceptions of the world problematique: communication procedure, communicating with those bearing collective responsibility (No. 1). DEMATEL Report (1973)

Gopalakannan, S., Senthilvelan, T.: Optimization of machining parameters for EDM operations based on central composite design and desirability approach. J. Mech. Sci. Technol. 28(3), 1045–1053 (2014)

Govindan, K., Rajendran, S., Sarkis, J., Murugesan, P.: Multi criteria decision making approaches for green supplier evaluation and selection: a literature review. J. Clean. Prod. 98, 66–83 (2015)

Hamidi, N., Yousefi, P., Rahimi, A., Jabari, F.: A hybrid of Borda and DEMATEL for productivity improvement. Manag. Sci. Lett. 2(8), 2757–2764 (2012)

Ho, K.H., Newman, S.T.: State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 43(13), 1287–1300 (2003)

Ho, W., Xu, X., Dey, P.K.: Multi-criteria decision making approaches for supplier evaluation and selection: a literature review. Eur. J. Oper. Res. 202(1), 16–24 (2010)

Hwang, C.L., Yoon, K.: Multiple Attribute Decision Making Methods and Applications. Springer, Berlin (1981)

Jagadish, Ray, A.: Multi-objective optimization of green EDM: an integrated theory. J. Inst. Eng. (India): Ser. C 96(1), 41–47 (2015)

Jagadish, Ray, A.: Optimization of process parameters of green electrical discharge machining using principal component analysis (PCA). Int. J. Adv. Manuf. Technol. 87(5–8), 1299–1311 (2016)

Janic, M., Reggiani, A.: An application of the multiple criteria decision making (MCDM) analysis to the selection of a new hub airport. Eur. J. Transp. Infrastruct. Res. 2(2), 113–141 (2002)

Joshi, S.N., Pande, S.S.: Intelligent process modeling and optimization of die-sinking electric discharge machining. Appl. Soft Comput. 11(2), 2743–2755 (2011)

Kung, K.Y., Horng, J.T., Chiang, K.T.: Material removal rate and electrode wear ratio study on the powder mixed electrical discharge machining of cobalt-bonded tungsten carbide. Int. J. Adv. Manuf. Technol. 40(1–2), 95–104 (2009)

Kuo, T.C., Chang, S.H., Huang, S.H.: Environmentally conscious design by using fuzzy multi-attribute decision-making. Int. J. Adv. Manuf. Technol. 29(3–4), 209–215 (2006)

Liu, F., Zhang, H.: A decision-making framework model of green manufacturing. Chin. J. Mech. Eng. 35, 11–15 (1999)

Marzouk, M.: A superiority and inferiority ranking model for contractor selection. Constr. Innov. 8(4), 250–268 (2008)

Mukherjee, R., Chakraborty, S.: Selection of EDM process parameters using biogeography-based optimization algorithm. Mater. Manuf. Process. 27(9), 954–962 (2012)

Rebai, A.: BBTOPSIS: a bag based technique for order preference by similarity to ideal solution. Fuzzy Sets Syst. 60(2), 143–162 (1993)

Rebai, A.: Canonical fuzzy bags and bag fuzzy measures as a basis for MADM with mixed non cardinal data. Eur. J. Oper. Res. 78(1), 34–48 (1994)

Reddy, V.V., Valli, P.M., Kumar, A., Reddy, C.S.: Multi-objective optimization of electrical discharge machining of PH17-4 stainless steel with surfactant-mixed and graphite powder-mixed dielectric using Taguchi-data envelopment analysis-based ranking method. Proc. Inst. Mech. Eng., Part B: J. Eng. Manuf. 229(3), 487–494 (2015)

Roy, B., Slowinski, R., Treichel, W.: Multicriteria programming of water supply systems for rural areas. J. Am. Water Resour. Assoc. 28(1), 13–31 (1992)

