Abstract

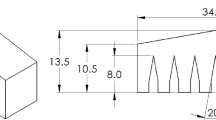

In the wet etching process of the flexible printed circuit board (FPCB), to obtain a symmetrical and stable circuit structure and improve the yield, it is necessary to control the uniformity of the etchant velocity and pressure on the surface of the FPCB as far as possible. In this paper, a numerical method implemented with Euler multiphase flow model is proposed to study the spraying uniformity of the wet etching process of the FPCB. A 3D full model of the multi-nozzle array is established to study the velocity distribution of the etchant in the spraying domain. The FPCB sample is manufactured based on the process parameters obtained by the parametric study. In the experiment, pressure sensors are applied to monitor the etchant pressure on the surface of the FPCB and the cross-section of the FPCB circuit is observed, which validates the numerical simulation method. The results of simulations demonstrate that when the nozzle rotation angle θ is 1.3°, the distribution of the low-speed flow zone on the surface of the FPCB is about 60 mm along the X axis direction, and the standard deviation of the pressure is reduced by 67.6% compared to 0°. The cross-section of the FPCB circuit is close to an isosceles trapezoid with an 18 μm line pitch, which is the center-to-center distance between the adjacent circuit lines.

Similar content being viewed by others

References

Chatterjee, S., Ujihara, M., Lee, D. G., Chen, J., Lei, S., & Carman, G. P. (2006). Spray etching 2 µm features in 304 stainless steel. Journal of Micromechanics and Microengineering, 16(12), 2585.

Kao, A. S., Stenger, H. G., Georgakis, C., & Covert, K. L. (1992). State estimation and control of spray etching processes. Journal of Process Control, 2(2), 87–101.

Zhu, Z., & Liu, C. (2000). Micromachining process simulation using a continuous cellular automata method. Journal of Microelectromechanical Systems, 9(2), 252–261.

George, S. K., & Koc, B. (2009). Free-form simulation of sequential etching and surface characterization for 3-D MEMS fabrication. Journal of Microelectromechanical Systems, 18(2), 296–307.

Wang, L., Zhang, N., Slocombe, J. W., Thierstein, G. E., & Kuhlman, D. K. (1995). Experimental analysis of spray distribution pattern uniformity for agricultural nozzles. Applied Engineering in Agriculture, 11(1), 51–55.

Liu, Y. J., Hua, H., Li, X. F., & Shi, J. Z. (2013). Experimental study on spray uniformity of spraying machinery. Advanced Materials Research, Xiamen, China. https://doi.org/10.4028/www.scientific.net/AMR.671-674.1993

Drocas, I., Marian, O., Ranta, O., Molnar, A., & Stanila, S. (2009). The influence of the working height and pressure on the uniformity of distribution for two nozzle types. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca, 66(1), 314–318.

Kim, Y. (2015). Experimental study on etching characteristics of a spin-etching method. Journal of Microelectromechanical Systems, 24(6), 1827–1831.

Jeong, H. C., Choi, D. W., Choi, G. M., & Kim, D. J. (2009). The effect of spray characteristics on the etching of invar alloy with FeCl3 solution. International Journal of Precision Engineering and Manufacturing, 10(4), 107–114.

Jung, J. W., Choi, G. M., & Kim, D. J. (2004). Experimental study on spray etching process in micro fabrication of lead frame. KSME International Journal, 18(12), 2294–2302.

Kartashev, A. L., & Kartashev, M. A. (2016). Designing of optimal annular nozzles with multiphase flows. Procedia Engineering, 150, 161–167.

Liu, F. P. (2011). “Analysis on design parameters of the atomizing nozzle with ring holes,” Powder Metallurgy Industry, pp. 1.

Wang, C., He, X., Cheng, L., Luo, C., Xu, J., Chen, K., & Jiao, W. (2019). Numerical simulation on hydraulic characteristics of nozzle in waterjet propulsion system. Processes, 7(12), 915.

Jiao, W., Cheng, L., Xu, J., & Wang, C. (2019). Numerical analysis of two-phase flow in the cavitation process of a waterjet propulsion pump system. Processes, 7(10), 690.

Milak, D. (2015). “Numerical simulation of twin nozzle injectors,” M.S. Thesis, Dept. Mar. Technol., N. T. N. U, Trondheim, Norway.

Zhou, M., Kong, L., Xie, L., Fu, T., Jiang, G., & Feng, Q. (2017). Design and optimization of non-circular mortar nozzles using finite volume method and Taguchi method. The International Journal of Advanced Manufacturing Technology, 90(9–12), 3543–3553.

Quintao, K. K. (2012). “Design optimization of nozzle shapes for maximum uniformity of exit flow,” M.S. Thesis, Depat. Mech. Eng., Florida International Univ., Miami, FL, USA.

Aabid, A., Chaudhary, Z. I., & Khan, S. A. (2019). Modelling and analysis of convergent divergent nozzle with sudden expansion duct using finite element method. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 63(1), 34–51.

Wang, H., Ji, H., & Lu, H. (2019). The influence of nozzle deflection on fluid dynamic and infrared characteristics of a two-dimensional convergent–divergent vectoring exhaust system. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 233(12), 4646–4662.

Oh, H., Kim, K., & Kim, S. (2008). Characterization of deposition patterns produced by twin-nozzle electrospray. Journal of Aerosol Science, 39(9), 801–813.

Jeong, H. C., Choi, G. M., & Kim, D. J. (2007). The precision of lead frame etching characteristics using Monte-Carlo simulations. International Journal of Precision Engineering and Manufacturing, 8(1), 73–78.

Xin, F., Ma, T., Chen, Y., & Wang, Q. (2018). Two-dimensional chemical etching process simulation for printed circuit heat exchanger channels based on cellular automata model. Heat Transfer Engineering, 39(7–8), 617–629.

Sheng, J., Li, H., Shen, S., Ming, R., Sun, B., Wang, J., Zhang, D., & Tang, Y. (2021). Investigation on chemical etching process of FPCB with 18 μm line pitch. IEEE Access, 9, 50872–50879.

Seo, M., Park, J. S., Park, S., & Jung, J. H. (2009). Optimal design of multi-nozzle etching process for shadow mask. Korean Journal of Chemical Engineering, 26(6), 1519–1527.

Choi, M., Eom, S., Sung, Y., Noh, K., & Choi, G. (2018). Experimental prediction of multi-nozzle spray characteristics for optimal design in a lead frame etching process. Journal of Mechanical Science and Technology, 32(5), 2127–2139.

Ming, R., Li, H., Shen, S., Sheng, J., Wang, J., Sun, B. (2021). “Investigation on etching process of FPCB with 18 μm line pitch,” submitted.

Acknowledgements

This work was supported by the National Key R&D Program of China under Grant No. 2019YFB1704600 and the Hubei Provincial Natural Science Foundation of China under Grant No. 2020CFA032.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ming, R., Li, H., Chen, A. et al. Investigation on Spraying Uniformity in Etching Process of FPCB with 18 μm Line Pitch. Int. J. Precis. Eng. Manuf. 23, 479–488 (2022). https://doi.org/10.1007/s12541-022-00636-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00636-z