Roy, B.: Multicriteria Methodology for Decision Aiding, vol. 12. Springer, Berlin (2013)

Roy, T., Dutta, R.K.: Integrated fuzzy AHP and fuzzy TOPSIS methods for multi-objective optimization of electro discharge machining process. Soft Comput. (2018). https://doi.org/10.1007/s00500-018-3173-2

Sheng, P., Srinivasan, M., Kobayashi, S.: Multi-objective process planning in environmentally conscious manufacturing: a feature-based approach. CIRP Ann.—Manuf. Technol. 44(1), 433–437 (1995)

Singh, J., Sharma, R.K.: Green EDM strategies to minimize environmental impact and improve process efficiency. J. Manuf. Sci. Prod. 16(4), 273–290 (2016)

Singh, N.K., Pandey, P.M., Singh, K.K., Sharma, M.K.: Steps towards green manufacturing through EDM process: A review. Cogent Eng. 3(1), 13 (2016). https://doi.org/10.1080/23311916.2016.1272662

Singh, P.N., Raghukandan, K., Pai, B.C.: Optimization by grey relational analysis of EDM parameters on machining Al-10% SiCP composites. J. Mater. Process. Technol. 155, 1658–1661 (2004)

Sivapirakasam, S.P., Mathew, J., Surianarayanan, M.: Multi-attribute decision making for green electrical discharge machining. Expert Syst. Appl. 38(7), 8370–8374 (2011)

Tam, C.M., Tong, T.K., Wong, Y.W.: Selection of concrete pump using the superiority and inferiority ranking method. J. Constr. Eng. Manag. 130(6), 827–834 (2004)

Tan, X.C., Liu, F., Cao, H.J., Zhang, H.: A decision-making framework model of cutting fluid selection for green manufacturing and a case study. J. Mater. Process. Technol. 129(1–3), 467–470 (2002)

Tang, L., Du, Y.T.: Experimental study on green electrical discharge machining in tap water of Ti–6Al–4V and parameters optimization. Int. J. Adv. Manuf. Technol. 70(1–4), 469–475 (2014)

Tang, L., Du, Y.T.: Multi-objective optimization of green electrical discharge machining Ti–6Al–4V in tap water via grey-Taguchi method. Mater. Manuf. Process. 29(5), 507–513 (2014)

Tavana, M., Zareinejad, M., Santos-Arteaga, F.J.: An intuitionistic fuzzy-grey superiority and inferiority ranking method for third-party reverse logistics provider selection. Int. J. Syst. Sci.: Oper. Logist. 5(2), 175–194 (2018)

Tönshoff, H.K., Egger, R., Klocke, F.: Environmental and safety aspects of electrophysical and electrochemical processes. CIRP Ann. 45(2), 553–568 (1996)

Wang, X., Chen, L., Dan, B., Wang, F.: Evaluation of EDM process for green manufacturing. Int. J. Adv. Manuf. Technol. 94(1–4), 633–641 (2018)

Wu, X., Zhang, S., Qiu, S., Sun, L.: Decision making method of process parameter selection for green manufacturing based on a DEMATEL-VIKOR algorithm. J. Mech. Eng. 49(7), 91–100 (2013)

Xu, X.: The SIR method: a superiority and inferiority ranking method for multiple criteria decision making. Eur. J. Oper. Res. 131(3), 587–602 (2001)

Yeo, S.H., Neo, K.G., Tan, H.C.: Assessment of health hazards in production of printed paper packages. Int. J. Adv. Manuf. Technol. 14(5), 376–384 (1998)

Yeo, S.H., New, A.K.: A method for green process planning in electric discharge machining. Int. J. Adv. Manuf. Technol. 15(4), 287–291 (1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, P.P., Chakraborty, S. Parametric analysis of a green electrical discharge machining process using DEMATEL and SIR methods. OPSEARCH 57, 513–540 (2020). https://doi.org/10.1007/s12597-019-00410-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12597-019-00410-2